Automatic spraying robot device

A technology of automatic spraying and robots, applied in the direction of spraying device, etc., to achieve the effect of uniform coating thickness, less environmental pollution and high spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

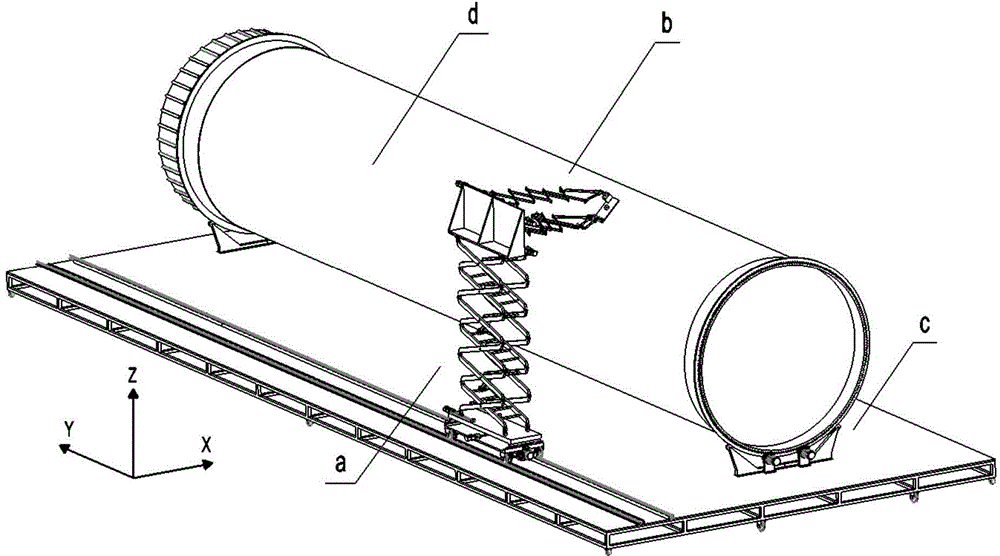

[0029] Such as figure 1 As shown, this embodiment includes: a three-vertical coordinate axis mobile platform a, a spraying actuator b, and a cylinder support rotation tooling c, wherein: the three vertical coordinate axis mobile platform a is slidably connected with the spraying actuator b to form a mobile spraying robot. On the slide rail on one side of the storage tank d, the cylinder supports the rotation tooling c and is rotatably connected with the storage tank.

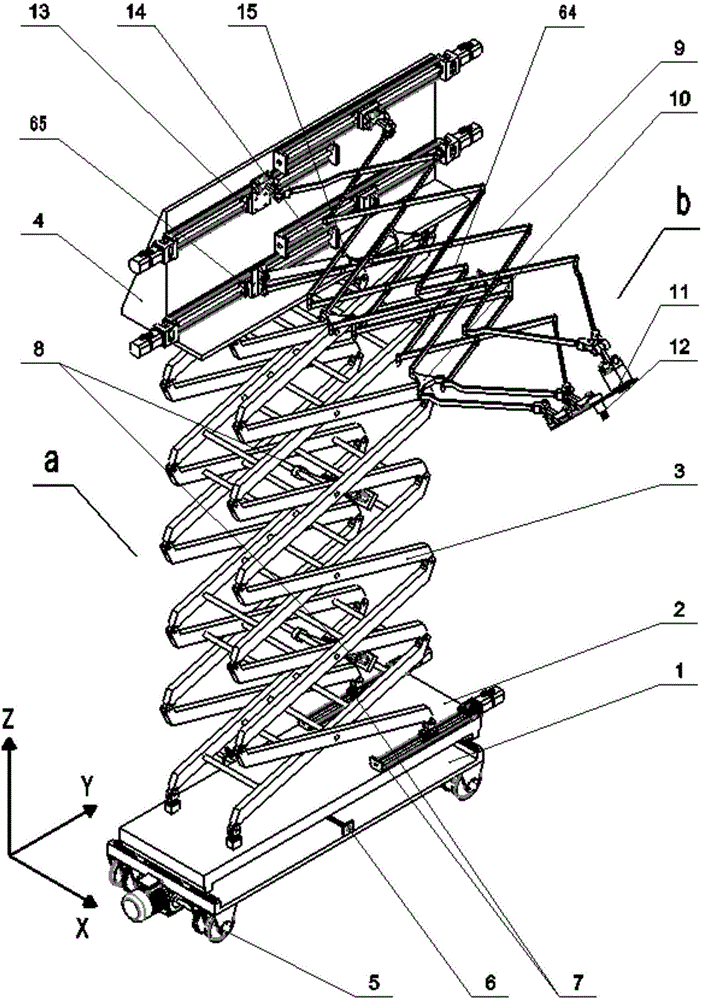

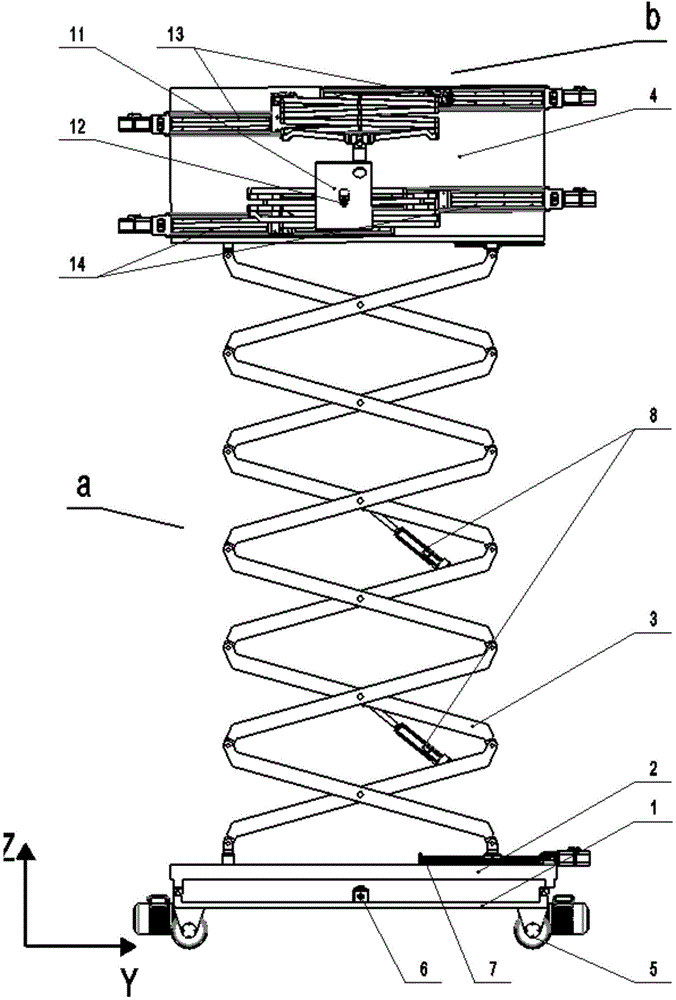

[0030] Such as figure 2 As shown, the three-vertical axis moving platform a includes: an X-axis moving base 1, a Z-axis moving base 2, an X-type motion mechanism 3, a top static platform 4, and a moving drive assembly 5, wherein: the moving drive assembly 5 includes AC servo motors 21, 22, pinions 23, 24, racks 31, 32 arranged on the X-axis moving base 1, and the output shafts of the AC servo motors 21, 22 respectively drive the pinions 23, 24 along the rack 31, 32 rolling, the Z-axis moving base 2 is sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com