Method for coating metallic surfaces with a composition that is rich in polymers

A technology of metal surface and composition, applied in the direction of surface coating liquid device, polyester coating, pretreatment surface, etc., can solve the problem that the effect of adding zirconium acetylacetonate has not been mentioned, so as to improve the strength and/or Or flexibility, improvement of adhesion, effect of paint adhesion improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example and comparative example

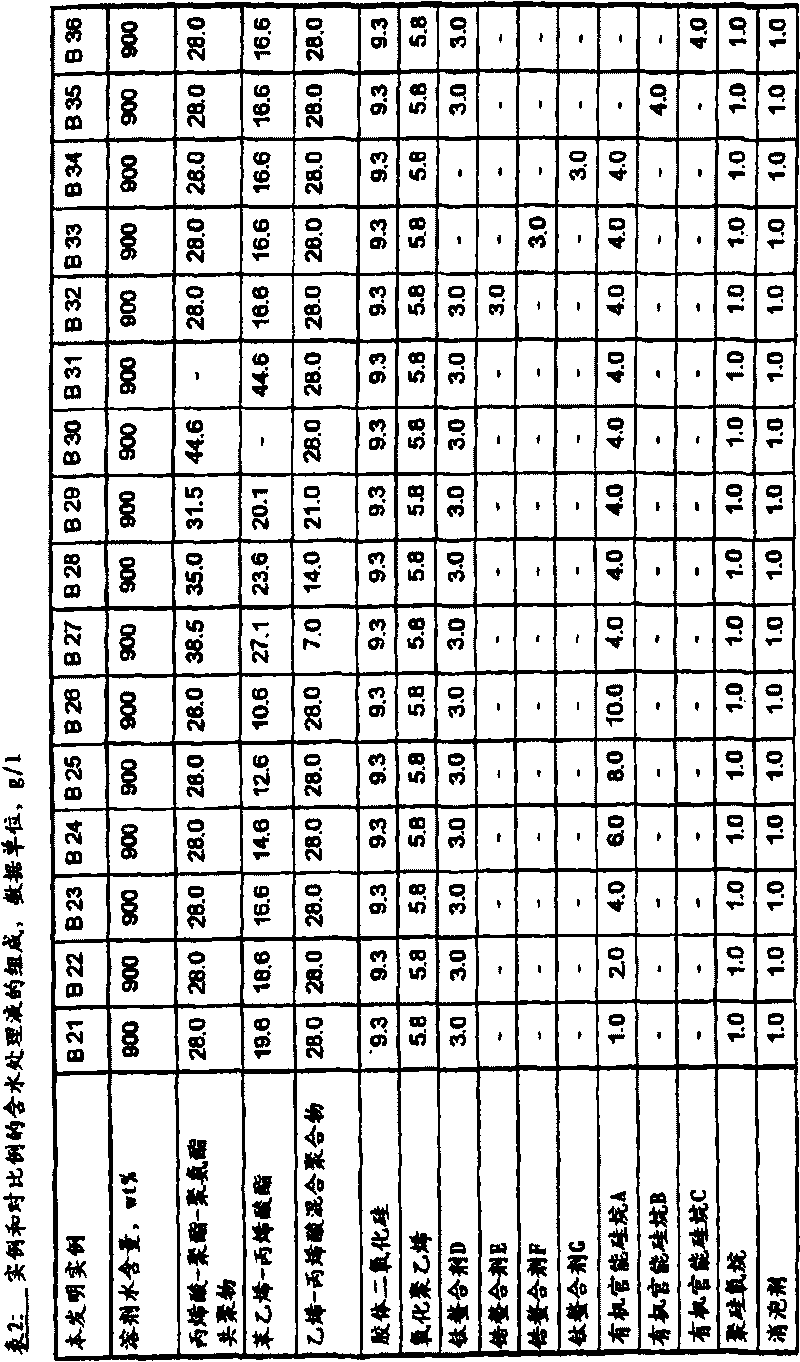

[0199] The examples described below are intended to describe the subject-matter of the invention in more detail.

