Three-way joint for aluminium materials and machining method thereof

A processing method and joint technology, applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of increasing product weight and inconvenient recycling of aluminum materials, and achieve the effects of weight reduction, good rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

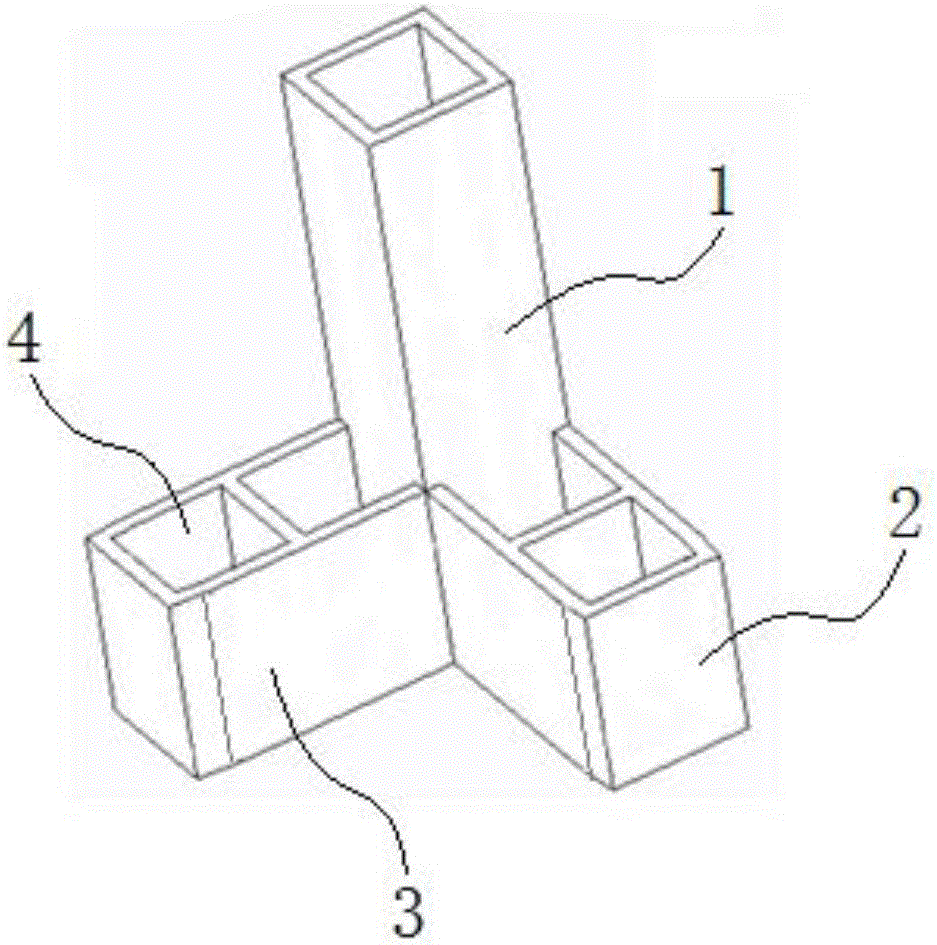

[0029] figure 1 It shows a schematic structural view of an aluminum three-way joint according to a preferred embodiment of the present invention, the aluminum three-way joint includes a first joint 1, a second joint 2 and a third joint 3, refer to figure 1 , one end of the second joint 2 is vertically connected to one end of the first joint 1, the length of the second joint 2 is the same as that of the third joint 3, and the end of the first joint 1 connected to the second joint 2 is also connected to the end of the third joint 3 One end is connected, and the third joint 3 is perpendicular to the first joint 1 and the second joint 2 at the same time, so that any two joints form an L shape, and each of the three joints is sleeved on the end of an aluminum material, so that the three Two aluminum materials are vertically connected together. In order to facilitate the socketing of each joint with the aluminum material, a chamfer can be set at the end of each joint. The chamfer pl...

