Spraying device, spraying mechanism and intelligent micro-spray pesticide applying system

A technology of spraying device and spraying mechanism, which is applied in the fields of trapping or killing insects, application, animal husbandry, etc. It can solve the problems of large soil pesticide residues, waste of human resources, ecological environment damage, etc., and achieve the improvement of spraying pesticides. Improve quality and efficiency, improve spray uniformity, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

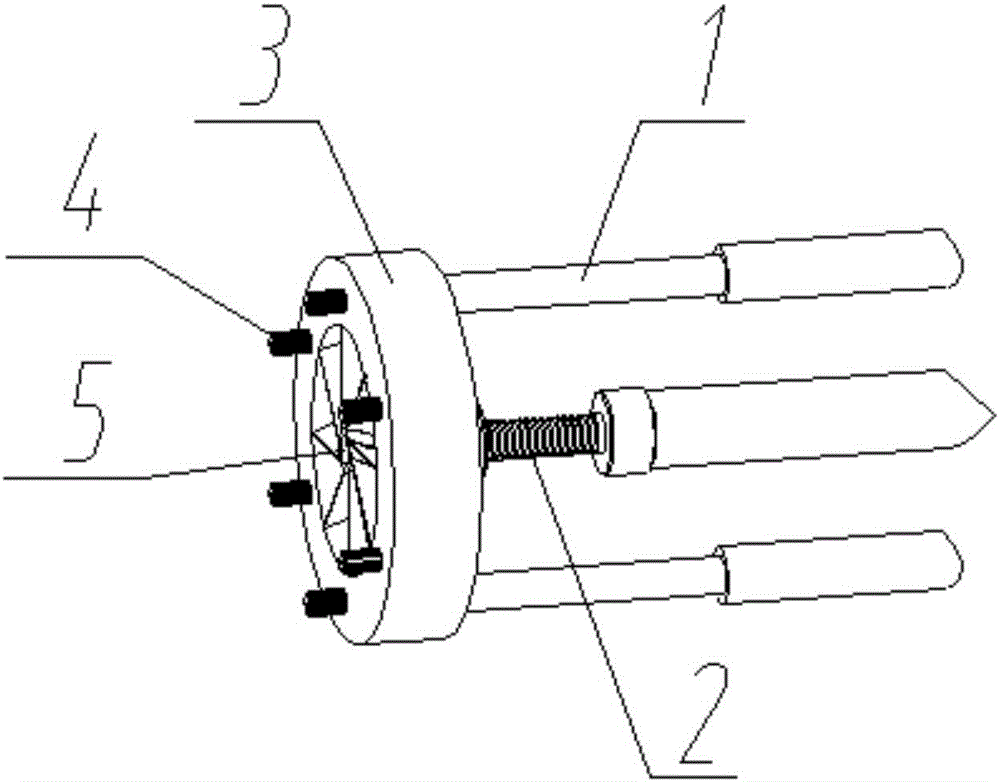

[0039] like figure 1 As shown, a spraying device includes two linear push rods 1, a high-pressure hose 2, a pressure communication box 3 and a plurality of atomizing nozzles 4, and the two linear push rods 1 are fixed to the pressure communication box 3 connection; the high-pressure hose 2 communicates with the pressure communication box 3; a fan 5 is arranged in the middle of the pressure communication box 3, and the fan 5 is directed toward the end of the pressure communication box 3 away from the linear push rod 1 Blowing: a plurality of the atomizing nozzles 4 are placed at the end of the pressure communication box 3 away from the linear push rod 1, and communicated with the pressure communication box 3, and the plurality of atomization nozzles 4 form a ring surrounding the edge of the pressure communication box 3;

[0040] The high-pressure hose 2 inputs the liquid medicine to be sprayed into the pressure communication box 3, and the liquid medicine in the pressure commu...

