Urea liquid supply module used for high-pressure vehicles and integrating liquid level sensor

A liquid level sensor, vehicle urea technology, applied in the direction of machine/engine, exhaust treatment, mechanical equipment, etc., can solve the problems of urea loss, personal injury, expensive pipeline and filter cost, etc., to prevent high-speed jet flow , high security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

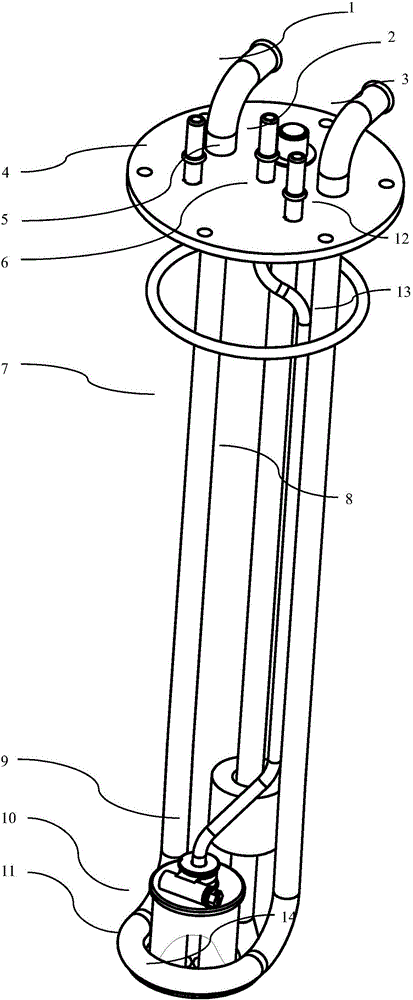

[0022] like figure 1 As shown, the urea supply module in this embodiment includes water inlet 1, electrical interface 2, water outlet 3, air inlet 4, urea outlet 5, exhaust port 6, cooling water pipe 7, liquid level and temperature sensor 8. Urea supply pipe 9, filter clamp 10, filter 11, flange 12, O-ring 13, damping hole 14. The water inlet 1, the electrical interface 2, the water outlet 3, the air inlet 4, the urea outlet 5 and the exhaust port 6 are all arranged on the flange 12; the flange 12 can seal the mouth of the urea tank, and pass through The sealing ring 13 realizes axial sealing;

[0023] Wherein, the urea liquid outlet 5 is connected with the urea liquid supply pipe 9, and the other end of the urea liquid supply pipe 9 is fixedly connected with the filter 11 at the bottom position of the urea tank through the filter clamp 10; The hot water pipe 7 and the two ends of the heat exchange pipe 7 are respectively connected to the water inlet 1 and the water outlet 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com