Mortar spraying device with gradually-changed spraying direction

A spraying device and gradient technology, which is applied in the field of spraying direction gradient mortar spraying device to achieve the effect of preventing precipitation or condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

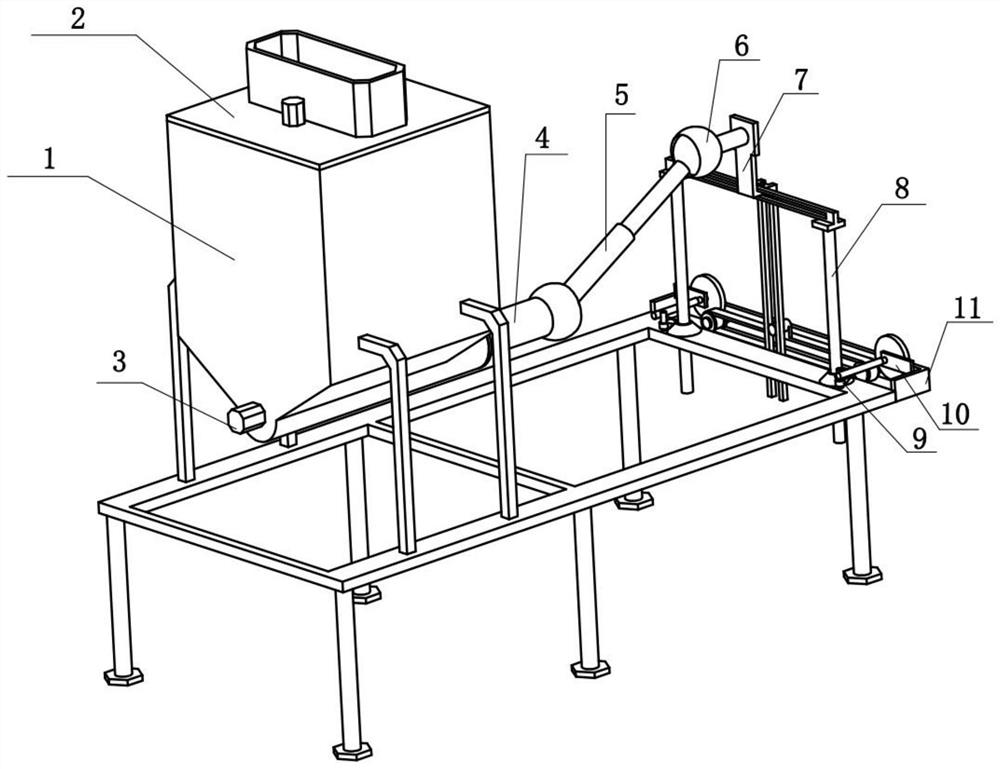

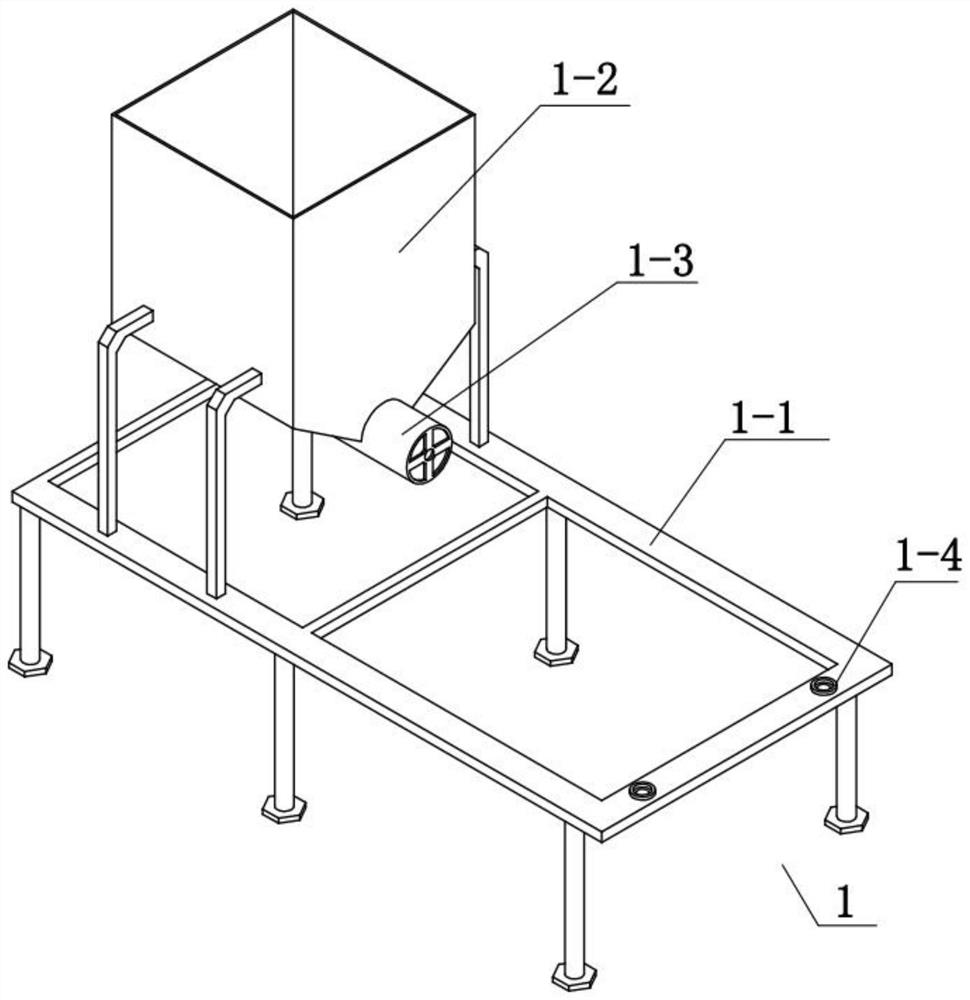

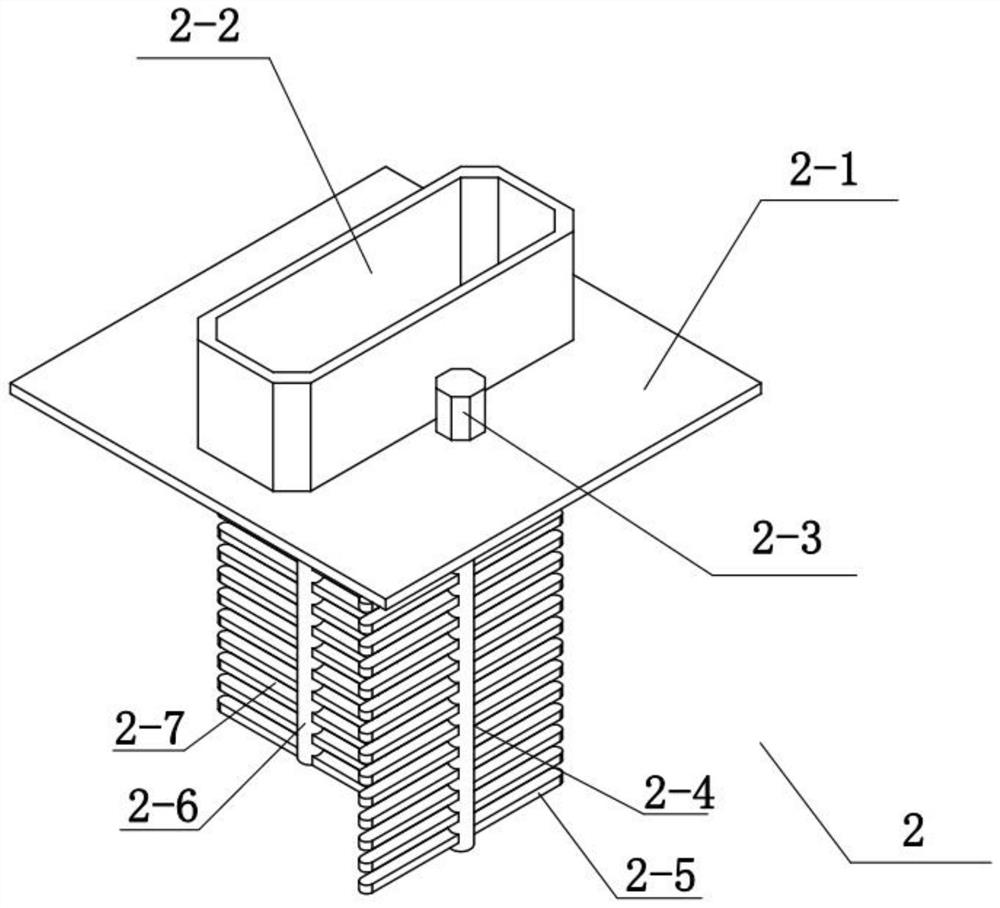

[0035] Combine below Figure 1-12Describe this embodiment, a spraying direction gradient type mortar spraying device, including a support frame assembly 1, a stirring assembly 2, a feeding assembly 3, a first connecting pipe 4, a second connecting pipe 5, a spraying pipe 6, a limit assembly 7, The lifting assembly 8, the intermittent transmission assembly 9, the transmission assembly 10 and the traverse assembly 11, the stirring assembly 2 is fixedly connected to the support frame assembly 1, the feeding assembly 3 is fixedly connected to the support frame assembly 1, and the first connecting pipe 4 is fixedly connected to the On the support frame assembly 1, the second connecting