Section-assembling bridge girder erection machine suitable for erecting bridges with minimum curve radii

A technology of curve radius and bridge erecting machine, which is applied in bridge construction, bridge erection/assembly bridge, etc. It can solve the problems that the bridge erecting machine cannot meet the erection requirements, uneven lateral load, etc., and achieves the convenience of adapting to variable span construction and construction The effect of high efficiency and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

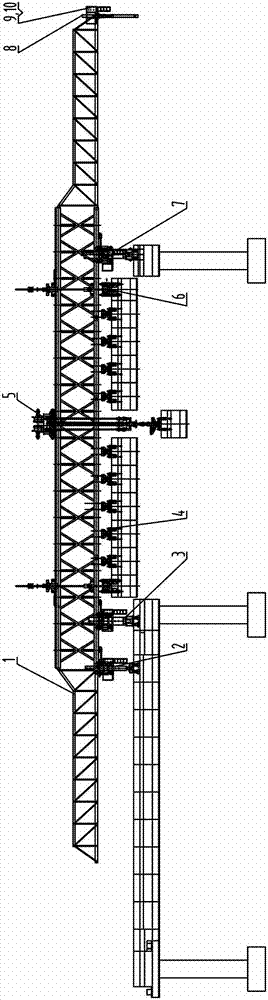

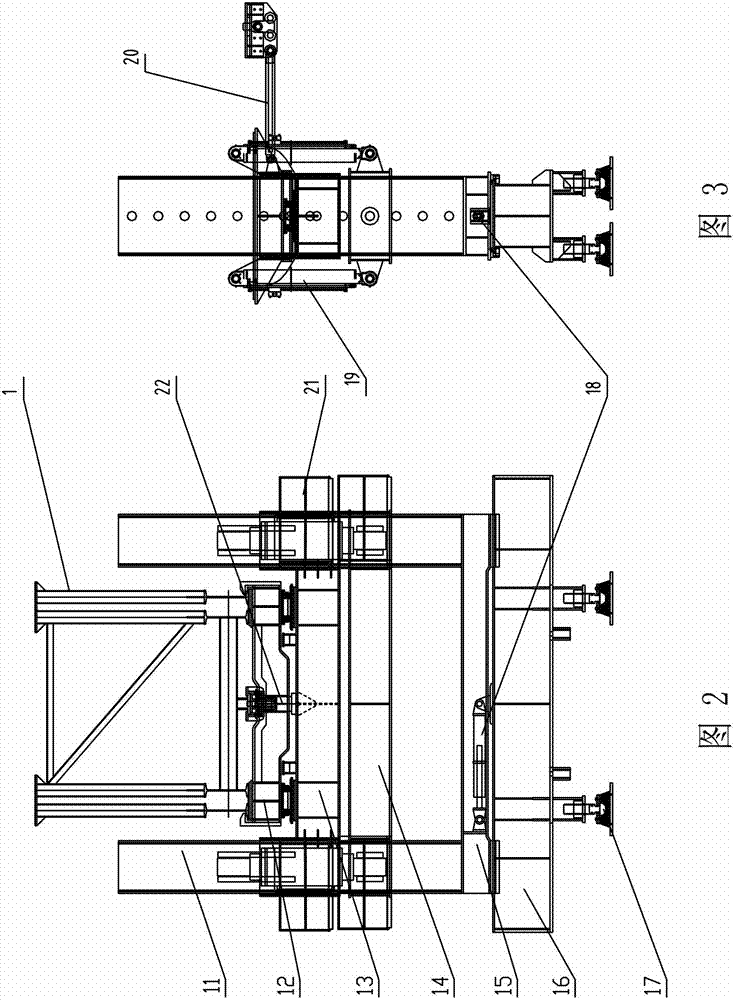

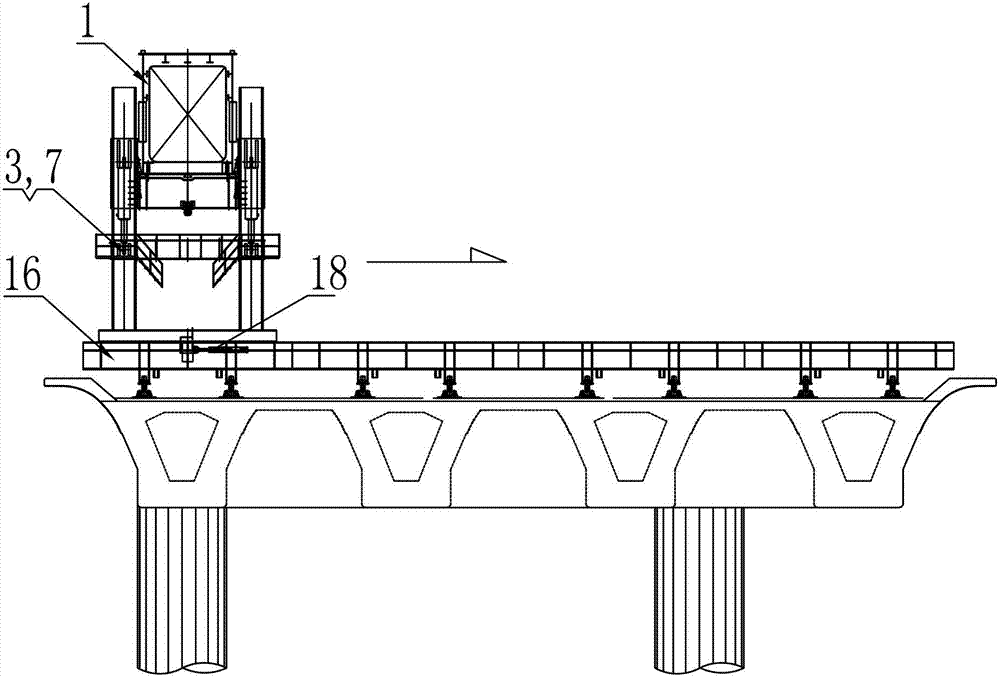

[0018] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 As shown, the segmental assembly bridge erecting machine suitable for the erection of extremely small curve radius bridges includes the main beam assembly 1, the front outrigger 8, the auxiliary outrigger 2, the No. 1 middle outrigger 7, and the No. 2 middle outrigger 3. Hoisting crane 5, middle suspension 4, hydraulic system 10, electrical system 9, the main girder assembly 1 is a single truss structure with simple structure and light weight, which is convenient for turning with a small radius. Such as figure 2 , 3 As shown, the No. 1 middle leg 7 or No. 2 middle leg 3 includes the inner column 11 of the middle leg, the upper crossbeam 12 of the middle leg turntable, the lower crossbeam 13 of the middle leg turntable, the support crossbeam 14 of the middle leg, the middle Outrigger connecting crossbeam 15, middle outrigger lower crossbeam 16, middle outrigger long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com