Steel pipe spraying device for construction engineering construction

A technology of construction engineering and spraying device, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of low efficiency and lack of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

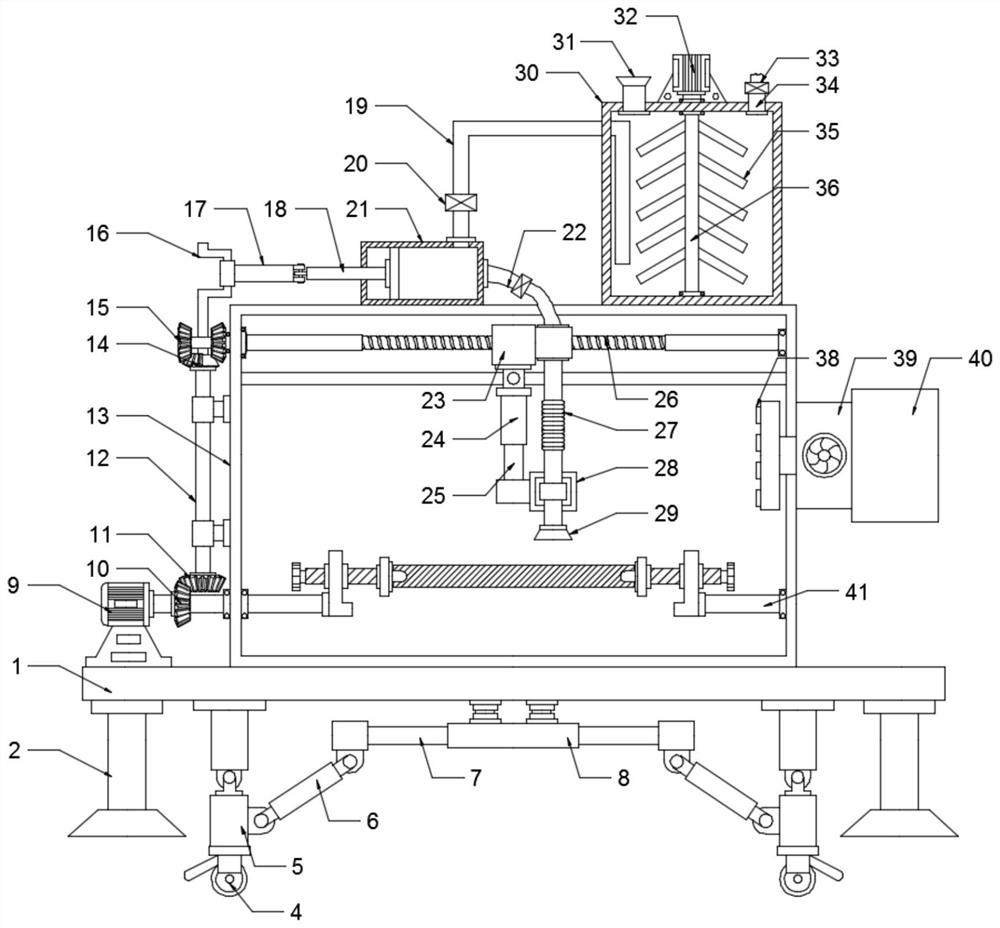

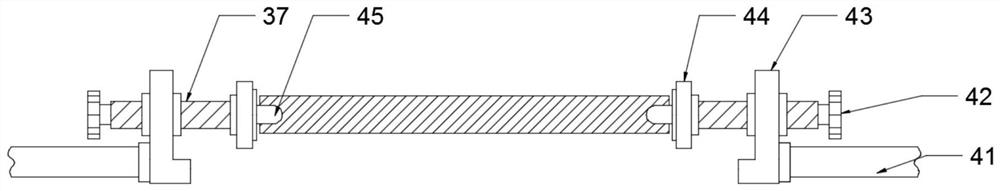

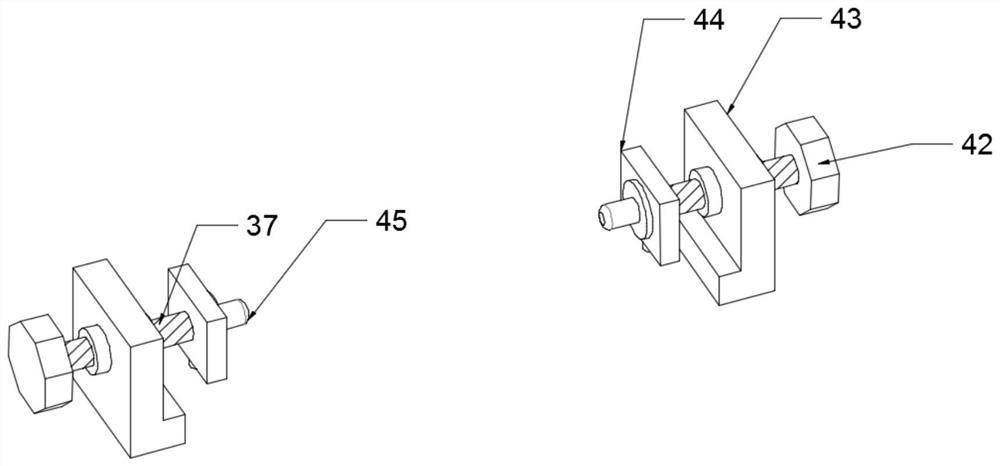

[0021] see Figure 1-3 , a steel pipe spraying device for construction engineering, comprising a support base 1 and a spray box 13, the spray box 13 is installed on the upper surface of the support base 1, the spray box 13 is fixedly connected to the support base 1 by welding, the The left side of the spraying box 13 is provided with a drive motor one 9, and the drive motor one 9 is fixedly connected with the support base 1, and the left and right sides are symmetrically arranged with bearings 43 in the spraying box 13, and the left and right sides are far away from each other. A rotating shaft 41 is fixedly installed on one side, and the rotating shaft 41 is rotationally connected with the inner wall of the spraying box 13. The end of the output shaft of the driving motor-9 passes through the spraying box 13 and is fixedly connected with the rotating shaft 41. 37, the ends of the fastening screw rods 37 on the left and right sides that are close to each other are fixedly conn...

Embodiment 2

[0028] see figure 1 , on the basis of Embodiment 1, in order to make the nozzle 29 move left and right to repeatedly spray the steel pipe, the driving motor-9 rotates, and the driving motor-9 drives the bevel gear-10 to rotate, and the bevel gear-10 drives the bevel gear The gear two 11, the rotating column 12 and the incomplete bevel gear 14 rotate. The incomplete bevel gear 14 drives the screw rod 26 to perform forward and reverse rotation by meshing with the bevel gear three 15 at the left and right ends. The nut 23 drives the bottom nozzle 29 in the horizontal direction. The direction moves back and forth left and right to realize repeated spraying of steel pipes.

[0029] The working principle of the present invention is: a steel pipe spraying device for construction engineering, inserting the left and right ends of the steel pipe to be sprayed into the positioning column 45, by turning the handle 42, the handle 41 drives the fastening screw 37 to rotate, and the fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com