Method for manufacturing plastic coiling tool bar and plastic coiling tool bar

A loop-forming tool, plastic technology, applied in textiles and papermaking, knitting, weft knitting, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

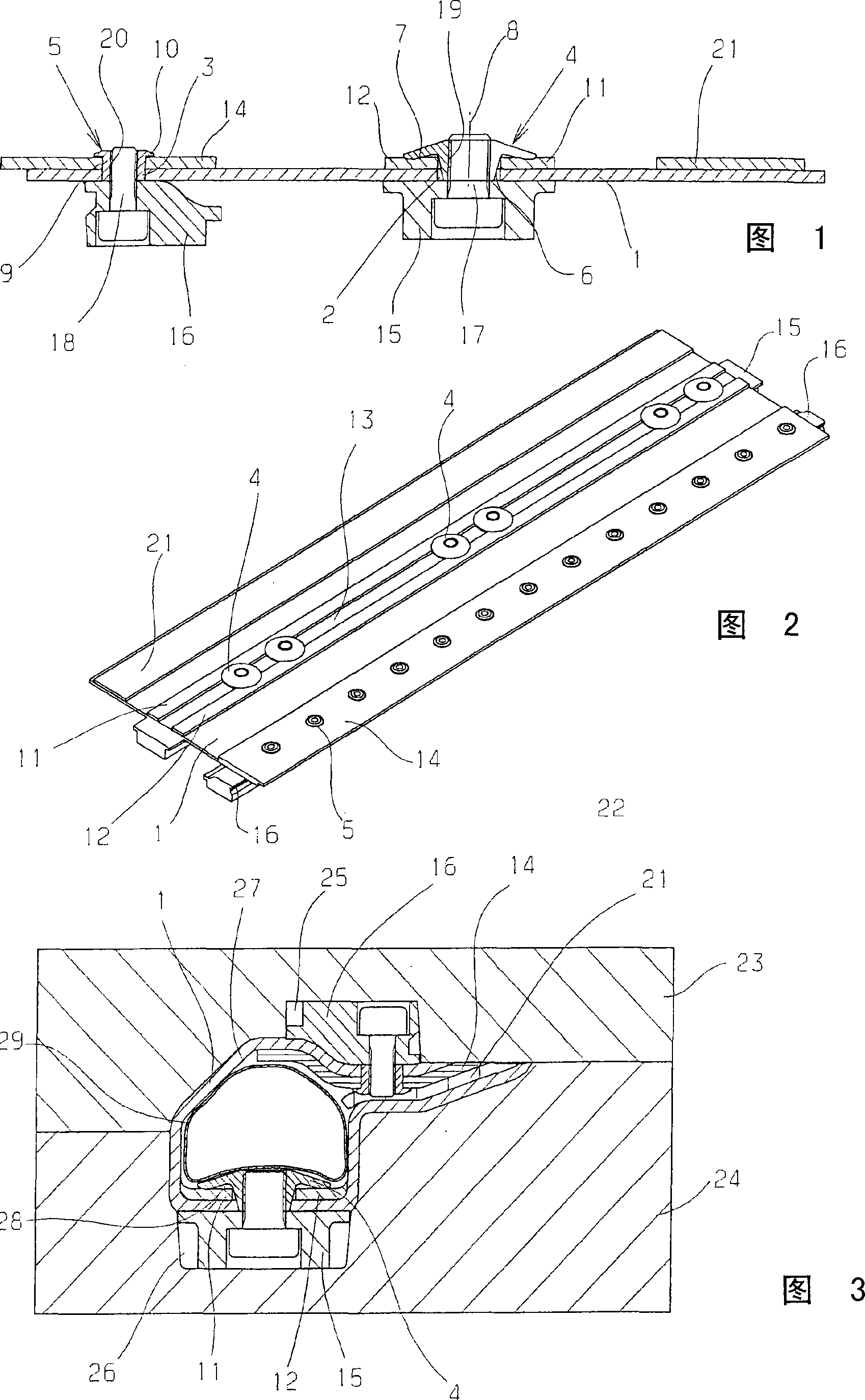

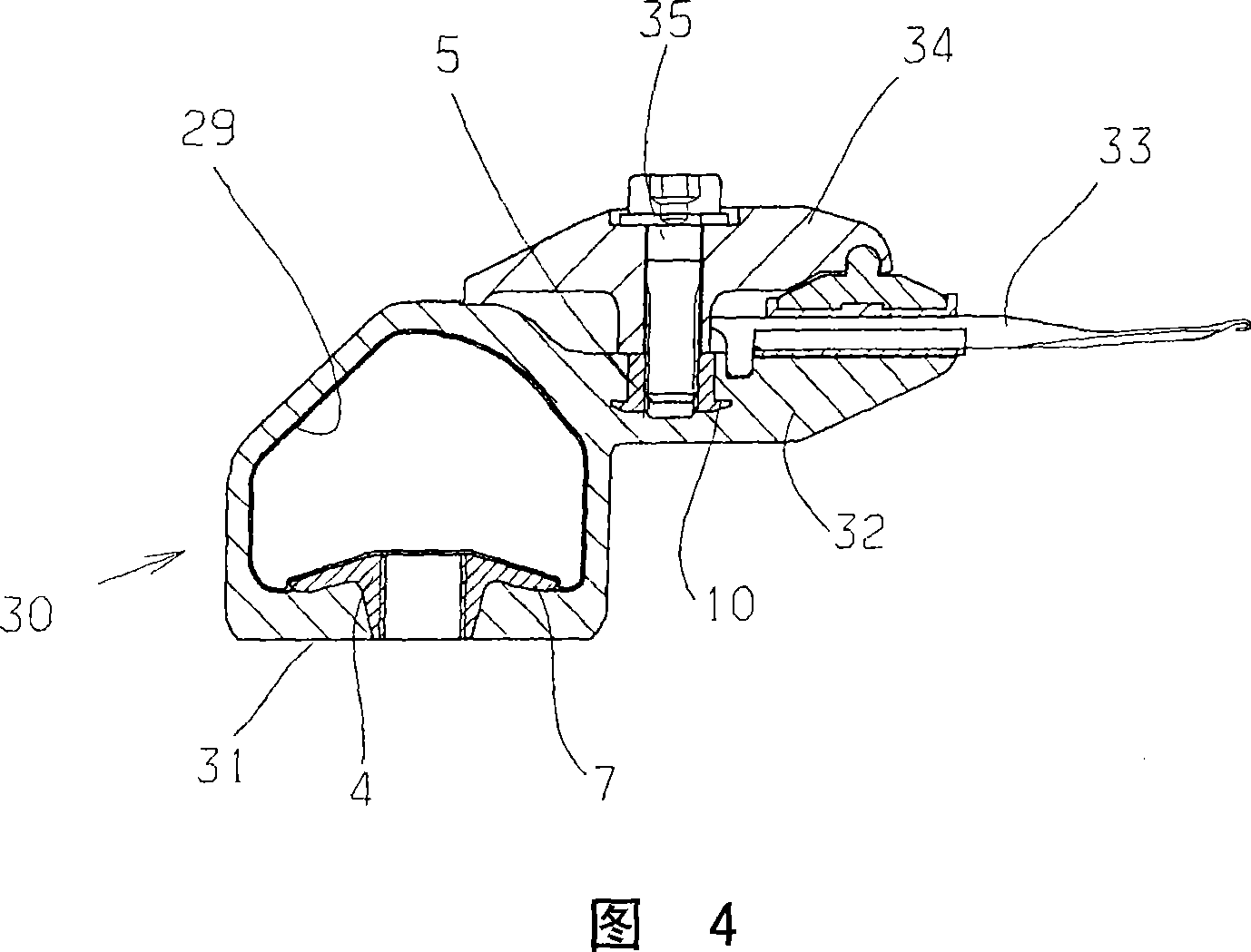

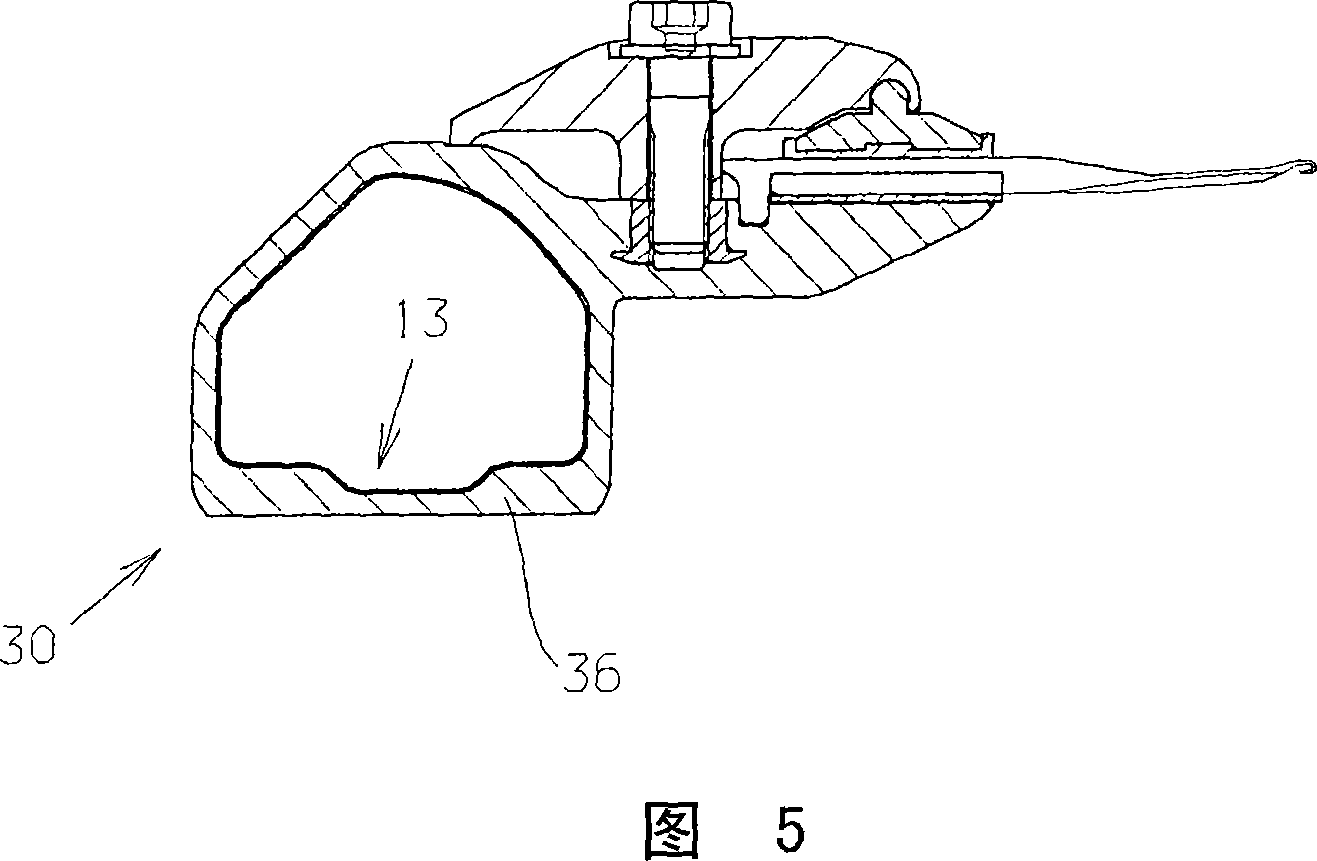

[0033] Figure 1 shows a semi-finished product 1 made of fiber-reinforced plastic, in expanded and flat form. The cross-section shown represents the semi-finished product corresponding to a cross-section of the finished bar as represented in FIGS. 4 and 5 . The semi-finished product 1 here consists of a pre-impregnated gel. For the following description this semi-finished product is also referred to as "layer", even though it actually consists of several layers. In this case the reinforcing fibers can be arranged parallel to each other in each individual layer. The fibers of the different layers have different orientations, the thickness of the semi-finished product 1 being eg 2 mm.

[0034] Holes 2 , 3 are punched in the semi-finished product 1 . Each hole passes through a fastening member 4,5. The holes 2, 3 can also be formed by pressing a pointed tool through the semi-finished product 1 so that the reinforcing fibers of the semi-finished product 1 are not cut but squeez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com