High temperature and high pressure in-situ fretting wear test device

A technology of fretting wear, high temperature and high pressure, applied in the direction of measuring devices, testing wear resistance, instruments, etc., can solve the problems that fretting wear is difficult to realize, electrochemical signals are difficult to measure, etc., to achieve stable movement, simple control, clamping reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

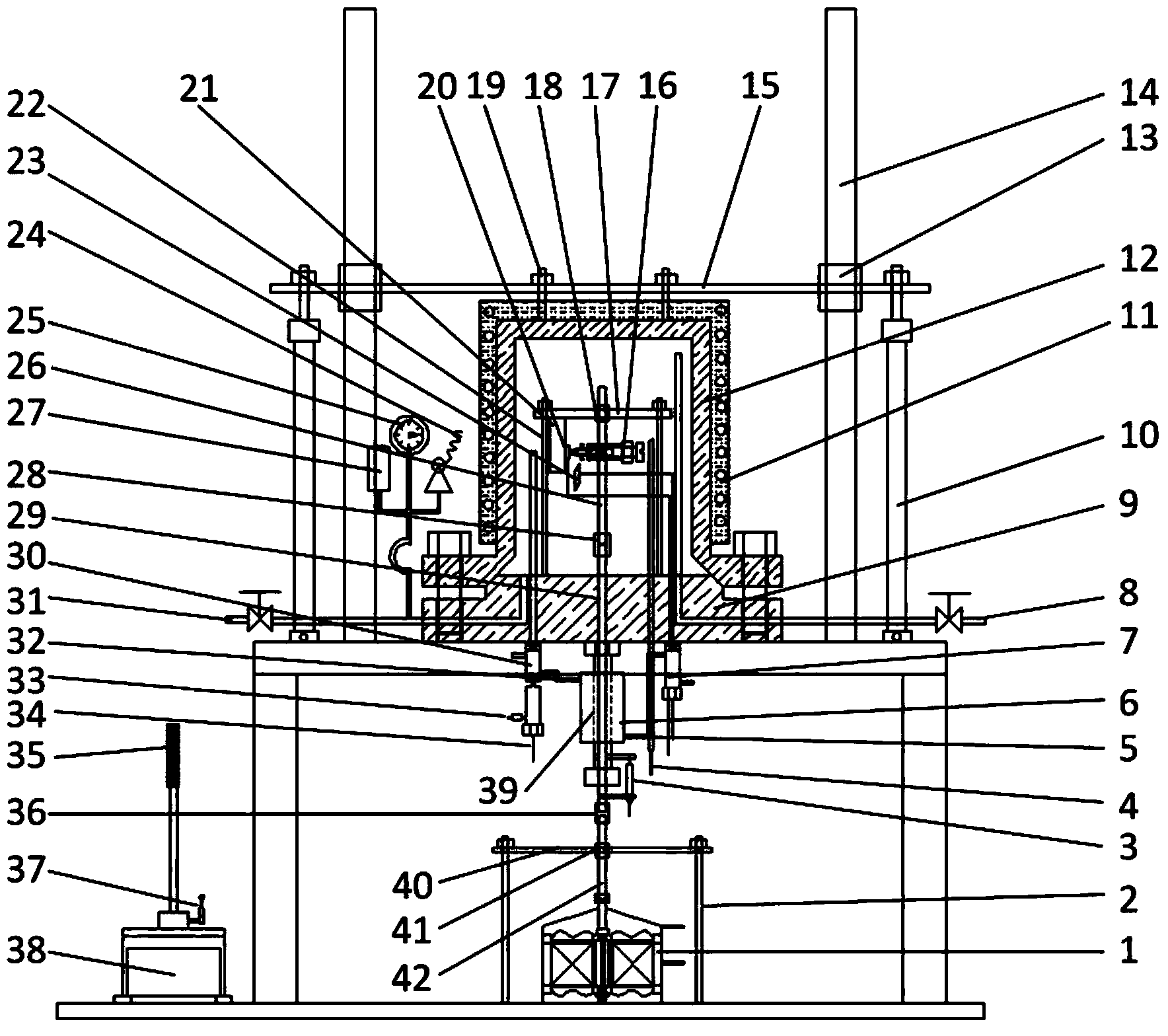

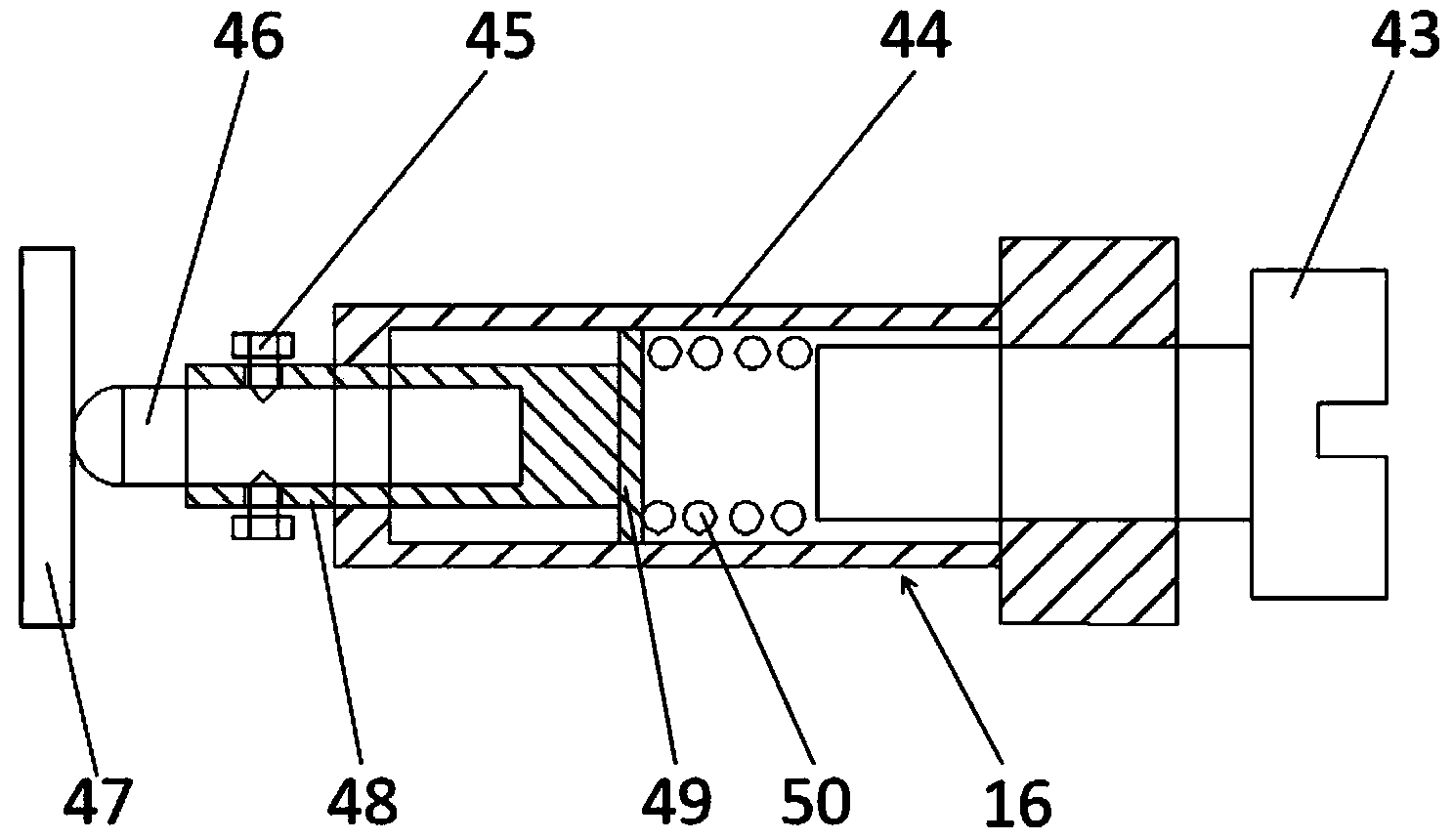

