Double-layer wire-to-board IDC connector

A connector, double-layer technology, applied in the direction of connection, fixed connection, conductive connection, etc., can solve the problems of insufficient holding force, broken hook, poor elasticity, etc., and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

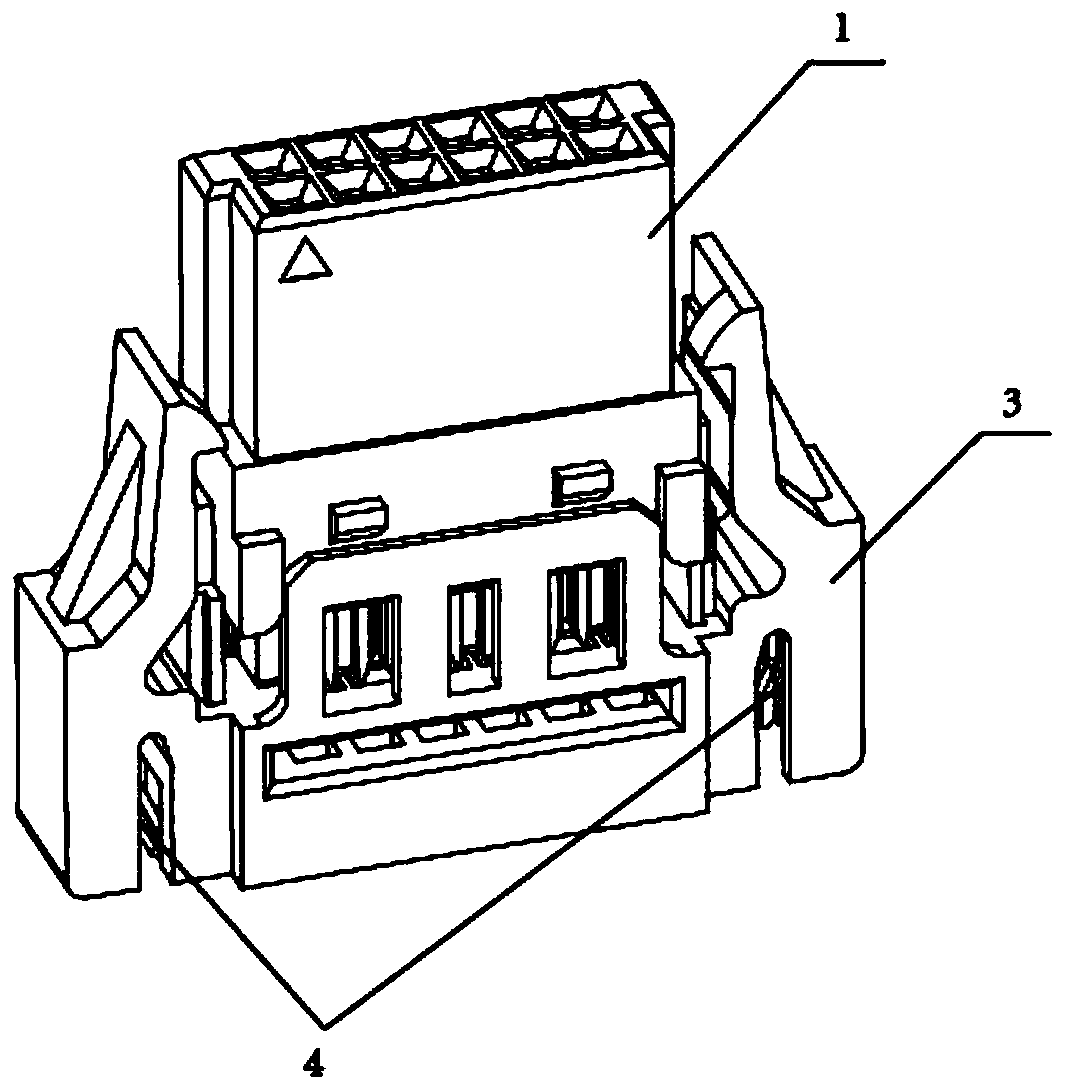

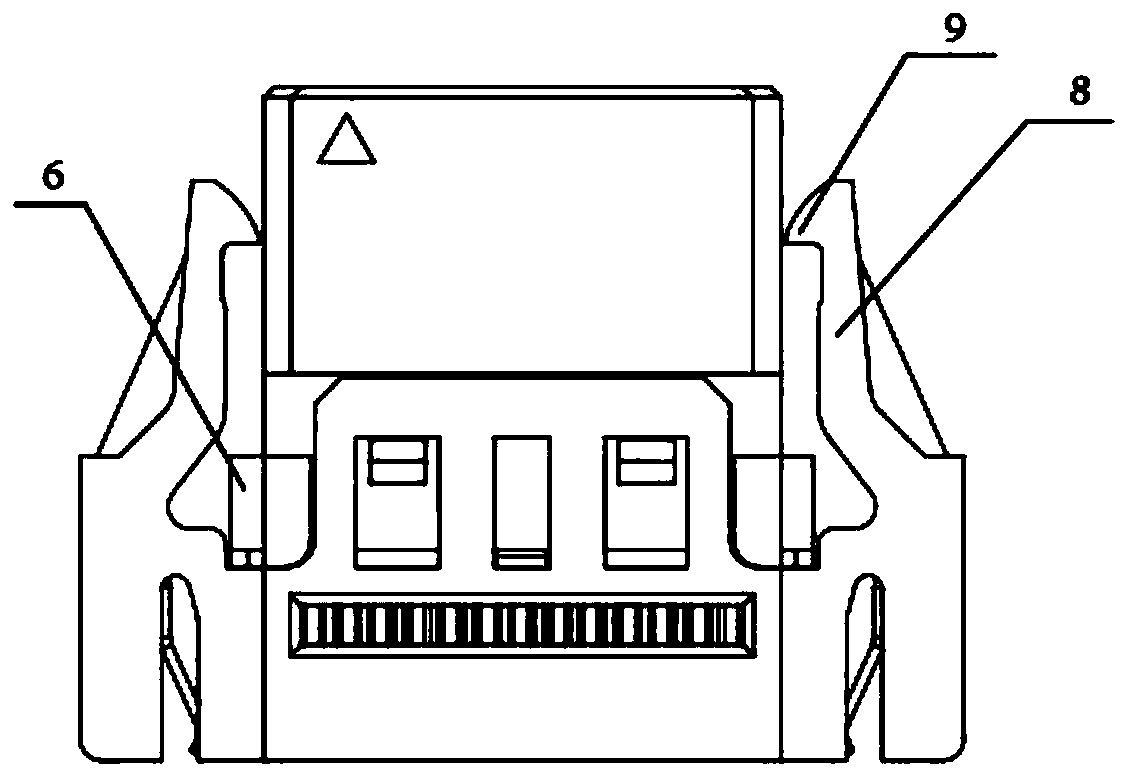

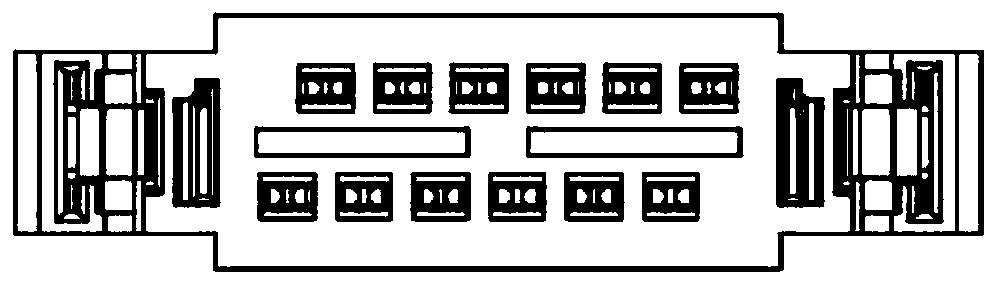

[0031] Such as Figure 1-5 A double-layer wire-to-board IDC connector is shown, including a plastic body 1, a wire terminal 2, a plastic back plug 3 and a shrapnel 4, and the plastic body 1 is provided with a main accommodation chamber and several first terminal accommodation chambers 5 The plurality of first terminal accommodation cavities 5 are integrally formed with the plastic body 1, the number of the plurality of first terminal accommodation cavities 5 is the same as the number of wire terminals 2, and the wire terminals 2 include first terminals 21 and second terminals 22. The first terminal 21 is inserted into the first terminal accommodating cavity 5, and a plurality of second terminal accommodating cavities 10 are opened in the plastic rear plug 3, and the plurality of second terminal accommodating cavities 10 are integrally formed with the plastic rear plug 3, several The number of the second terminal accommodating chamber 10 is the same as the number of wire termin...

Embodiment 2

[0034] The number of the first terminal accommodating cavity 5 , the lead terminals 2 and the second terminal accommodating cavity 10 in this embodiment is different from that in the first embodiment.

[0035] Way of working:

[0036] Such as Figure 7 As shown, insert the cable 14 into the slot 15 of the plastic rear plug 3, press the plastic body 1 downward, and then move the wire terminal 2 downward, so that the second terminal 22 punctures the cable 14, and then Continue to press so that several snap-in bumps 7 snap into the first snap-in portion 12 on the connection plate 11, and the metal conductive terminal is forced to be pierced by the sharp part 23 through the outer skin of the connector through the closure of the back plug, and contacts with the core wire of the cable 14 , so as to realize the conduction of the circuit; when the connector is disassembled, press the elastic arm 8 inward, so that the elastic arm 8 is opened, so that the plastic back plug 3 is removed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com