Automatic spraying system and method based on workpiece contour information three-dimensional reconstruction

An automatic spraying and three-dimensional reconstruction technology, applied in the direction of spraying devices, can solve the problems of low flexibility, uneven local spraying, and long time-consuming preset spraying paths, so as to achieve the effect of improving efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

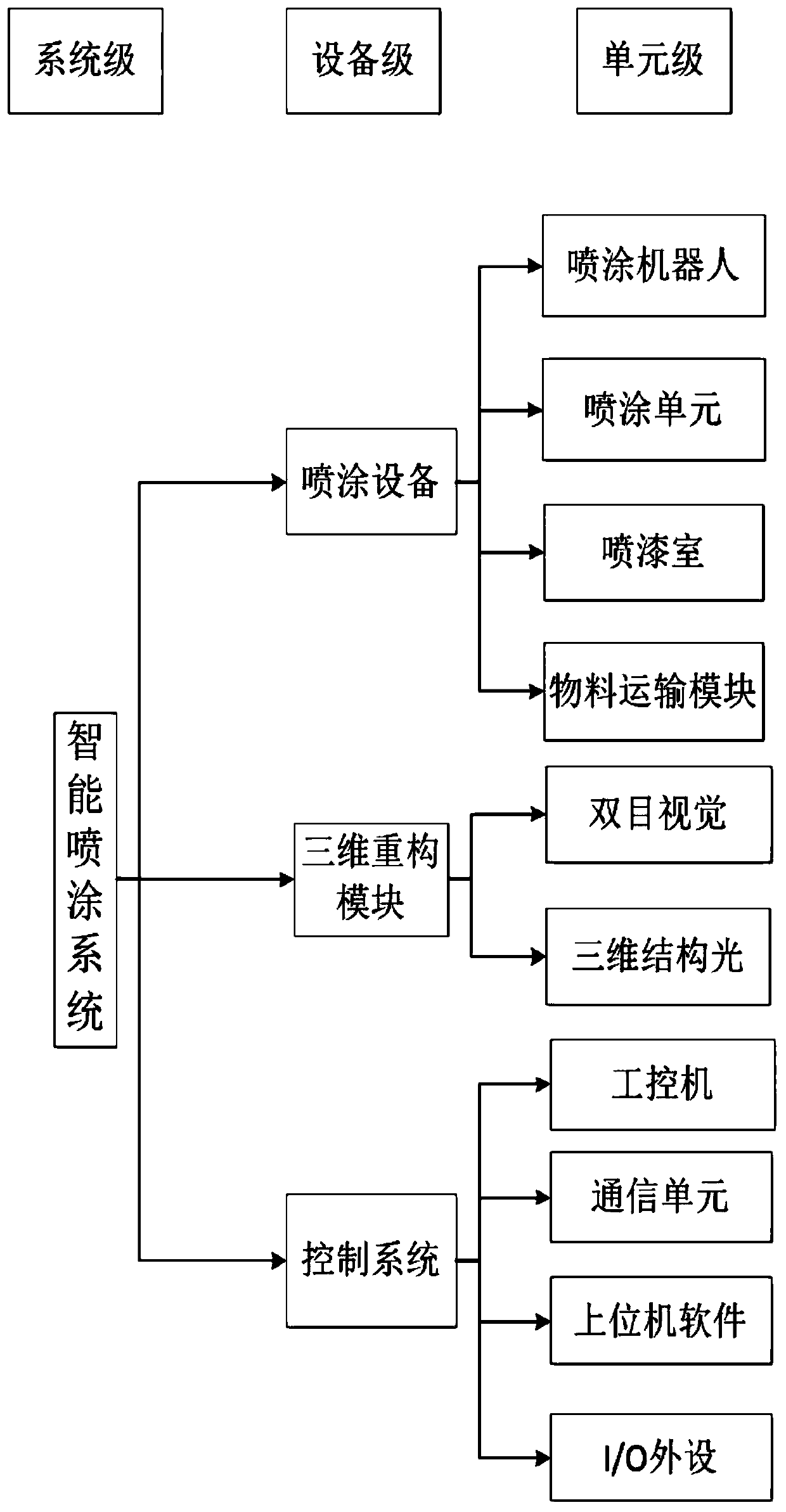

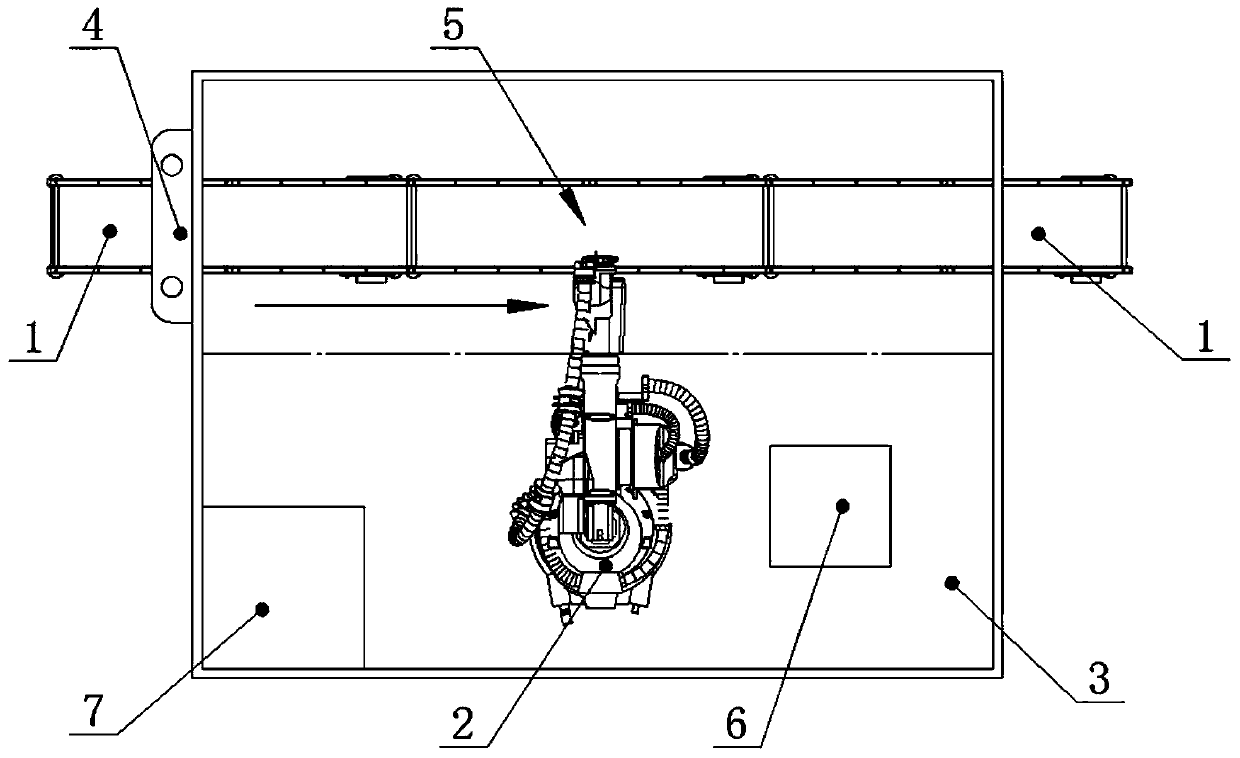

