Hose clamps

A technology of hose clamps and hoses, applied in the field of hose clamps, can solve problems such as high cost and achieve high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

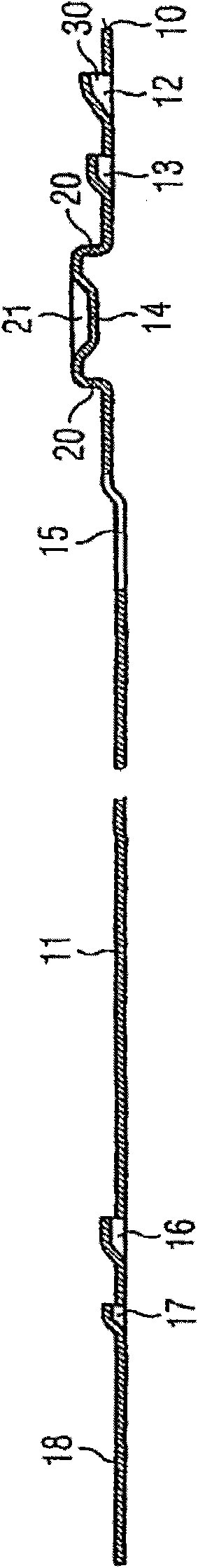

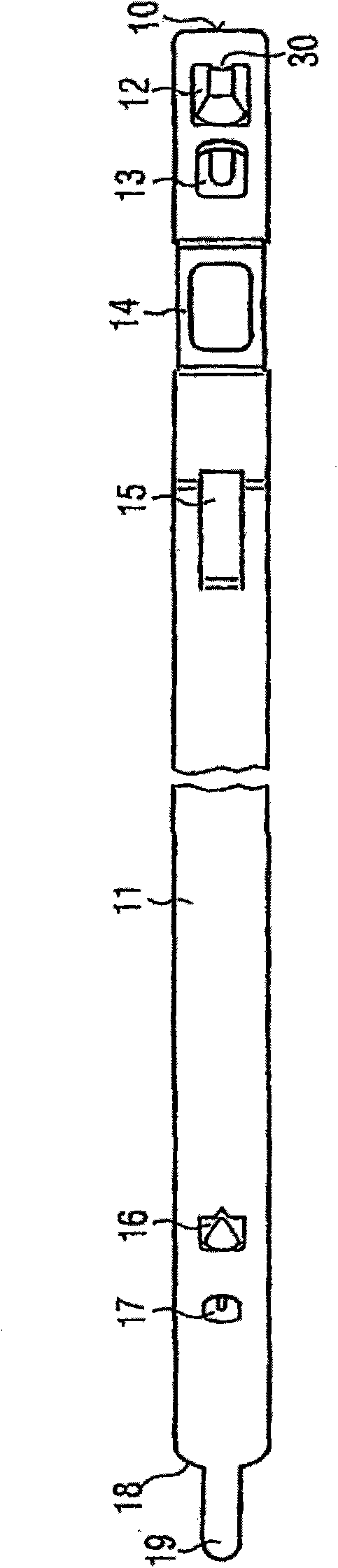

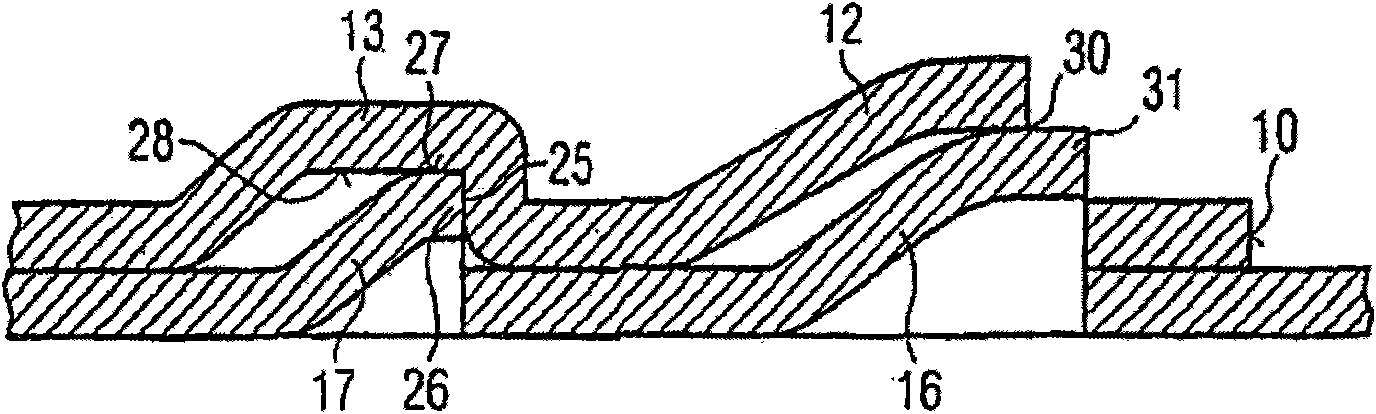

[0014] from figure 1 with figure 2 Proceeding from the band end 10 shown on the right, which is located on the outside in the closed state of the hose clamp, the hose clamp illustrated in the drawing has the following features formed from a steel band 11 by cold forming: Guide receiver 12, holding receiver 13, tensioning device 14 in the form of a so-called "Oetiker-Ohr", tongue guide 15, guide hook 16, holding hook 17, and in soft A tongue 19 on the other inner strap end 18 in the closed state of the pipe clip.

[0015] exist image 3 In the closed state of the hose clamp shown in , the guide hook 16 engages in the guide receptacle 12 , the retaining hook 17 engages in the retaining receptacle 13 and the tongue 19 engages in the tongue guide 15 .

[0016] In order to tighten the hose clamp by reducing the diameter of the hose clamp, two legs 20 of the tensioning lug (Spannohr) 14 originating from the belt and extending substantially perpendicularly to the belt are placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com