Vacuum evaporation device

An evaporation and vacuum technology, applied in the directions of vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problem of uneven coating thickness and achieve the effect of uniform coating thickness and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

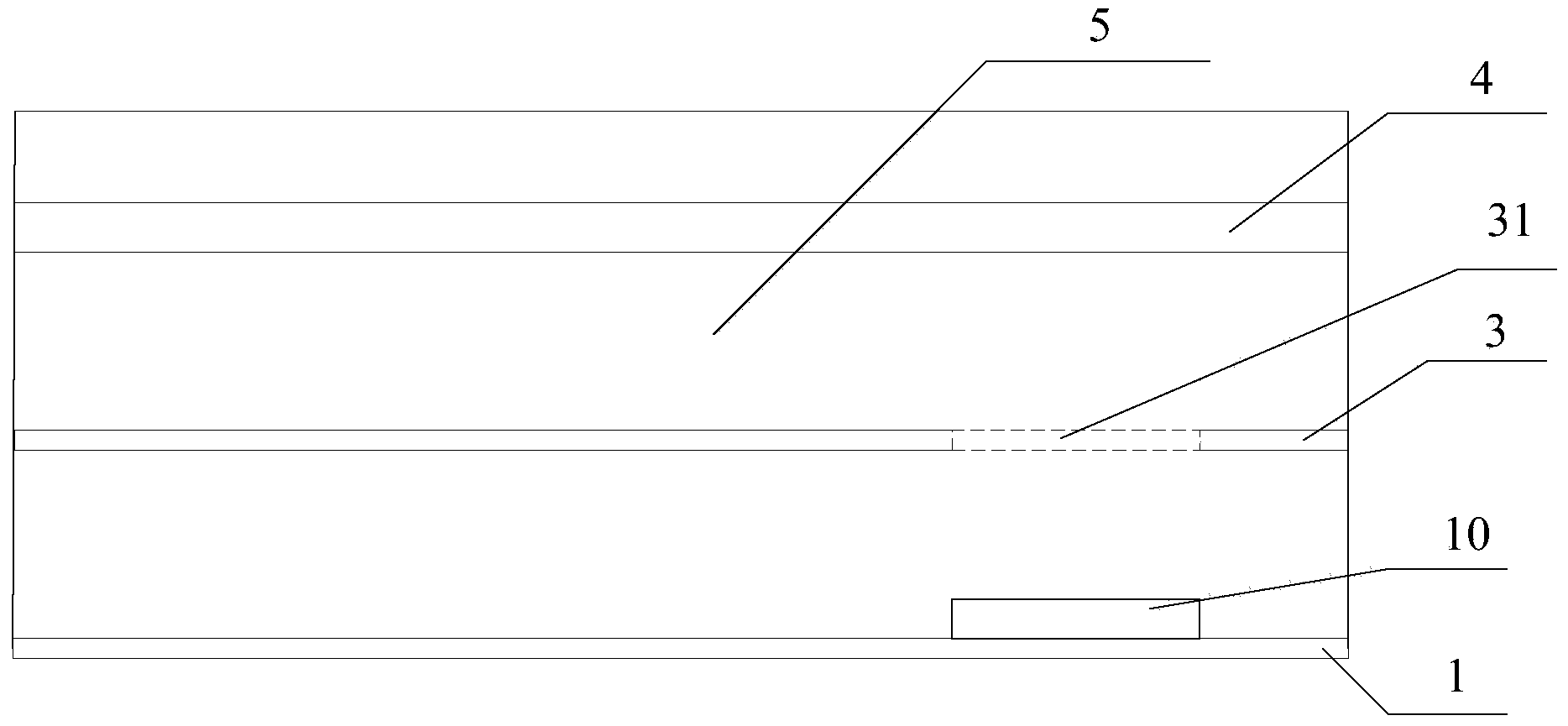

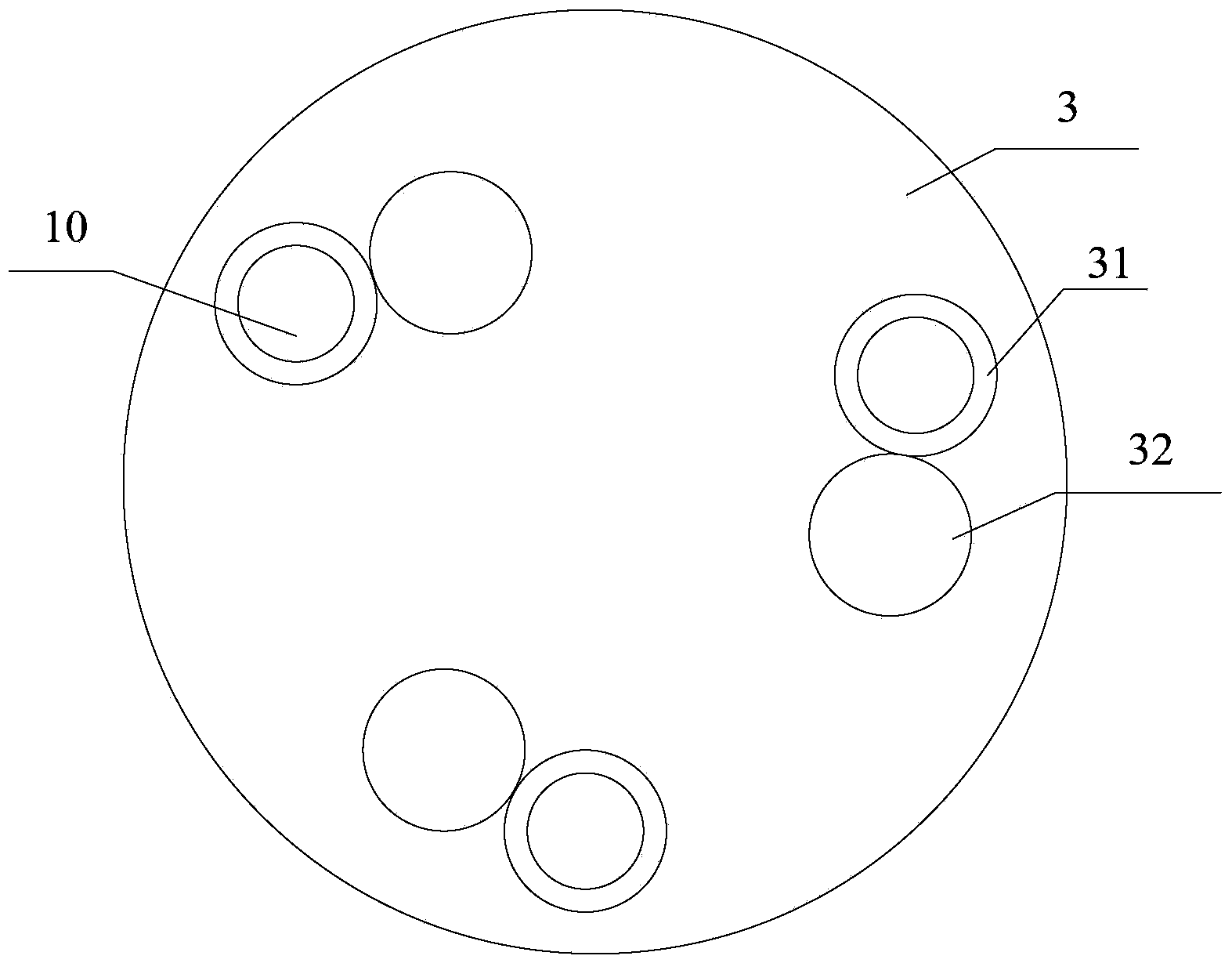

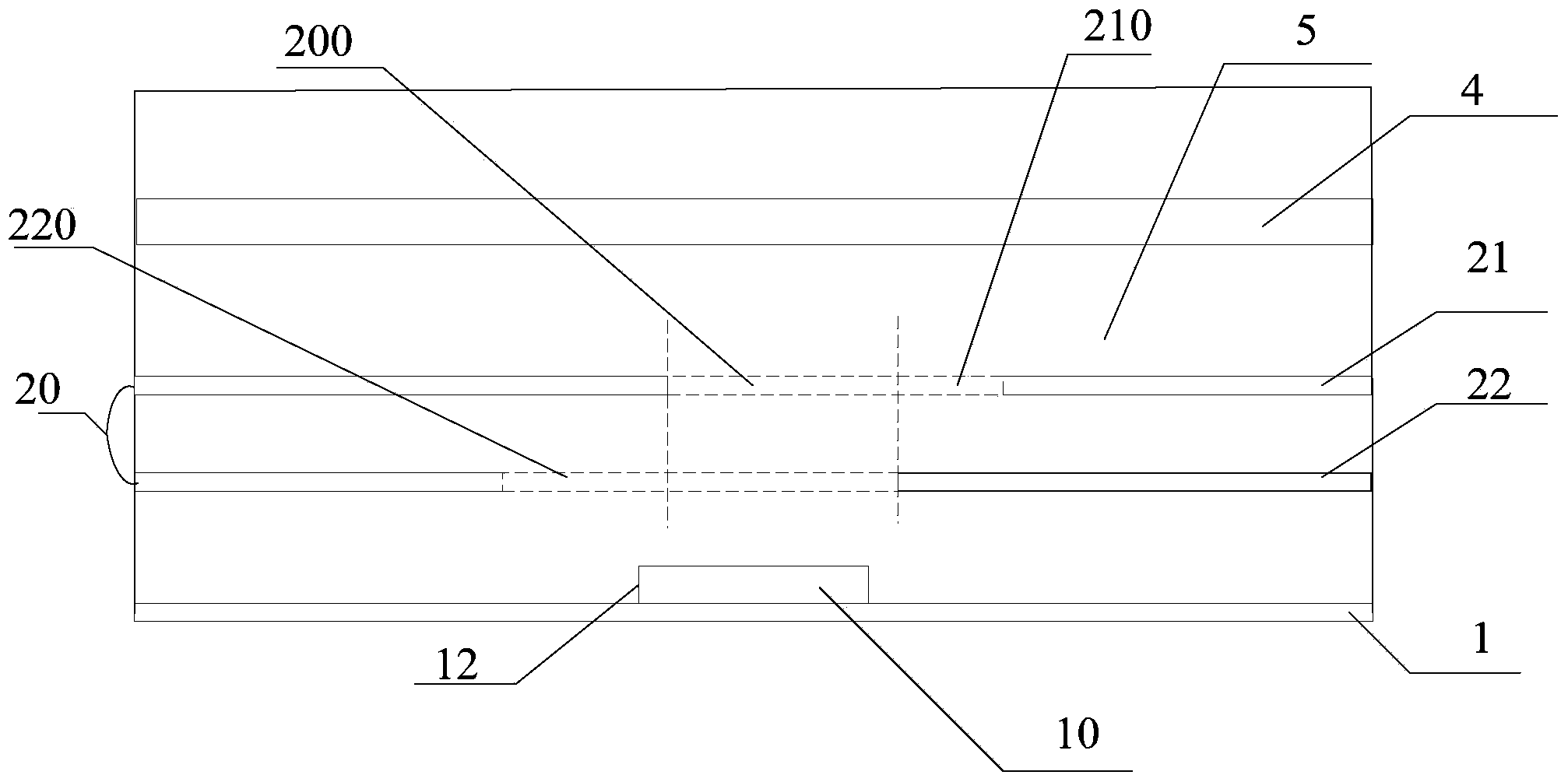

[0035] Such as Figure 3-5 As shown, this embodiment provides a vacuum evaporation device.

[0036] Such as image 3 As shown, the vacuum evaporation device includes an evaporation chamber 5, an evaporation source device 10 arranged in the central area of the bottom plate 1 of the evaporation chamber 5, and a baffle assembly for preventing evaporation substances from contaminating the inner surface of the evaporation chamber 5 20 ; the baffle assembly 20 has a baffle assembly opening 200 corresponding to the position of the evaporation source device 10 .

[0037] The substrate 4 to be evaporated is placed on the upper part of the evaporation chamber 5, and the evaporation material of the evaporation source device 10 is evaporated on the plane of the entire substrate 4 through the opening 200 of the baffle assembly, and the size of the opening 200 of the baffle assembly can prevent evaporation. The substance contaminates the inner surface of the evaporation chamber 5 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com