Gravity loading type fretting wear testing equipment capable of simulating high-temperature environment

A technology of gravity loading and fretting wear, which is applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of inconsistent load and lower precision, and achieve accurate measurement of lateral force and lateral fretting displacement, and heat insulation effect Good and convenient for practical application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

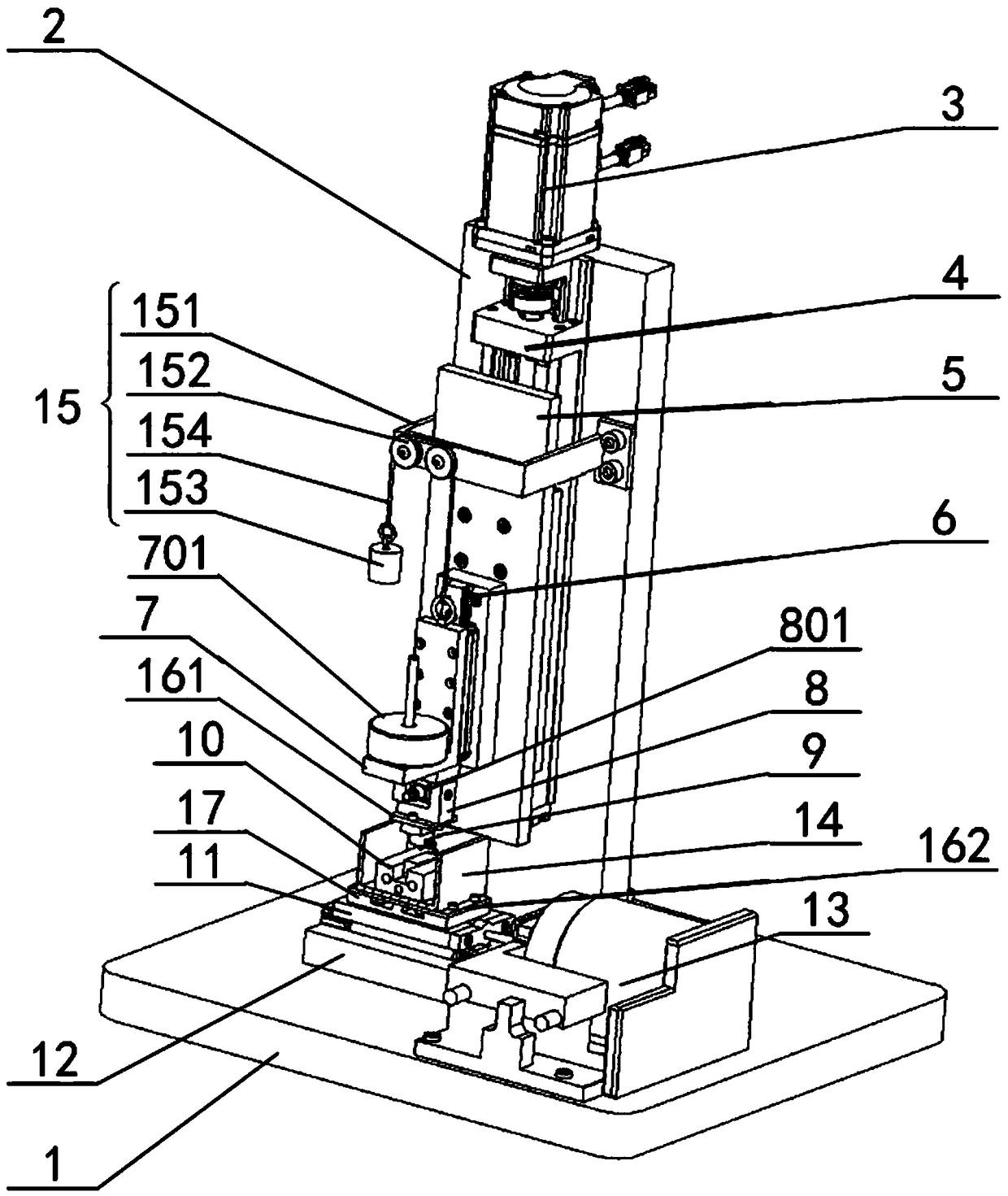

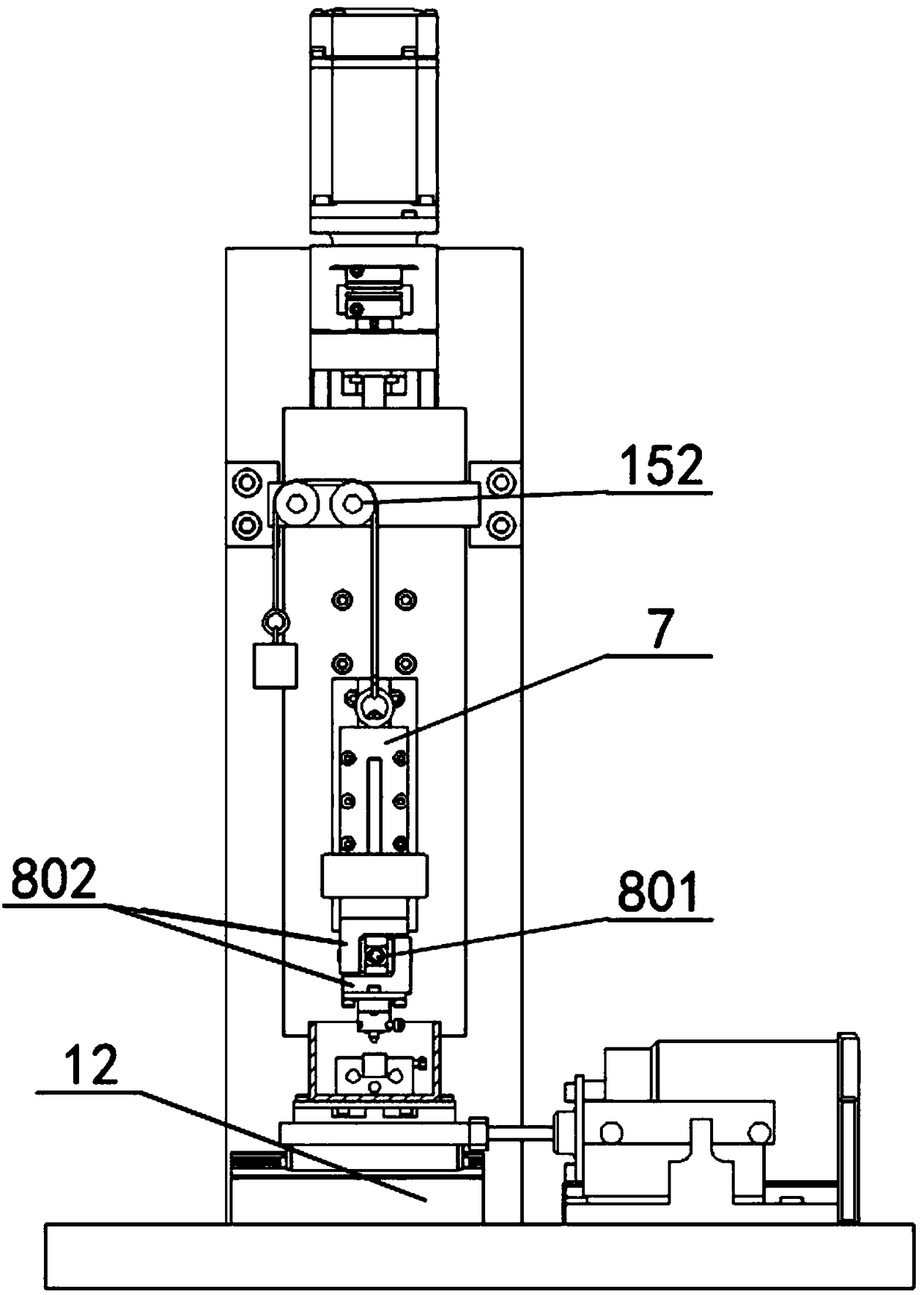

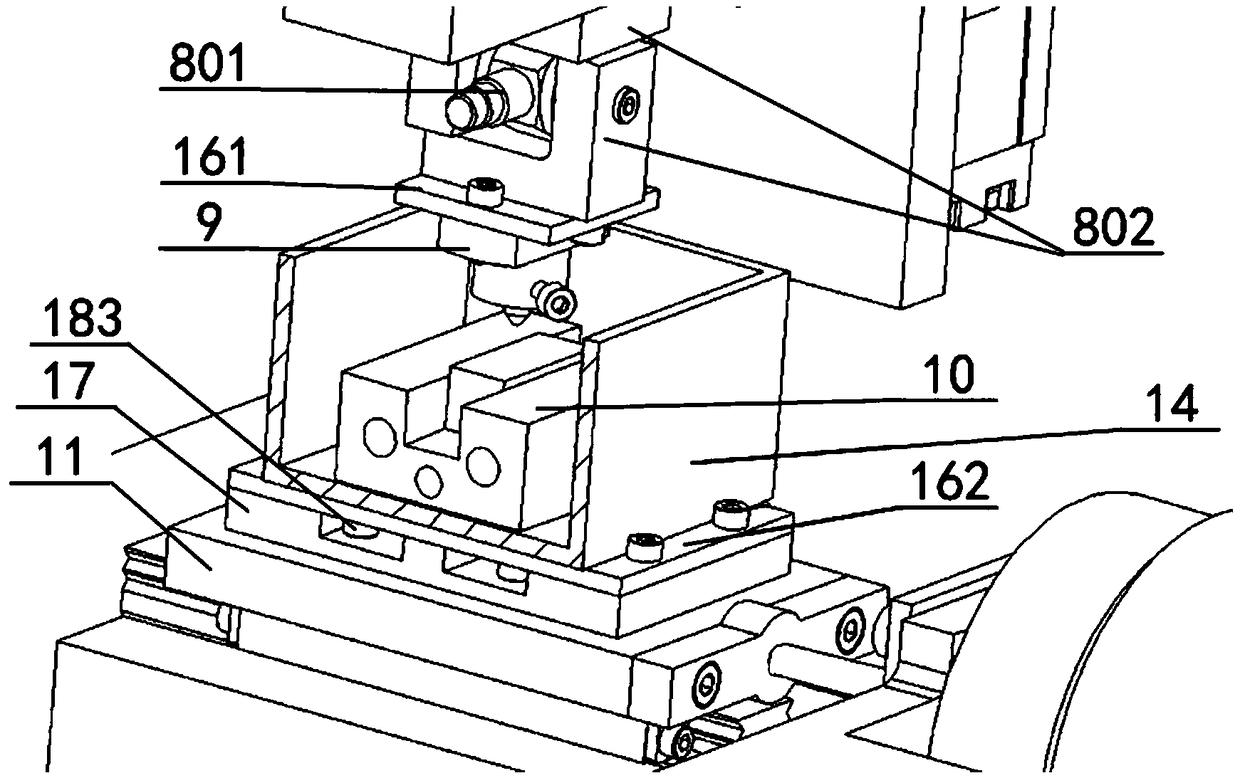

[0035] Such as Figure 1~3As shown, the gravity-loaded fretting wear test equipment capable of simulating a high-temperature liquid environment provided in this embodiment includes a base plate 1, a vertical plate 2, a servo motor 3, a screw module 4, a lifting platform 5, a vertical