Kelp shredding cutter

A technology of cutting tools and kelp, applied in metal processing and other directions, can solve the problems of easy deformation under force, limited width of kelp, poor strength and rigidity, etc., and achieves fast shredding speed, good strength and rigidity, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

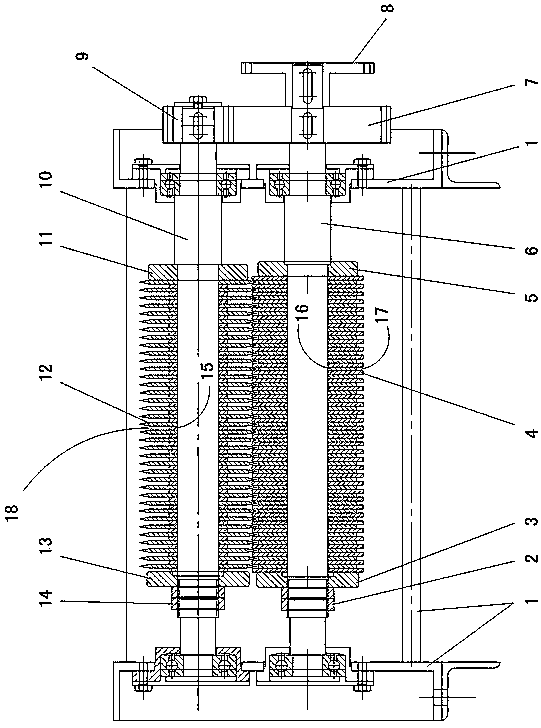

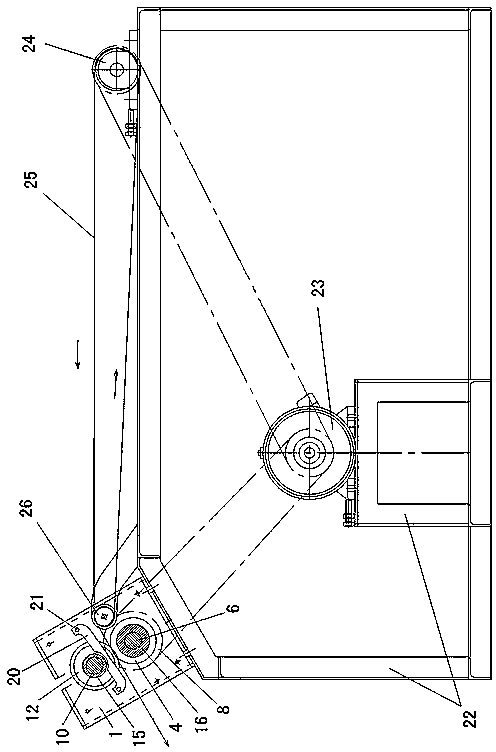

[0009] like figure 1 Shown: 1 is the frame that is arranged in parallel on both sides, and two parallel shafts are installed on the frame 1 through bearings, that is, the driving shaft 6 and the driven shaft 10 .

[0010] A plurality of circular spacers 4 are installed on the driving shaft 6, spacer pads 16 are arranged between adjacent spacers 4, and a plurality of spacer gaps 17 are formed on the periphery of the spacer 4, each spacer 4 and each spacer The driving shaft 6 at one end of the pad 16 is covered with a driving shaft back plate 5, and the other end has a driving shaft pressure plate 3 and a driving shaft back cap 2 threaded with the driving shaft 6 for clamping the spacer 4 and the spacer pad 16 . The thickness of the spacer 4 and the width of the spacer gap 17 are both 0.615 mm.

[0011] A plurality of circular blades 12 are installed on the driven shaft 10 , there are blade pads 15 between adjacent blades 12 , and a plurality of blade gaps 18 are formed around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com