Nuclear waste material barrel jacking vibration filling device and filling method thereof

A filling device and a technology for nuclear waste, which are applied in the field of nuclear waste bucket lifting and vibrating filling devices, can solve the problems of human harm, no solution to the bucket, and no human involvement, and achieve the effect of stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

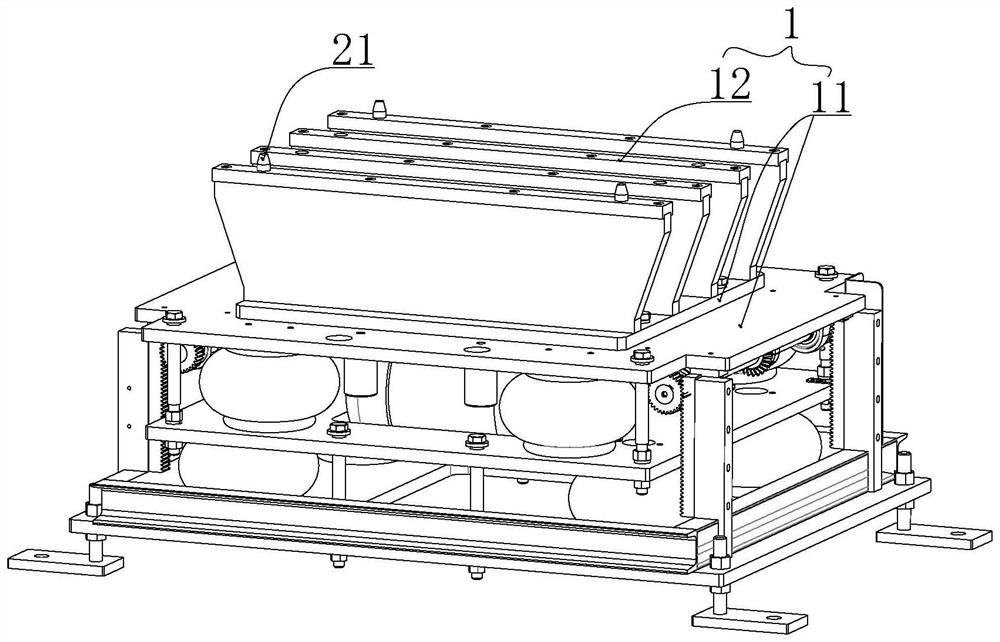

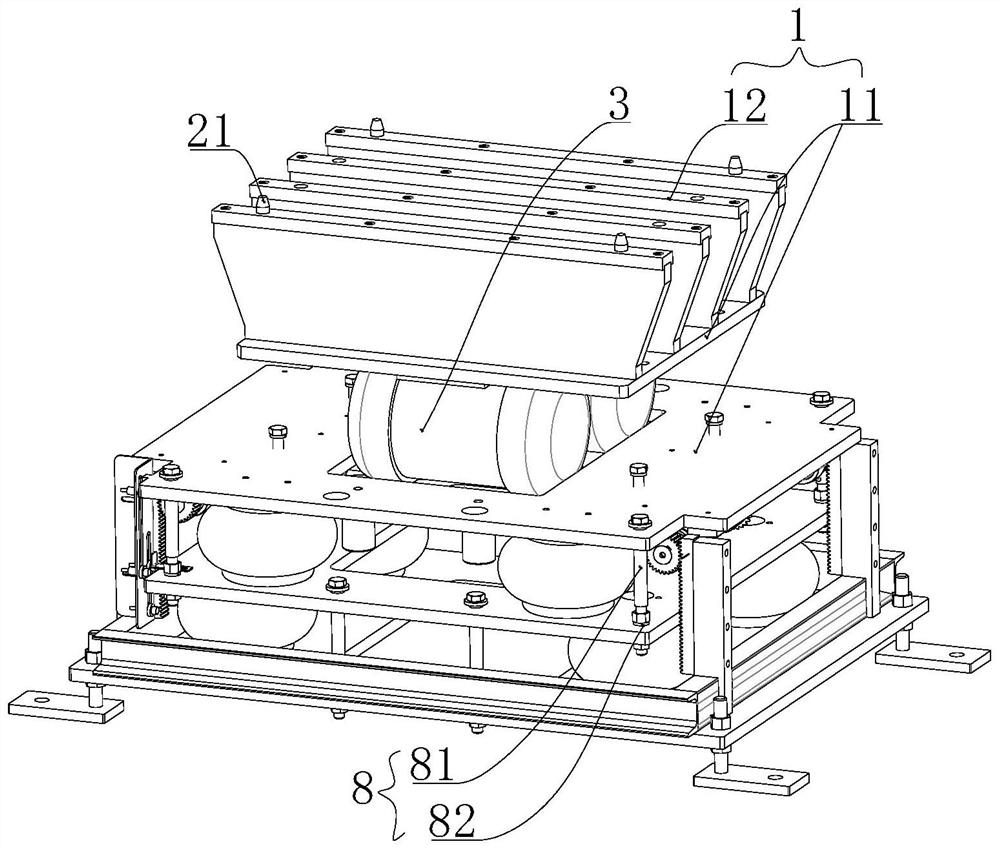

[0075] The present invention provides a nuclear waste barrel jacking vibration filling device, comprising: a support platform 1, a lifting assembly 4, a filling part 9 and a vibration motor 3, wherein;