Embodiment 2

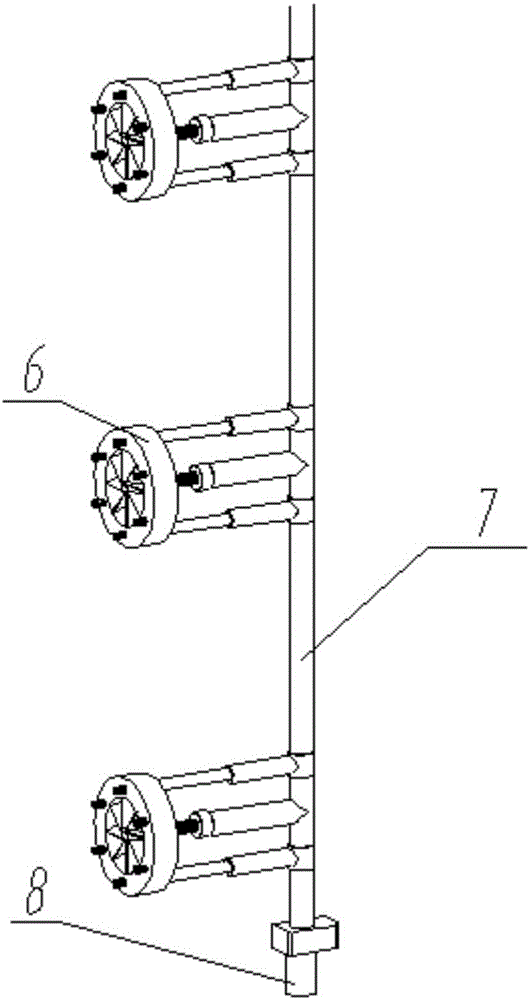

[0042] like figure 2 As shown, a spraying mechanism includes a plurality of spraying devices 6 and high-pressure water pipes 7, a plurality of spraying devices 6 are vertically arranged on one side of the high-pressure water pipe 7, and a plurality of spraying devices 6 are linearly pushed Rod 1 is all fixedly connected with described high-pressure water pipe 7, and for the fruit tree with larger canopy structure, linear push rod 1 can effectively adjust the angle of spraying device 6, increases the range of spray width on the vertical direction; Multiple described spraying devices The high-pressure hoses 2 of 6 are all communicated with the high-pressure water pipe 7; the entrance of the high-pressure water pipe 7 is connected with a joint 8; The water pressure is greater than or equal to 3Mpa; the high-pressure water pipe 7 can provide high-pressure medicinal liquid to a plurality of spraying devices 6, so that the atomizing nozzle 4 can reduce the diameter of the spray dro...

Embodiment 3

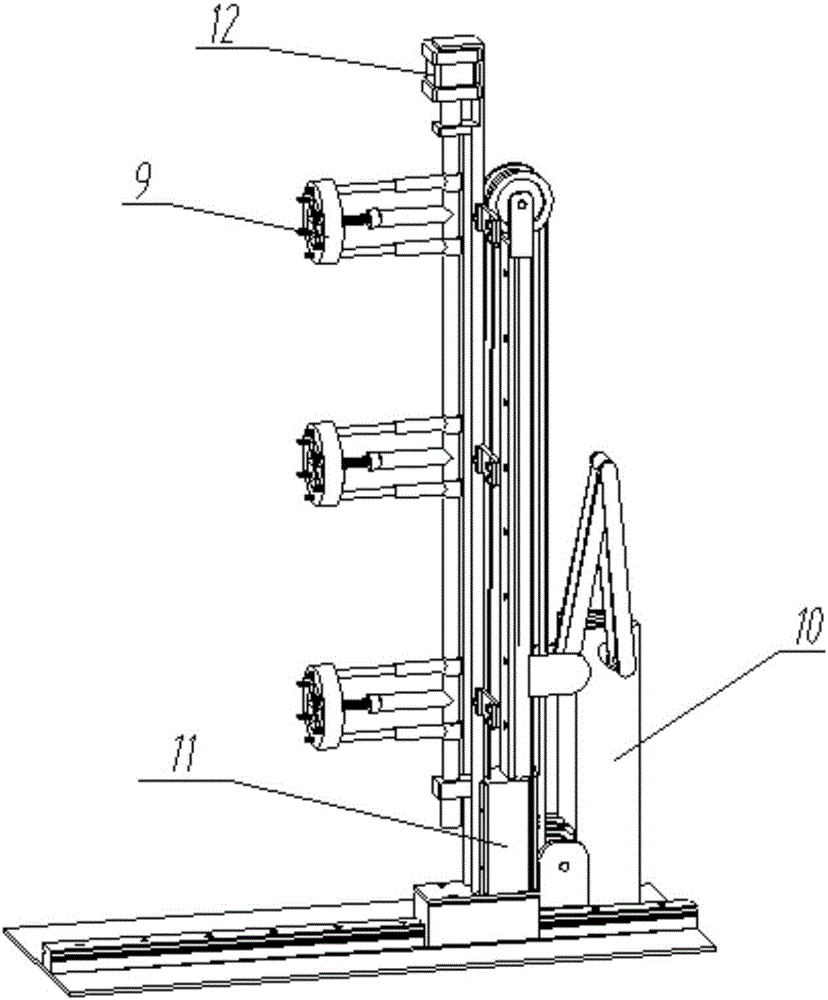

[0044] like Figure 3 to Figure 8 Shown, a kind of intelligent micro-spray drug application system comprises base 13, spray mechanism 9, horizontal movement mechanism 10, vertical movement mechanism 11 and rotary movement mechanism 12, and described vertical movement mechanism 11 and described horizontal movement mechanism 10 are installed on the base 13, the rotary motion mechanism 12 is placed on the upper end of the vertical motion mechanism 11, the vertical motion mechanism 11 drives the rotary motion mechanism 12 to move vertically, and the spray mechanism 9 is placed on the On the rotary motion mechanism 12, the rotary motion mechanism 12 drives the spray mechanism 9 to rotate; the horizontal motion mechanism 10, the vertical motion mechanism 11 and the rotary motion mechanism 12 operate in coordination, and can drive the spray mechanism 9 in the horizontal and vertical directions At the same time, the rotary motion mechanism 12 can drive the spray mechanism to rotate, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com