Multidirectional fretting wear device and testing method for heat transmission pipe of steam generator

A technology of steam generator and fretting wear, which is applied in the direction of testing wear resistance, etc. It can solve the problems that affect the safety and reliable operation of nuclear power plants, restrict the integrity evaluation and life prediction of steam generators, and achieve high precision and reproducibility Good, accurate experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

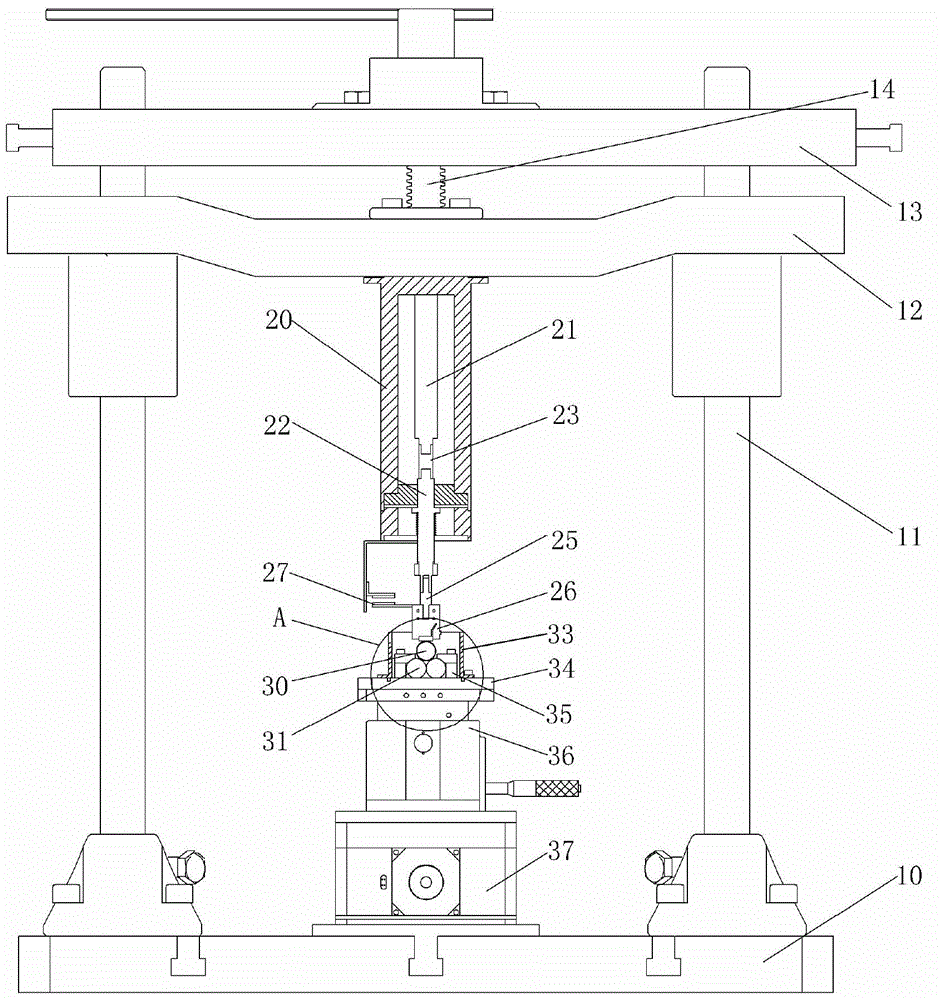

[0032] figure 1 , figure 2 Shown is a multi-directional fretting wear device for steam generator heat transfer tubes, which consists of a frame, a driving device, a leveling and lifting system, and a data acquisition and control system, wherein:

[0033] The composition of the frame is: the base 10 is provided with a gantry frame, the two columns 11 of the gantry frame are covered with a vertically movable center beam 12, and the upper surface of the center beam 12 is connected to the gantry through the screw pair 14. The top beam 13 of the frame is connected;

