A rotary potato processing device

A processing device and rotary technology, applied in the field of machinery, can solve the problems of reducing the labor intensity of operators, inability to process potato shreds, and low processing efficiency, and achieve the effects of reducing labor intensity, convenient and quick adjustment, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

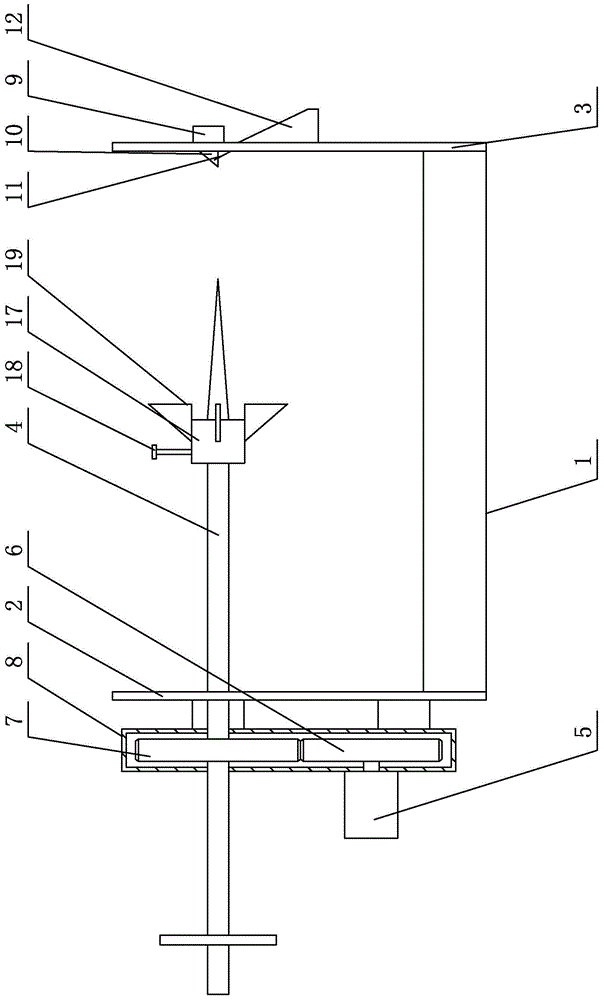

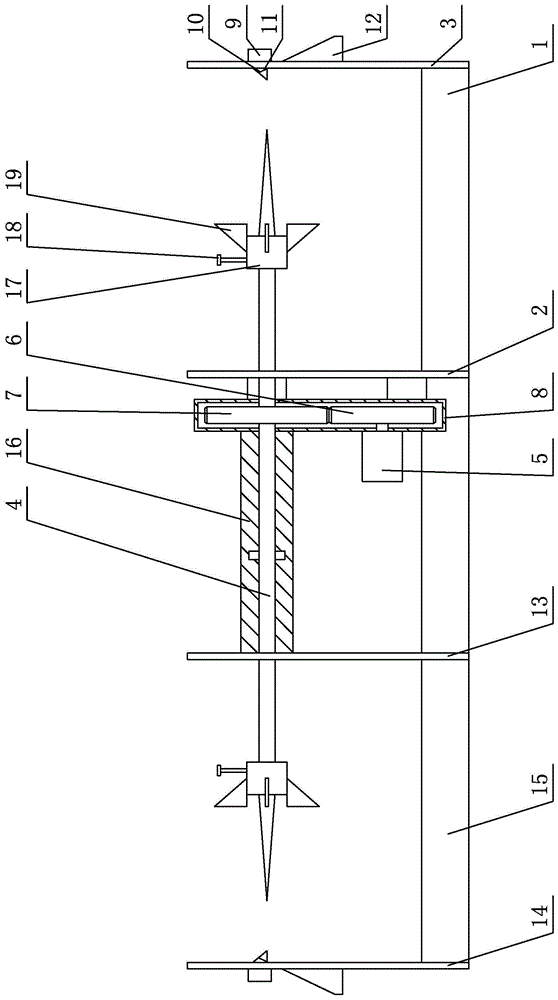

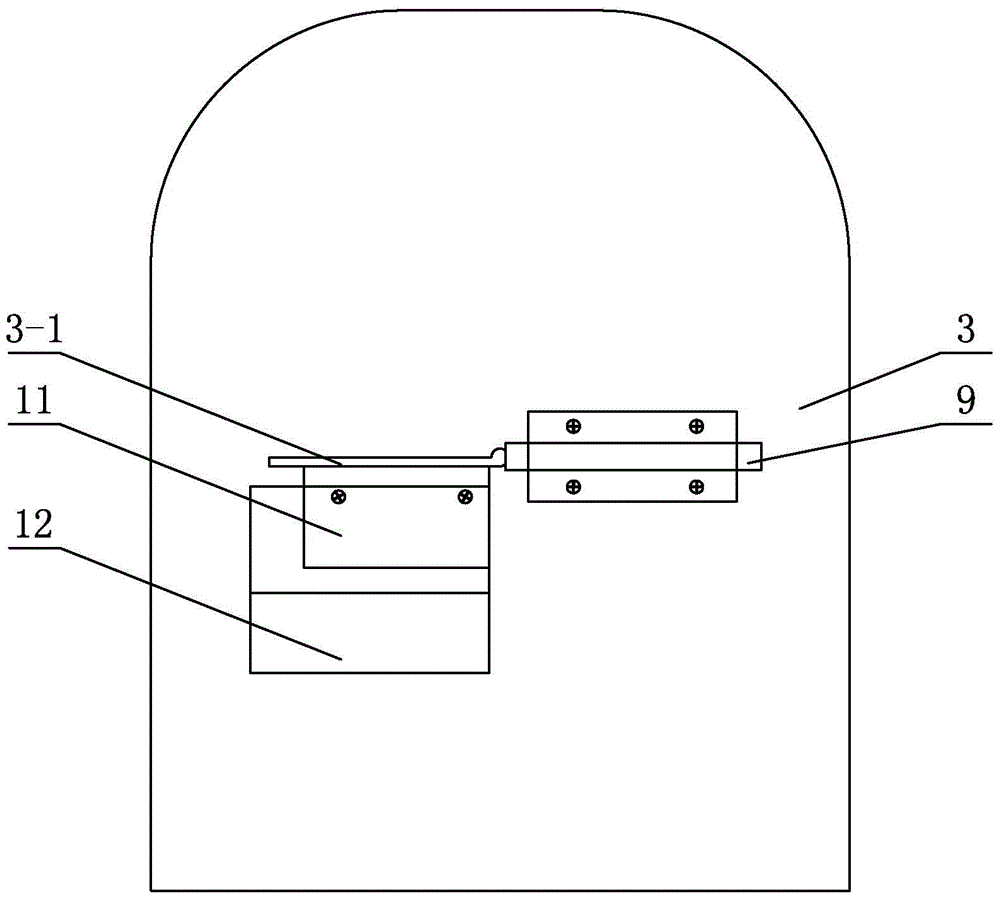

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, a rotary potato processing device described in this embodiment includes a first base 1, a first vertical plate 2, a second vertical plate 3, a long rod 4, a first cutter assembly and a driving mechanism, and the base 1 is horizontal Setting, the first vertical plate 2 and the second vertical plate 3 are respectively vertically arranged at both ends of the base 1, the drive mechanism is installed on the first vertical plate 2, and the long rod 4 is inserted horizontally on the first vertical plate 2 , and one end of the long rod 4 is located between the first vertical plate 2 and the second vertical plate 3, the drive mechanism is connected with Chang’an 4, and the first cutter assembly is installed in the inline through hole on the second vertical plate 3 3-1 place.

