Patents

Literature

41results about How to "Reduced fretting wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

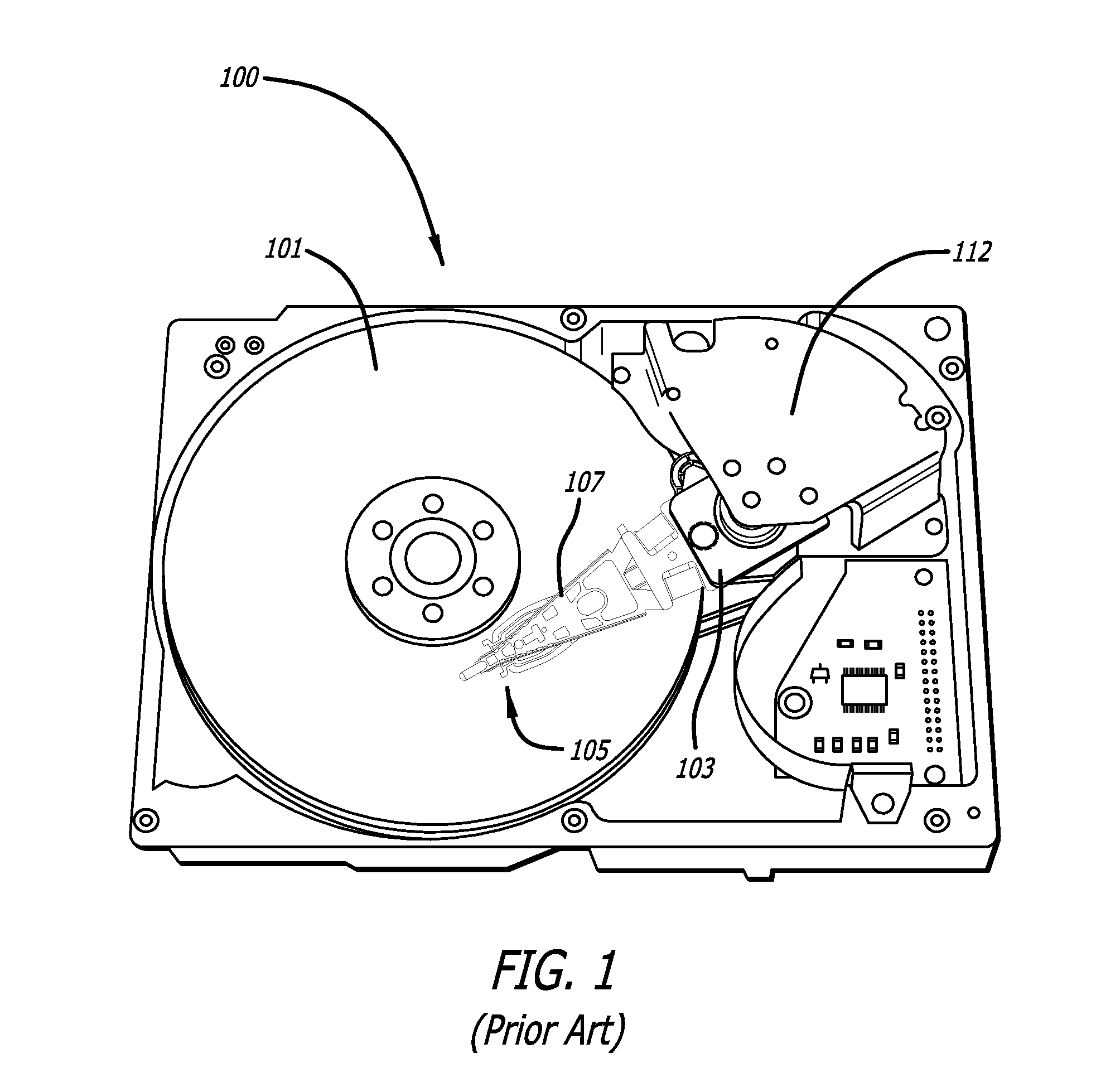

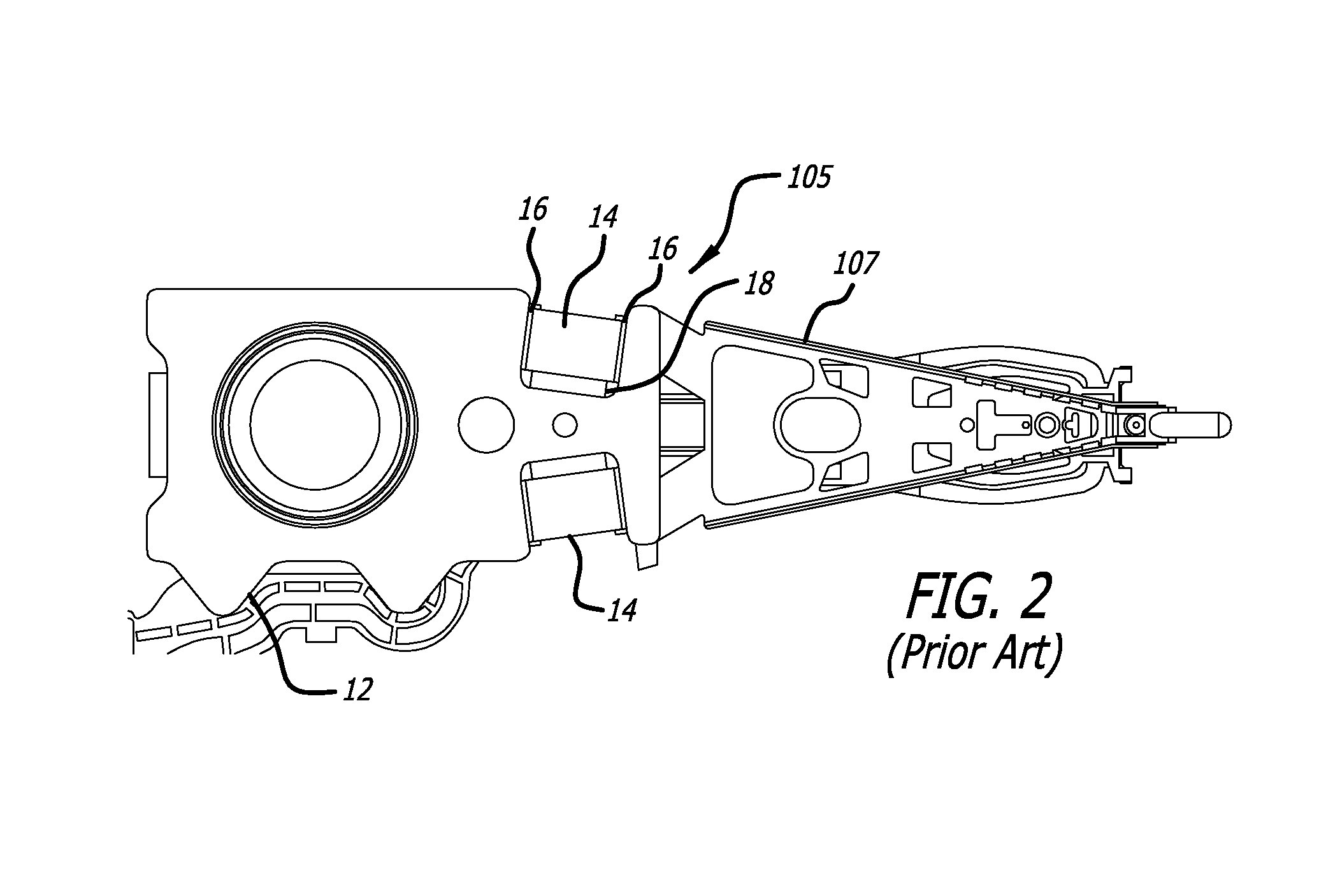

