External diameter grinding machine pressurized by cylinder

A grinding machine and cylinder technology, applied in the field of cylinder pressurized outer diameter grinding machine, can solve the problems of impractical weight pressurization, troublesome adjustment operation, complicated manufacturing and processing, etc., achieve simple structure, reduce labor intensity, reduce The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

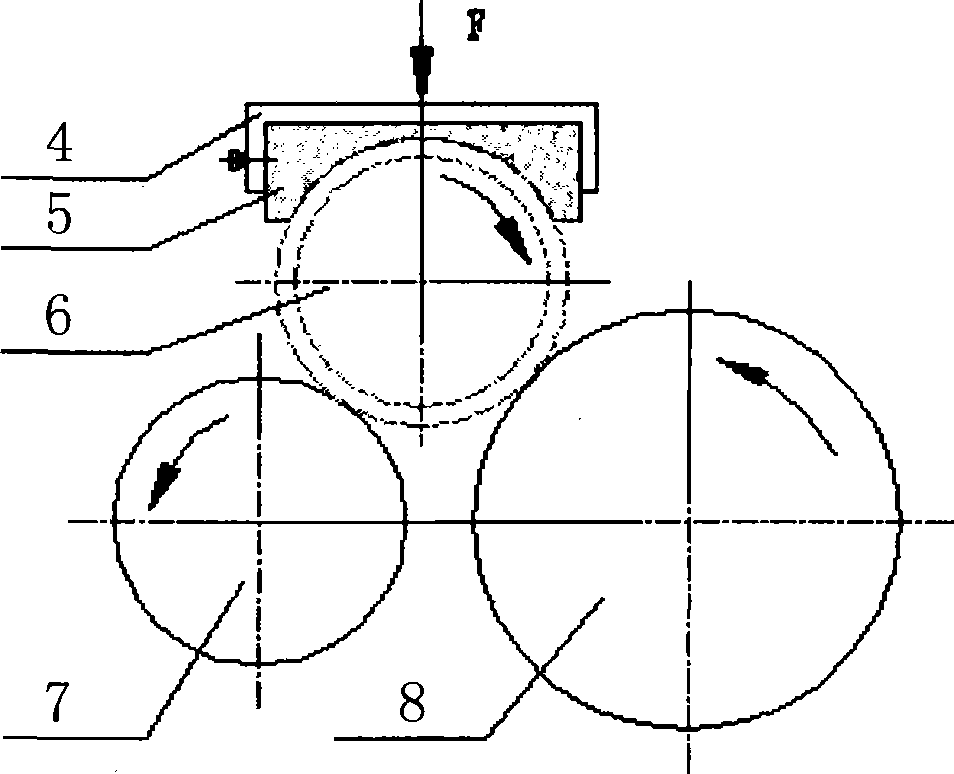

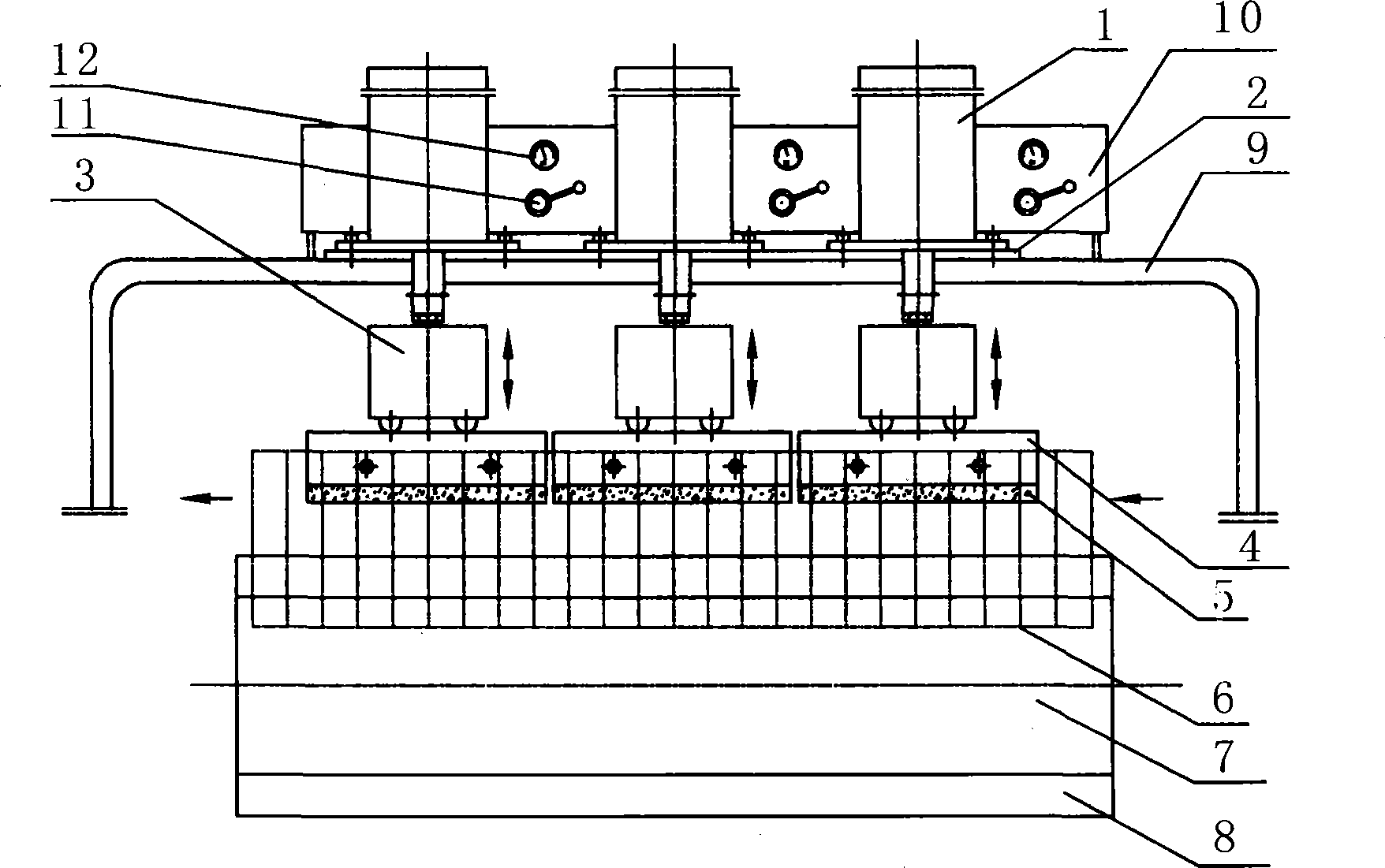

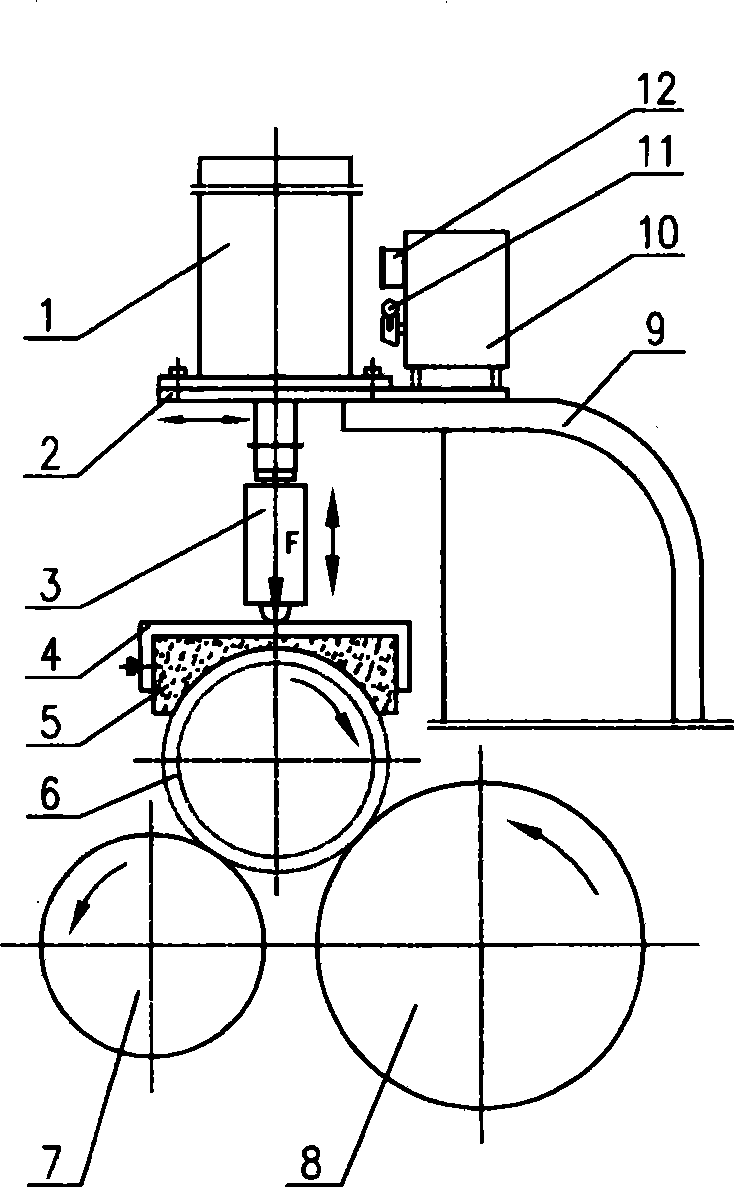

[0020] The outer diameter grinding machine pressurized by the cylinders of the present invention, the method is to fix the three cylinders on the support plate that can move back and forth, the support plate is installed on the large guide roller seat, and the piston rod extension ends of the three cylinders are connected to the Three flexible pressing devices are connected and can drive it to move up and down in a large stroke; the flexible pressing device is pressed on the oilstone splint, and the transmission system is adjusted according to the opening distance of the large and small guide rollers during grinding. The rings are stacked next to each other on the large and small guide rollers, and three oilstones and splints are placed on the rings. According to the size of the outer diameter of the bearing ring to be ground, according to the rough and fine grinding requirements, through the pressure gauge, manual valve, adjust the pressure of the cylinder and the up and down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com