Intelligent shear type lifting wall painting machine fixed in step length and adjustable in working range

A technology with a working range and a fixed step length, which is applied in the direction of construction and building construction, can solve the problems of cost increase, paint waste, uneven application, etc., and achieve the effect of increasing the speed of wall painting, reducing costs, and increasing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

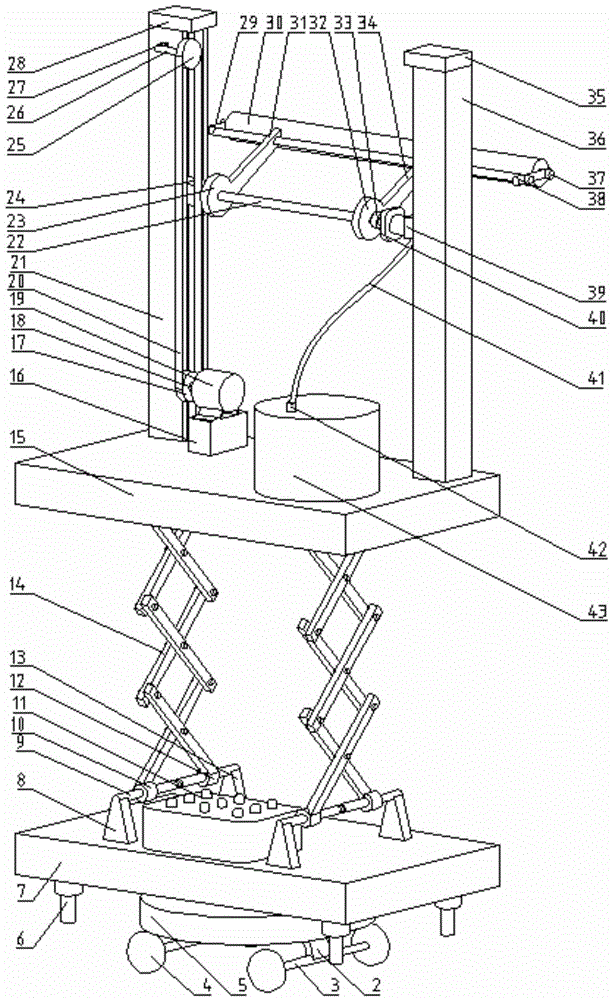

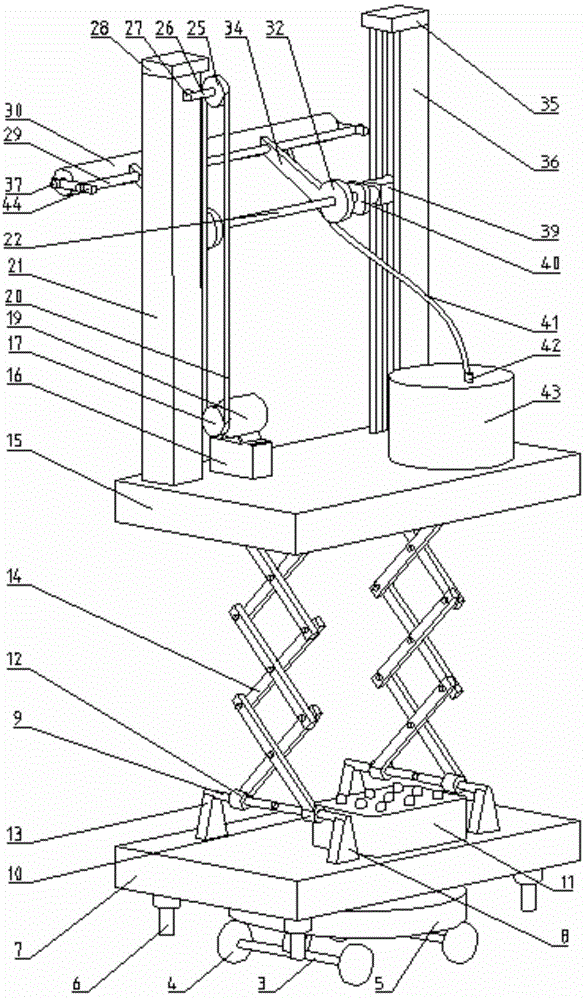

[0016] Below in conjunction with accompanying drawing, the scissor type lifting wall painting machine of the present invention will be further described.

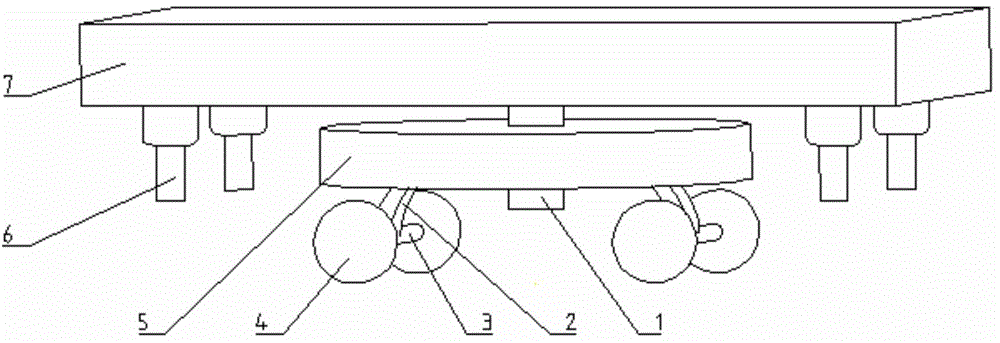

[0017] Such as figure 1 and figure 2 As shown, two symmetrically arranged left uprights 21 and right uprights 36 are fixed on the second base 15, and the left upright 21 and the right upright 36 are respectively provided with a slidingly fitted left slider 24 and a right slider on the opposite inner sides. 39. The bottom of left column 21 is provided with driving sprocket 17, and driving sprocket 17 is driven by the motor 19 that is installed on the second base 15, and motor 19 is installed on the 3rd fixed block 16, and the 3rd fixed block 16 is fixed on the second base 15, the driving sprocket 17 is fixedly installed on the second shaft 18, and the second shaft 18 is connected with the output shaft of the motor 19 through a coupling. The top of the left column 21 is provided with a driven sprocket 25, the driven sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com