[0076] Support table 1: used to hold material bucket 5, please refer to figure 2 shown, combined with image 3 As shown, it includes a horizontal board 11 and four vertical boards 12, wherein the four vertical boards 12 are equidistantly arranged on the top of the horizontal board 11 in an integrated manner (using integral molding to strengthen the vertical board 12 and The connection strength between the horizontal plates 11 makes the support platform 1 body more durable), and the bucket 5 is placed on the four vertical plates 12.

[0077] Lifting component 4: used to vibrate the support platform 1, please refer to Figure 4 As shown, four first airbag cylinders 41 and four first mounting plates 42 are included, wherein the output end of one of the first airbag cylinders 4...

Embodiment 3

[0087] In embodiment 1 or 2, although it can solve the technical problem that the cement will not be sprayed out of the material tank 5 during the filling process of the cement to the material tank 5, but, in the actual operation process, especially related to the treatment of nuclear waste, there will be There is a risk of nuclear radiation, and in the process of nuclear waste treatment, multiple independent processes are required for production, that is, sorting → compaction → compression into cakes → barrel cake filling → grouting → sealing, as far as this application is concerned In the first step, it is necessary to place the bucket 5 on the support platform 1, and it is not suitable for workers to carry it or use a forklift to carry it. For this reason, the present invention provides another preferred embodiment:

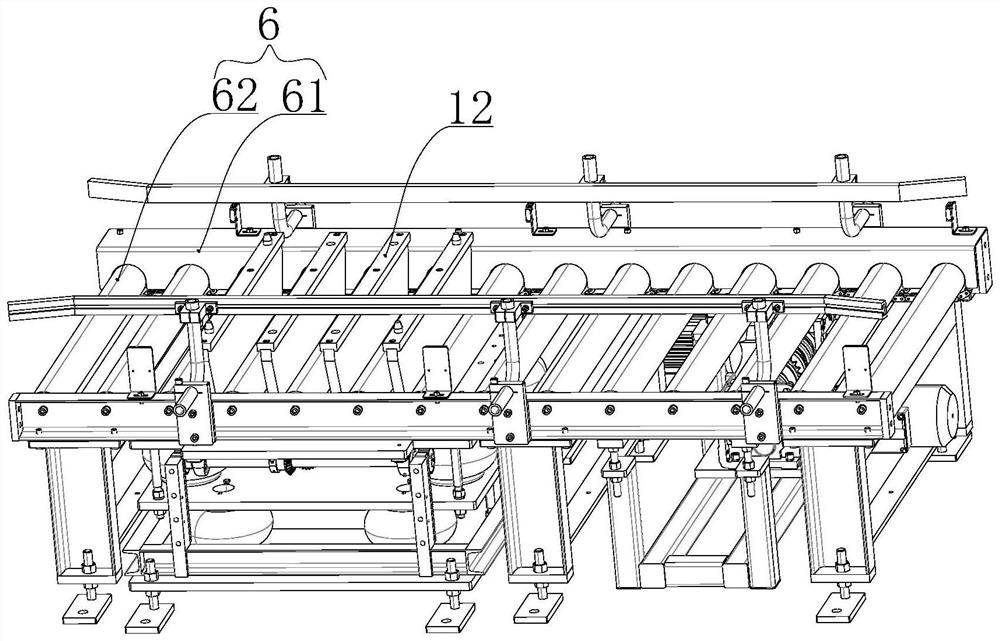

[0088] Since the conveying assembly 6 is not within the protection scope of the present application, the present application only organically combines the fill...

Embodiment 4

[0095] The present invention provides another embodiment of embodiment 3:

[0096] Only the transmission assembly 6 is changed, and other settings are the same as in embodiment 3, wherein the transmission assembly 6 is a plurality of conveyor belts, and a vertical plate 12 is arranged between two adjacent two conveyor belts, when the first airbag When both the air cylinder 41 and the second airbag cylinder 44 were not activated, the vertical plate 12 was positioned below the conveyor belt, and when the second airbag cylinder 44 was activated, the vertical plate 12 passed through the conveyor belt, and the top of the vertical plate 12 was positioned above the conveyor belt .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com