Preparation method of battery slurry with high solid content

A high solid content, conductive slurry technology, applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of uneven dispersion of carbon nanotubes, low solid content of battery slurry, etc., to achieve high weight consistency, The effect of improving dispersion performance and increasing solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

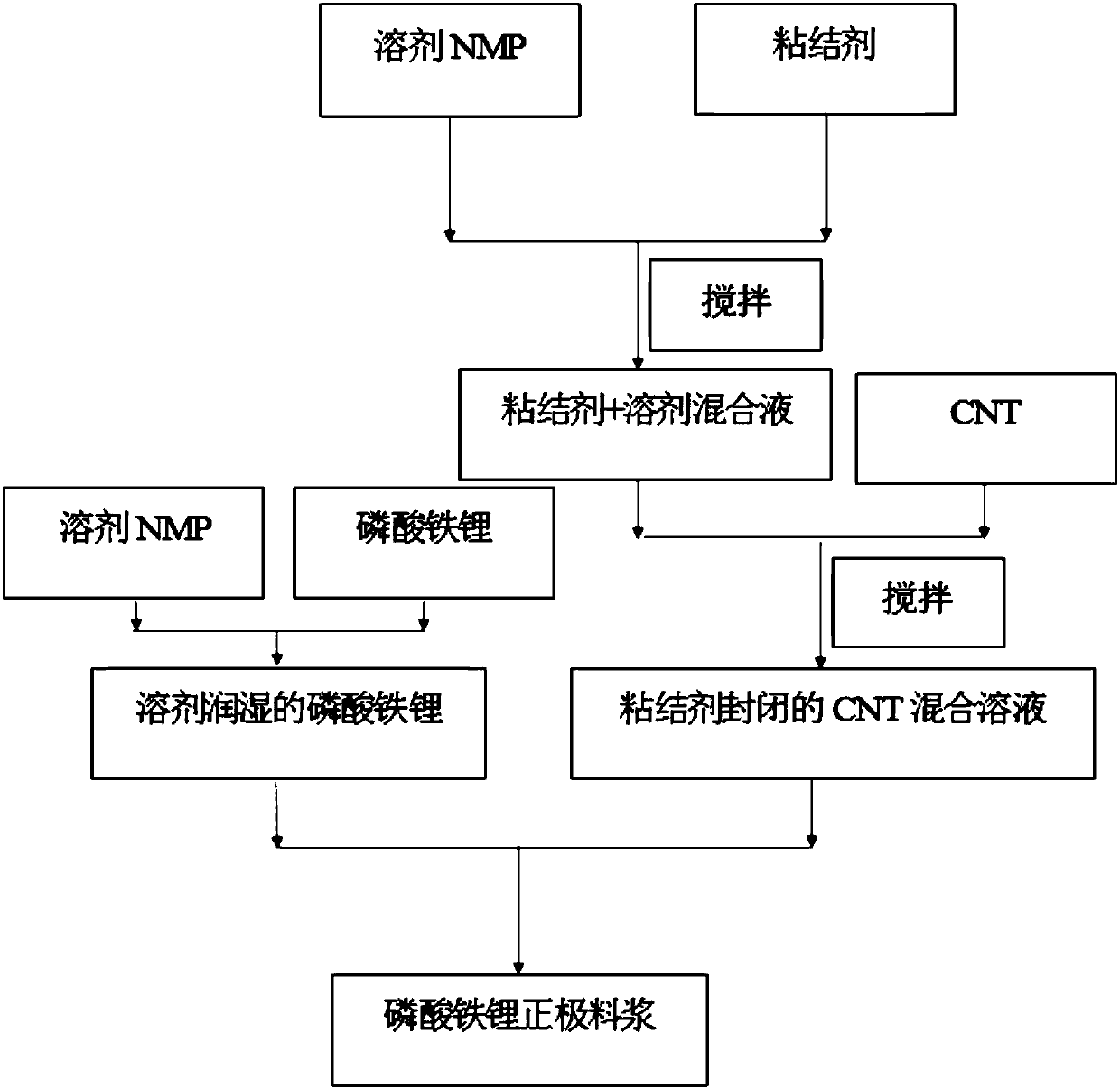

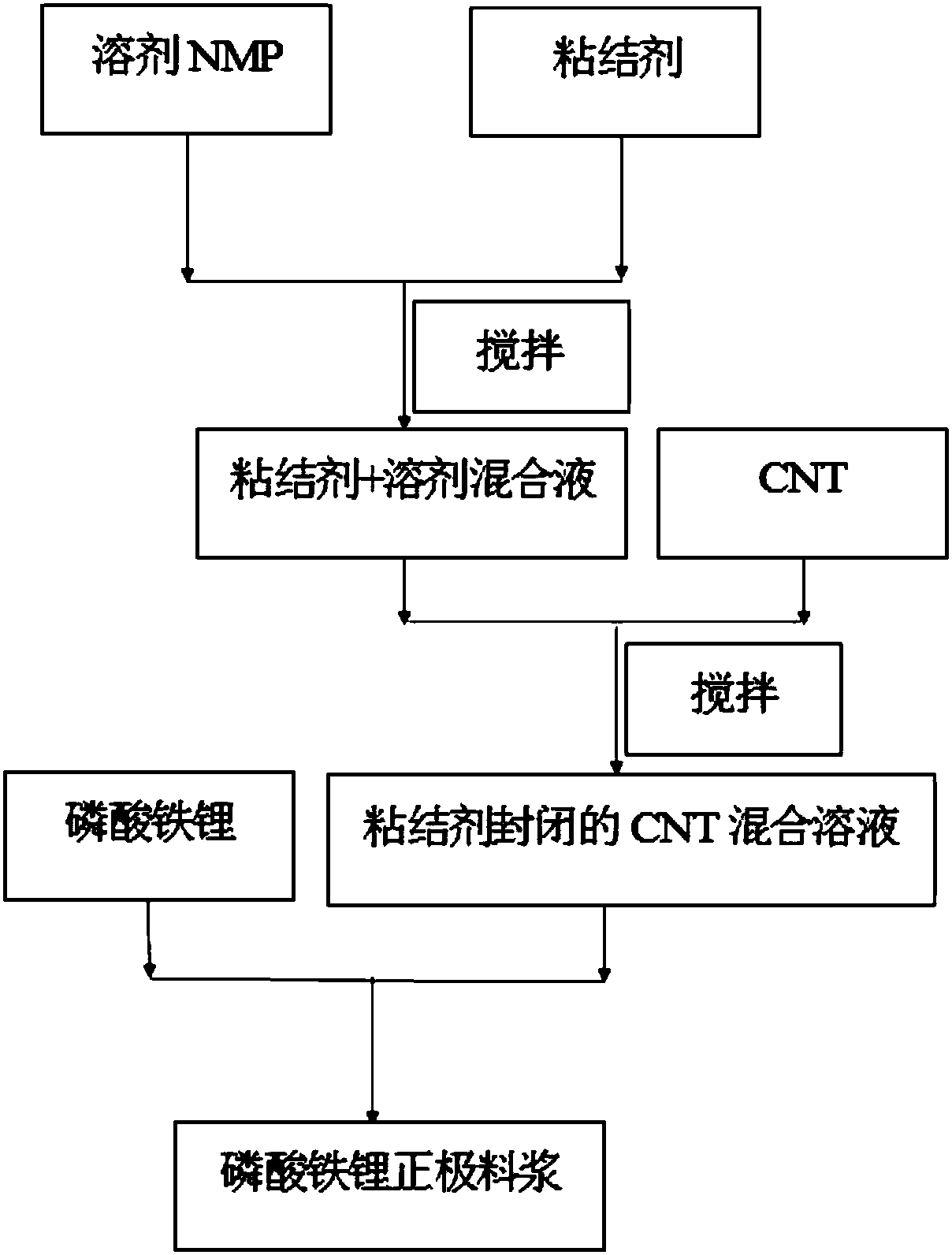

[0050] In this embodiment, the preparation method of the positive electrode slurry of high solid content battery containing carbon nanotubes (for the process flow chart, see figure 1 ), including the following steps:

[0051] (1) Mix and stir polyvinylidene fluoride resin and N-methylpyrrolidone according to the mass ratio of 5:95 to make polyvinylidene fluoride glue; the steps of stirring and dispersing are as follows: first stir at a revolution speed of 20rpm for 5min, Fully wet the polyvinylidene fluoride resin; then stir at a speed of 25 rpm for revolution and 1500 rpm for dispersion (rotation) for 90 minutes to prepare polyvinylidene fluoride glue.

[0052] (2) Add carbon nanotube (CNT) conductive paste and surfactant sodium dodecylbenzene sulfonate into polyvinylidene fluoride glue and stir, wherein carbon nanotube conductive paste, surfactant and partial Polyvinyl difluoride glue is mixed and stirred according to the mass ratio of 1:0.5:15 to obtain the CNT mixed solut...

Embodiment 2

[0060] In this embodiment, the preparation method of the positive electrode slurry of high solid content battery containing carbon nanotubes (for the process flow chart, see figure 1 ), including the following steps:

