Spraying equipment for building decoration

A technology for spraying equipment and architectural decoration, applied in the direction of spraying devices, etc., can solve the problems of difficult spraying medium, affecting the effect of spraying, scratching, etc., to prevent uneven spraying, improve spraying effect, and improve the effect of adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

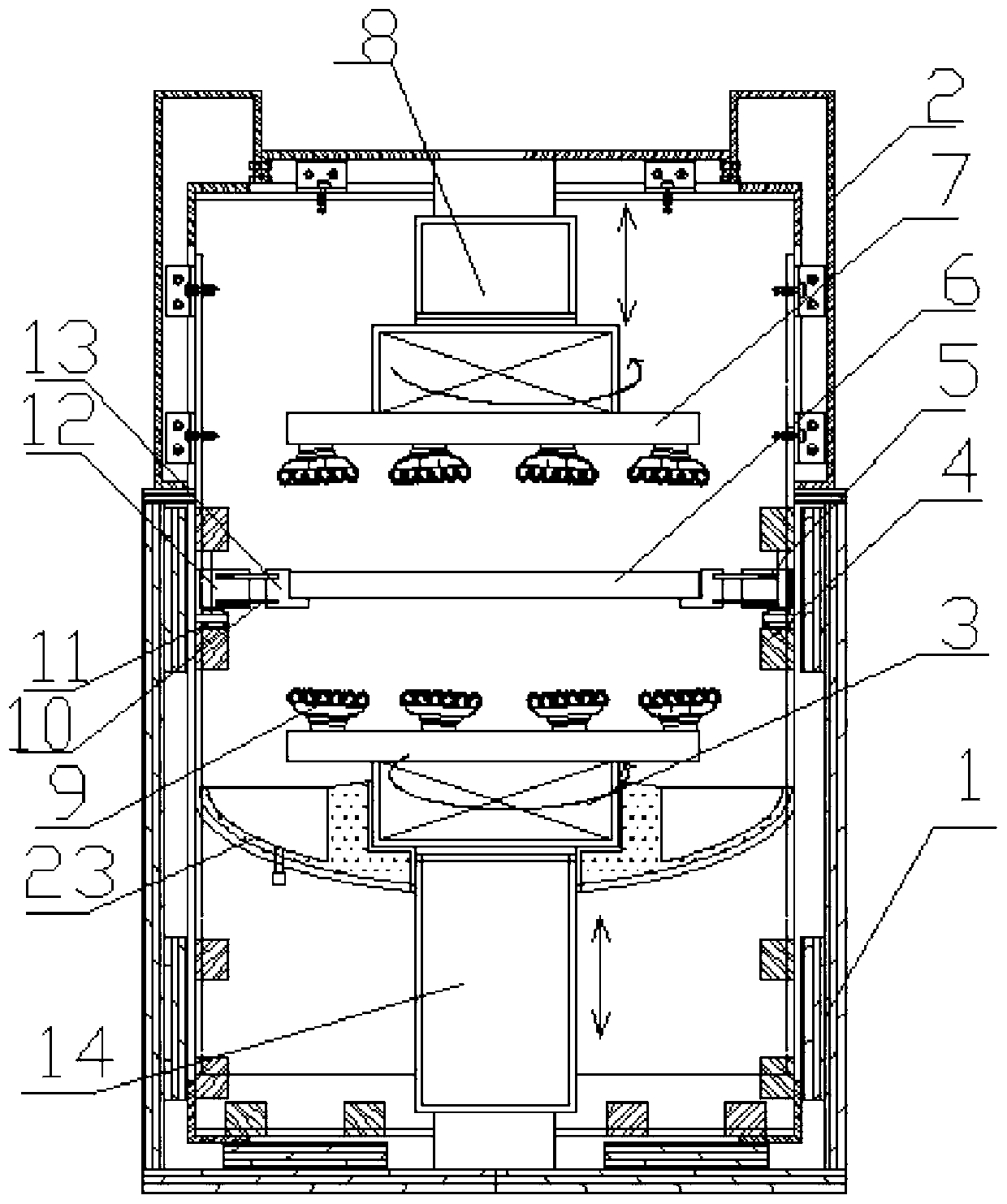

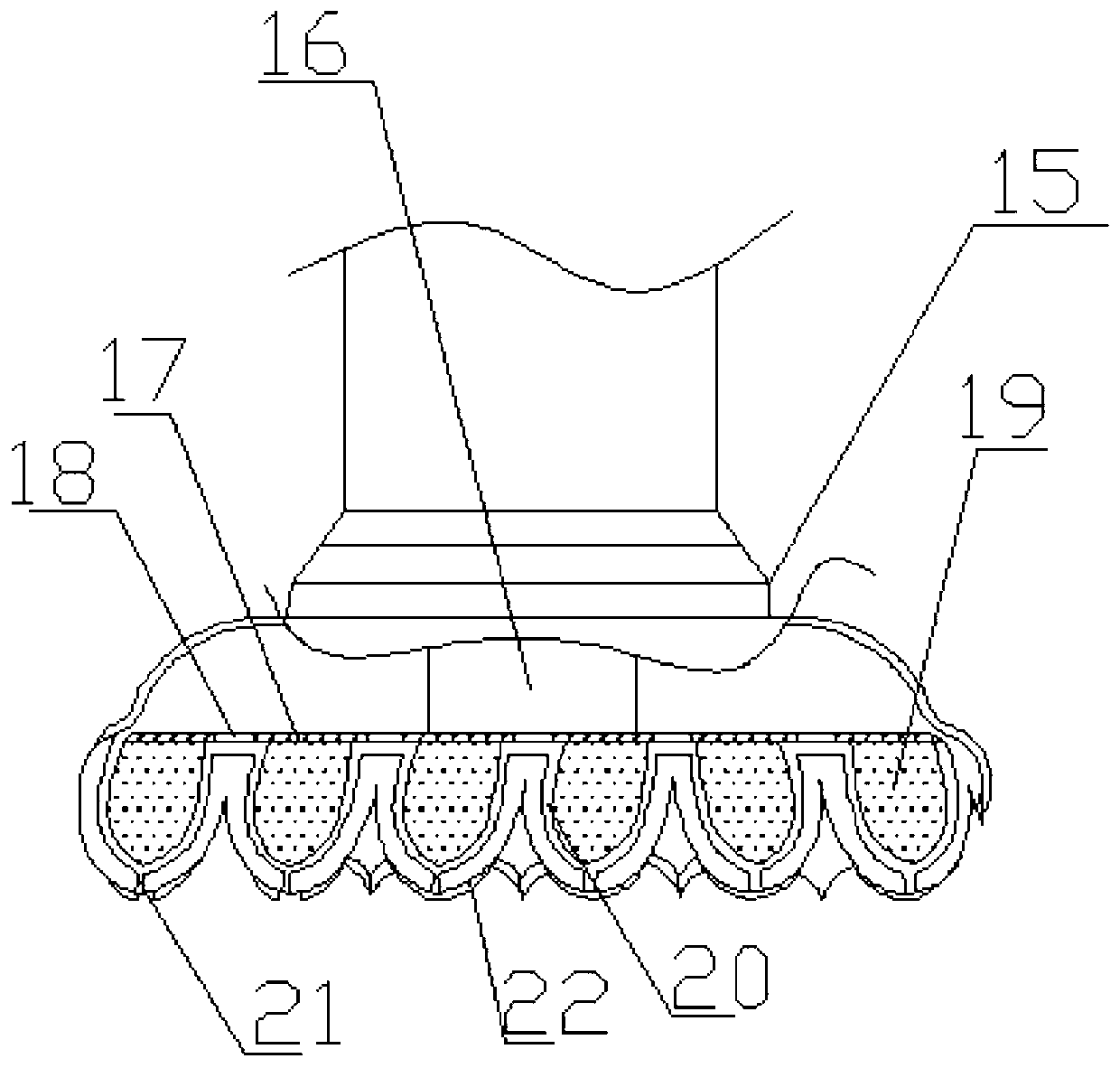

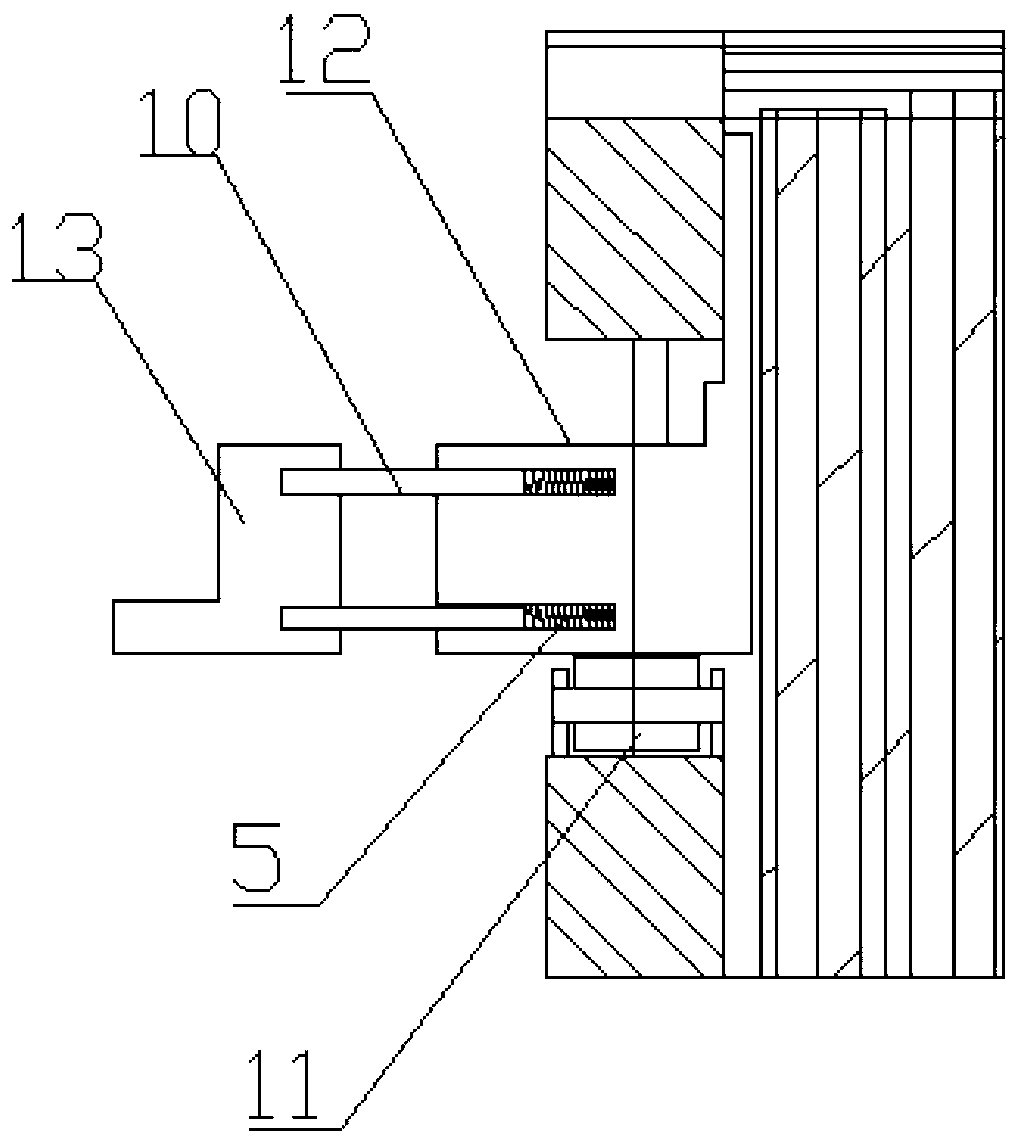

[0025] see Figure 1~4 , in an embodiment of the present invention, a spraying equipment for architectural decoration, including an upper frame 2, a lower frame 1, an upper spraying mechanism, a lower spraying mechanism, and a decoration positioning and moving mechanism, wherein the upper frame 2 and the The lower frame 1 constitutes a vertically arranged door-shaped structure, the middle or middle upper part of the door-shaped structure is provided with the positioning and moving mechanism for the decorative part that can move horizontally, and the inner side of the upper bracket is provided with a direction The upper spraying mechanism facing downwards to the positioning and moving mechanism of the decorative part, the inner side of the lower bracket is provided with the lower spraying mechanism facing upwards to the positioning and moving mechanism of the decorative part, it is characterized in that the upper spraying mechanism Both the mechanism and the lower spraying mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com