Aluminum alloy die casting mold

A die-casting mold and aluminum alloy technology, which is applied in the field of aluminum alloy die-casting molds, can solve the problems of low production efficiency, difficult to achieve automatic spraying, and affect the safety of operators, so as to improve efficiency, improve cooling and demoulding effects, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

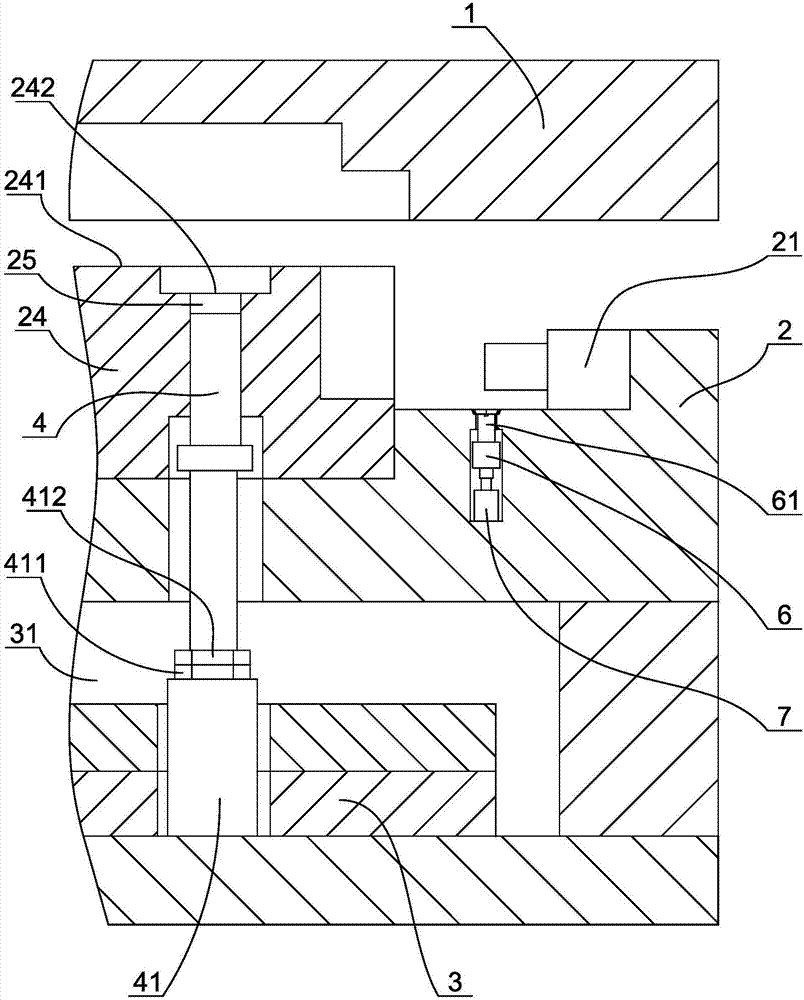

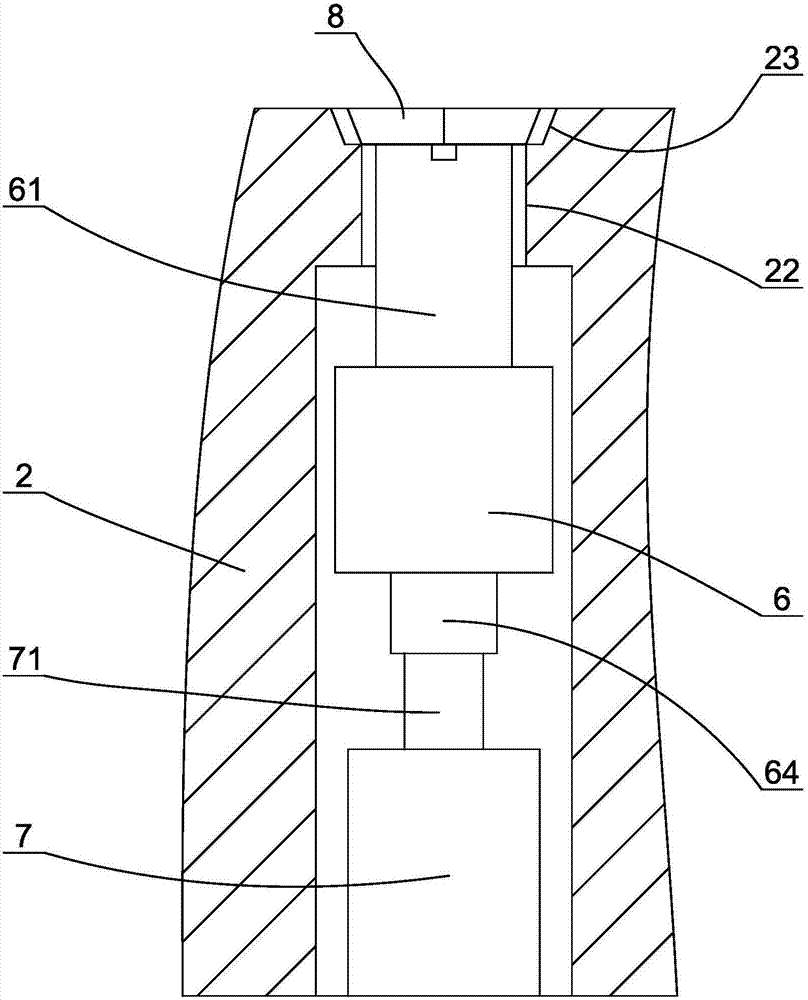

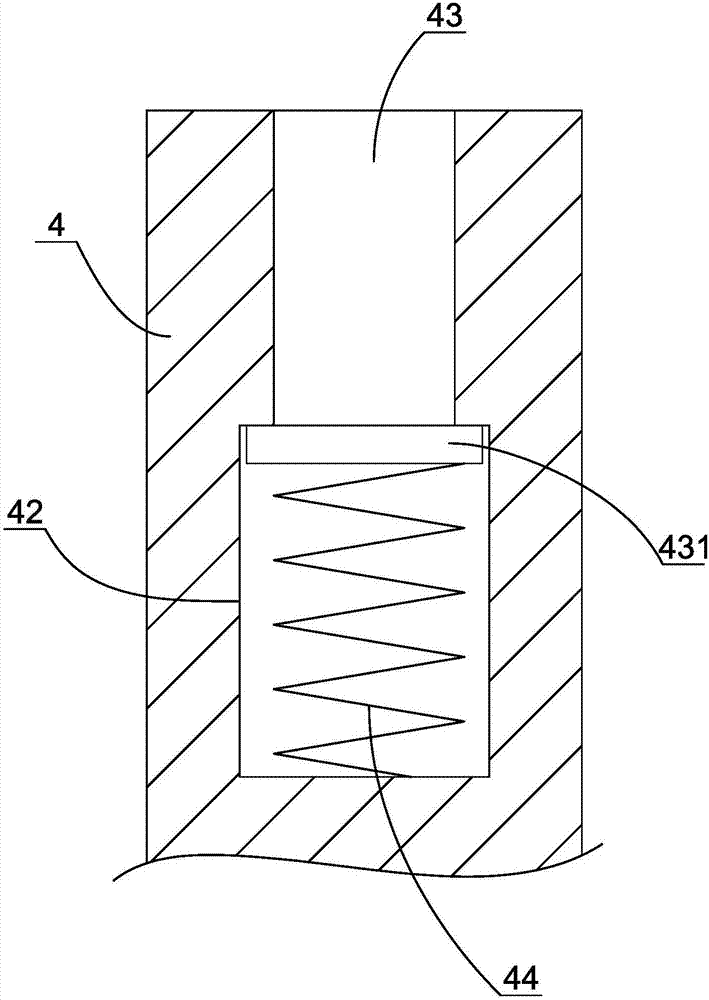

[0027] Such as figure 1 As shown, an aluminum alloy die-casting mold is suitable for forming aluminum alloy die-casting parts with sudden changes in wall thickness and deep lateral holes. Concretely comprise the upper mold 1 that is positioned at die-casting mold top and has mold cavity, the lower mold 2 that is positioned at die-casting mold bottom, the mold core 24 that is fixedly arranged on the lower mold, the transverse core-pulling slider 21 that is movably arranged on the lower mold and is positioned at The bottom of the lower mold has a top plate 3 of a push rod, and an ejection gap 31 is arranged between the top plate and the lower mold. There is a lateral hole forming part on the lower mold, and one end of the horizontal core-pulling slider is a forming end matched with the lateral hole forming part, so that the lateral hole groove c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com