Water-based paint uniform spraying device and method for color steel plate spraying

A technology of water-based paint and uniform spraying, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc. It can solve the problems of uneven spraying, low work efficiency, complex structure, etc., achieve uniform spraying and improve practicability , Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

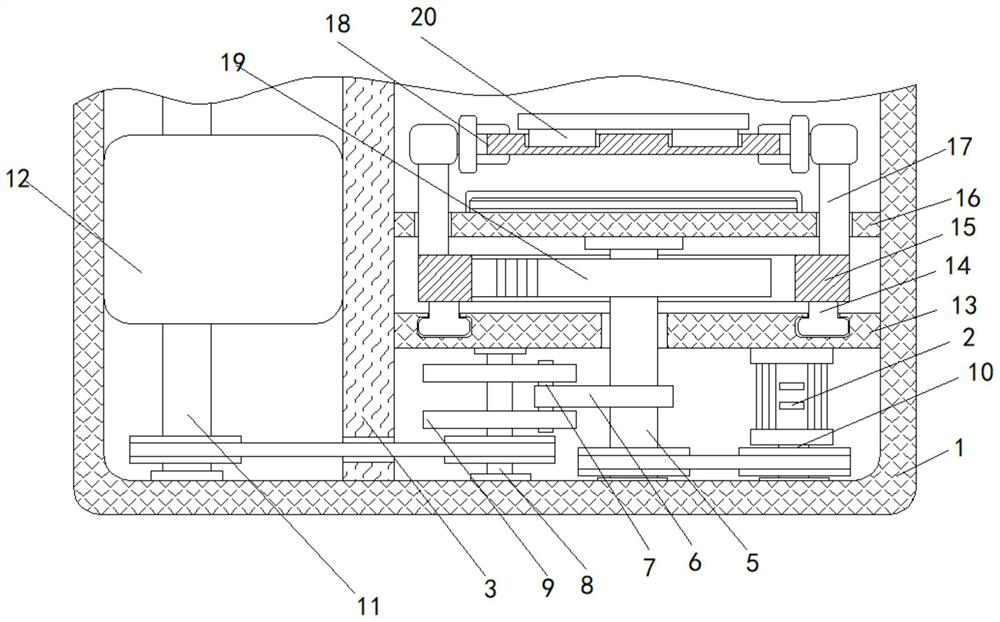

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

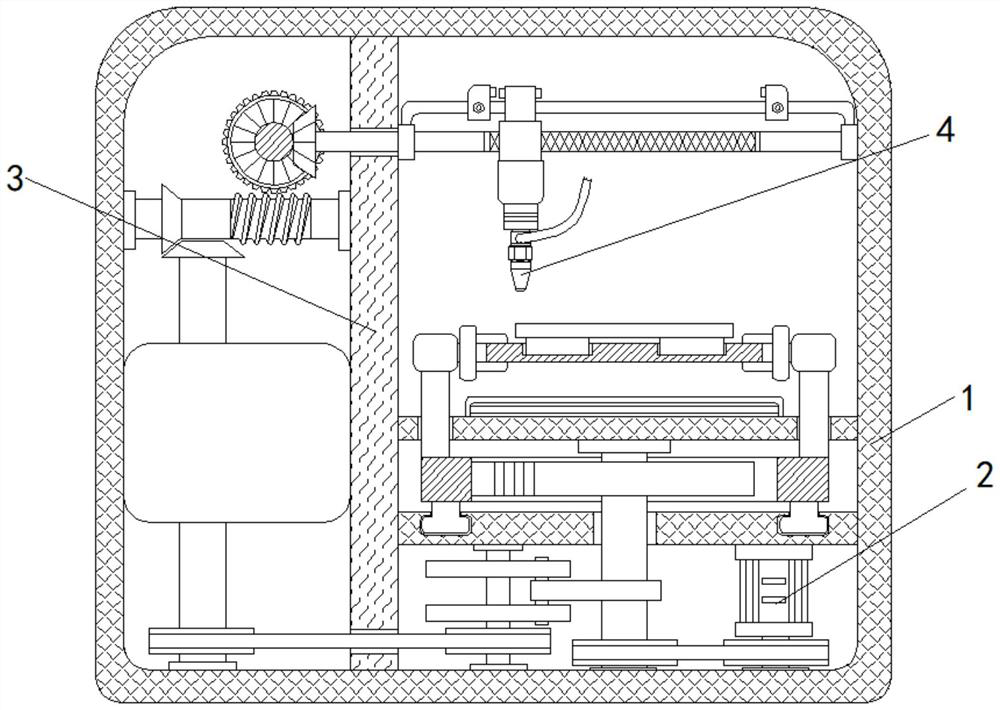

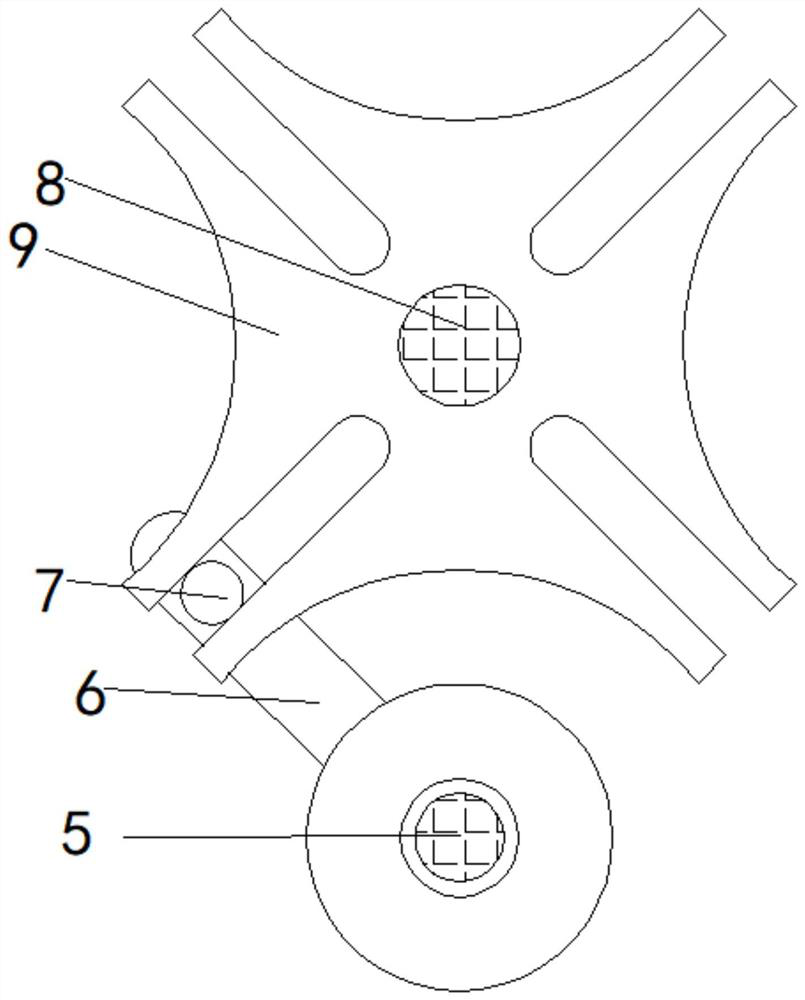

[0037] refer to Figure 1-8 , a method for evenly spraying water-based paint for color steel plate spraying, comprising the following steps:

[0038]S1. Place the color steel plate to be sprayed in the middle of the placement table 18, start the electromagnet 20, the electromagnet 20 can absorb the color steel plate, complete the fixing of the color steel plate, and prevent the color steel plate from shaking during spraying;

[0039] S2. Simultaneously start the electric push rod 24, and the electric push rod 24 drives the nozzle 4 to move downward, so as to facilitate the adjustment of the height of the nozzle 4, and the nozzle 4 works;

[0040] S3, start motor 2 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com