Pressing head of shred cutting machine and food shred cutting machine and method

A technology of cutting machine and indenter, applied in metal processing and other directions, can solve the problems of increased cutting resistance, different shapes and sizes, low efficiency, etc., and achieves broad market promotion prospects, stable wire quality, and fast cutting speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

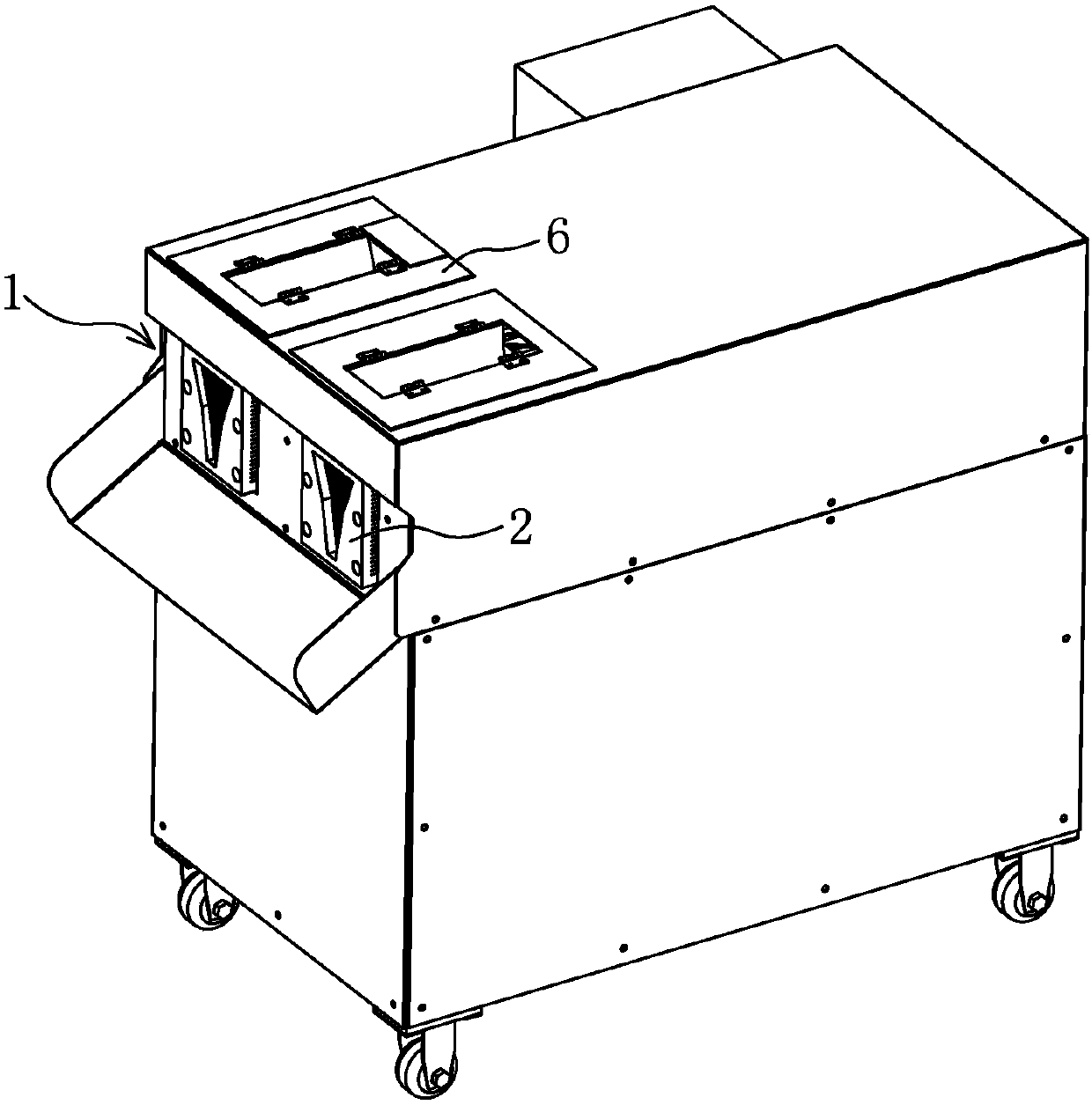

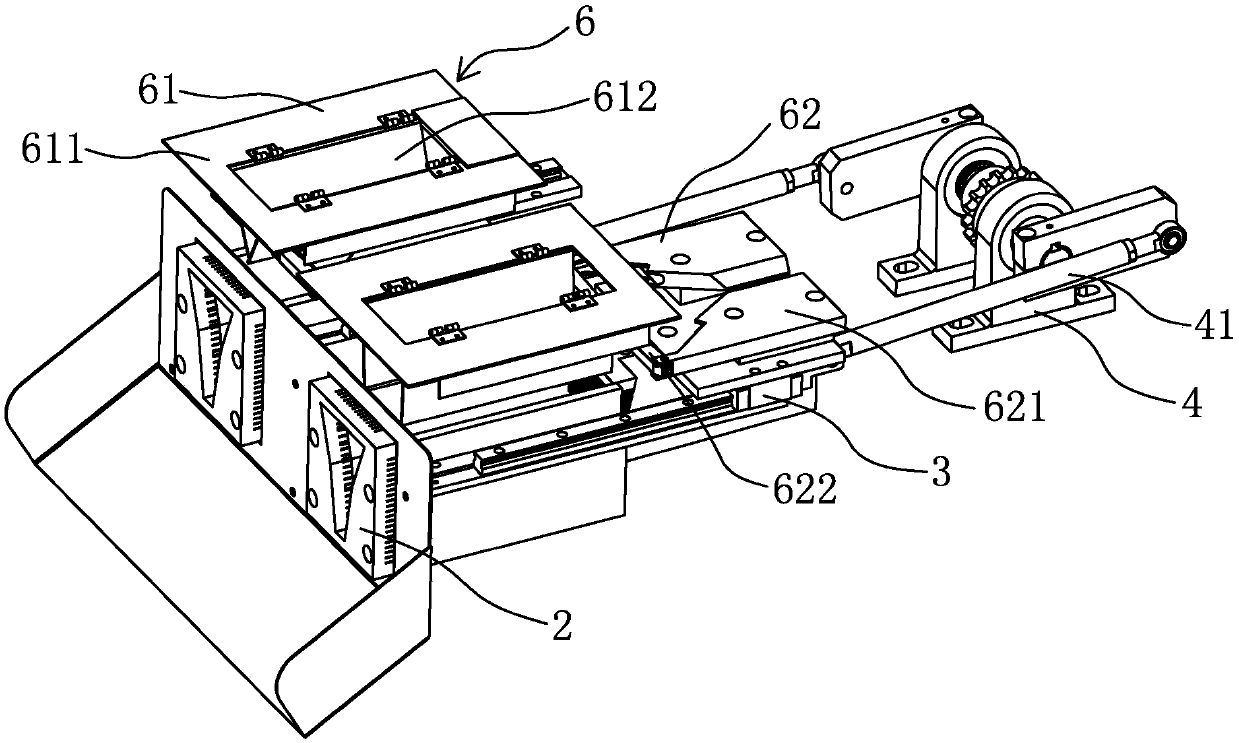

