Clamping device for pipe-flat plate line contact fretting wear experiments

A technology of fretting wear and clamping devices, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high cost of biaxial fretting wear testing machines, and achieve the effects of reducing experimental costs, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

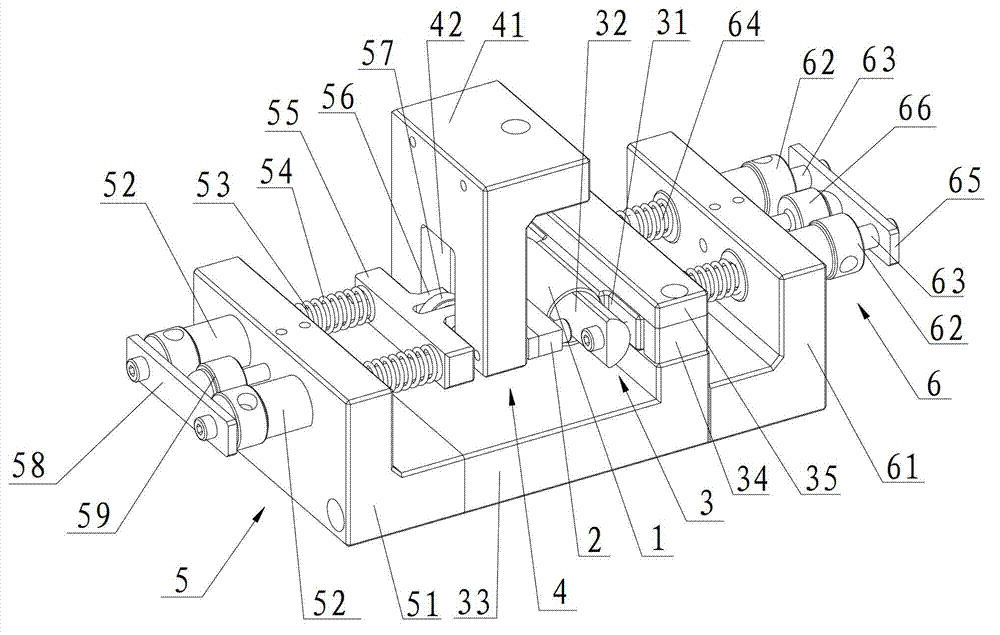

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] see figure 1 The shown clamping device for the tube-flat line contact fretting wear test is set on the testing machine for clamping the cylindrical tube 1 and the flat plate 2 in the tube-plate line contact fretting wear test, where The testing machine is an ordinary uniaxial fatigue testing machine. The cylindrical tube 1 and the flat plate 2 both extend along the horizontal front-back direction on the clamping device. The front-back direction here refers to the observation by the observer. figure 1 The front and rear direction of the line of sight, correspondingly, the horizontal left and right direction refers to the observer's observation figure 1 Time figure 1 in the left-right direction. The clamping device includes a cylindrical tube clamping assembly 3 for clamping the cylindrical tube 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com