Method for reducing temperature of cable tunnel

A technology of cable tunnel, temperature difference between inside and outside, applied in cable installation, cable installation in tunnel, ventilation of mine/tunnel, etc., can solve the problems of cable tunnel temperature rise, high cost, cable can not make full use of cooling costs, etc., to reduce The effect of cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

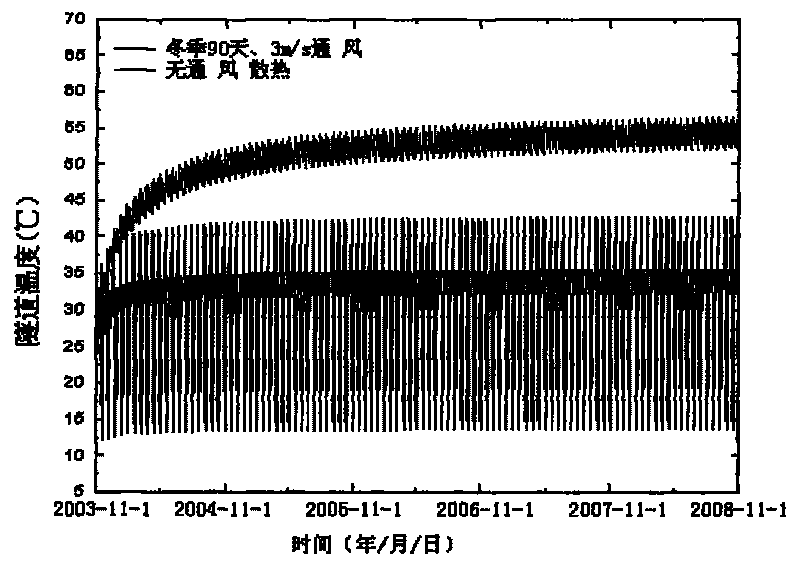

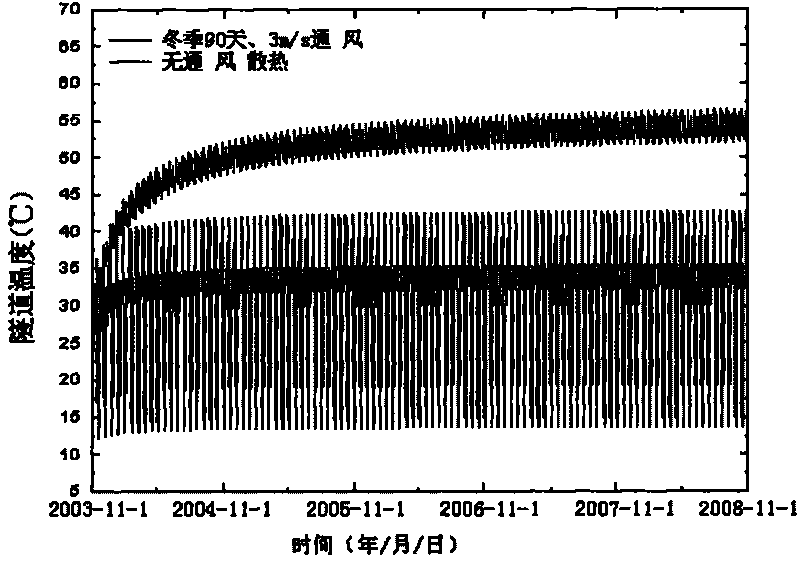

[0026] Embodiment 1 of the present invention is an internal experimental system, such as figure 1 As shown, a result of the temperature change in the cable tunnel after a certain cable tunnel is ventilated at a ventilation frequency is provided.

[0027] The cable tunnel is composed of two lines. The basic configuration and cable settings of the two lines are exactly the same. The average load of the cable in the cable tunnel is 81W / m, and the maximum load is 252W / m.

[0028] A ventilation system is installed on one of the lines, and no ventilation system is installed on the other line. In a cable tunnel line with a ventilation system, the ventilation system is used for ventilation during the three months of winter (from November 1st to February 1st of the following year), and the ventilation strategy adopted is to use blowers and exhaust fans every day Forced ventilation.

[0029] At the same time, use a thermometer to record the temperature of another cable tunnel line without a v...

Embodiment 2

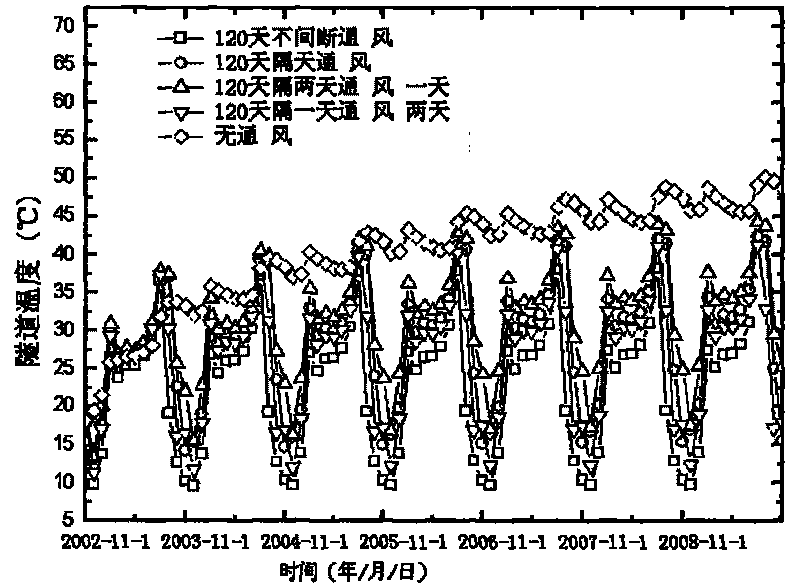

[0032] Embodiment 2 of the present invention is another internal experimental system, such as figure 2 As shown, the results of the temperature change in the cable tunnel after a certain cable tunnel is ventilated with multiple ventilation frequencies are provided.

[0033] The cable tunnel is composed of five lines. The basic configuration and cable settings of each line are exactly the same. The average load of the cable in the cable tunnel is 96W / m, and the maximum load is 297W / m.

[0034] Ventilation system is installed on four of the lines and no ventilation system is installed on the other line. In the four cable tunnel lines with ventilation system, the ventilation system is used during the four months of winter (from November 1st to 3rd of the following year). February 1) for ventilation, the ventilation strategy adopted is:

[0035] Line 1 has uninterrupted ventilation every day;

[0036] Line 2 is ventilated every other day and circulates;

[0037] Line 3 is ventilated for ...

Embodiment 3

[0044] In order to control the temperature in the cable tunnel in a more intelligent way, this embodiment uses the temperature detector in the ventilation system to simultaneously measure the temperature in the cable tunnel and the temperature of the ground environment, and uses the program to set a first set value such as 20 ℃.

[0045] When the temperature difference between the temperature in the cable tunnel and the temperature of the ground environment reaches 20°C, the blower and exhaust fan in the ventilation system are started to discharge the hot air in the cable tunnel. With the operation of the blower and exhaust fan, the temperature difference between the temperature in the cable tunnel and the temperature of the ground environment gradually becomes smaller. A second set value such as 15°C is set by the program. When the temperature in the cable tunnel and the ground When the temperature difference between the ambient temperature reaches the second set value, the blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com