Integrated paint dip-coating and drying device

A drying device, an integrated technology, applied to the surface coating liquid device, coating, surface pretreatment, etc., can solve the problems of troublesome drying, easy corrosion, and difficult simultaneous coating, etc., to improve efficiency, The effect of saving paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

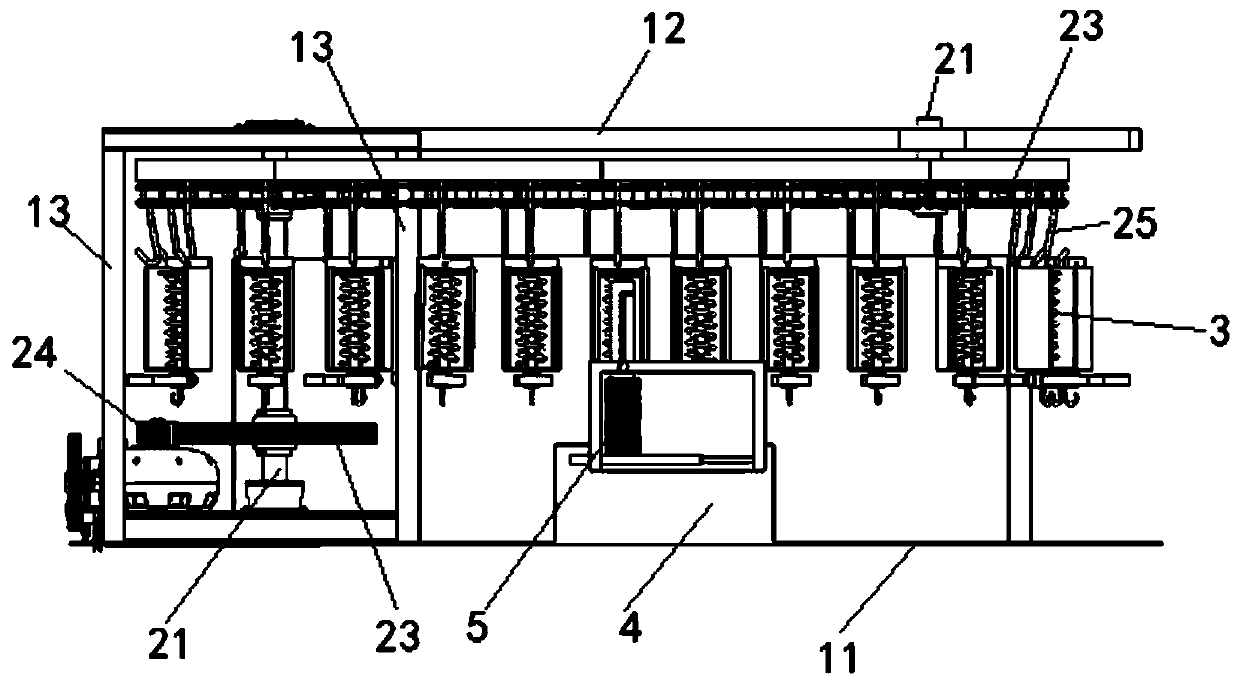

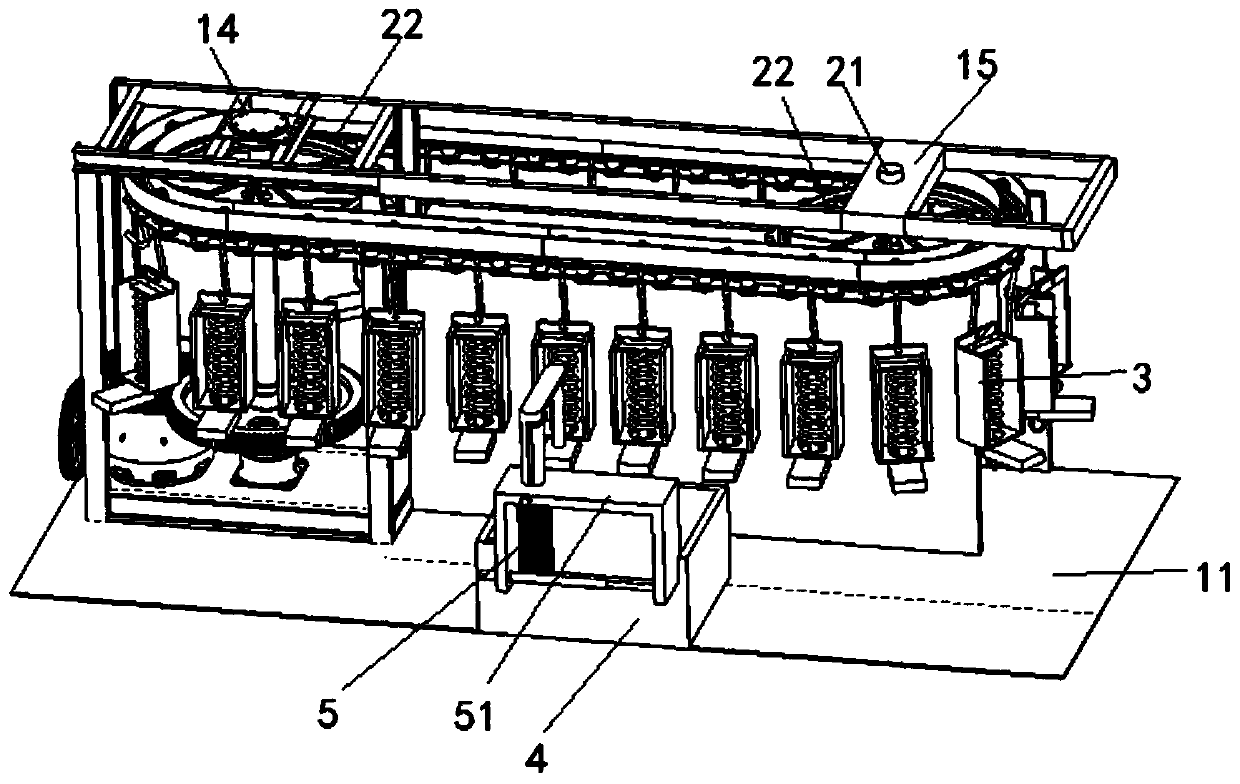

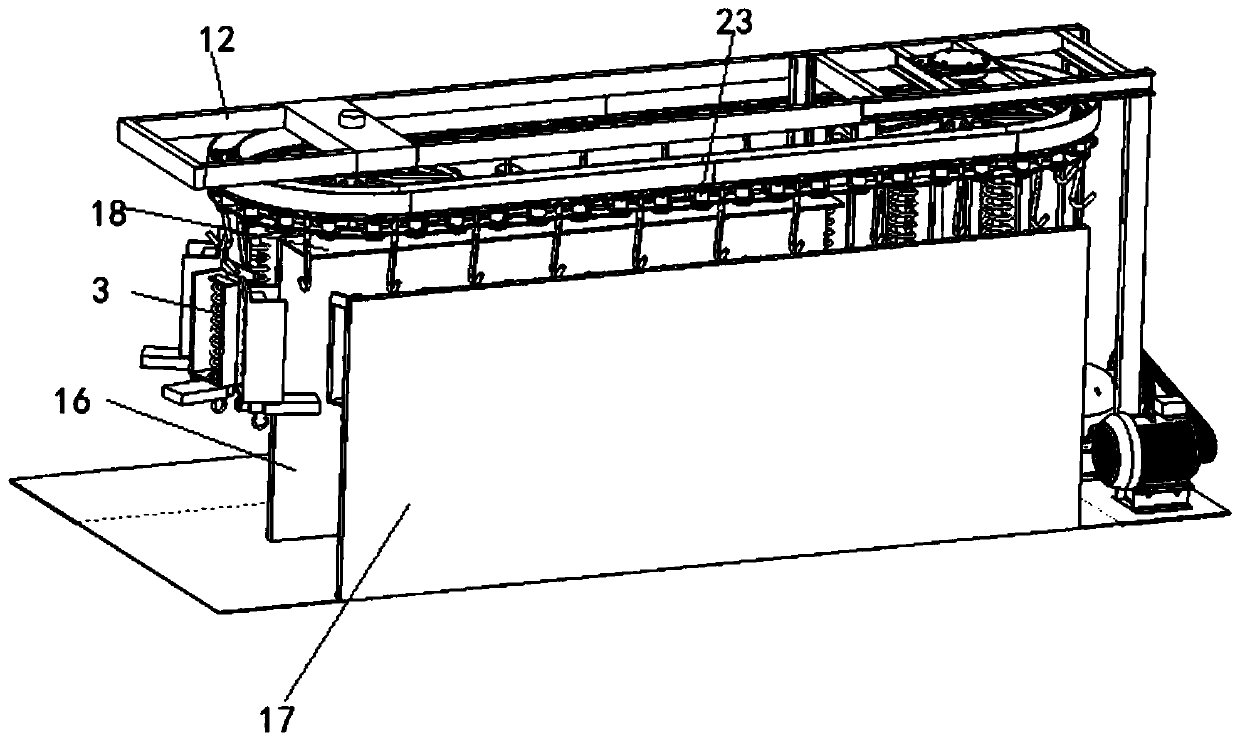

[0033] An integrated paint dipping and drying device, such as figure 1 , figure 2 and image 3 As shown, it includes a support frame 1 and a chain transmission mechanism 2 installed on the top of the support frame 1. A number of elastic suspension mechanisms 3 are suspended and fixed on the chain transmission mechanism 2. The object to be dipped is suspended at the bottom of the elastic suspension mechanism 3. The bottom of the support frame 1 is provided with a material box 4, which is loaded with paint, the material box 4 is located directly below the elastic suspension mechanism 3, and there is a certain distance between the elastic suspension mechanism 3 and the material box 4 , so that after the objects to be dipped are suspended, the objects one by one can pass smoothly from the top of the material box 4; the side of the top of the material box 4 is equipped with a rotary lifting positioning mechanism 5, which can push the elastic The suspension mechanism 3 moves down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com