Potato shredding machine

A technology of shredding machine and potato shreds, applied in metal processing and other directions, can solve the problems of slow shredding speed, easy to hurt hands, and uneven potato shreds, etc., and achieve the effect of uniform size, fast shredding speed, and uniform thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

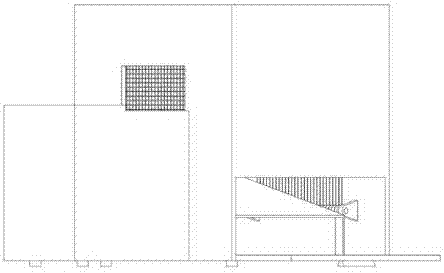

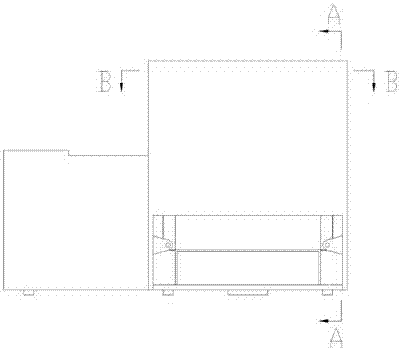

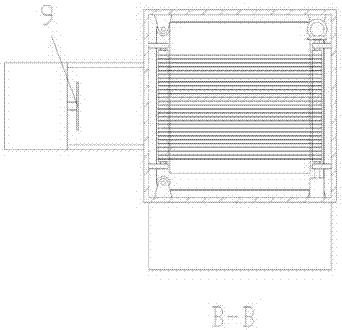

[0021] The potato shredding machine of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] The potato shredding machine of the present invention comprises a shredded net formed by crossing a group of horizontal wires 1 and a group of vertical wires 2, the group of horizontal wires 1 and the group of vertical wires 2 are perpendicular to each other, and the group of horizontal wires 1 and the group of vertical wires 2 are perpendicular to each other. The horizontal wire 1 includes a plurality of horizontal wires parallel to each other, and the set of vertical wires 2 includes a plurality of vertical wires parallel to each other. The vertical wire support device is supported, and all form a closed loop, and are driven by the driving device to circulate around the loop. The potatoes are cut by the circularly moving horizontal and vertical wires to form potato shreds that pass through the mesh of the shredder. .

[0023] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com