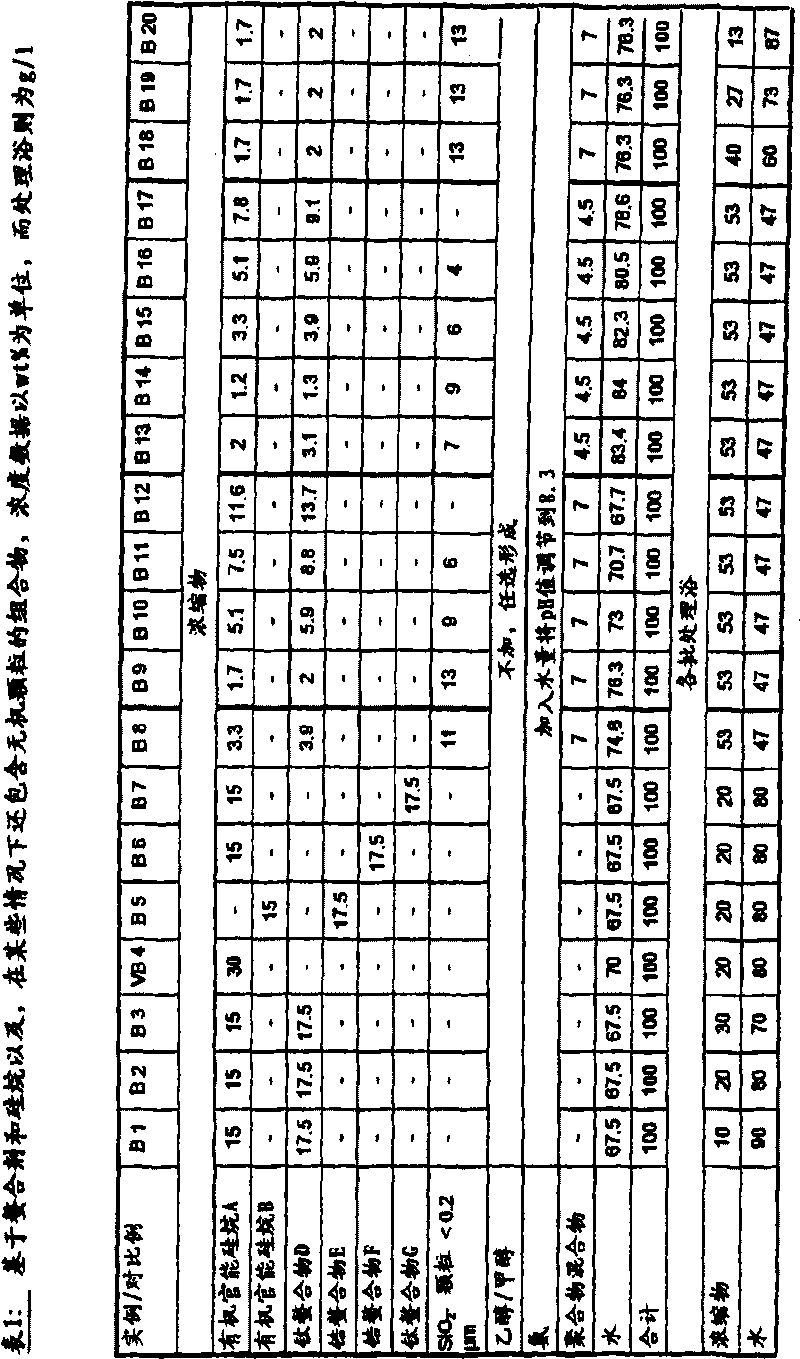

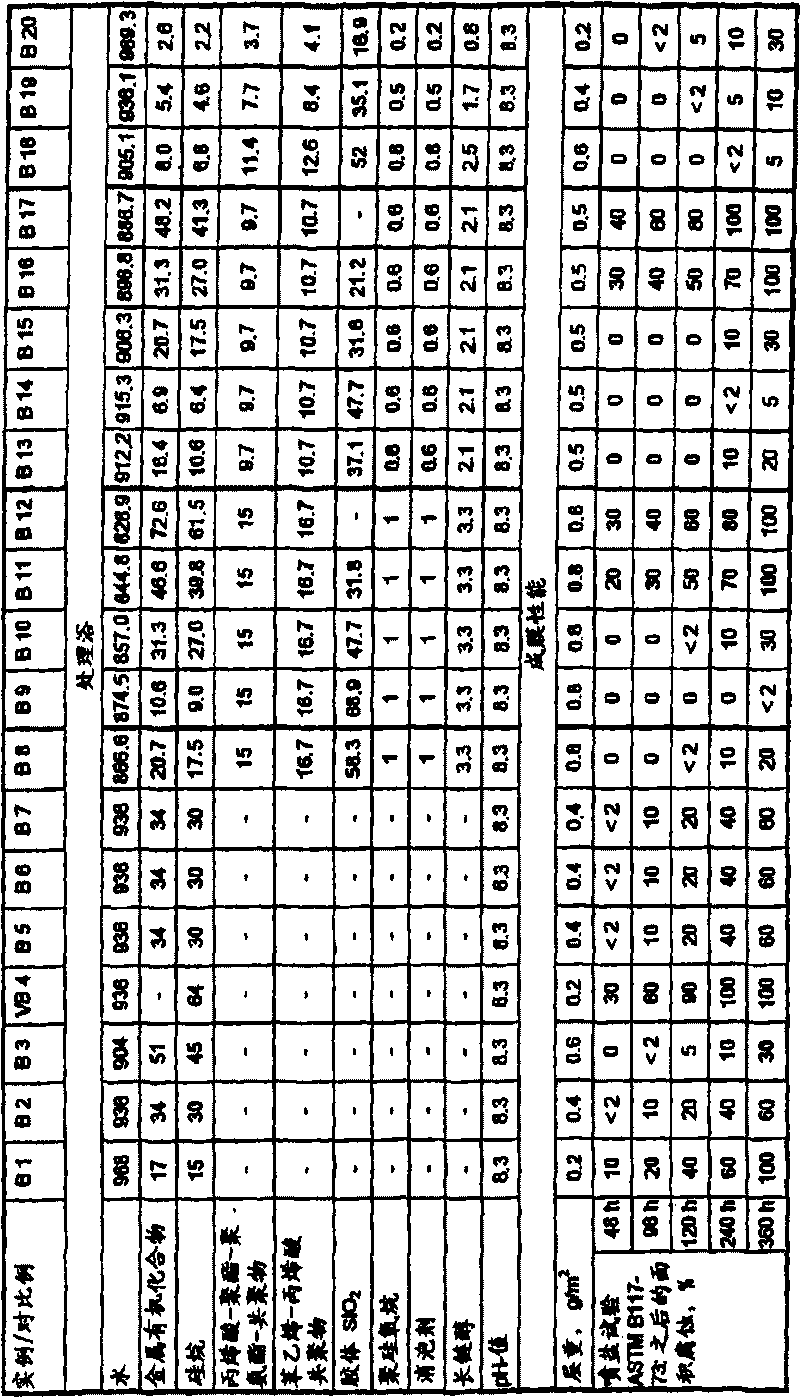

[0200] A) Compositions mainly based on chelating agents and silanes:

[0201] For the preparation of the aqueous concentrate, at least one partially hydrolyzed silane is aged for at least 2 weeks and optionally hydrolyzed thereby. Subsequently, the metal chelating agent listed in Table 1 was added. Subsequently, this concentrate is diluted with water, optionally with the addition of agents for adjusting the pH, such as ammonia, in order to obtain a ready-to-use treatment solution. In each case, at least 3 pieces of hot-dip galvanized steel or The steel plates were contacted with the corresponding treatment solution at 25°C by roll coating and drying. The metal sheets thus treated were dried at 90°C PMT and subsequently tested for their corrosion protection capabilities.

[0202] Examples E1-E8, including Comparative Example CE4, show the effect of adding a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com