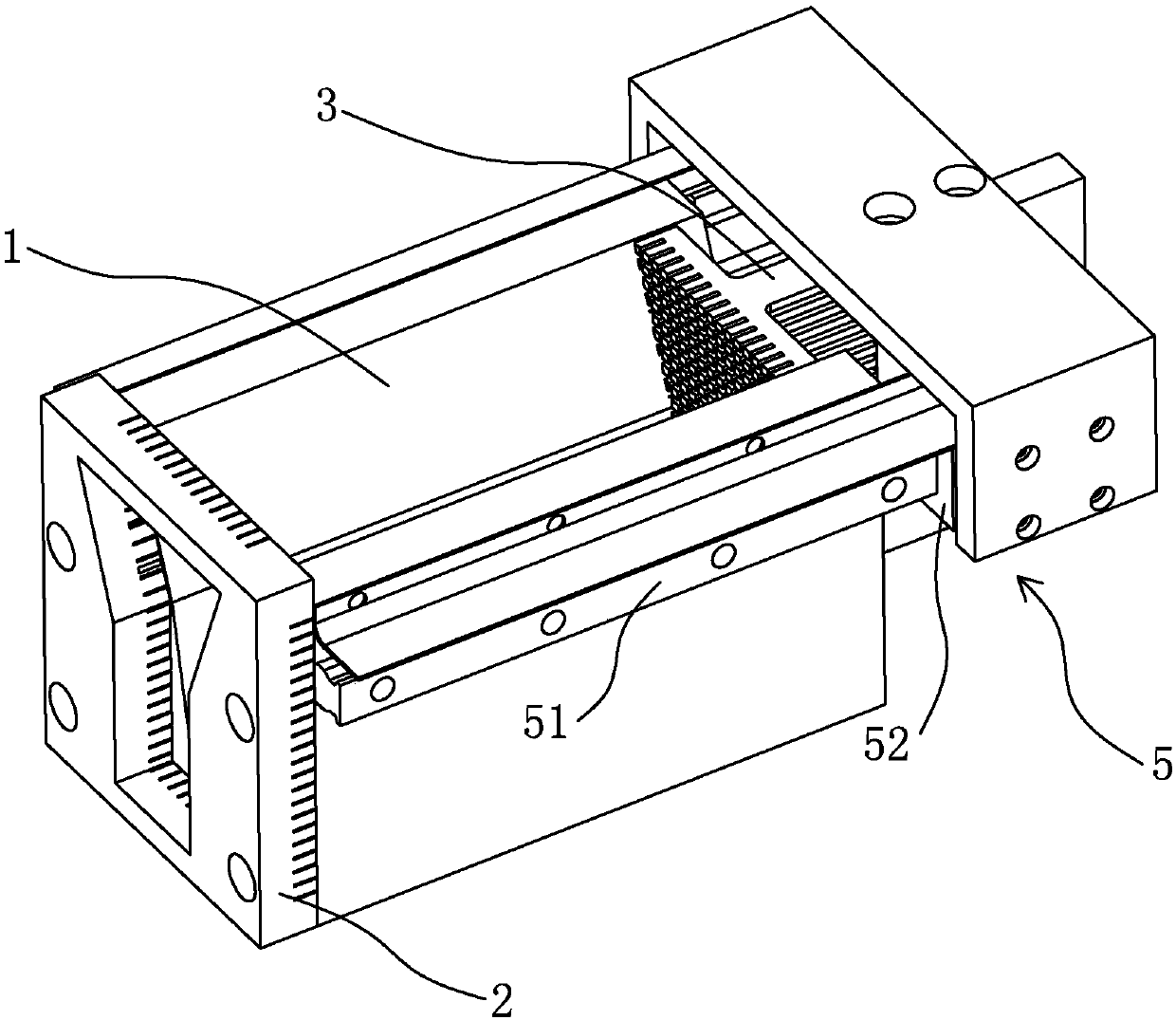

[0025] refer to Figure 1 to Figure 6 As shown, taking shredded fresh bamboo shoots as an example, a food shredding machine includes a material tank 1 with an open upper end, a knife net 2 arranged at the front end of the material tank 1, and a pressure head 3 set on the opposite side of the knife net 2 , the drive mechanism 4 that drives the pressure head 3 to move, the slide rail mechanism 5, and the safety protection mechanism 6.

[0026] The cross-section of the material trough 1 is gradually reduced from the upper opening to the bottom, so that the fresh bamboo shoots entering the material trough 1 are shredded along the growth direction of the length.

[0027] The indenter 3 includes a mounting frame 31 connected to the drive mechanism 4, a plurality of pressing pieces 32 vertically spaced on the mounting frame 31, and a plurality of guides arranged on the mounting frame 31 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com