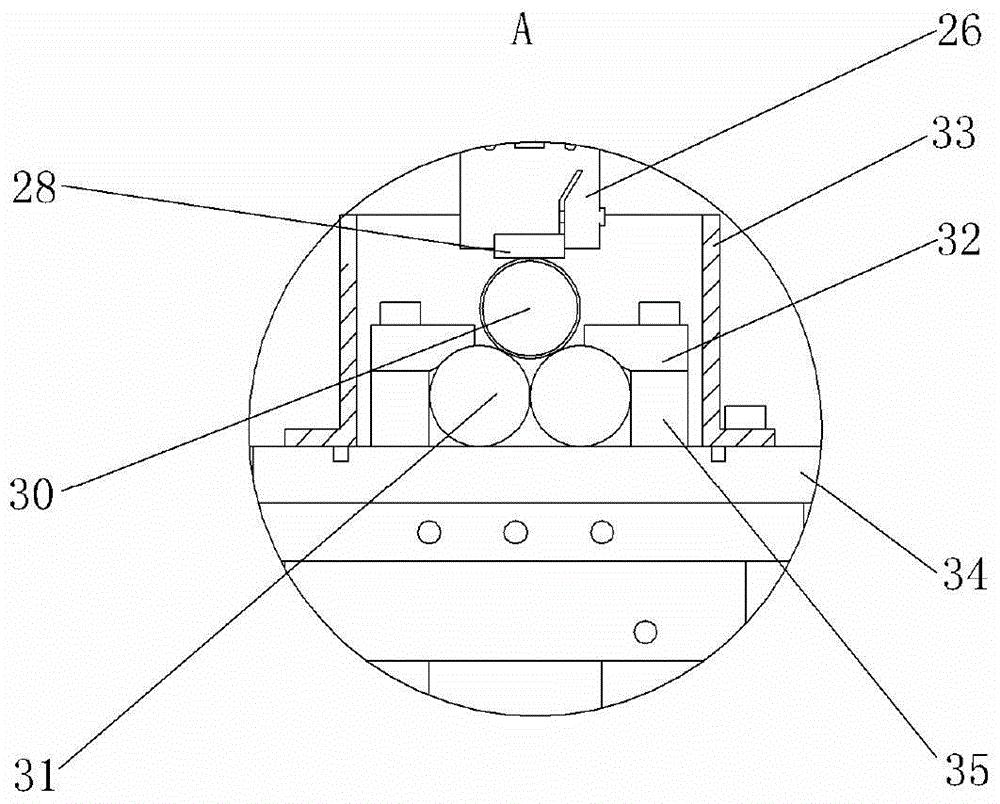

[0034] The composition of the test piece driving device is: the upper end of the piezoelectric ceramic actuator 21 is fixedly connected to the lower surface of the middle part of the center beam 12, and the lower end passes through the flexible joint 23, the connecting rod 22, the load cell 25 and the clamping block test piece in sequence. The upper clamp 26 of 28 is connected, and a displacement sensor 27 is instal...

Embodiment 2

[0046] The structure of the multi-directional fretting wear device of the heat transfer tube in this example is basically the same as that of the device in Example 1, except that the liquid holding wall 33 is removed.

[0047] The method of using the multi-directional fretting wear device of this example to carry out the multi-directional fretting wear test of the heat transfer tube is as follows:

[0048] a. Clamp the block test piece 28 on the upper fixture 26, adjust the vertical height of the middle beam 12 through the screw pair 14, make the block test piece 28 close to the heat transfer tube 30, and then adjust the front and rear of the angular displacement table 37 The inclination angle keeps the heat transfer tube 30 parallel to the plane of the block test piece 28, and then the lifting platform 36 is adjusted to keep the block test piece 28 in good line contact with the heat transfer tube 30;

[0049] b. The data acquisition control system controls the piezoelectric c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com