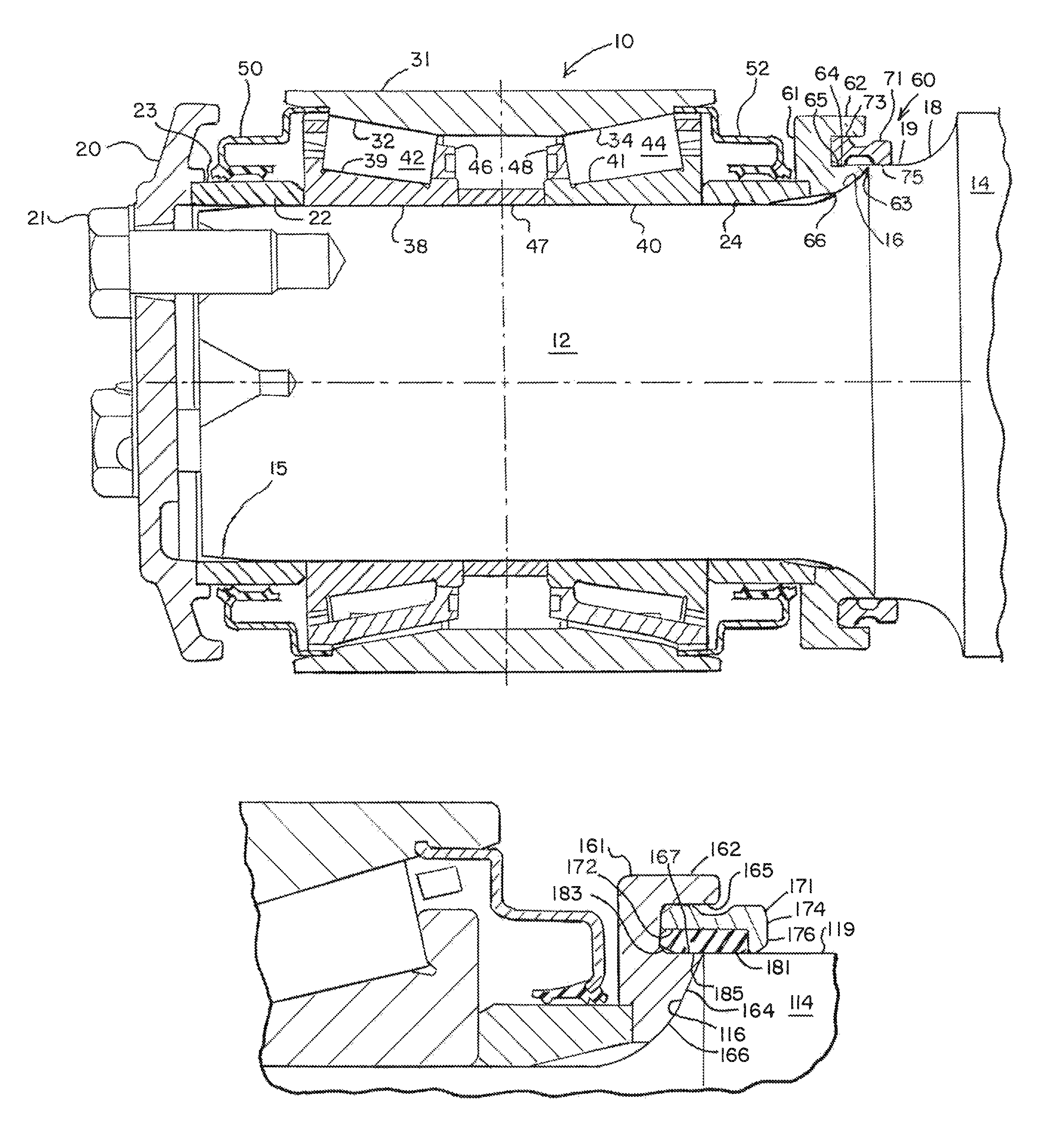

