Tangential fretting test device and its test method

A test device and testing machine technology, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, test wear resistance, etc., can solve problems such as economic loss and shorten the life of parts, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

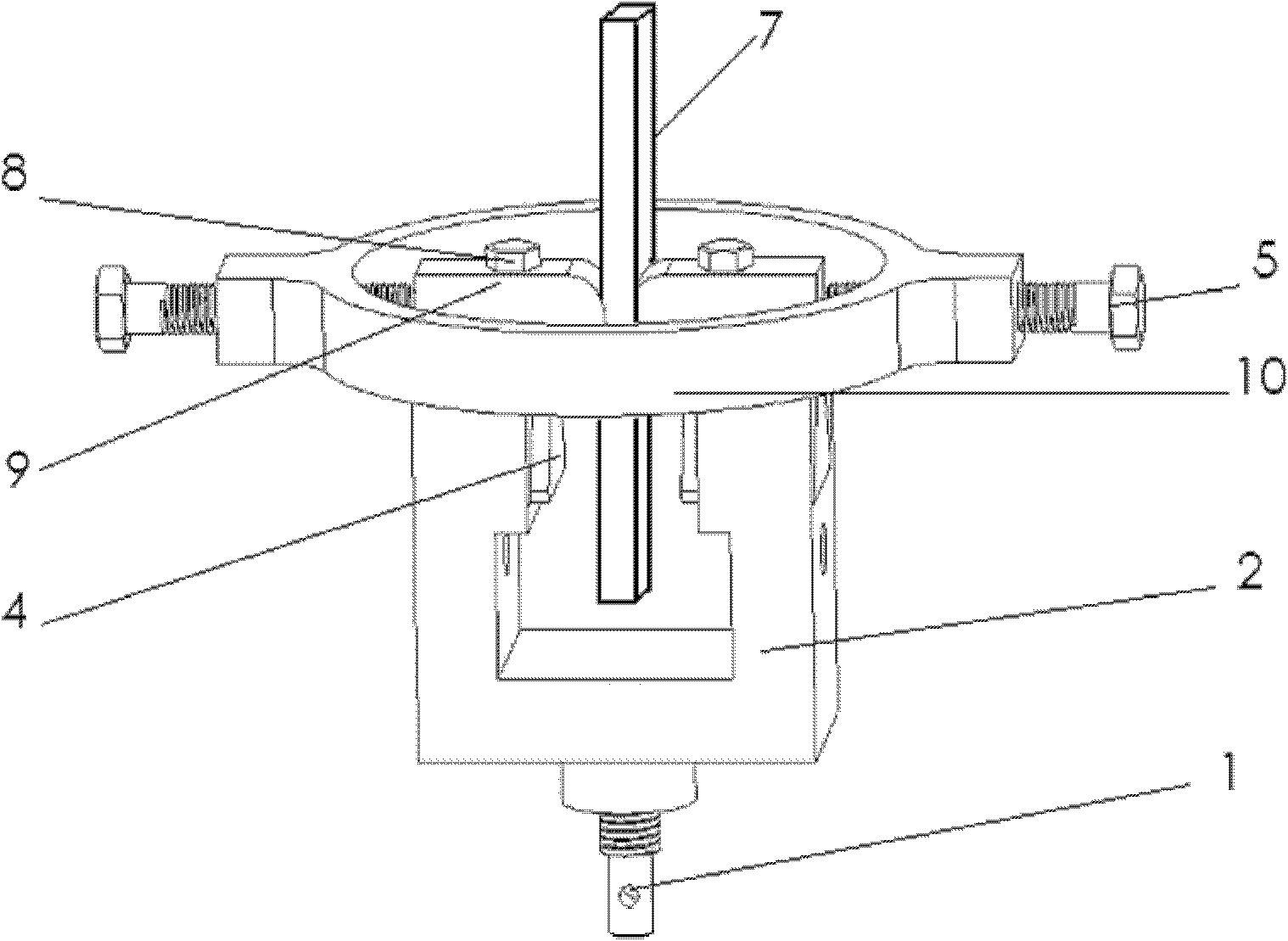

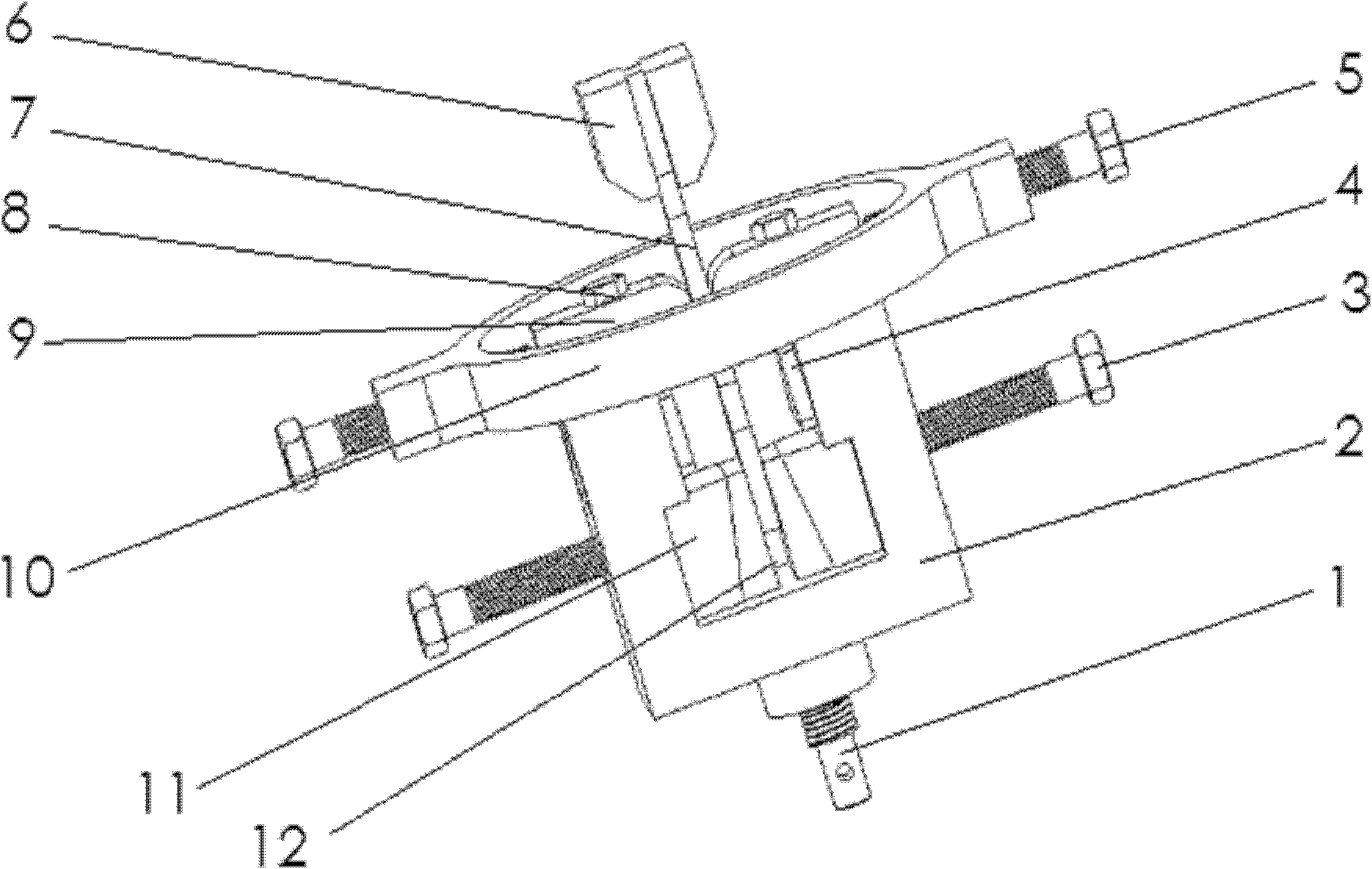

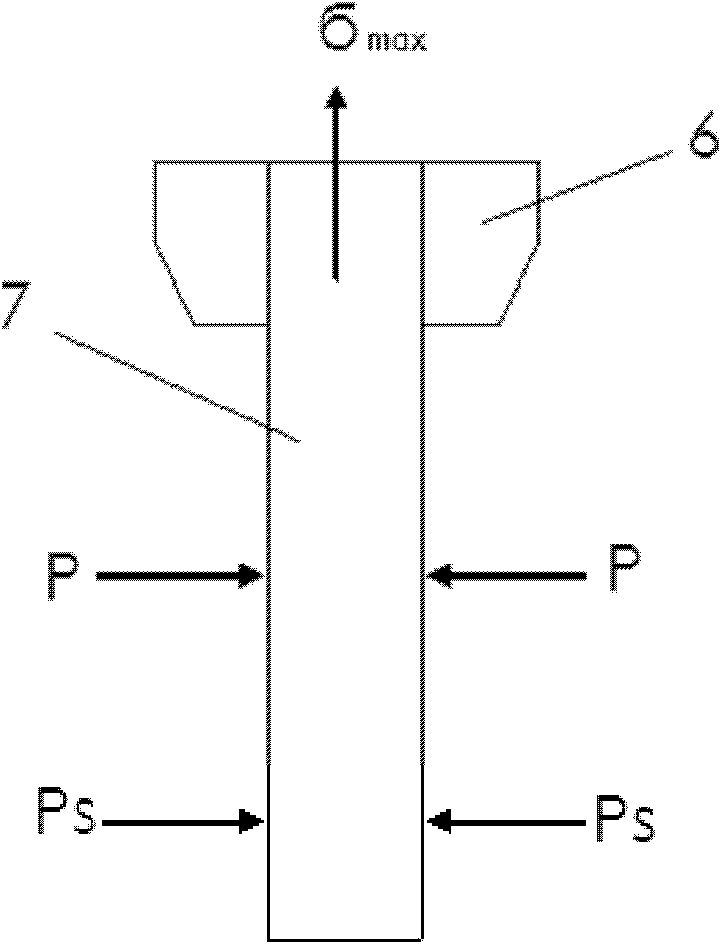

[0024] Such as figure 2 As shown, in the device for realizing the fretting fatigue test, the locking part includes the first pair of wedge blocks 11 and the second pair of wedge blocks 12 placed in the U-shaped holder 2, and the two sides of the U-shaped holder are symmetrically provided with screws. The screw hole is connected with a locking bolt 3, and the end of the locking bolt extends