Manufacturing method of automobile engine cover made of carbon filer composite materials

A technology of automobile engine and manufacturing method, which is applied in the field of carbon fiber composite automobile parts manufacturing, and can solve the problems of no lightweight space and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

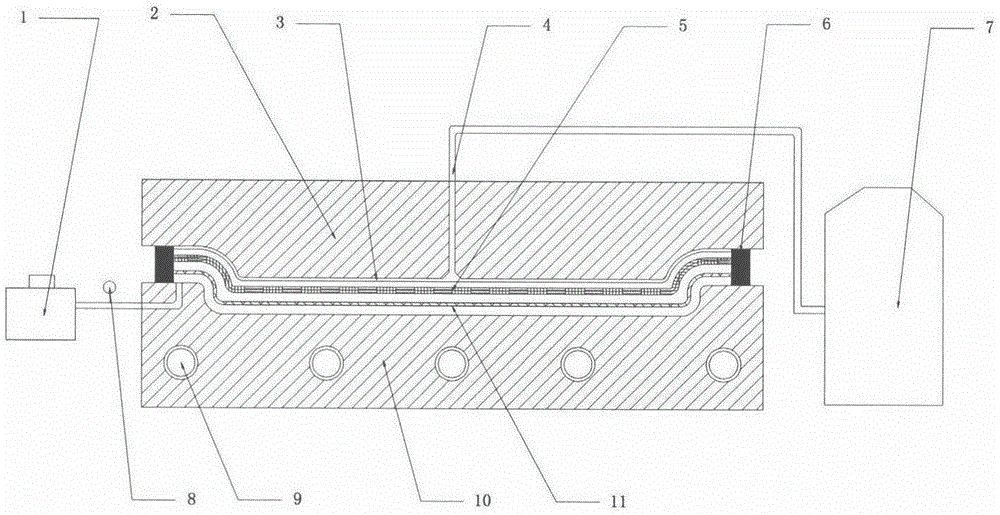

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 Manufacturing and processing of a certain engine cover

[0036] 1. Material preparation:

[0037] The carbon fiber cloth used in the experiment is 3K220g carbon fiber plain cloth provided by Lianyungang Yingyou Group, and the experimental resin is R-3895 epoxy resin provided by Xiamen Weiman Material Technology Co., Ltd.

[0038] 2. Parts manufacturing process

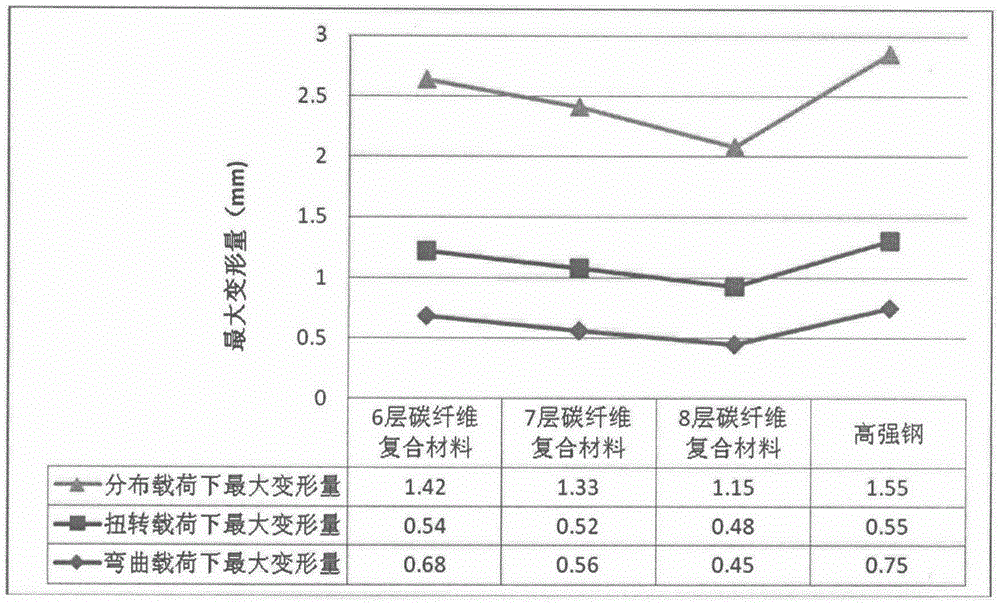

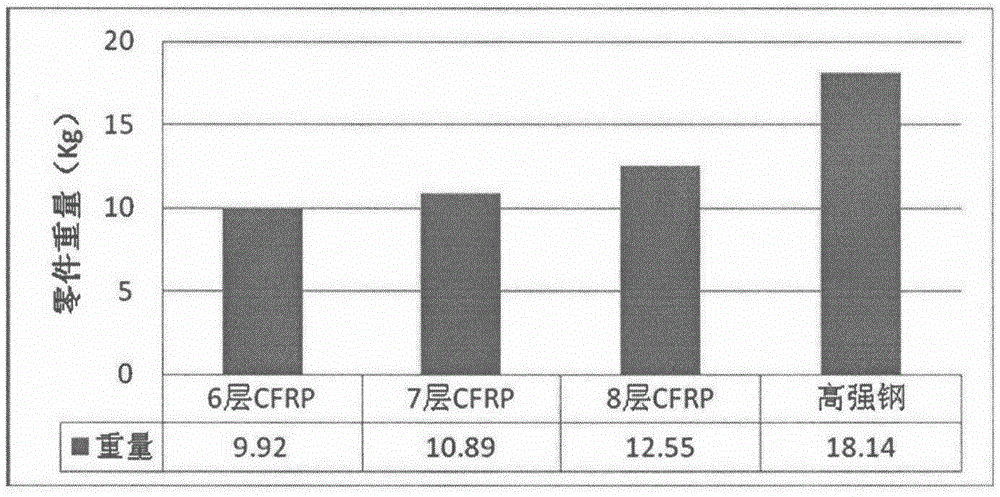

[0039] Through the CAE analysis of the strength and stiffness of the hood, the reinforced area of the hood is designed, and the 3-layer carbon fiber cloth is cut into the shape of the reinforced part.

[0040] Cut 3-5 layers of carbon fiber cloth into the expanded size of the engine hood.

[0041] Stack the multi-layer carbon fiber cloth according to the order and size, and use a small amount of spray glue to bond and fix the two layers of carbon fiber cloth.

[0042] Lay a layer of flow guide net and a layer of release cloth on the mold, and then put the stacked multi-layer carbon fiber cloth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com