Driving device for forming machine

A driving device and forming machine technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve problems such as stuck, shortened replacement cycle, and reduced work efficiency, and achieve a simple overall structure, long service life, and ingenious design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

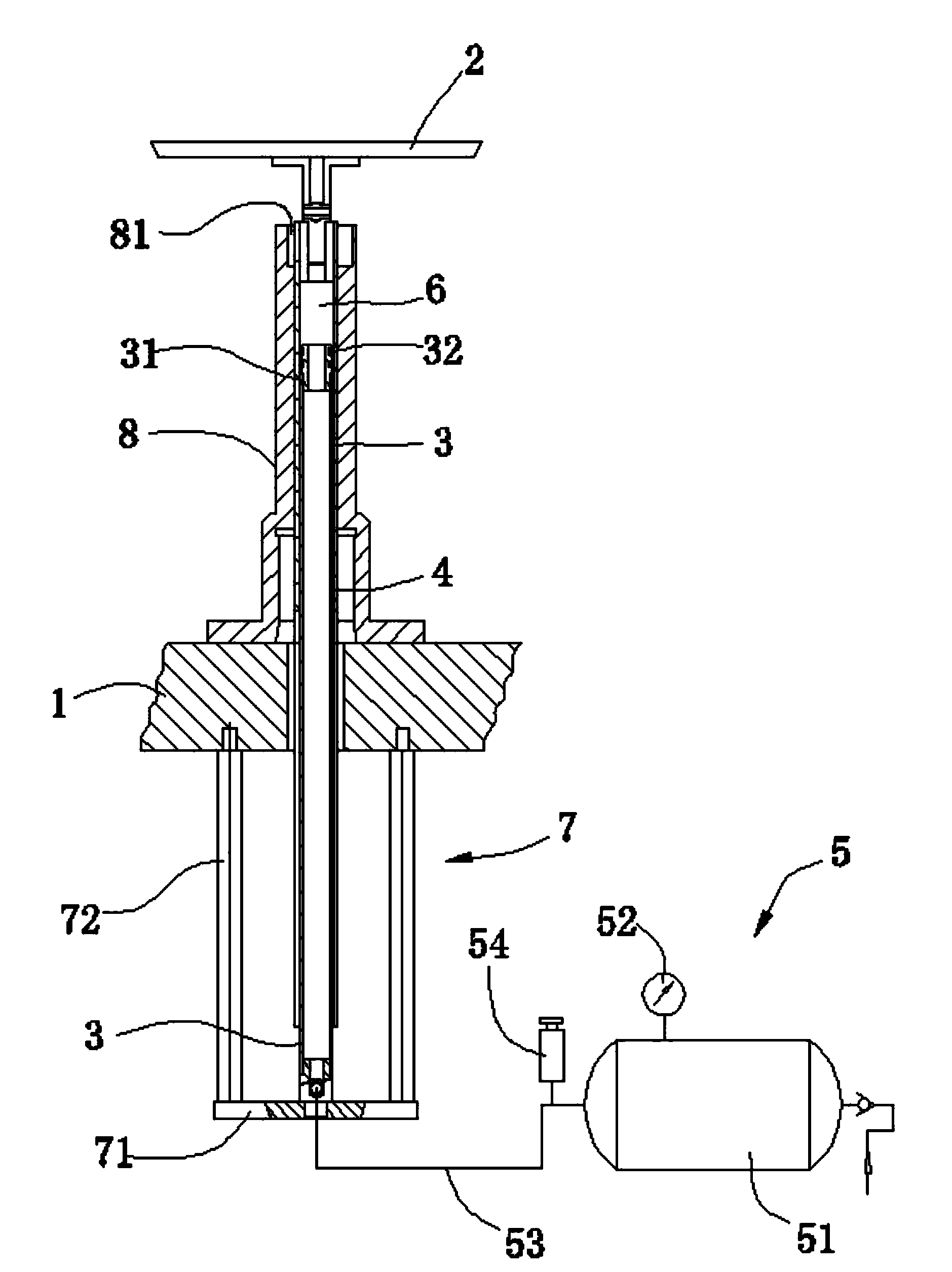

[0014] See figure 1 This embodiment provides a molding machine driving device, which includes a base 1 and a lower mold base plate 2, which also includes a lower mold inner sleeve 3, a lower mold outer sleeve 4, and an air supply device 5. The in-mold sleeve 3 is fixed on the support 1, the lower mold base plate 2 is fixed on the top of the lower mold outer sleeve 4, and the bottom of the lower mold outer sleeve 4 is movably sleeved on the lower mold On the inner sleeve 3, a closed space 6 is formed between the inner sleeve 3 of the lower mold and the inner hole of the outer sleeve 4 of the lower mold, and the air supply device 5 communicates with the closed space 6.

[0015] The lower end of the lower mold inner sleeve 3 penetrates the support 1, and corresponding to the bottom of the support 1 is provided with a fixing frame 7 for fixing the lower mold inner sleeve 3 on the support 1 .

[0016] The fixing frame 7 includes a connecting plate 71 and two fixing posts 72. The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com