While these and many other series

capacitor advantages are well known,

unit cost, size requirements,

voltage limitations, current limitations, dv / dt limitations, di / dt limitations, insulation limitations,

dielectric limitations, electromechanical limitations and thermodynamic limitations, have prevented widespread implementation of series capacitors, especially in

low frequency applications.

Unfortunately, non-polarized capacitors—especially in series configurations—are not well-suited for many AC and DC applications due to limitations in size,

capacitance, weight, efficiency,

energy density, and cost.

Singular polarized capacitors traditionally have been limited to use in DC and small AC

signal coupling applications due to their unidirectional, forward biasing requirements.

The rated voltage of such capacitors is limited by the dielectric constant,

dielectric strength, and material and fabrication defects.

The

failure mechanism of shorting and then burn through can be disruptive in sensitive circuits such as digital devices.

Further, metalized film capacitors tend to poorly dissipate heat.

This creates internal hot spots and tends to accelerate

capacitor failure.

In such implementations, dielectric breakdown and failure of such capacitor embodiments often are associated with concentrations of charge accumulations at corners and sharp points of the conductive plates and material defects and variation of thickness in high

electric field conditions.

Although the capacitor can be designed and the dielectric material chosen such that the capacitor theoretically should withstand such conditions, conventional macroscopic manufacturing methods often do not provide the accuracy and control needed to ensure that the fabricated capacitor can perform at its theoretical capability.

For example, conventional techniques cannot ensure that sharp corners or burrs on the conductors will be avoided, or that the thickness of the dielectric material will be uniform throughout its area, or that the dielectric will be disposed on the conductors in a conformal manner.

Further the surface area of parallel-plate-type capacitors has been generally limited to flat place construction and conventional enhancement techniques such as plate sharing and

spiral wound packaging.

Polarized capacitors have enhanced surface area as compared to non-polarized capacitors, which, unfortunately, introduces additional capacitor components, a charge transport mechanism, and additional losses.

Despite these advantageous properties, polarized capacitors also have their drawbacks.

The electrically directional

capacitance versus rectification circuit behavior due to

electron tunneling is often disadvantageous.

Still further, the maximum AC

ripple current that can be tolerated by electrolytic capacitors is limited by the ESR, rated voltage and the thermodynamic, mechanical, and venting properties of the capacitor

package that allow it withstand the

resultant heat and

pressure buildup without rupturing.

Further, the most commonly used material, aluminum, requires great energy to refine conventionally.

Other conventionally constructed polarized charge storage devices suffer innumerable similar disadvantages.

These methods, though somewhat effective tend to increase costs substantially and in many cases substantially increase the physical size and weight of the components.

Typically, for both polarized and non-polarized discrete capacitors, neither the theoretical

dielectric strength nor the theoretical dielectric constant, have been effectively realized due to material imperfections, imprecise manufacturing processes, and boundary interface problems.

These factors, in turn, limit both the maximum rated device voltage and capacitance that may be attained for a given capacitor implementation.

Still further, imbalances in

conduction current and

displacement current capabilities combined with inconsistent material properties limit the transient and sustained current capabilities for a given capacitor.

Structural thermodynamic limitations further tend to limit transient and

steady state electrical current capabilities and capacitor operational lifetime.