To the linear guide rail 6, the right-angle weight plate 7, the force sensor fixture 8, the upper sample fixture 9, the lower sample fixture 10, the slider connecting plate 11, the transverse linear guide rail 12 and the linear motion motor 13, wherein the right-angle weight A weight 701 is placed on the code disc 7, the force sensor fixture 8 clamps a force sensor 801 for measuring the lateral force, and a displacement sensor for measuring the lateral displacement of the corresponding slider is installed on the lateral linear guide rail 12; The bottom of the vertical plate 2 is vertically connected to the base plate 1, the servo motor 3 is fixedly installed on the top of the vertical plate 2, and...

Embodiment 2

[0050] Such as Figure 4 As shown, this embodiment provides another gravity-loaded fretting wear test equipment capable of simulating a high-temperature gas environment. The difference from Embodiment 1 is that there is no liquid container 14 installed, but the test A thermal resistance heating rod 101 and a thermocouple sensor 102 are respectively embedded in the side of the sample holder 10 . Such as Figure 4 As shown, the thermal resistance heating rod 101 is used to conduct electrical heating on the lower sample holder 10 so as to provide a high-temperature gas environment. The thermocouple sensor 102 is used to collect real-time temperature values. During heating, if the collected temperature value reaches the set temperature value, the heating needs to be stopped, and if the collected temperature value does not reach the set temperature value, the heating needs to be continued. When experimenting in a gas environment, since the sample is in direct contact with the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com