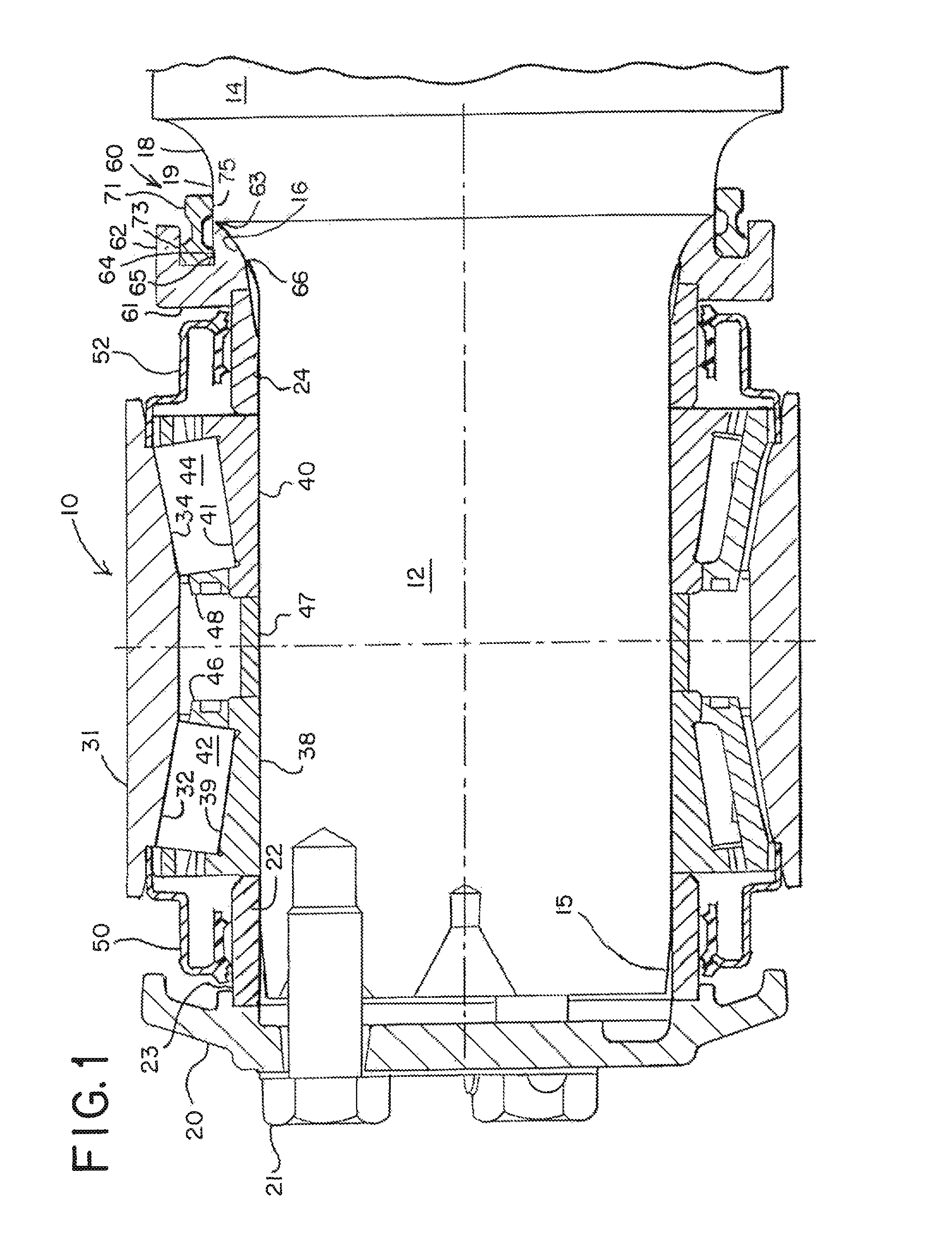

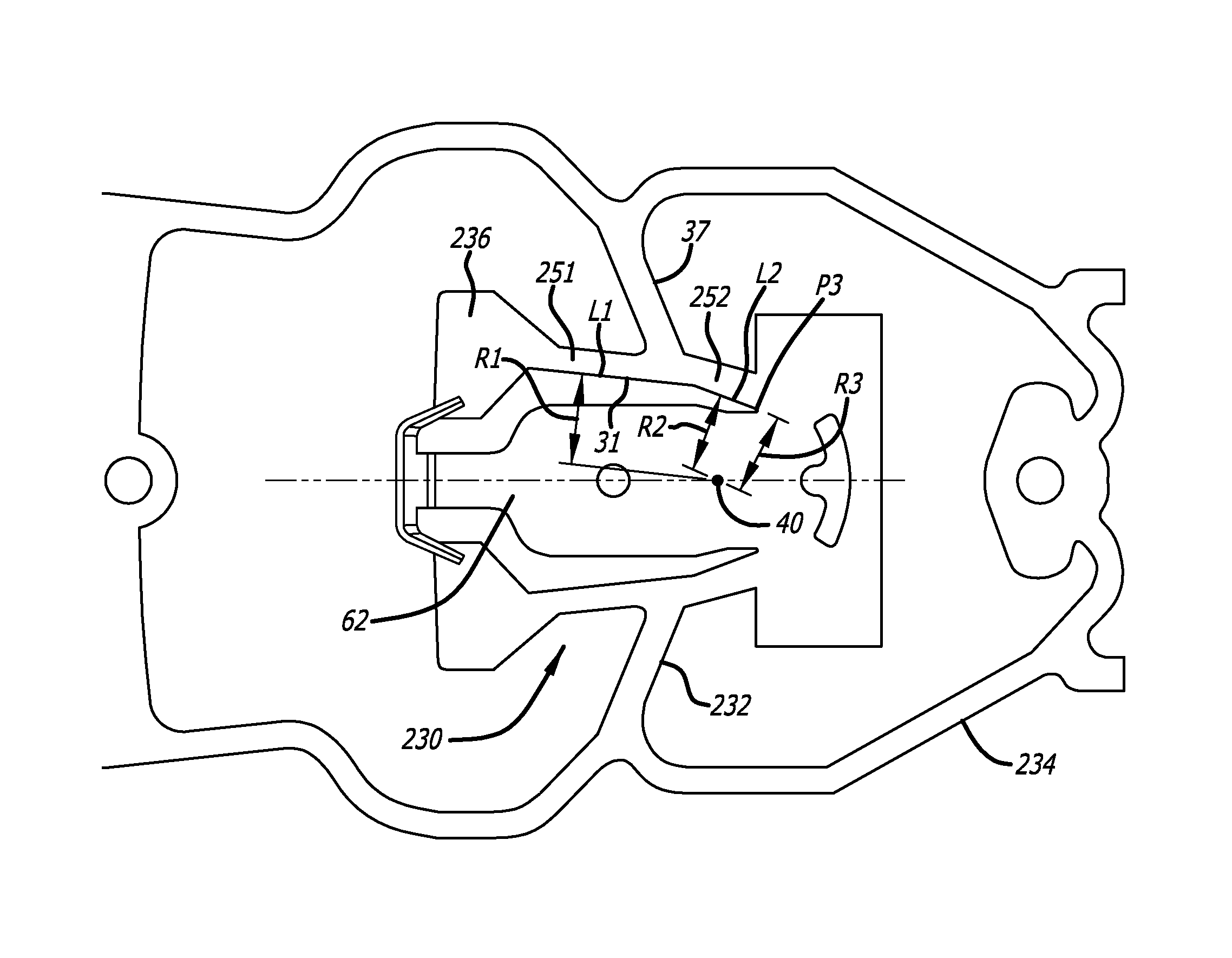