Embodiment 2

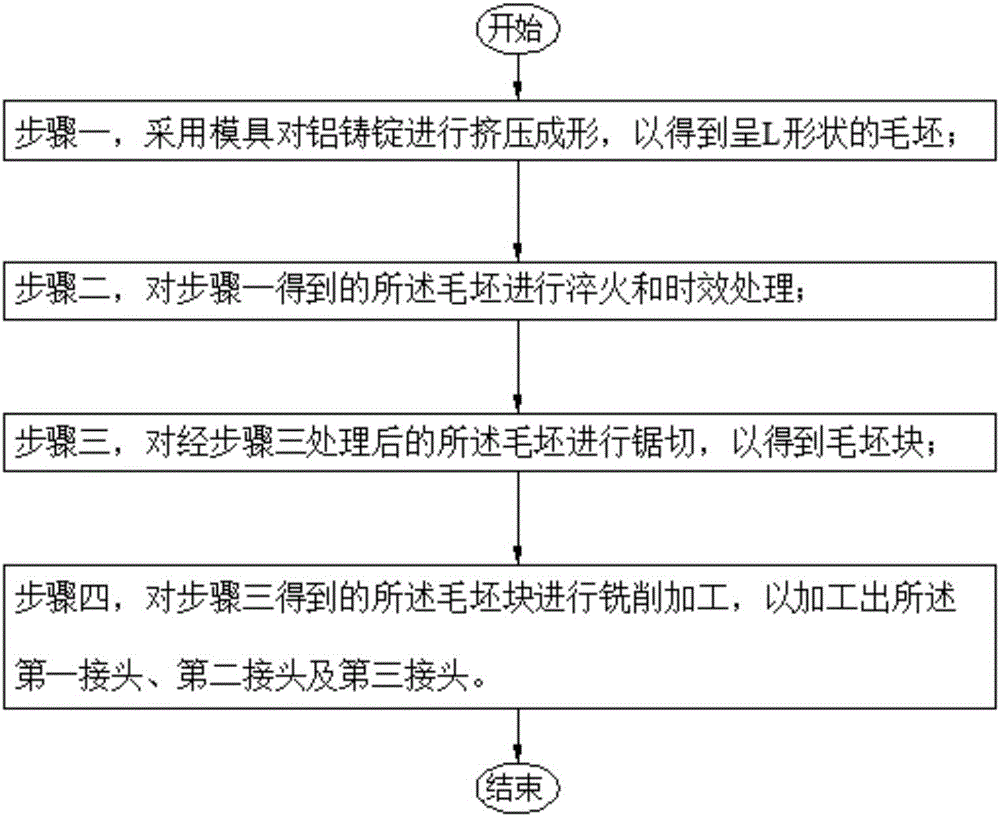

[0033] figure 2 Shows a flowchart of a method for processing an aluminum three-way joint according to a preferred embodiment of the present invention, which includes the following steps:

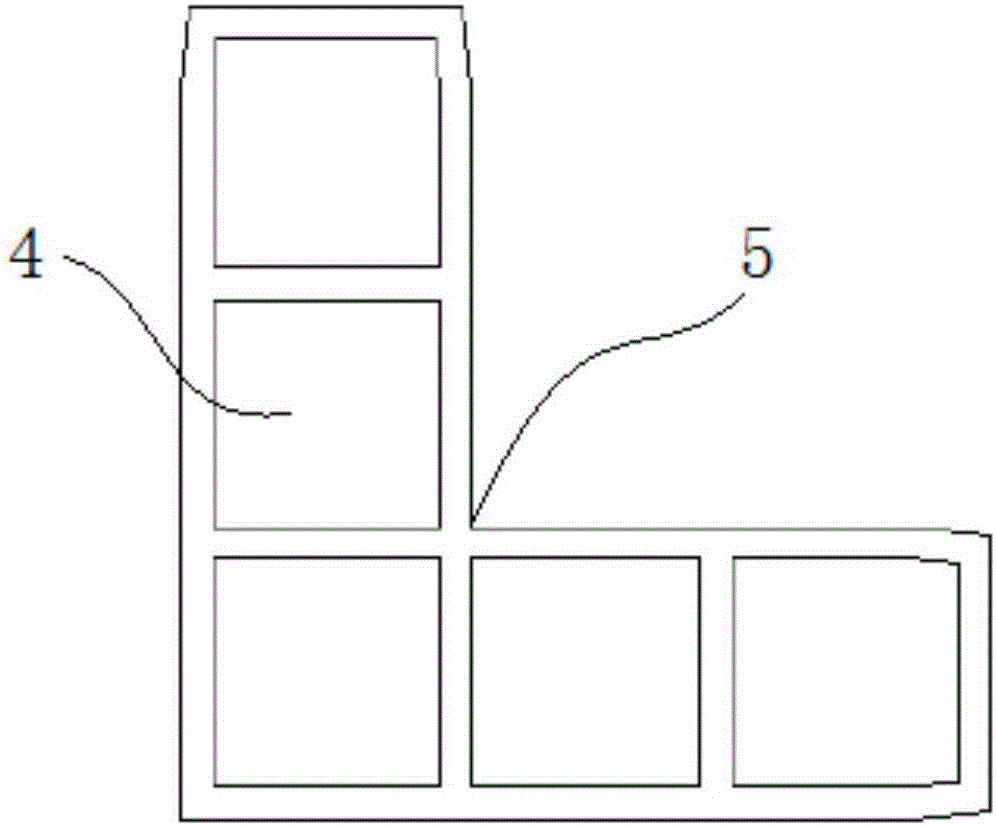

[0034] Step 1, refer to image 3 , the cross-sectional shape of the blank 5 required in the processing is designed as an L shape, the two sides of the blank 5 are square structures, and the lengths of the two sides are the same, the mold is designed according to the cross-sectional shape, and then the designed mold is used to A cylindrical aluminum ingot is extruded to obtain an L-shaped blank 5 . Preferably, the aluminum casting ingot is made of 6xxx series aluminum alloy, so that the material of the finally obtained three-way joint is 6xxx series aluminum alloy.

[0035] In step two, quenching and aging treatment are performed on the blank 5 obtained in step one, so as to improve its strength and eliminate stress.

[0036] Step 3, sawing the blank 5 processed in step 2 to obtain the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com