Hydraulic control pressure difference spray marking device of plunger pump type normal temperature marking machine

A technology of plunger pump and marking machine, which is applied in the field of hydraulic control pressure difference spraying marking device, which can solve problems such as easy problems in the control system, affecting the efficiency of marking construction, and increasing the weight of hand-push equipment, so as to save working time , high construction efficiency, and the effect of improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

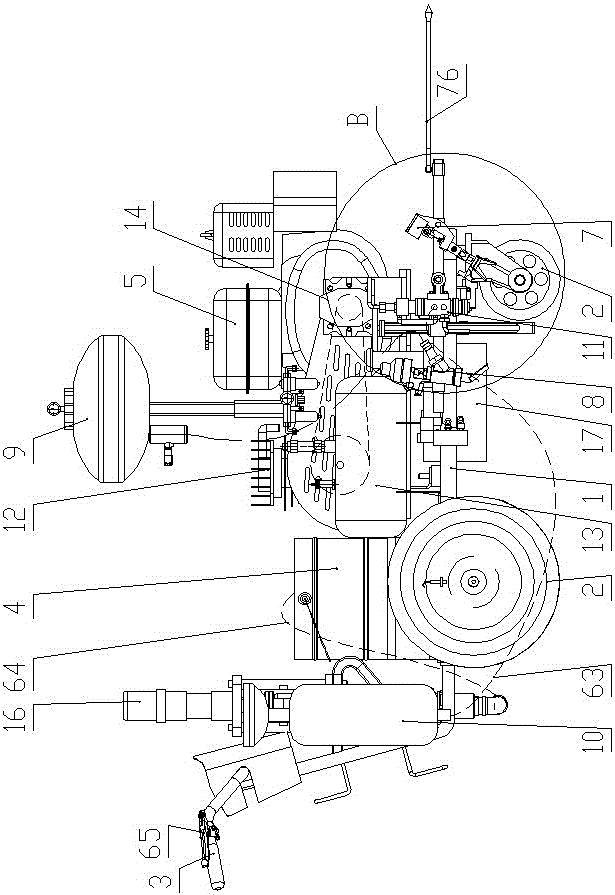

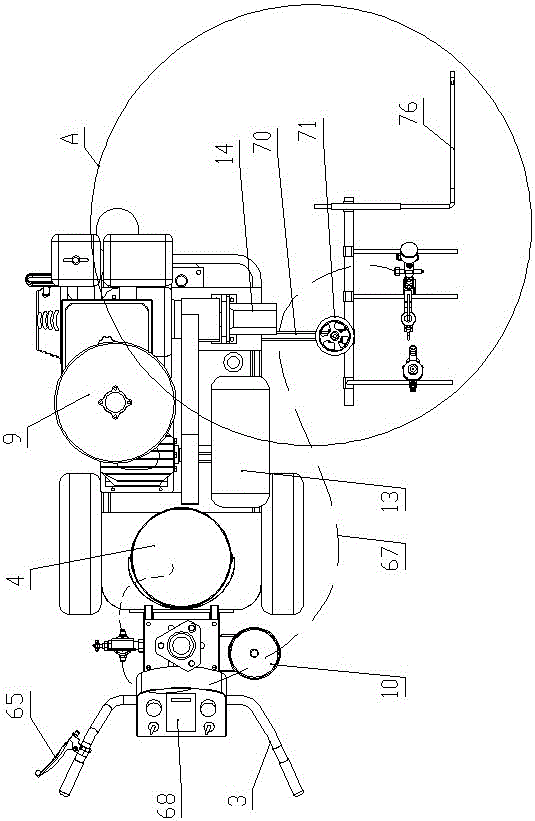

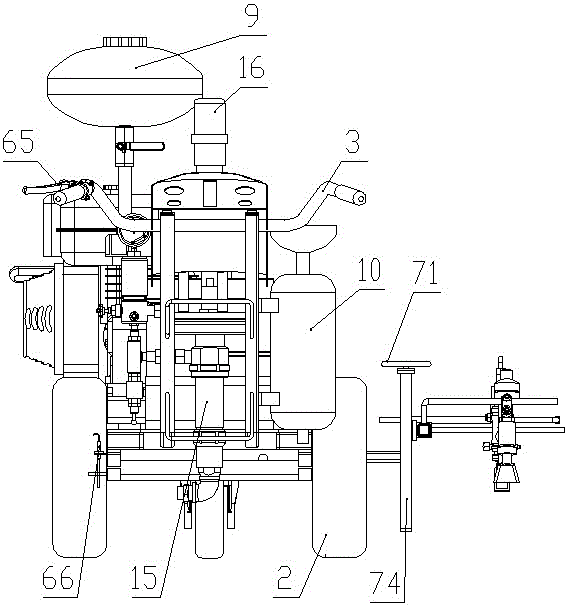

[0032] Such as Figure 1-8 As shown, the plunger pump type room temperature marking machine includes a frame 1, and the bottom of the frame 1 is rotatably connected with three wheels 2, one of which is arranged on the front side of the bottom of the frame 1, and the other two wheels 2 are arranged side by side on the frame 1 bottom rear side, frame 1 rear side is equipped with handrail 3, and frame 1 is equipped with paint bucket 4, engine 5, electric control system, hydraulic control pressure difference spraying marking device, pneumatic control system and walking steering system; engine 5 are respectively connected to the hydraulic control differential pressure system and the pneumatic control system, and the electric control system is connected to the pneumatic control system through a control cable.

[0033] The pneumatic control system includes a high-pressure paint spray gun 7, a glass bead spray gun 8, a glass bead tank 9, a curing agent tank 10, a curing agent spray gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com