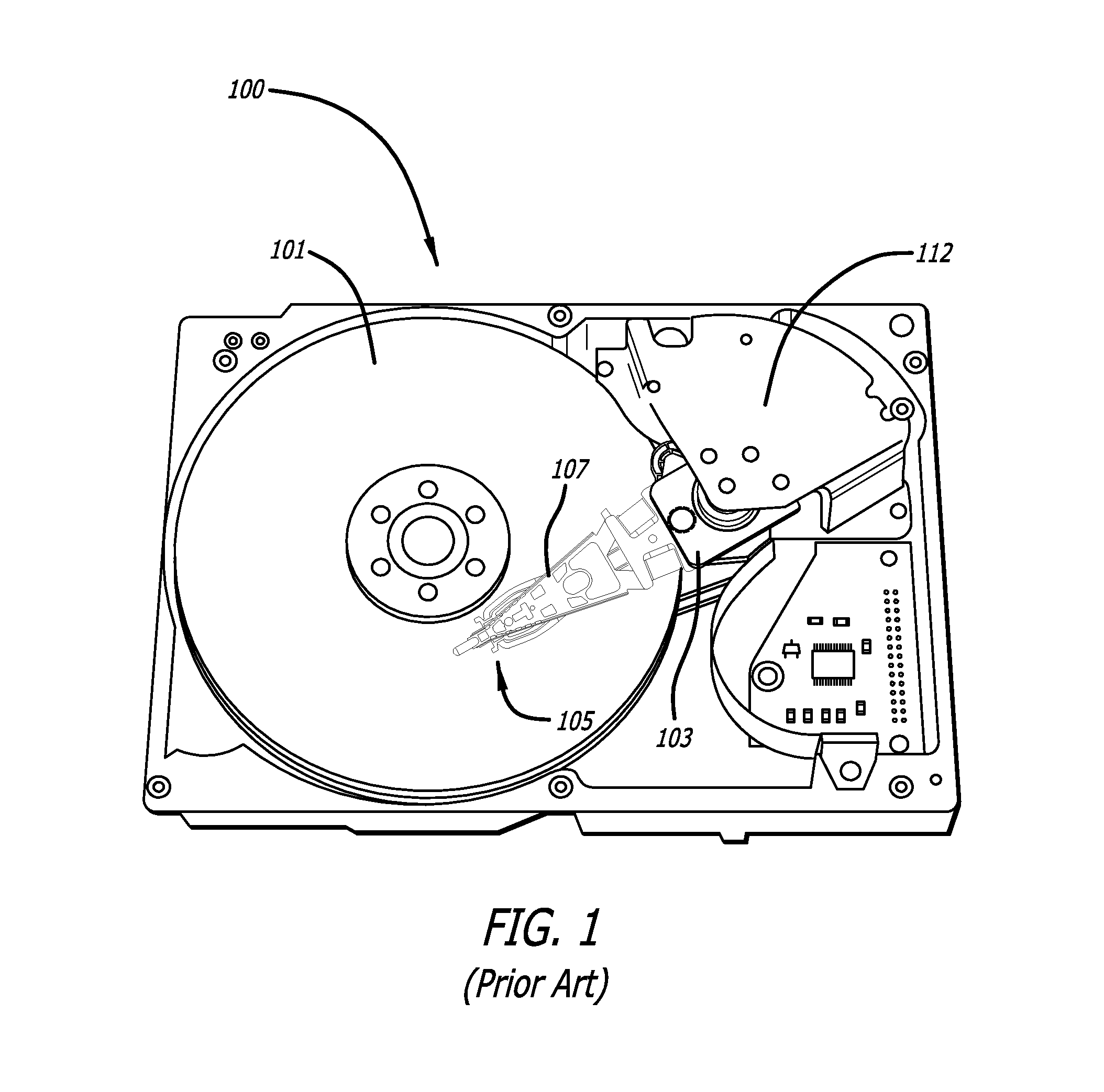