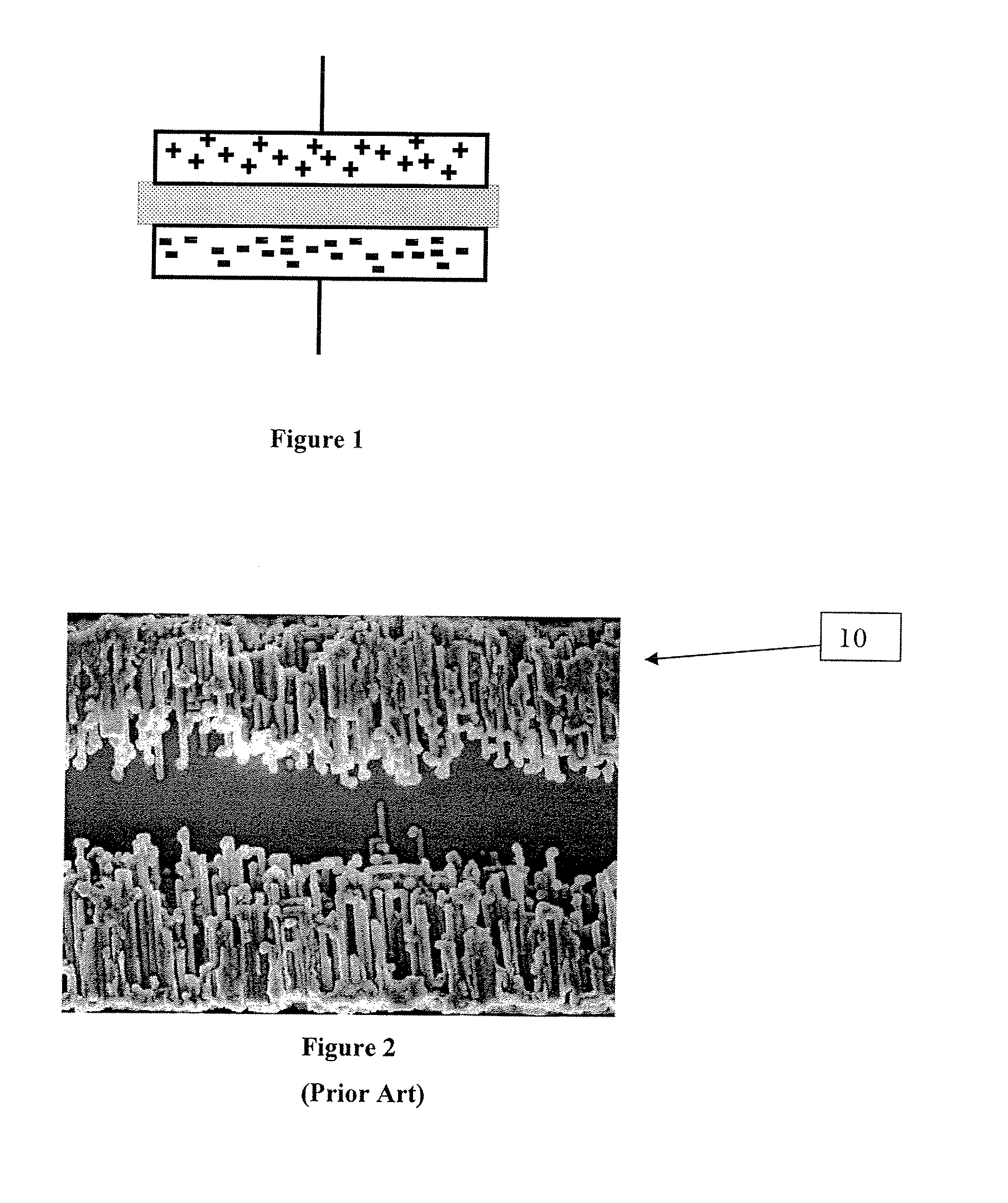

However, it is difficult to charge the capacitor, particularly at high voltages due to spatial distance variations between the extremities of the

broom-

straw-like structures and the attendant

displacement current limitations.

The configuration illustrated in FIG. 2 has many characteristics which ultimately limit the performance and

longevity of the capacitor.

Mechanical

weakness of the structure and required anodization thickness limit capacitor rated voltage.

Another drawback to aluminum electrolytic capacitors is the enormous quantity of energy required for fabrication.

Great amounts of electrical power are required for heating, oxidizing and forming the

aluminum foil and tab materials.

These steps and inputs are highly energy intensive.

Thus, conventional manufacturing techniques for aluminum electrolytic capacitors require a substantial quantity of energy.

This operating condition alternates every

half cycle and greatly shortens capacitor

assembly life and is a source of electrical

harmonic current and ground reference voltage disturbances.

Printed circuit board electrical, thermal and mechanical limitations severely limit integrated capacitor materials and construction techniques.

Also integrated capacitance variation cannot be easily controlled using conventional manufacturing techniques.

