Fretting-wear ultrasonic-vibration ultralong-life fatigue test apparatus

A technology of fretting friction and fatigue testing, which is applied in testing wear resistance, etc., can solve the problems of low experimental accuracy and difficult design, and achieve the effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

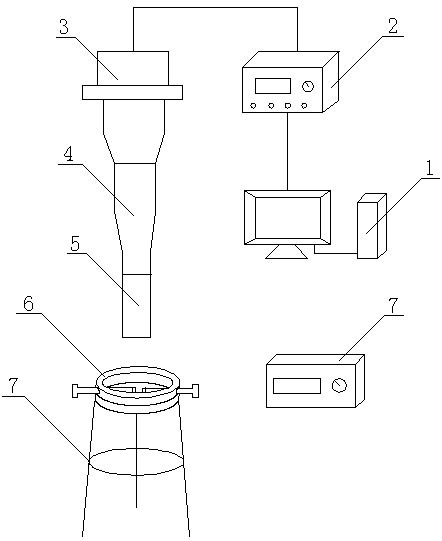

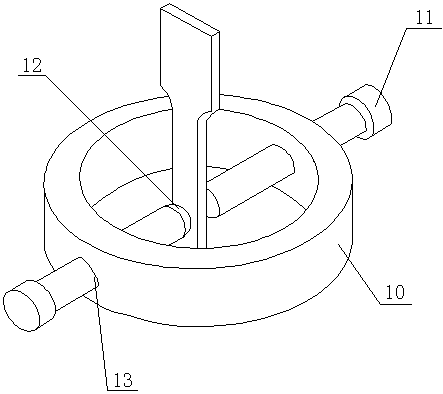

[0022] Such as figure 1 , figure 2 and Figure 4 As shown, the present invention includes an ultrasonic fatigue test device, a fretting friction device 6 and a temperature test device. The ultrasonic fatigue test device includes a computer system 1, an ultrasonic generator 2, a piezoelectric ceramic transducer 3 connected in sequence, and a piezoelectric ceramic transducer The lower end of the transducer 3 is fixedly connected with the horn 4, and the output end of the horn 4 is connected with a cylindrical extension rod 5 coaxial with the horn 4, and the cross section of the output end of the horn 4 is the same as that of the extension rod 5. The cross-sections are equal in size, and the temperature testing device includes a thermometer 8, which is used to measure the temperature of the friction section of the sample. A support device 7 is provided directly below the extension rod 5, and the support device 7 is a triangular support frame. The friction device 6 is fixed on ...

Embodiment 2

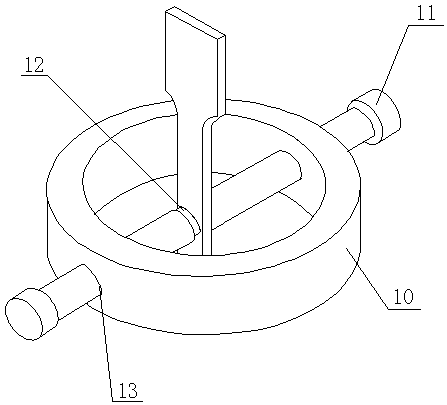

[0026] Such as figure 1 , image 3 and Figure 4 This embodiment is basically the same as Embodiment 1, except that the contact surface of the front end of the friction pressure head 12 is a plane.

[0027] The working principle of the present invention is: as Figure 5 As shown, first, under the control of the computer system 1, the ultrasonic generator 2 converts the 50Hz electrical signal into a 20KHz ultrasonic sine wave signal output, and then the piezoelectric ceramic transducer 3 converts the ultrasonic sine wave signal into a mechanical The vibration signal, the horn 4 amplifies the vibration displacement amplitude from the piezoelectric ceramic transducer 3 to the displacement amplitude required by the sample 9, and at the same time determines the position for installing the fretting friction device 6 according to the displacement amplitude to realize the fretting friction system . Among them, the fretting friction system adjusts the position of the fixed ring 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com