[0061] (1) Mix and stir polyvinylidene fluoride resin and N-methylpyrrolidone according to the mass ratio of 3:97 to make polyvinylidene fluoride glue; the steps of stirring and dispersing are as follows: first stir at a revolution speed of 10 rpm for 5 minutes, Fully wet the polyvinylidene fluoride resin; then stir at a speed of 30 rpm for revolution and 1000 rpm for dispersion (rotation) for 90 minutes to prepare polyvinylidene fluoride glue.

[0062] (2) Add carbon nanotube (CNT) conductive paste and surfactant polyethylene glycol into polyvinylidene fluoride glue and stir, wherein carbon nanotube conductive paste, surfactant and polyvinylidene fluoride The glue is mixed and stirred according to the mass ratio of 1:0.3:20 to obtain the CNT mixed solution sea...

Embodiment 3

[0069] In this embodiment, the preparation method of the positive electrode slurry of high solid content battery containing carbon nanotubes (for the process flow chart, see figure 1 ), including the following steps:

[0070](1) Mix and stir polyvinylidene fluoride resin and N-methylpyrrolidone according to the mass ratio of 4:96 to make polyvinylidene fluoride glue; the steps of stirring and dispersing are: first stir at a revolution speed of 10 rpm for 10 minutes, Fully wet the polyvinylidene fluoride resin; then stir for 60 minutes at a speed of 20 rpm in revolution and 1000 rpm in dispersion (rotation) to prepare polyvinylidene fluoride glue.

[0071] (2) Add carbon nanotube (CNT) conductive paste and surfactant diethanolamide laurate to polyvinylidene fluoride glue and stir, wherein carbon nanotube conductive paste, surfactant and polyvinylidene fluoride The vinyl fluoride glue is mixed and stirred according to the mass ratio of 1:0.8:19 to obtain the CNT mixed solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com