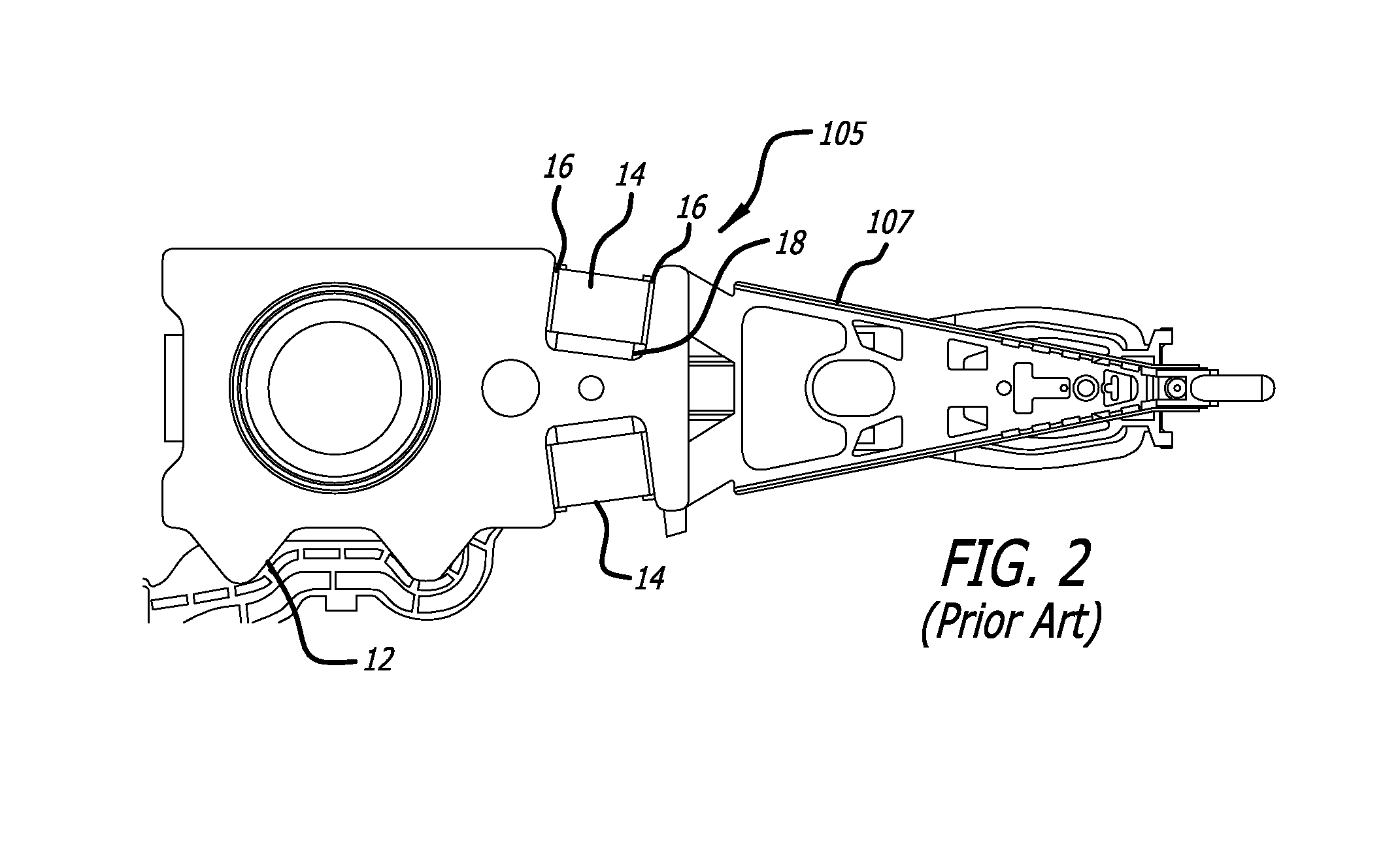

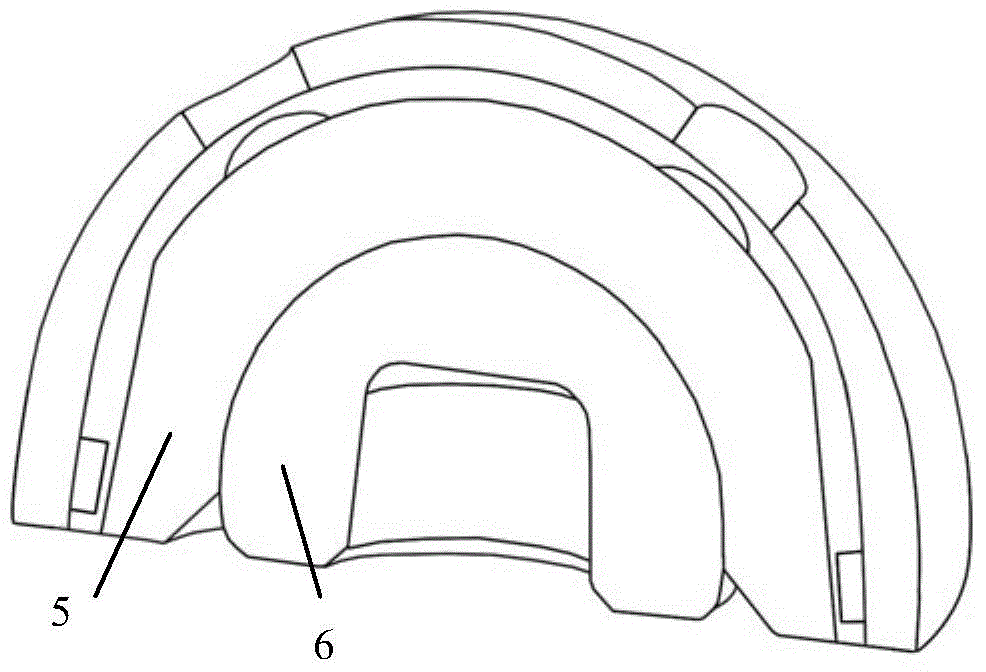

