A track self-propelled multi-mode greenhouse automatic sprayer

A sprayer and track technology, applied in the field of agricultural engineering, to achieve the effect of good uniformity, high efficiency and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

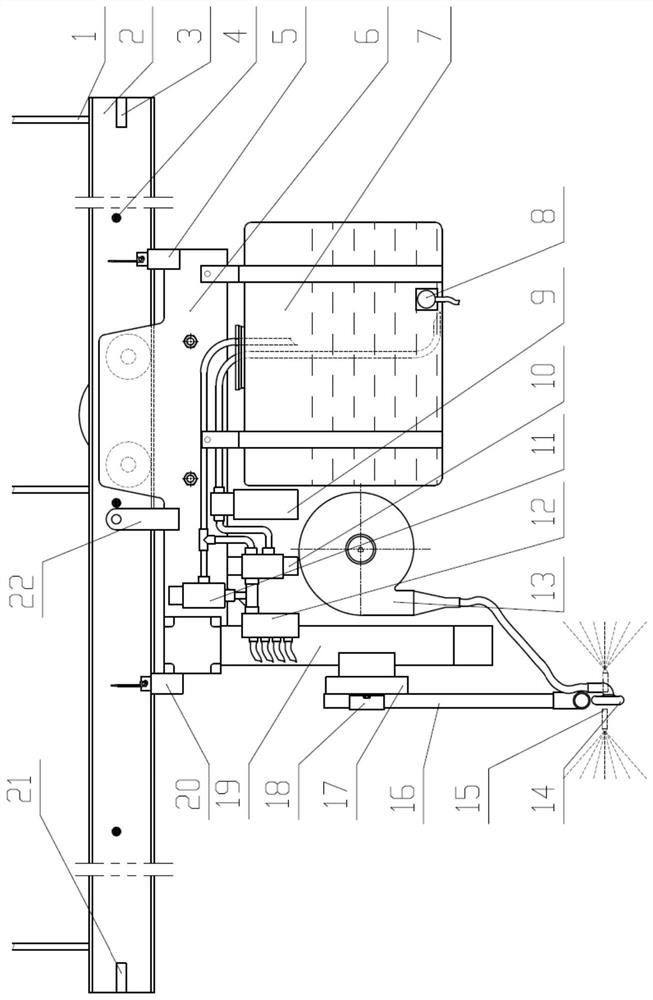

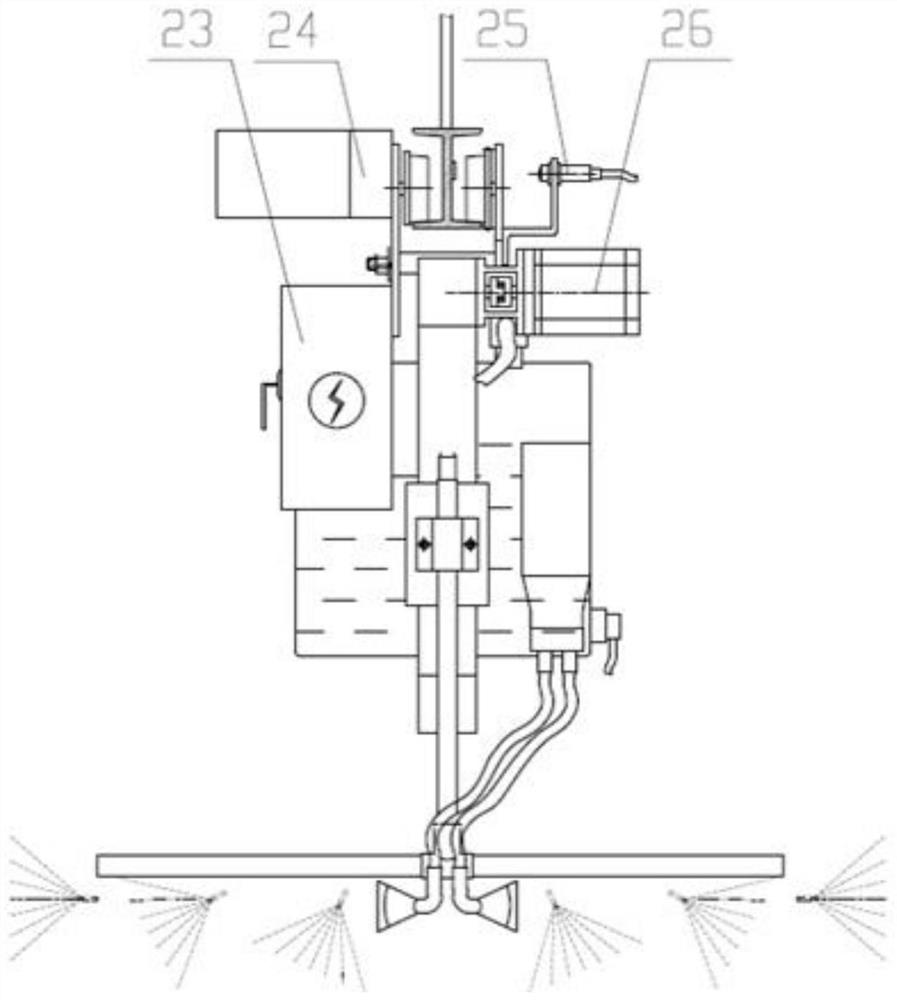

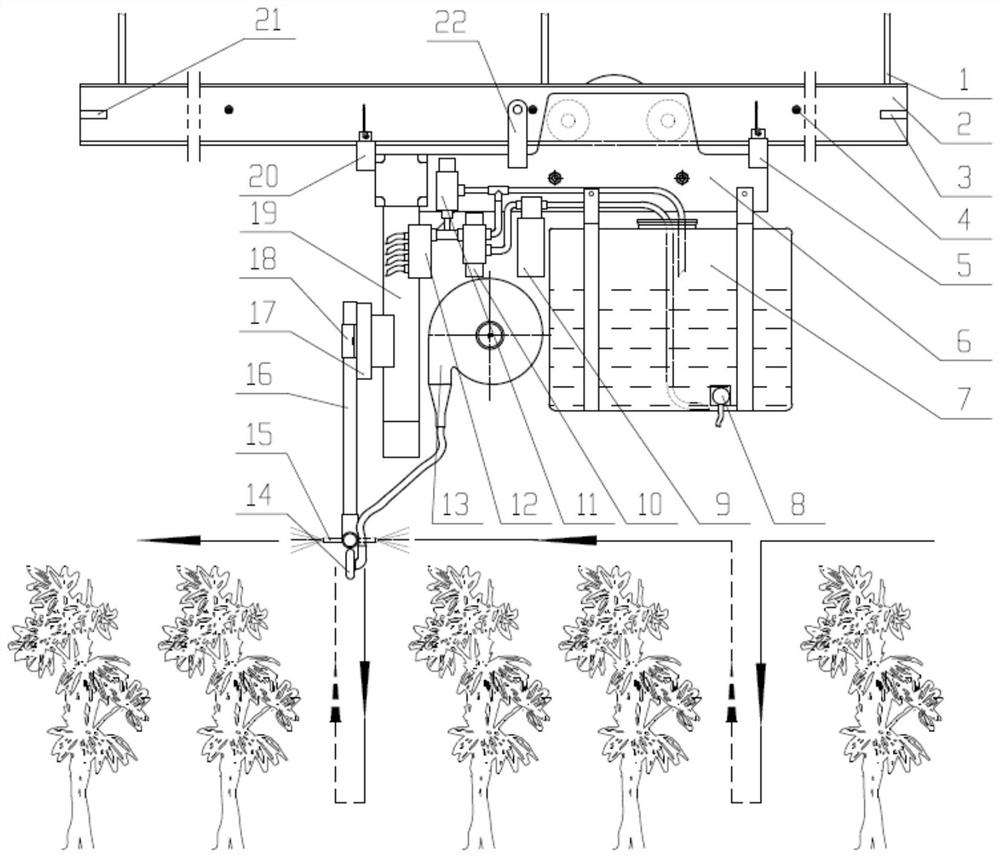

[0034] Example 1, see figure 1 —— Picture 9 The track self-propelled multi-mode greenhouse automatic sprayer, the track 2 is suspended and erected under the arch pipe of the greenhouse ceiling along the length of the greenhouse via the boom 1; the self-propelled platform is composed of a self-propelled trolley 6 and a motor 24. The self-propelled platform is placed on the track 2. The platform is driven by the motor 24, which can perform continuous work advancement, intermittent work advancement, fast forward, fast reverse and other actions;

[0035] The lifting module includes a vertical sliding rail 19, a T-shaped bracket 16, a sliding block 17, a stepping motor 26, a timing belt wheel, a timing belt, etc. The vertical sliding rail 19 is installed in the front of the frame of the self-propelled trolley 6 through a connector along the vertical direction The middle position. The two ends of the vertical slide rail 19 are equipped with a timing belt wheel seat and a timing belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com