Optimization method for spray gun track of spraying robot on irregular polyhedron

A spraying robot and trajectory optimization technology, applied in the direction of instruments, spraying devices, special data processing applications, etc., can solve the problems of not being able to use three-dimensional polyhedrons, time-consuming, harmful environment for workers, etc., to improve work efficiency and product quality, strong and practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

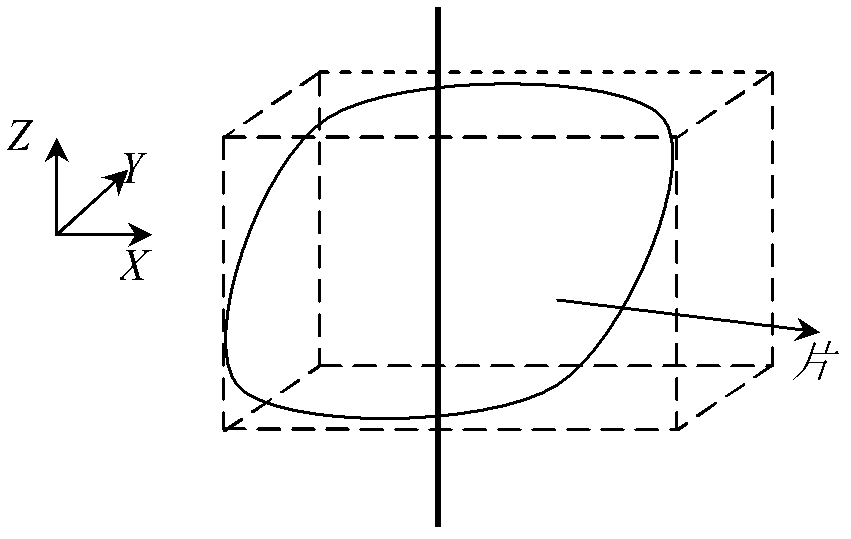

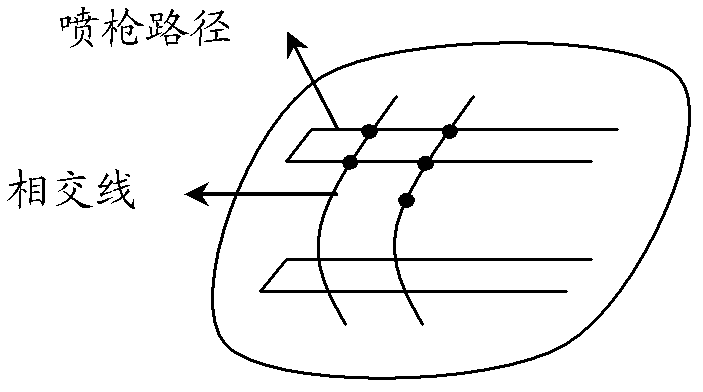

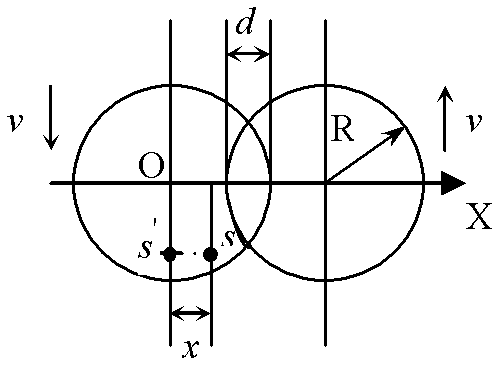

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The implementation steps of the present invention are composed of three parts: the generation of the space path of the spray gun of the spraying robot on the polyhedron, the optimization of the trajectory of the spray gun on each face of the polyhedron, and the optimization of the combination of the trajectory of the spray gun. The specific implementation is as follows.

[0021] 1 Spatial Path Generation of Spraying Robot Spray Gun on Polyhedron

[0022] The specific steps of spraying robot spray gun space path on polyhedron are as follows:

[0023] (1) The irregular polyhedron is determined by the CAD model of the workpiece. After inputting the CAD graphics of the irregular polyhedron in the GID7.2 software, the triangular mesh graphic of the irregular polyhedron is obtained through the GID grid graphic output function (allowable error 2mm, each The mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com