into the U-shaped clamping seat to apply a clamping force to the first pair of wedges, and then the first pair of wedges clamps the second pair of wedges. The second pair of wedge blocks finally locks the lower end of the test piece 7; the purpose of designing two pairs of wedge blocks 11 and 12 is to make the test piece 7 tighter and tighter without axial displacement. The cylindrical contact indenter 9 is connected with the dovetail block 4 through the connecting bolt 8, and slides along the dovetail groove, and the lower chuck 1 of the U-shaped clamp 2 is connected with the testing machi...

Embodiment 2

[0031] Such as Figure 4 , Figure 5 As shown, in the fretting wear experimental device, the pre-tension member 19 includes a tension force measuring ring 16 vertically placed in the pressure force measuring ring 10 and the U-shaped holder 2, and the tension force measuring ring is provided with clamps respectively. Hold the upper and lower two specimen clamps 20 (connected by pins 18) on the upper and lower ends of the specimen 7. The upper specimen clamp is connected with the upper chuck of the testing machine through the upper connector 17 on the upper end of the tension measuring ring. The clamp is connected to the lower connecting piece 13 at the lower end of the tensile force measuring ring, and the pretensioning force is applied to the test piece 7 by tightening the pretension nut 14 on the lower connecting piece 13, and the ring body at the lower end of the force measuring ring is provided with a set bolt 15 The lower connecting piece is locked to ensure that the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com