Method and device for inserting weft thread into a loom

A technology of weft insertion loom and weft yarn is applied to the shed of air-jet weft insertion looms and the fields of air-jet weft insertion looms, which can solve the problems of inaccurate control of weft insertion and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

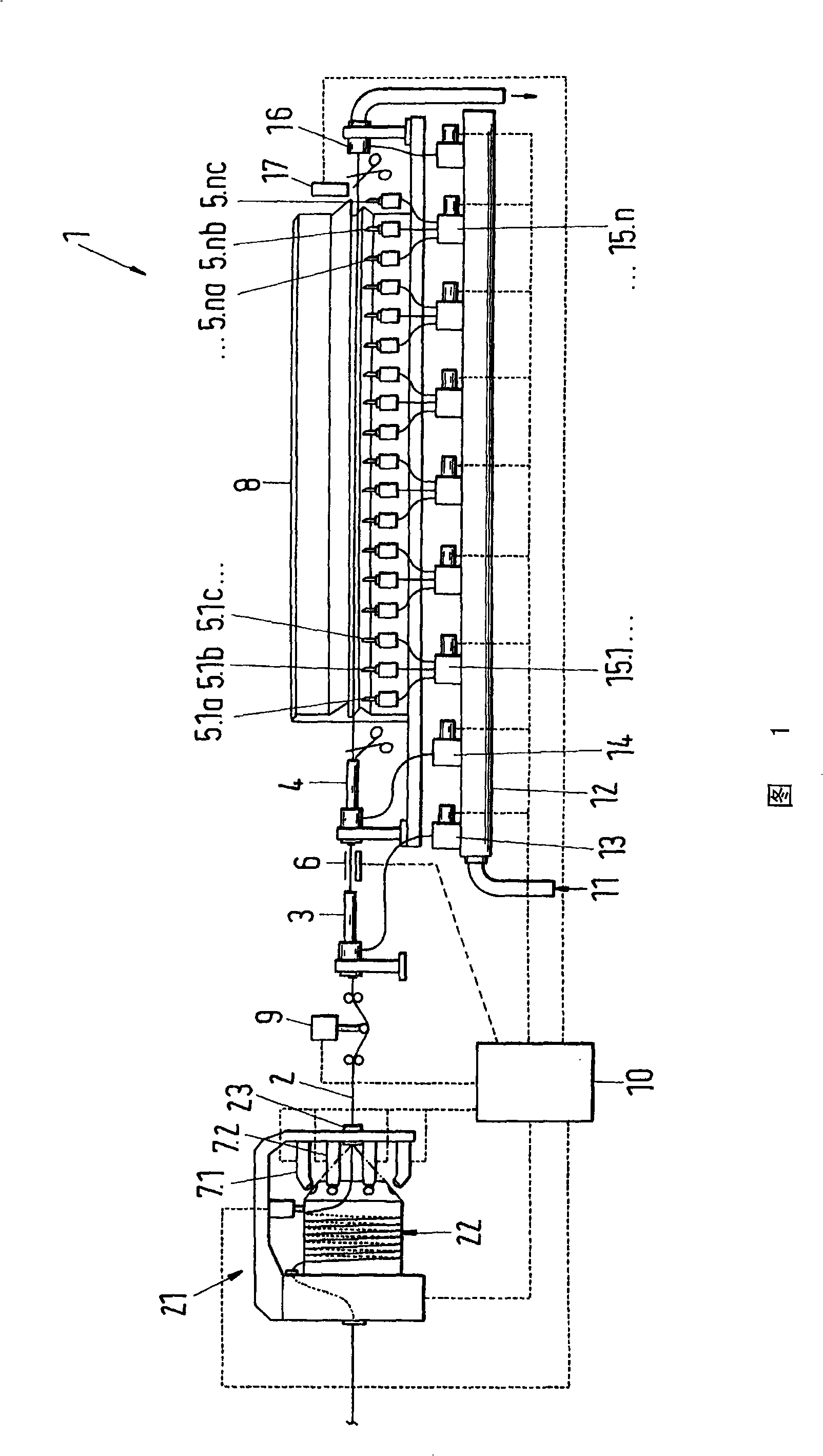

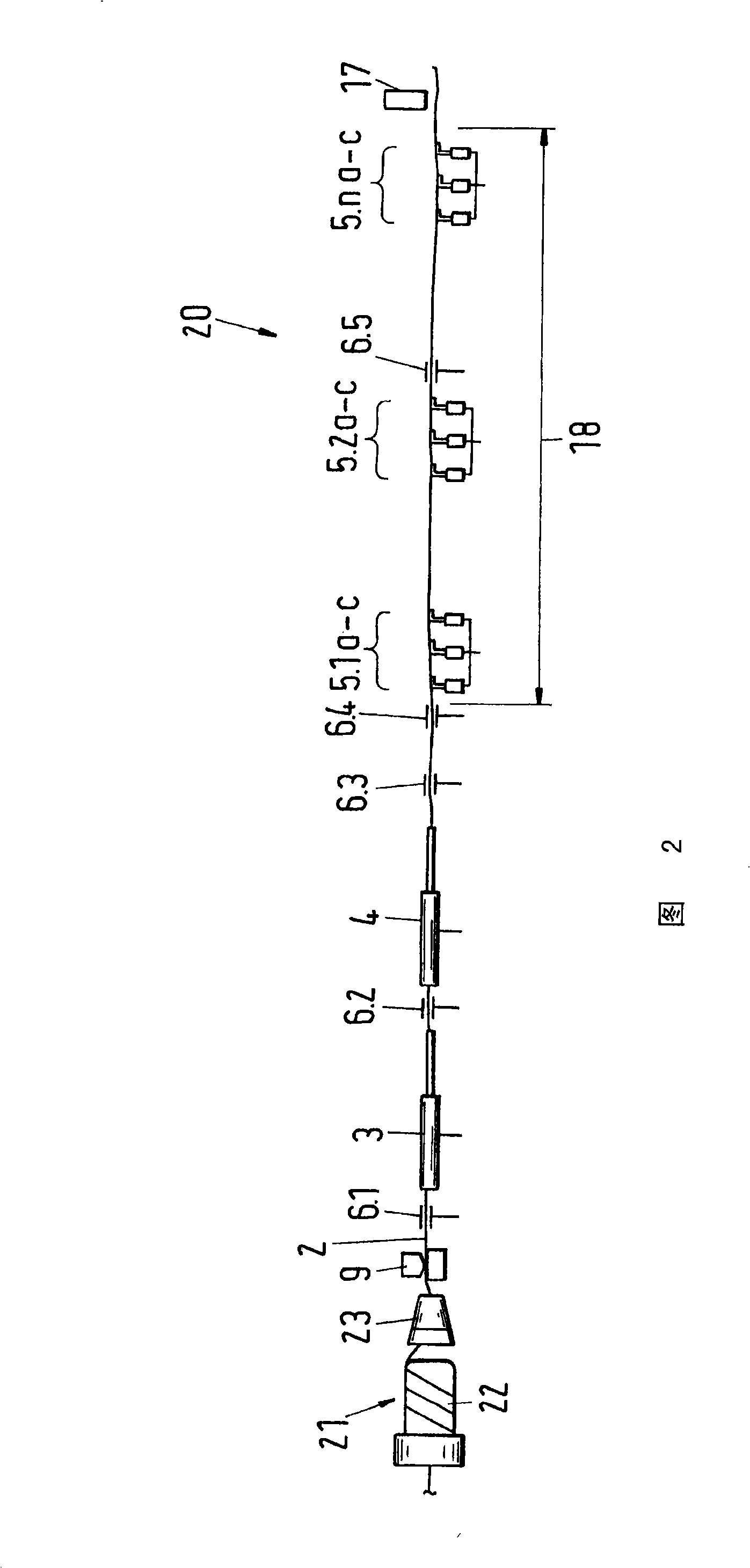

[0025] Figure 1 shows an embodiment of an air-jet weft insertion loom with the device according to the invention. The device for inserting weft yarn 2 into the shed (not shown in FIG. 1 ) comprises a yarn store 21, which may for example comprise a store drum 22; at least one accelerating nozzle 3, 4 to accelerate from The weft yarn that yarn storehouse is pulled out and conveys in the shed; A plurality of auxiliary nozzles 5.1a-c to 5.na-c, so that continue to convey the weft yarn in the shed; And one or more measuring sensors 7.1,7.2,17, such as one or A plurality of turns counters 7.1, 7.2 arranged on or in the vicinity of the yarn store 21 in order to detect the number of turns or partial turns withdrawn from the store drum 22; and / or arranged in the shed A weft thread detector 17 on the end on the intercepting side of the spool, in order to detect the arrival of the weft thread 2 introduced.

[0026] Also in the device of the present invention, at least one measuring sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com