Anti-ultraviolet high-heat-insulation window film

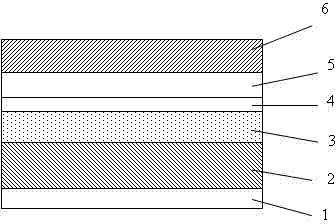

A heat-insulating window film and anti-ultraviolet technology, applied to synthetic resin layered products, shading screens, layered products, etc. The preparation process is simple and convenient, the effect of good visible light transmittance and high infrared rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Anti-scratch coating solution preparation:

[0030] Multifunctional urethane acrylate prepolymer 30%, multifunctional acrylate 25%, photoinitiator 4%, solvent 40%, leveling agent 1%, the above substances are mixed evenly, the viscosity is 5~10cpa, and the anti-scratch coating is obtained liquid.

[0031] Preparation of heat insulation layer coating solution:

[0032] Nano antimony tin oxide (ATO) powder 30% (total weight), of which 3 / 4 of ATO powder, polymer wetting and dispersing agent 6% (powder weight), leveling agent and defoaming aid 1% ( total weight), the solvent is twice the weight of the powder and mixed evenly, using a sand mill to grind to a slurry with an average particle size of tin antimony oxide of 30nm and a distribution of 0.102, and another 1 / 4 of the ATO powder is ground to an average particle size of 15nm. A slurry with a particle size distribution of 0.15. After mixing various slurries, add 23% (total weight) of the light-curing coating system, m...

Embodiment 2

[0040] Preparation of heat insulation layer coating solution:

[0041]Nano powder 30% (total weight), of which 3 / 4 tin antimony oxide ATO powder (total nano powder weight), polymer wetting and dispersing agent 6% (powder weight), leveling agent and defoaming aid Mix 1% (total weight) and 2 times the weight of the powder evenly, use a sand mill to grind to a slurry with an average particle size of tin antimony oxide at 30nm and a distribution of 0.201, and add 1 / 4 of the nanometer indium tin oxide ITO powder (Total nano powder weight) The powder is ground into a slurry with an average particle size of 15nm and a particle size distribution of 0.110. After mixing various slurries, add 23% (total weight) of the light-curing coating system, mix and stir evenly, and obtain the heat-insulating coating.

[0042] The preparation of the anti-scratch layer coating liquid, the ultraviolet barrier layer coating liquid, and the pressure-sensitive adhesive layer coating liquid is the same a...

Embodiment 3

[0046] Preparation of heat insulation layer coating solution:

[0047] Nano powder 20% (total weight), including 4 / 5 nanometer indium tin oxide ITO powder (total nano powder weight), polymer wetting and dispersing agent 6% (powder weight), leveling agent and defoaming agent Mix 1% additive (total weight) and solvent twice the weight of the powder evenly, use a sand mill to grind to a slurry with an average particle size of tin oxide and antimony at 30nm and a distribution of 0.162, and add 1 / 5 indium tin oxide ITO powder Body (total nano-powder weight) powder is ground into a slurry with an average particle size of 15nm and a particle size distribution of 0.186. After mixing various slurries, add 23% (total weight) of the light-curing coating system, mix and stir evenly, and obtain the heat-insulating coating.

[0048] The preparation of the anti-scratch layer coating liquid, the ultraviolet barrier layer coating liquid, and the pressure-sensitive adhesive layer coating liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com