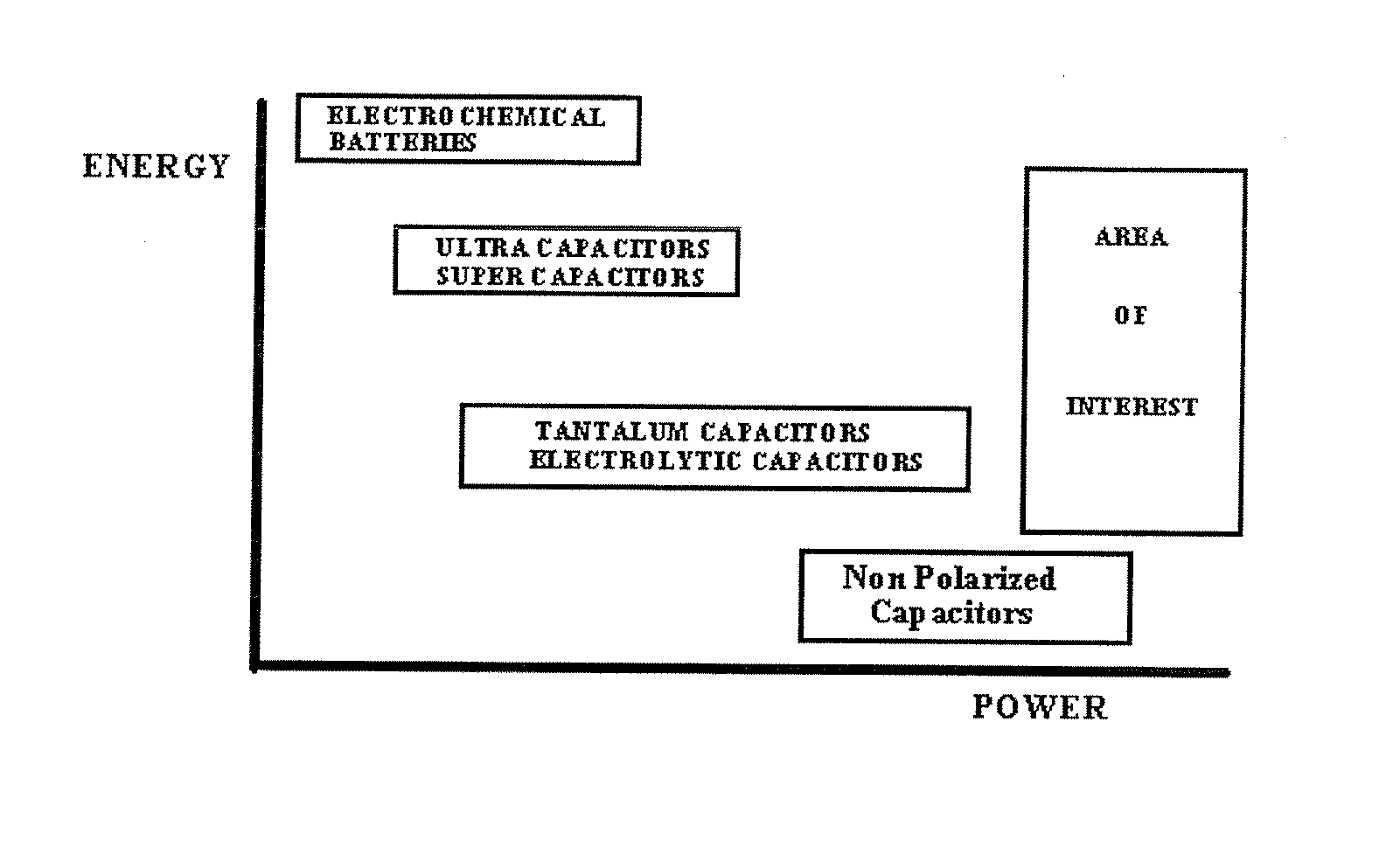

Super capacitors, ultra capacitors and double layer capacitors, however, have many limiting characteristics which inhibit their usefulness for power applications.

Further, the devices are polarized charge storage devices, thus restricting their usefulness in

AC power applications.

Further, such devices often fail to deliver the full charge stored

on demand.

A great deal of the stored charge can remain unavailable.

More particularly, electrical motors presently consume about 65% of metered real power.

Login to View More

Login to View More