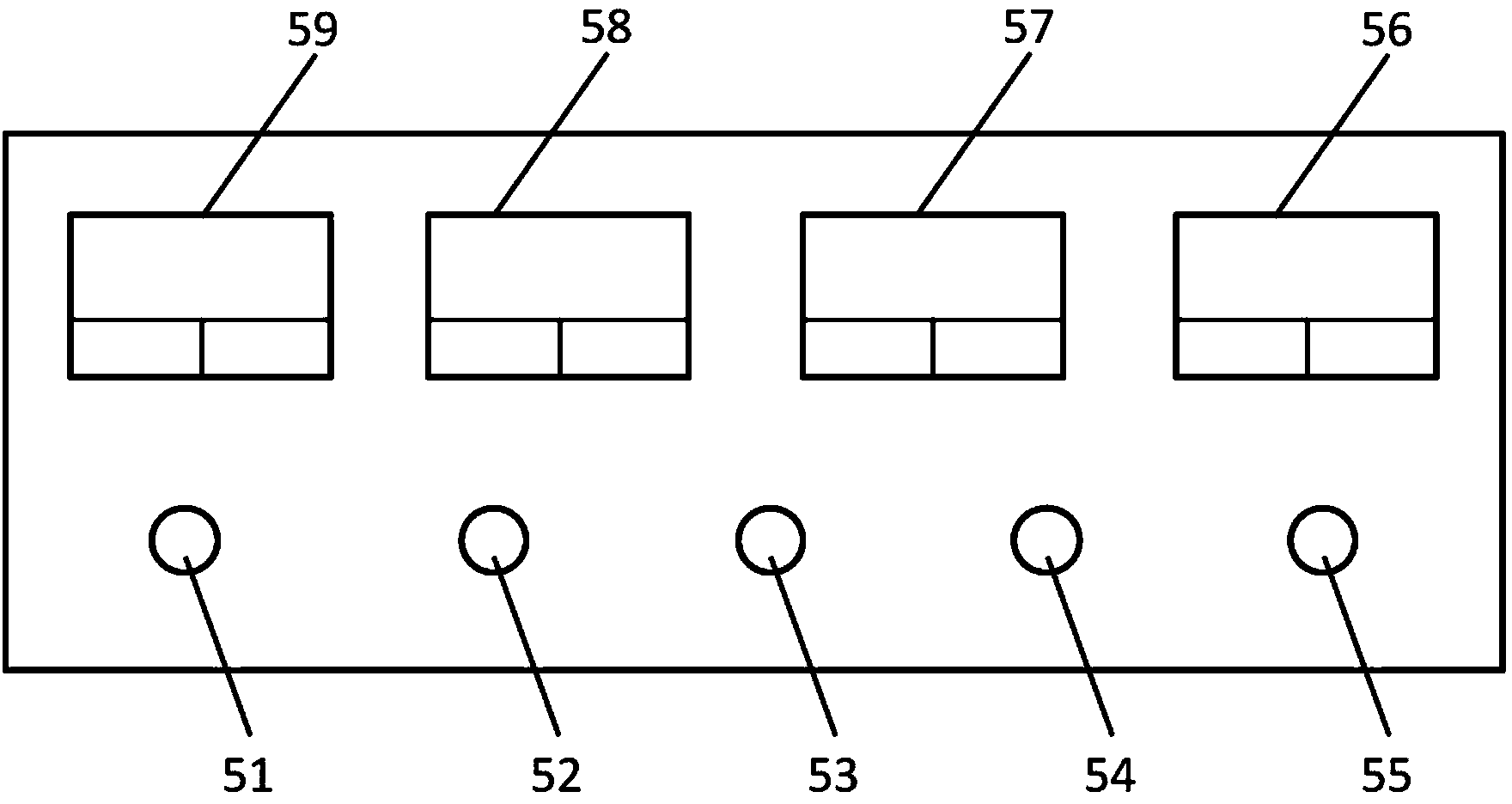

[0029]The high-temperature and high-pressure in-situ fretting wear test device of the present invention is composed of a vibration exciter, a displacement sensor, an autoclave, a ceramic heating jacket, a radial loading device, a motion shaft, a signal acquisition and processing control system, and a fixed bracket, and can realize high temperature and high pressure In-situ fretting wear is performed on the surface of the sample, and the amplitude and frequency of the fretting wear process can be precisely controlled through the signal acquisition and processing control system, and the radial load between the friction pairs can be adjusted through the radial loading device. The electrochemical signal during the fretting wear process is detected by installing the reference electrode, working electrode and auxiliary electrode on the autoclave and cooperating with the electrochemical workstation.

[0030] Such as Figure 1-Figure 2 As shown, the high temperature and high pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com