Formula of plastic material with metallic luster and preparation method thereof

A technology of plastic materials and metallic luster, applied in the field of formulation and preparation of plastic materials, can solve the problems of inability to use for a long time, low layer adhesion, poor adhesion, etc. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

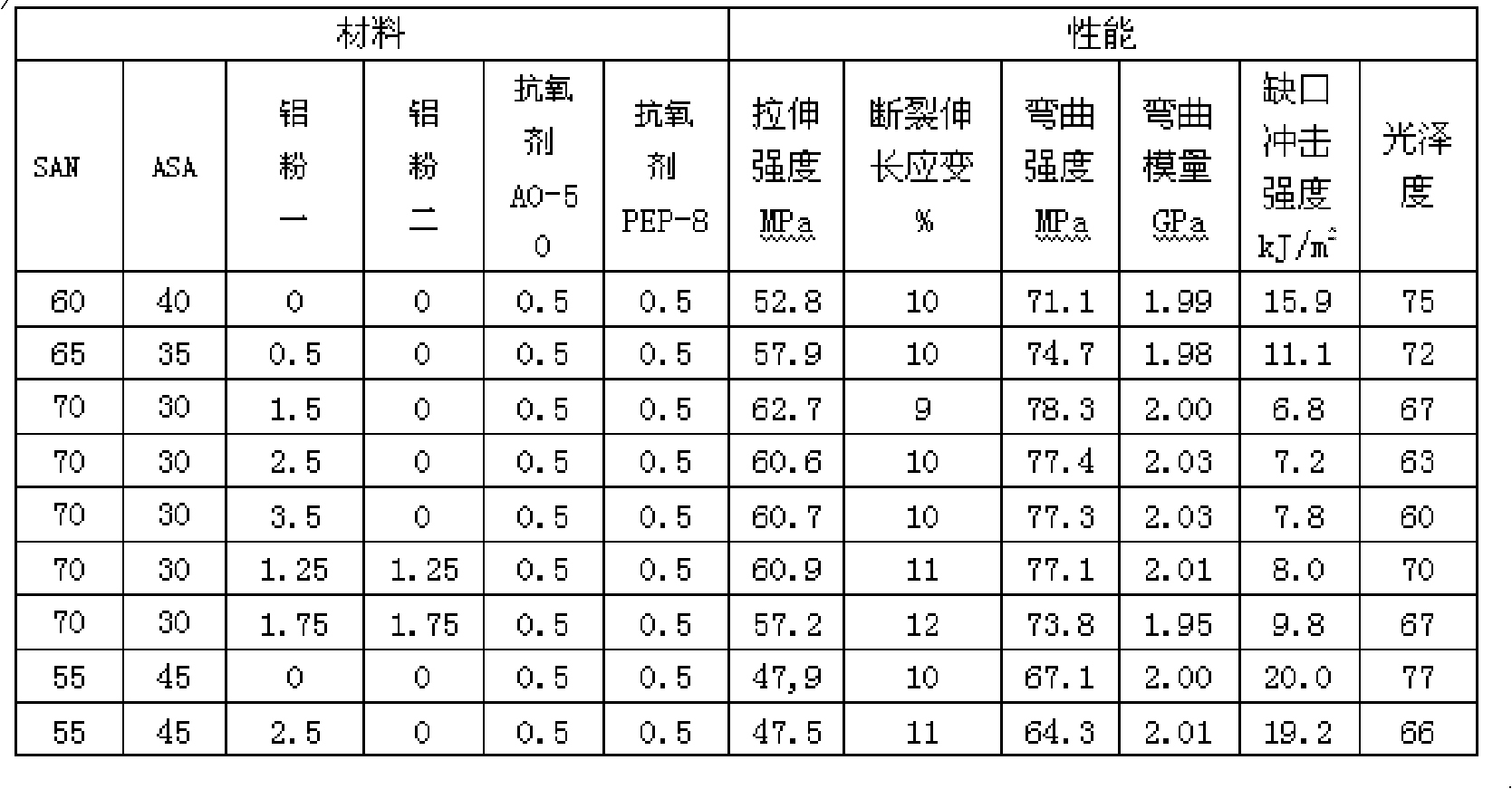

[0018] Embodiment of the present invention: the formula of plastic material with metallic luster, calculated in parts by weight, includes 70 parts of SAN resin, 30 parts of ASA resin, 1.25 parts of silver dollar type aluminum powder, 1.25 parts of scaly aluminum powder, hindered phenols 0.5 part of antioxidant AO-50 (CAS No. 2082-79-3) and 0.5 part of phosphite antioxidant PEP-8 (CAS No. 3806-34-6).

[0019] The preparation method of the plastic material with metallic luster, calculated by weight, 70 parts of SAN resin, 30 parts of ASA resin, 1.25 parts of silver dollar type aluminum powder, 1.25 parts of scaly aluminum powder, 0.5 part of hindered phenolic antioxidant AO -50 and 0.5 parts of phosphite antioxidant PEP-8 were added to the blender for blending, and mixed thoroughly to obtain the mixture A; the mixture A was added to the twin-screw extruder and melted at 200°C And extrusion granulation, the screw speed of the twin-screw extruder is 300rad / min, to obtain plastic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com