Container outside paint spraying system

A container and spray gun technology, which is applied to spray devices, devices for coating liquid on surfaces, coatings, etc., can solve problems such as the inability to spray paint on containers, uneven paint thickness, and the inability to solve the problem of container end plate spray paint, etc. The effect of efficiency, simple structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

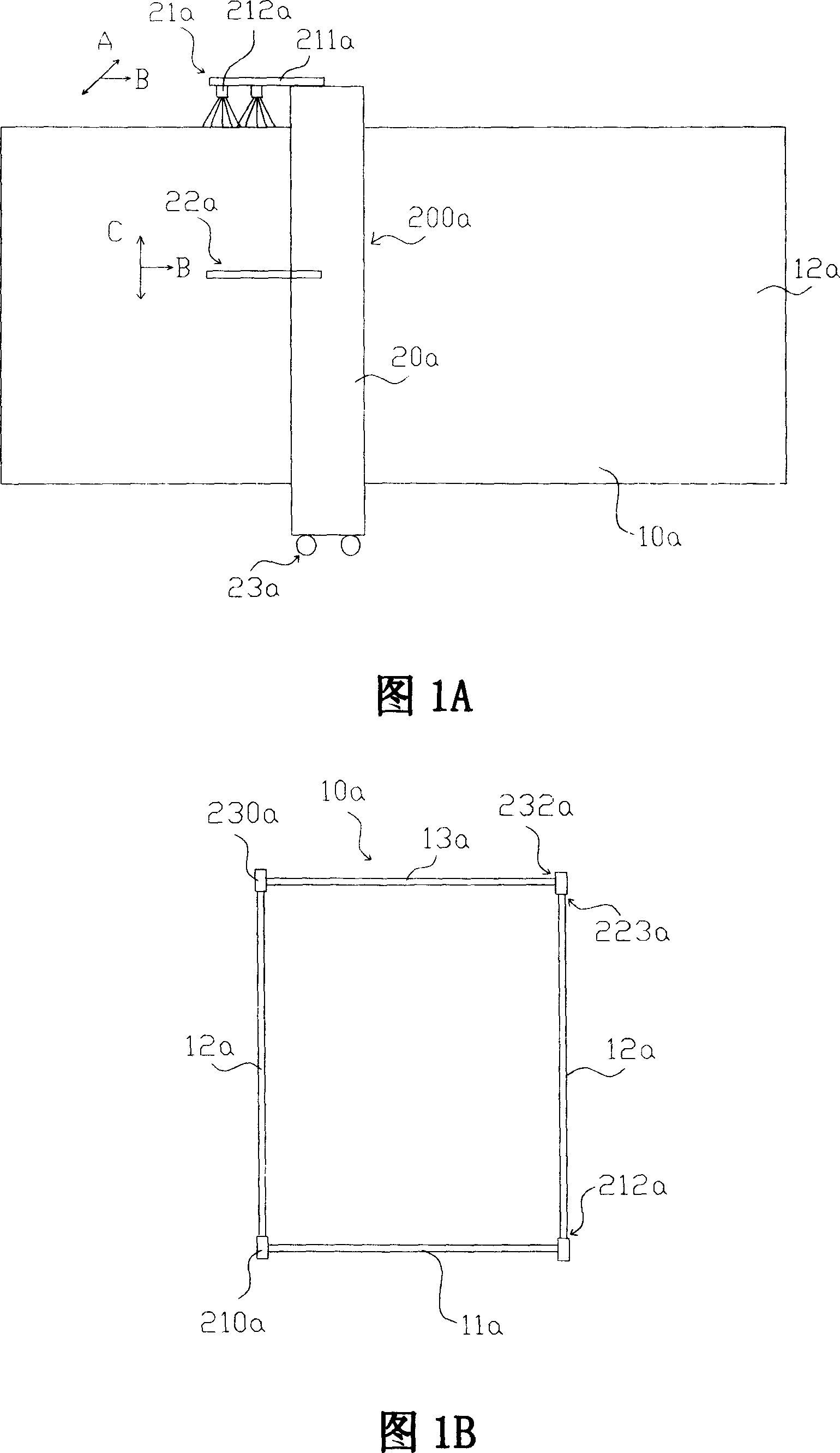

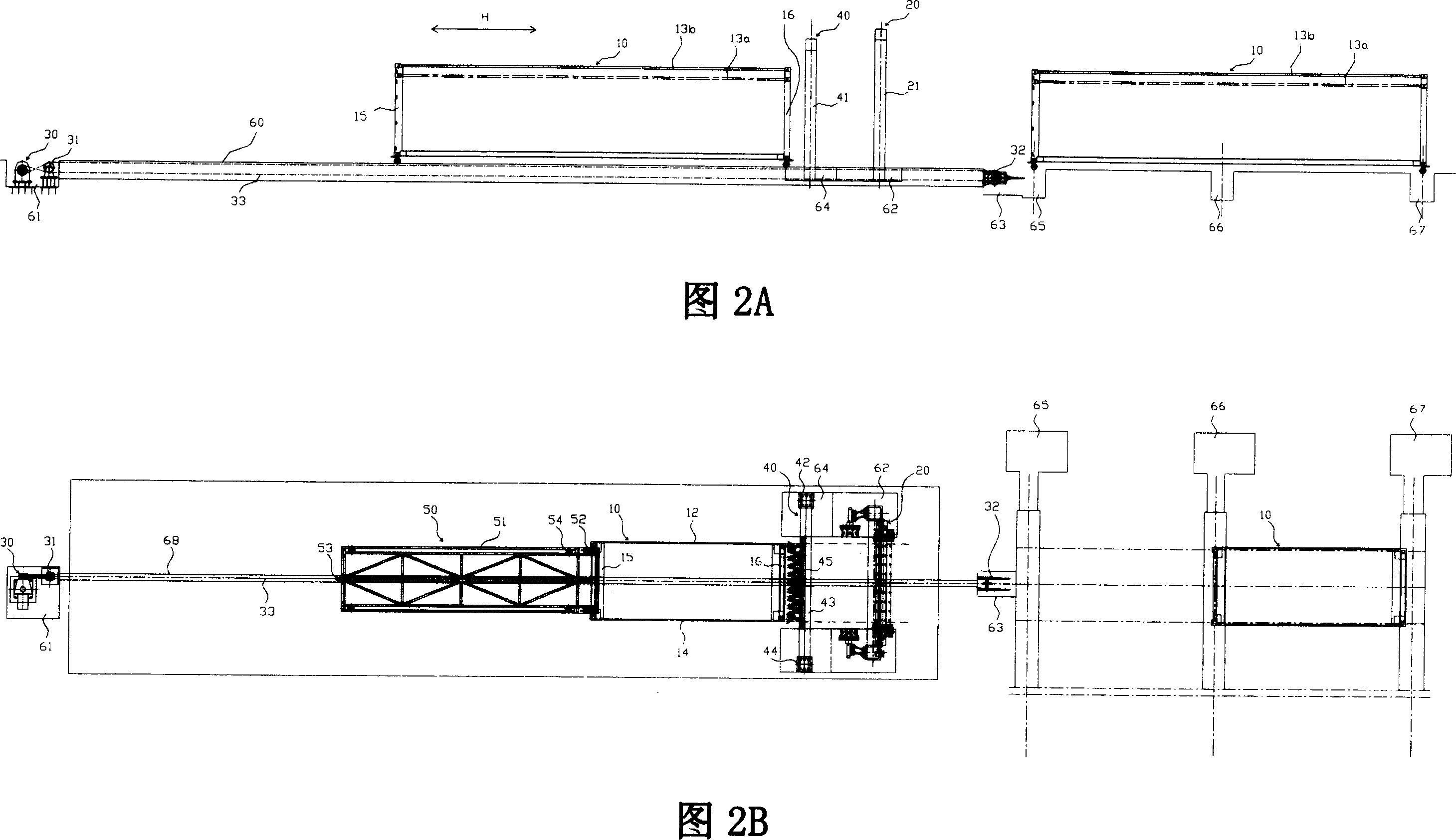

