Flexible rotary workbench for preparing physical vapor deposition (PVD) coating on tool

A rotary table and coating technology, which is applied in the metal material coating process, coating, ion implantation plating, etc., can solve the problems of many types of coating tools, inconsistent sizes, large quantities, etc., and achieve a reliable coating process. control, uniform coating height and uniform coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

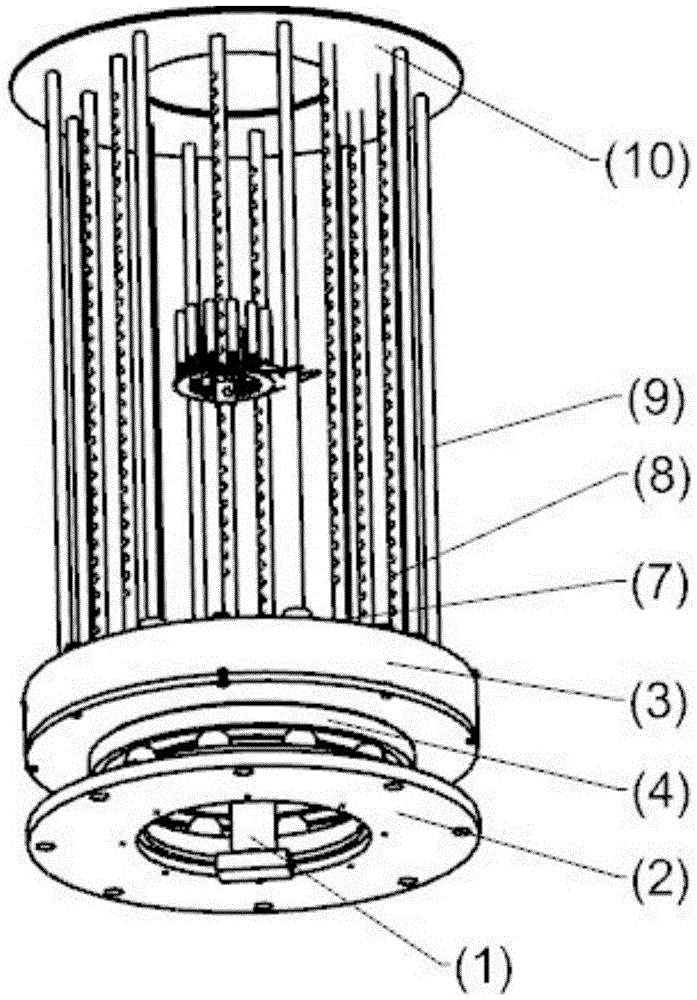

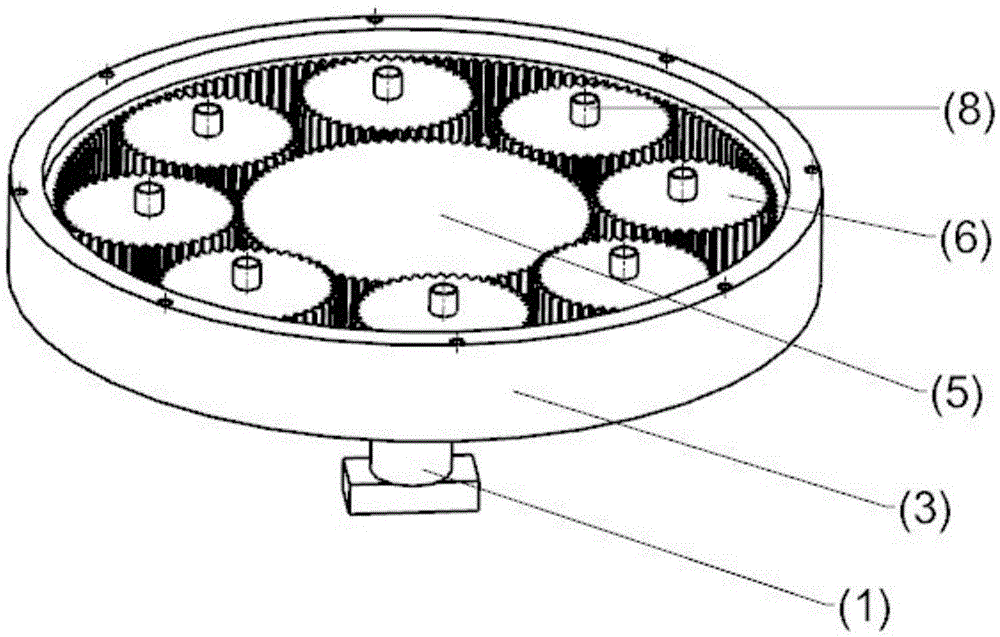

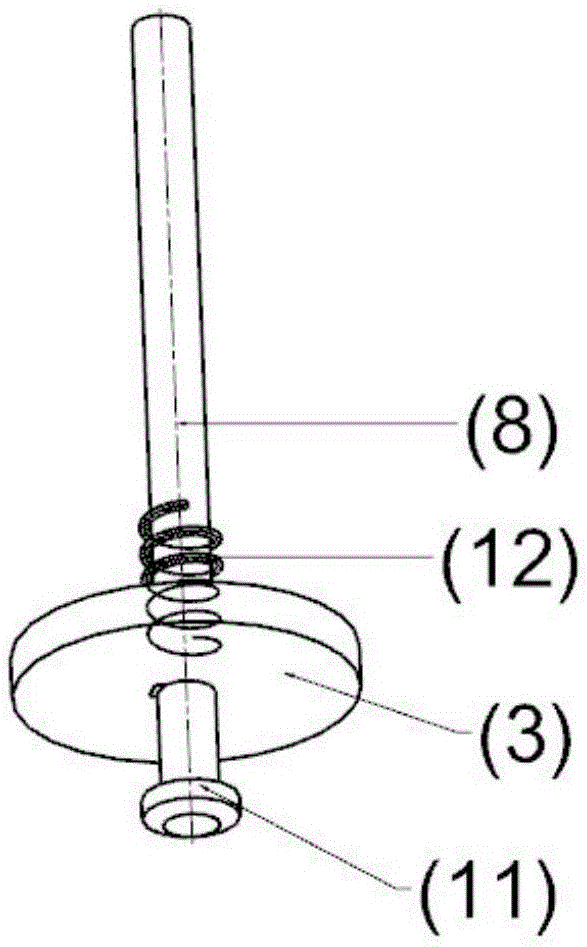

[0028] As shown in the accompanying drawings, the present invention includes: a driving rod 1, a lower turntable 2, an upper turntable 3, a thrust ball bearing 4, a large gear 5, a pinion 6, a cover plate 7 and a clamp body fixing rod 8, and the thrust ball bearing 4 is set Between the upper turntable 3 and the lower turntable 2, the lower turntable 2 is fixed on the support platform on the lower surface of the furnace cavity during operation, and the upper turntable 3 is equipped with a clamp body fixing rod, rolling bearing and other self-rotation systems, and the upper turntable 3 is equipped with a planetary gear structure , the planetary gear structure includes a bull gear 5 and a pinion 6, the pinion 6 is arranged on the periphery of the bull gear 5 along the circumferential direction, and is meshed with the bull gear 5, the bull gear 5 is in interference f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com