Boat spray painting machine system

A boat and spray booth technology, applied in coatings, paint booths, spray devices, etc., can solve the problems of workpiece surface roughness and deformation, affecting flatness, and difficulty in coating thickness and uniformity, so as to reduce the labor intensity of employees. , Improve the flatness, the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

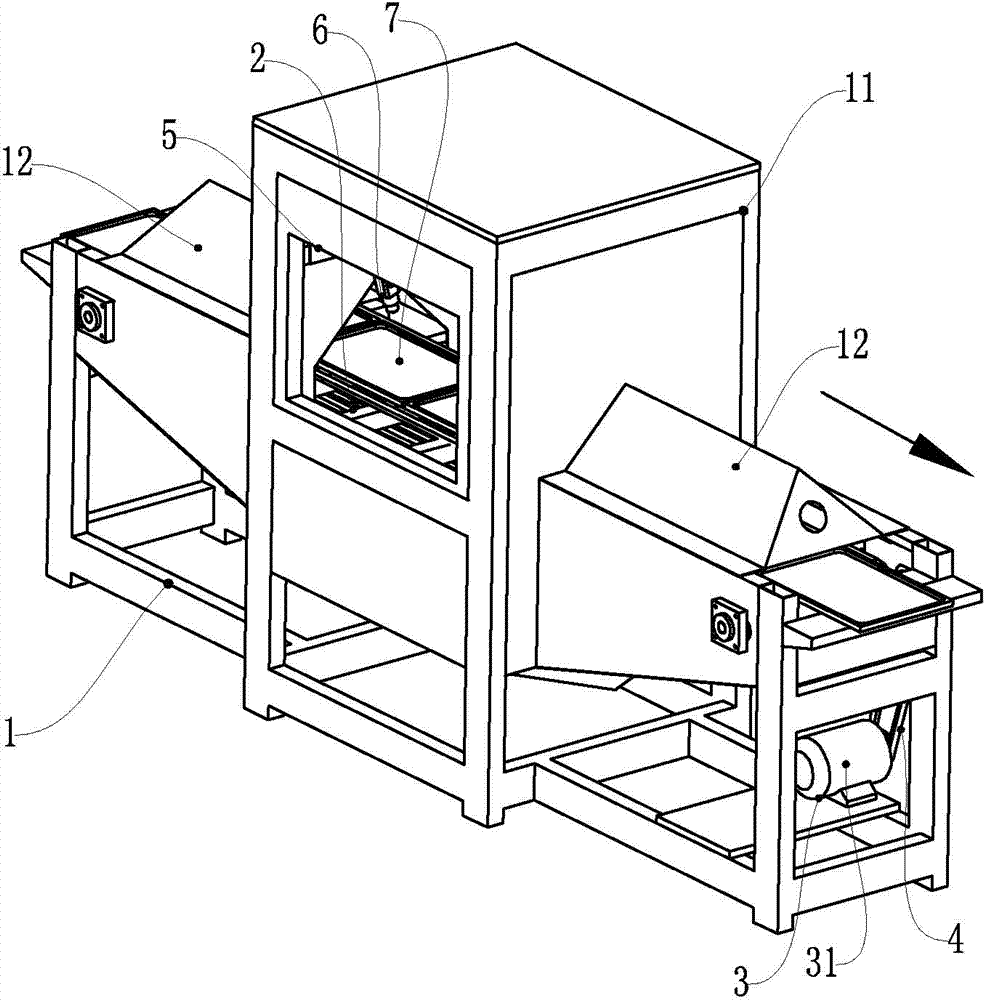

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

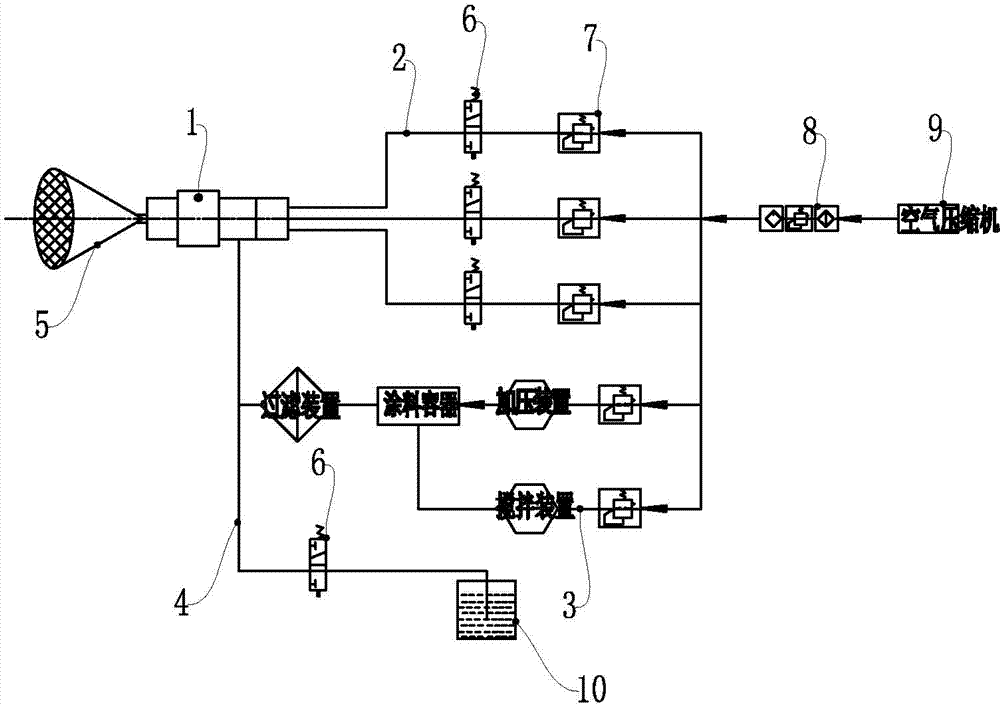

[0023] like figure 1 The embodiment of the feeding system of the boat spraying automatic line of the present invention shown, comprises paint spray gun 1, compressed air circuit 2, paint circuit 3 and cleaning circuit 4, and the output end of described compressed air circuit 2 is communicated with described paint spray gun 1, the output end of the paint circuit 3 and the cleaning circuit 4 share a section of pipeline connected to the paint input hole of the paint spray gun 1, and the input ends of the compressed air circuit 2 and the paint circuit 3 are connected to the air output of compressor 9.

[0024] The compressed air circuit 2 is arranged as three circuits connected in parallel with each other. The compressed air circuit 2 is designed with a two-position three-way electromagnetic reversing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com