Pneumatic material feeding roller brush

A material roller and roller technology, which is applied in the field of roller coating devices, can solve the problems of increased physical exertion of workers, pollute the environment, and high labor intensity, and achieve the effects of improving work efficiency, reducing environmental pollution, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] A specific embodiment of the present invention is as follows:

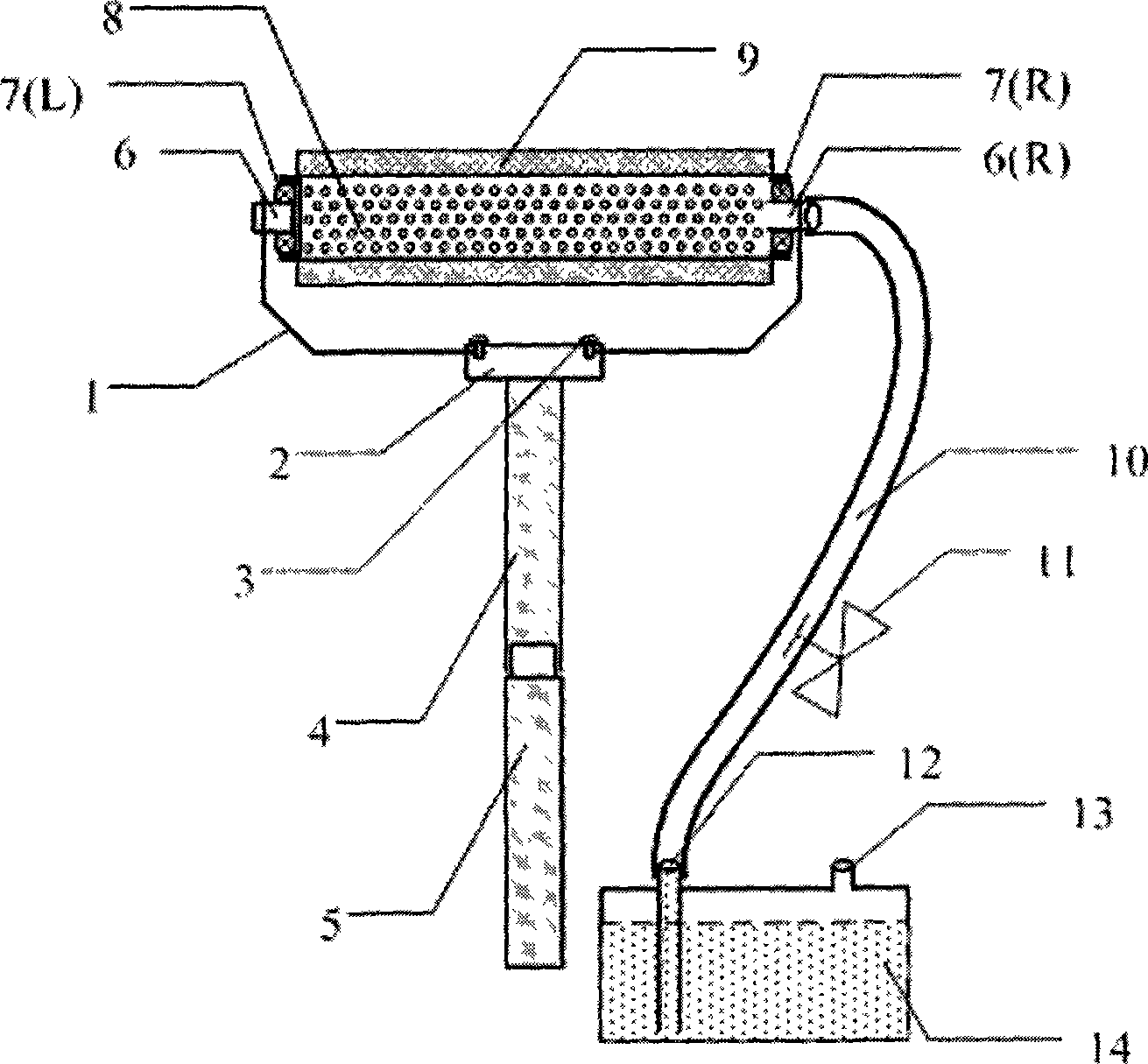

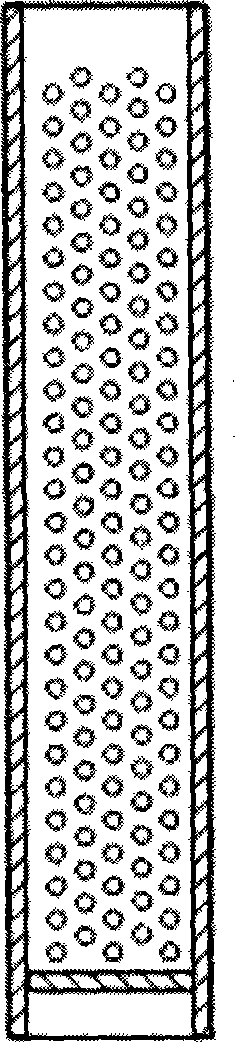

[0022] See attached figure 1 , the pneumatic feeding roller brush involved in the present invention, its structure is: the columnar cylinder 8 that spreads through hole is connected with hollow shaft 6 through common bearing 7; The wrapping layer 9, under the action of air pressure, the liquid paint is soaked through the through holes; the hollow shaft 6 is fixed on the support frame 1; and the support frame 1 is fixed on the connecting plate 2 by screws 3; the bottom end has internal threads The handle 4 is welded or threaded to the lower part of the connecting plate 2; the extension handle 5 with internal and external threads at both ends is connected to the handle 4 through threads, and the cascade extension handle 5 can extend the handle to an appropriate length; plastic or rubber One end of the injection hose 10 is sleeved on the outside of the right end 6R of the hollow shaft; a flow regulating valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com