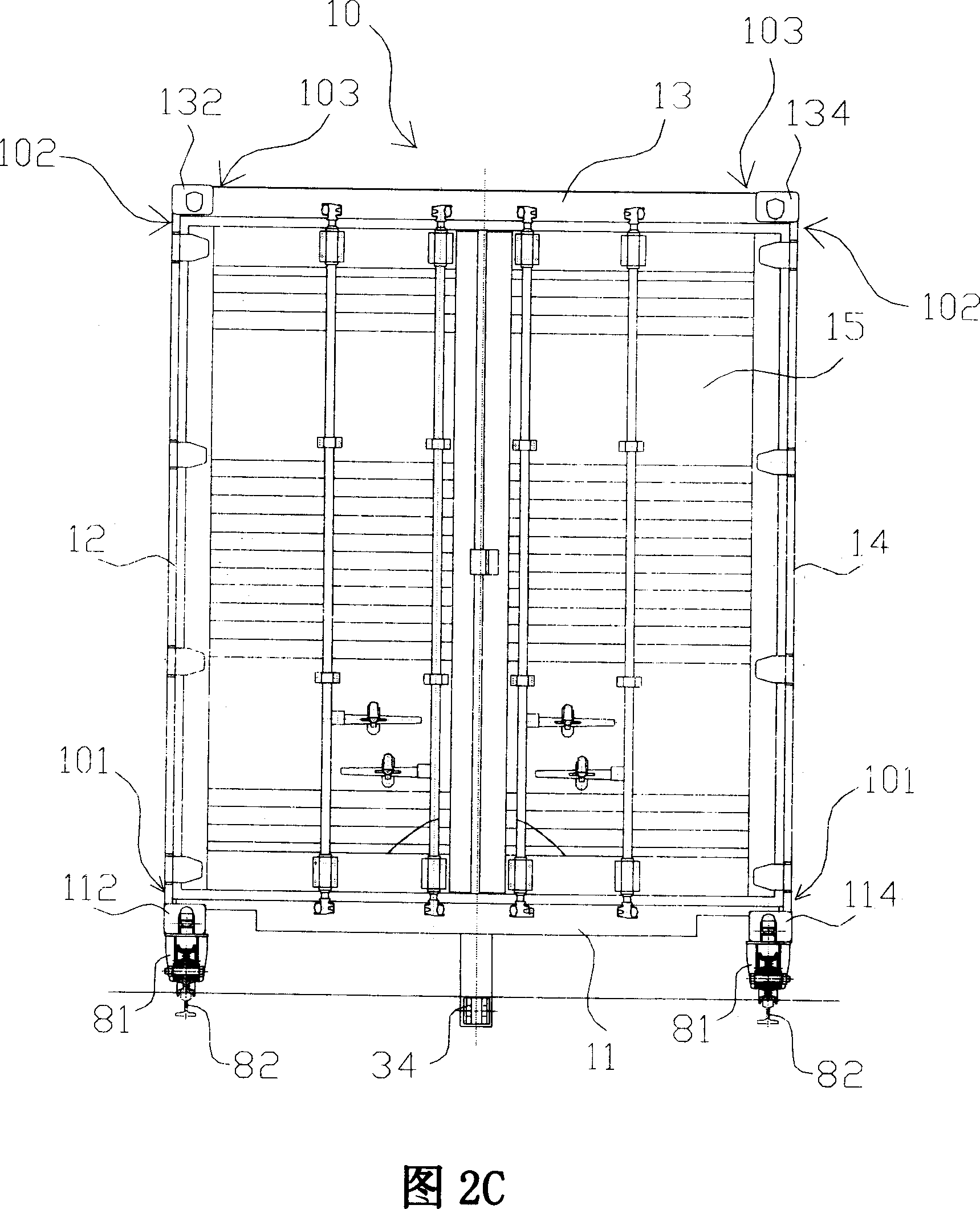

[0062] As shown in Fig. 2A, 2B, 2C, have shown the first preferred embodiment of the paint spraying system outside the container box of the present invention, wherein this container 10 that needs to spray paint is made up of a bottom plate 11, two side plates 12 and 14, top plate 13a (or 13b), chamber door 15 and rear frame end plate 16 constitute. The painting system outside the box mainly includes the gantry 20 outside the box and the spray gun installed thereon, the driving mechanism 30, and the end plate painting device 40 and the like. In FIG. 2A, the roof 13a represents the roof of a standard container, and the roof 13b represents the roof of an extra-high container.

[0063] And, in the present invention, this outer gantry 20 is fixed on the predetermined position on the ground 60, and this spray gun is installed on this outer gantry 20, is connected with a spray paint source (not shown in the figure), and is arranged to be connected with the container 10 corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com