pipe 5 is hinged on the first connecting pipe 4, the spraying pipe 6 is hinged on the second connecting pipe 5, the limit assembly 7 is fixedly connected to the spraying pipe 6, and the lifting assembly 8 slides Connected to the support frame assembly 1, there are two intermittent transmission assemb...

specific Embodiment approach 2

[0038] Combine below Figure 1-12 To illustrate this embodiment, the traversing assembly 11 includes a traversing frame 11-1, a reciprocating motor 11-2, a pulley 11-3, a toothed belt 11-4, a reciprocating rod 11-5 and a motor output wheel 11-6 , the reciprocating motor 11-2 is fixedly connected to the traversing frame 11-1, and the two motor output wheels 11-6 are respectively fixedly connected to the front and rear sides of the traversing frame 11-1, and the two motor output wheels 11-6 are There are two pulleys 11-3 fixedly connected, the motor output pulley 11-6 at the front end is fixedly connected on the output shaft of the reciprocating motor 11-2, the two pulleys 11-3 are driven by the toothed belt 11-4, and the reciprocating rod 11-5 is fixedly connected on the toothed belt 11-4.

[0039] Start the reciprocating motor 11-2, the reciprocating motor 11-2 drives the motor output wheel 11-6 fixedly connected with it to rotate, the motor output wheel 11-6 at the front end...

specific Embodiment approach 3

[0041] Combine below Figure 1-12 To illustrate this embodiment, the transmission assembly 10 includes a transmission fixing plate 10-1, a transmission worm shaft 10-2 and a reduction gear 10-3. The transmission worm shaft 10-2 is rotatably connected to the transmission fixing plate 10-1, and the reduction gear 10-3 is fixedly connected to the transmission worm shaft 10-2, two transmission fixing plates 10-1 are respectively fixedly connected to the front and rear sides of the traverse frame 11-1, and the two reduction gears 10-3 are respectively connected to the two motor output Wheel 11-6 engages the transmission.

[0042] The two motor output wheels 11-6 mesh respectively to drive the two reduction gears 10-3 to rotate, and the two reduction gears 10-3 drive the two transmission worm shafts 10-2 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com