A kind of continuous shredding machine and method for fresh bamboo shoots

A technology of shredding machine and fresh bamboo shoots, which is applied in metal processing and other fields, can solve the problems of poor product taste, low processing efficiency, difficult texture shredding, etc., achieve better product taste, fast shredding speed, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through specific embodiments.

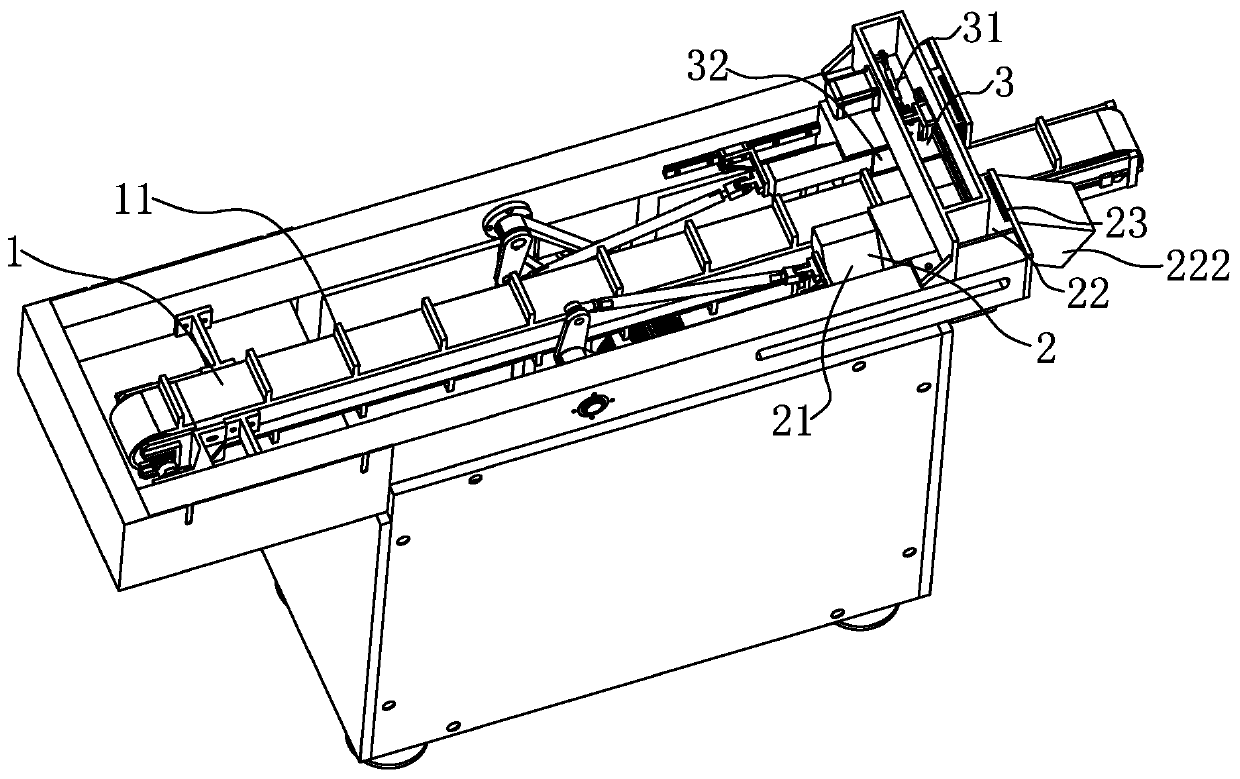

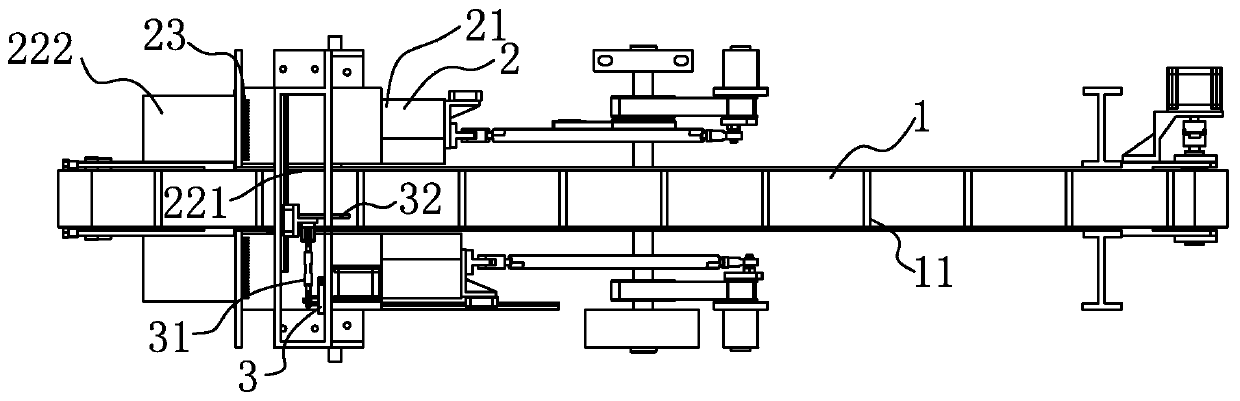

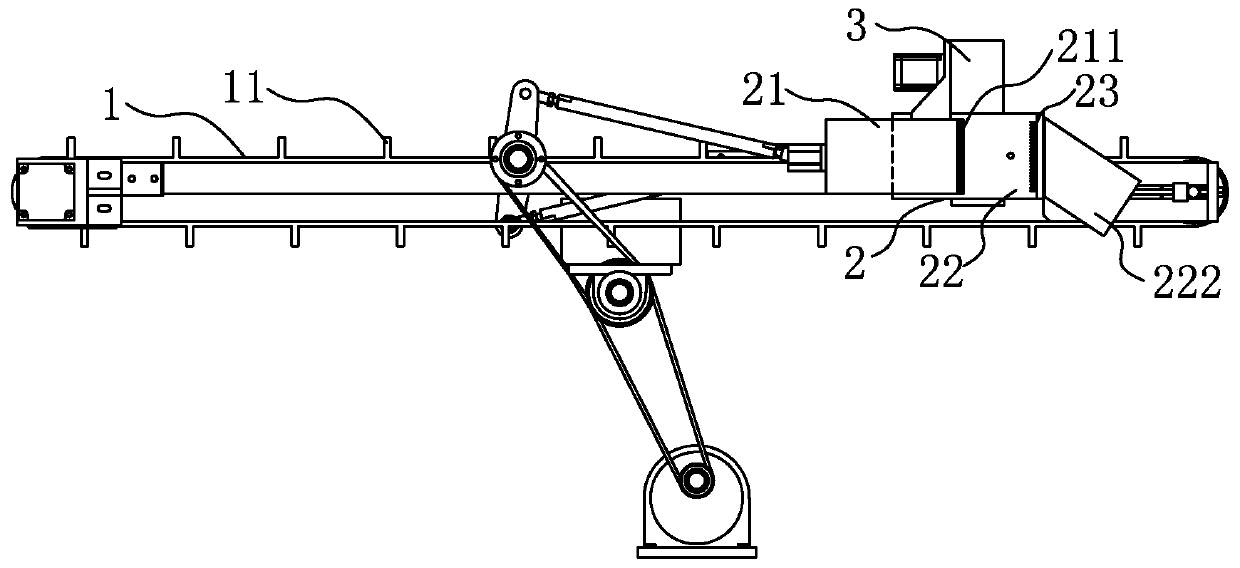

[0023] refer to Figure 1 to Figure 4 Shown, a kind of fresh bamboo shoots continuous shredding machine, comprises material conveying device 1, shredding device 2, pushing material device 3, on the material conveying device 1 evenly distributes partition board 11, and partition board 11 evenly distributes material conveying device 1 Divided into a plurality of small compartments, the shredded device 2 is arranged beside the material conveying device 1, the shredded device 2 includes a pressure head 21, a pressing box 22, and a knife net 23, and the pressing box 22 includes a material inlet 221 and a material outlet 222, the press box 22 is a structure with a narrow bottom and a wide top, and it is arranged on the side of the material conveying device 1 inclined downward. The feed port 221 of the press box 22 communicates with the material conveying device 1, and the knife net 23 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com