Heat-absorbing piece for five-tube gas water heater

A gas-fired water heater and heat sink technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of low thermal efficiency and short life of heat sinks, reduce heat loss, avoid burnout, and eliminate heat accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

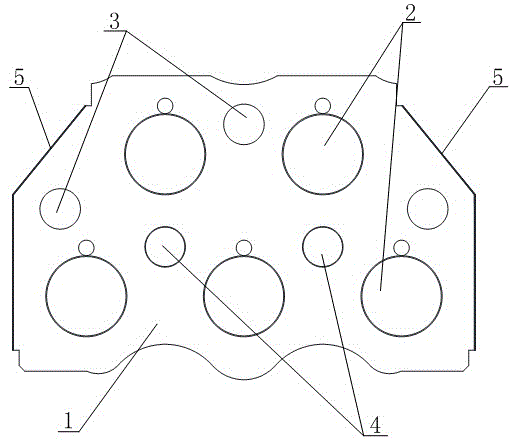

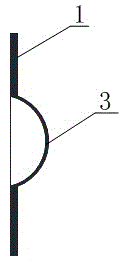

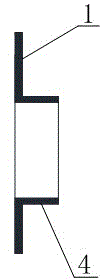

[0019] Such as Figure 1~3 As shown, the heat-absorbing sheet for a five-tube gas water heater includes a heat-absorbing plate 1, and the heat-absorbing plate is provided with five mounting holes 2 for the heat-absorbing pipes to pass through; the heat-absorbing plate is also provided with three relative absorbing plates. The protruding convex shell 3 of the heat plate is provided with two perforated flaps 4 on the heat absorbing plate to prevent heat accumulation; the two ends of the heat absorbing plate are respectively provided with folded edges for turning the hot gas back to the heat absorbing plate 5; The center distance between adjacent mounting holes is 32mm. Wherein, the convex hull and the driving flap are located on the same side of the heat-absorbing plate, and the specific positions of the above-mentioned components are set as follows: five installation holes are distributed in two rows, two are arranged on the upper part of the heat-absorbing plate, three are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com