Method for preparing hot-spraying T400 coating material and coating layer

A coating material, thermal spraying technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of shortened service life, reduced engine efficiency, shortened service time of turbine blades, etc. Process control, low oxygen content, easy coating process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of T400 coating material of the present invention comprises the following steps:

[0020] 1) Take metal materials: 7-12% by weight of chromium, 20-30% by weight of molybdenum, 2-5% by weight of silicon, and the balance of Co, or choose 7-12% by weight of chromium, 20-30% by weight of molybdenum, 2-30% by weight of silicon 5% by weight, chromium-molybdenum-silicon-cobalt alloy with the balance of Co;

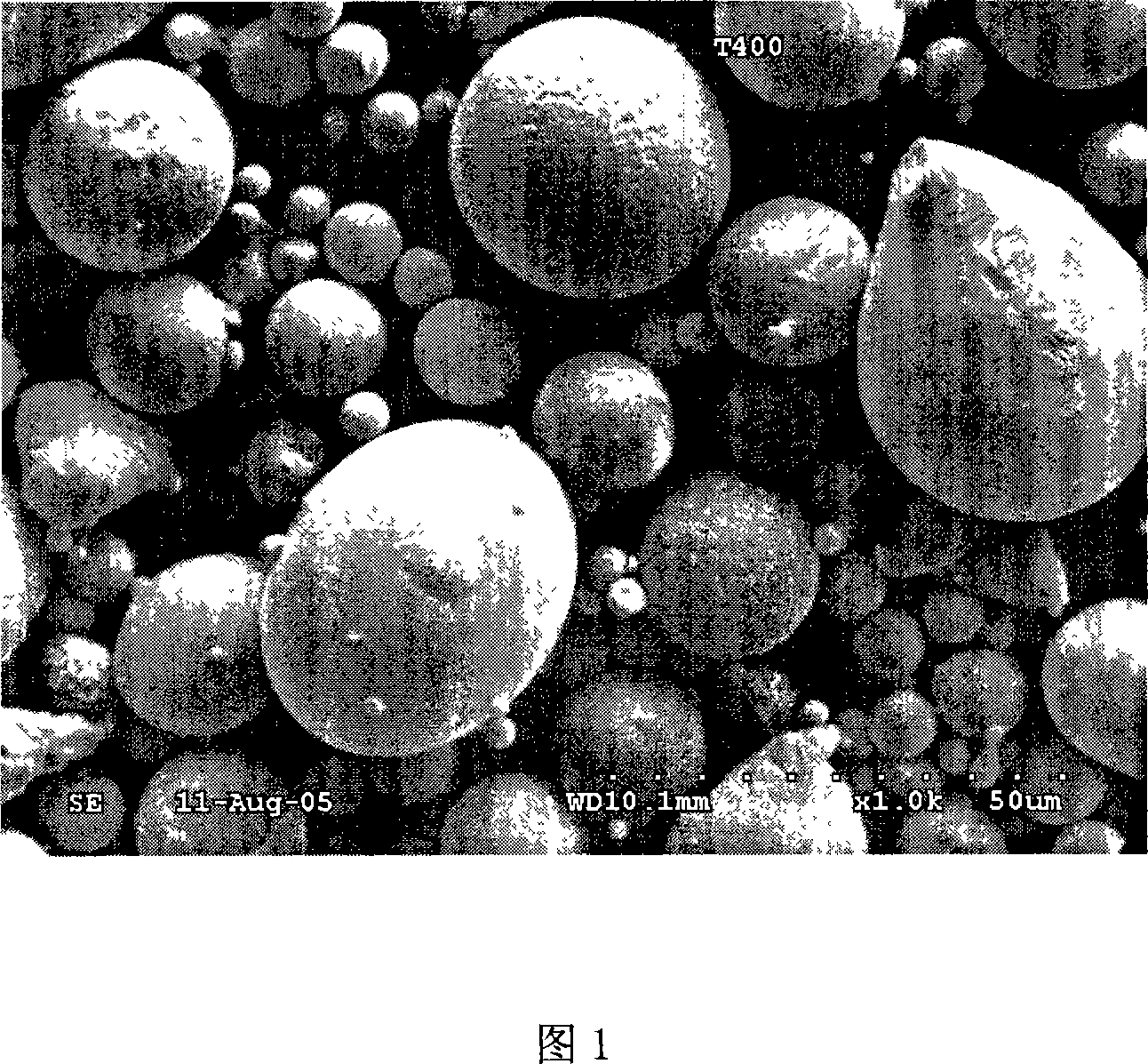

[0021] 2) Put the selected raw materials into the gas atomization equipment, and obtain chromium molybdenum silicon cobalt alloy powder through gas atomization technology;

[0022] The gas atomization technology described is: heating the gas atomization equipment by medium frequency induction, raising the temperature to 1300-1550°C, keeping it warm for 10-60 minutes, and using conventional T400 alloy refining and degassing to produce the alloy powder, that is, in the smelting furnace The alloy is in a semi-molten state, add a little CaF 2 , when th...

Embodiment 1

[0026] Take the alloy composition Cr9wt%, Mo26wt%, Si4wt%, Co balance, put it into non-vacuum atomization equipment, use medium frequency induction heating, when the temperature is heated to 1450 ℃, keep it warm for 18 minutes, after the alloy liquid is homogenized, with CaF 2 Refining and degassing; using argon atomization, the atomization process parameters are: atomization pressure is 2.5MPa, and the diameter of the diversion tube is 5mm. Then sieve.

[0027] The process parameters of thermal spraying T400 coating prepared by atmospheric plasma thermal spraying process for the above materials are: arc current 470A; arc voltage 70V; argon pressure 0.7MPa; argon flow 50L / min, powder feeding speed 35g / min, spraying distance 150mm. Then sieve.

Embodiment 2

[0029] Take the alloy composition Cr9.5% by weight, Mo29.5% by weight, Si3% by weight, and the balance of Co, put it into a non-vacuum atomization equipment, use intermediate frequency induction heating, heat it for 20 minutes when the temperature is heated to 1500 ° C, and wait for the alloy liquid After homogenization, use CaF 2 Refining and degassing, using argon atomization, the atomization process parameters are: atomization pressure is 205MPa, and the diameter of the diversion tube is 7mm. Then sieve.

[0030] The process parameters of thermal spraying T400 coating prepared by atmospheric plasma thermal spraying process for the above materials are: arc current 530A; arc voltage 80V; argon pressure 0.85MPa; argon flow rate 55L / min powder feeding speed 50g / min spraying distance 200mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com