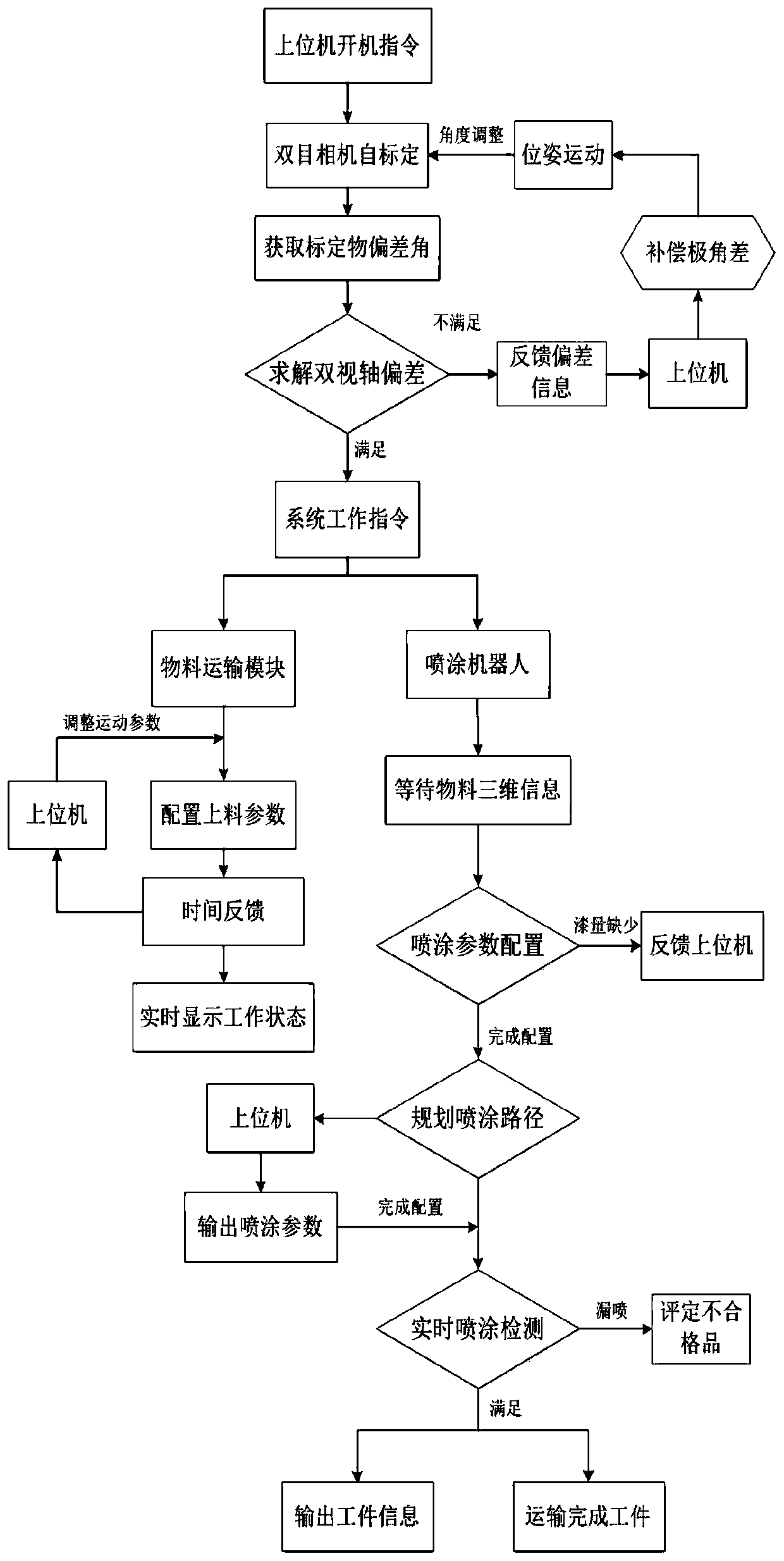

[0028] The invention discloses an automatic spraying system based on three-dimensional reconstruction of workpiece contour information, which includes a control system, a three-dimensional reconstruction module 4 and automatic spraying equipment. The unit is used to obtain the phase and reflection time parameters of the three-dimensional structured light reflection of the workpiece to be sprayed, extract the three-dimensional data according to the different parameters and fit the data into continuous interactive contour modeling information and send it to the control system, and solve it through coordinate transformation The position and posture of the whole work in the world coordinate system of the spraying robot are obtained, and the spraying path is automatically planned. The painting equipment includes a spraying room 3, which is connected to the control system, and can automatically spray the workpiece to be sprayed according to the spraying path.

[0029] see figure 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com