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the drive mechanism of a kind of rotary potato processing device described in this embodiment includes motor 5, driving gear 6, driven gear 7 and housing 8, and housing 8 is installed on the first vertical plate 2, and driving The gear 6 and the driven gear 7 are sequentially arranged in the housing 8 from bottom to top, and the driving gear 6 meshes with the driven gear 7, the driving gear 6 is set on the rotating shaft of the motor 5, and the driven gear 7 is set on the long rod 4 , and the driven gear 7 is connected with the long rod 4 by a sliding key. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 2 To illustrate this embodiment, a rotary potato processing device described in this embodiment also includes a third vertical plate 13, a fourth vertical plate 14, a second base 15, a screw sleeve 16 and a second cutter assembly, and the second base 15 is horizontal Set, the third vertical plate 13 and the fourth vertical plate 14 are respectively arranged on the two ends of the second base 15, the screw sleeve 16 is horizontally arranged between the third vertical plate 13 and the first vertical plate 2, and one end of the screw sleeve 16 It is fixedly connected with the outer side wall of the first vertical plate 2, and the other end of the screw sleeve 16 is fixedly connected with the outer side wall of the third vertical plate 13, and the other end of the long rod 4 passes through the screw sleeve 16 and the third vertical plate 13 successively. Between the 3rd vertical board 13 and the 4th vertical board 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com