Coating device for aircraft fuselage surface machining

A technology for surface processing and aircraft fuselage, applied in the direction of spraying devices, etc., can solve the problems of inconsistent coating thickness, inconvenient spraying, harmful gas, etc., and achieve the effect of uniform coating thickness, small spraying limitation and high spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the examples.

[0031] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

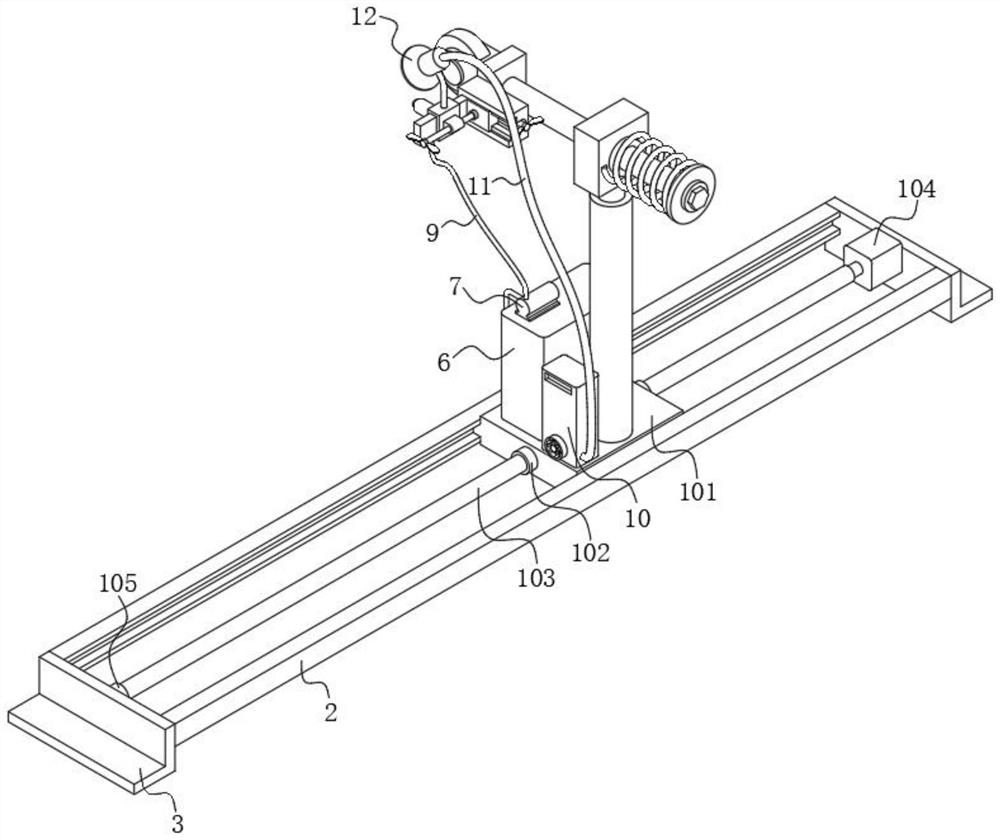

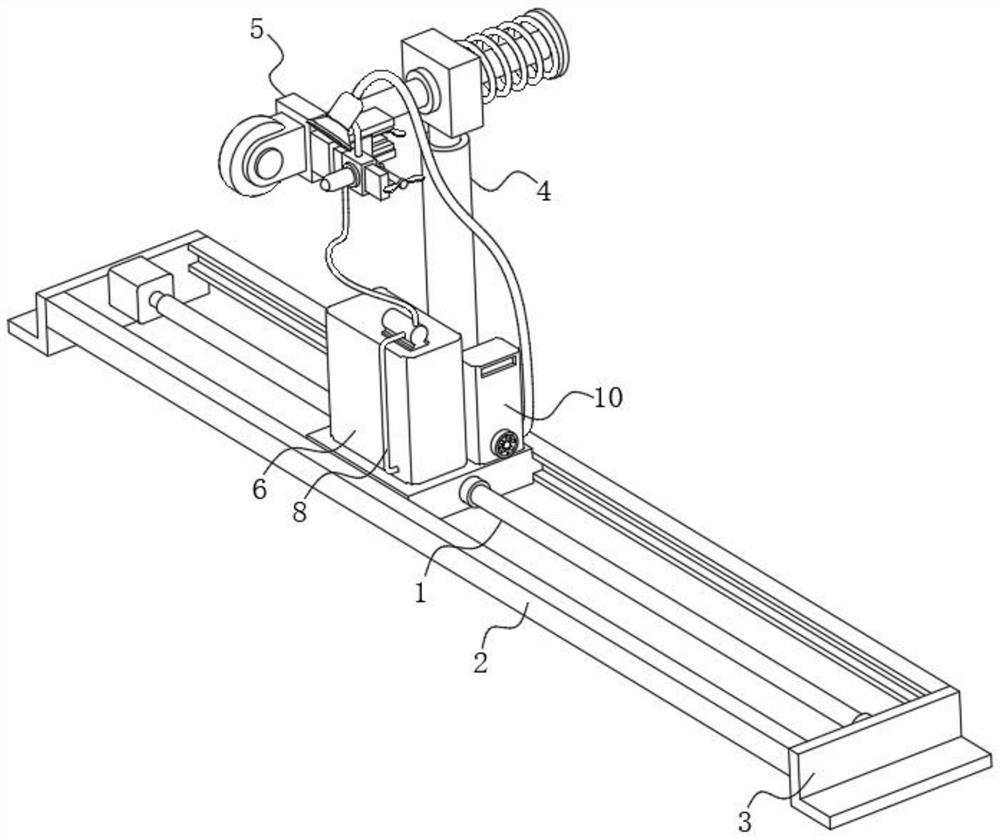

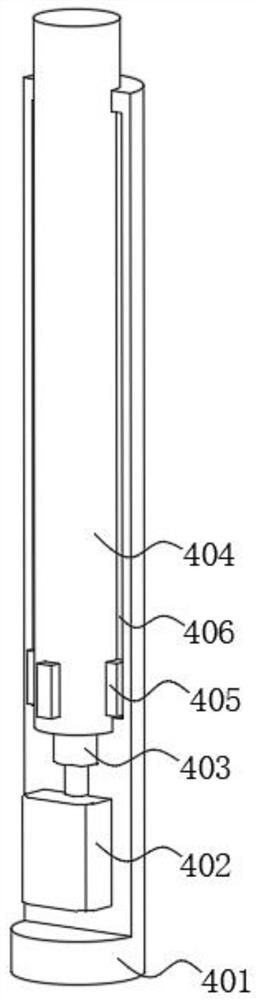

[0032] see Figure 1-6 , the invention provides a kind of coating device for aircraft fuselage surface processing, comprising:

[0033] The lateral movement mechanism 1 is slidably connected in two U-shaped plates 2, and the two ends of the two U-shaped plates 2 are jointly welded with a base plate 3, and a paint liquid tank 6 is installed on the transverse movement mechanism 1, and the paint liquid A spray pump 7 is installed on the tank 6, and the input po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com