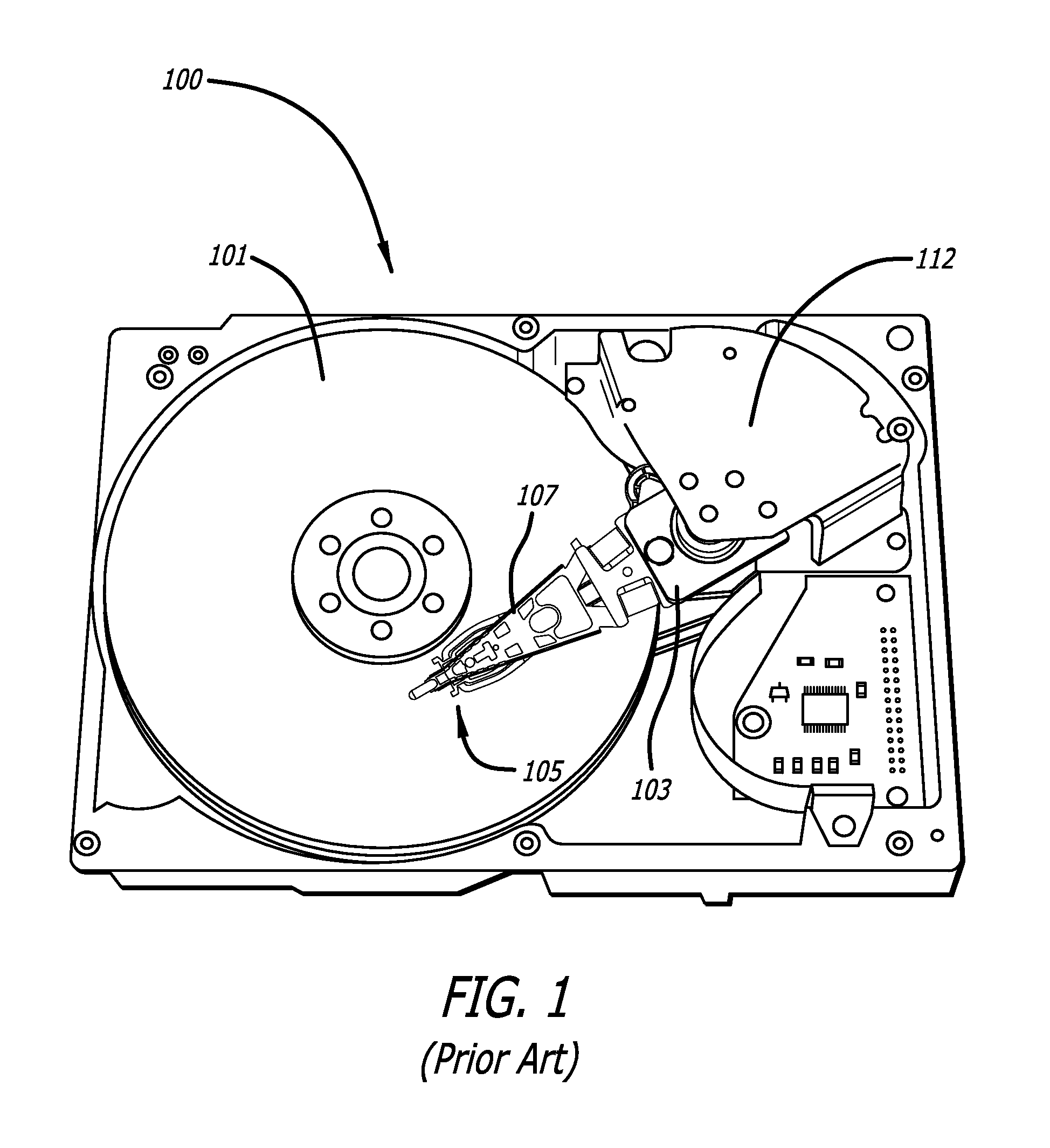

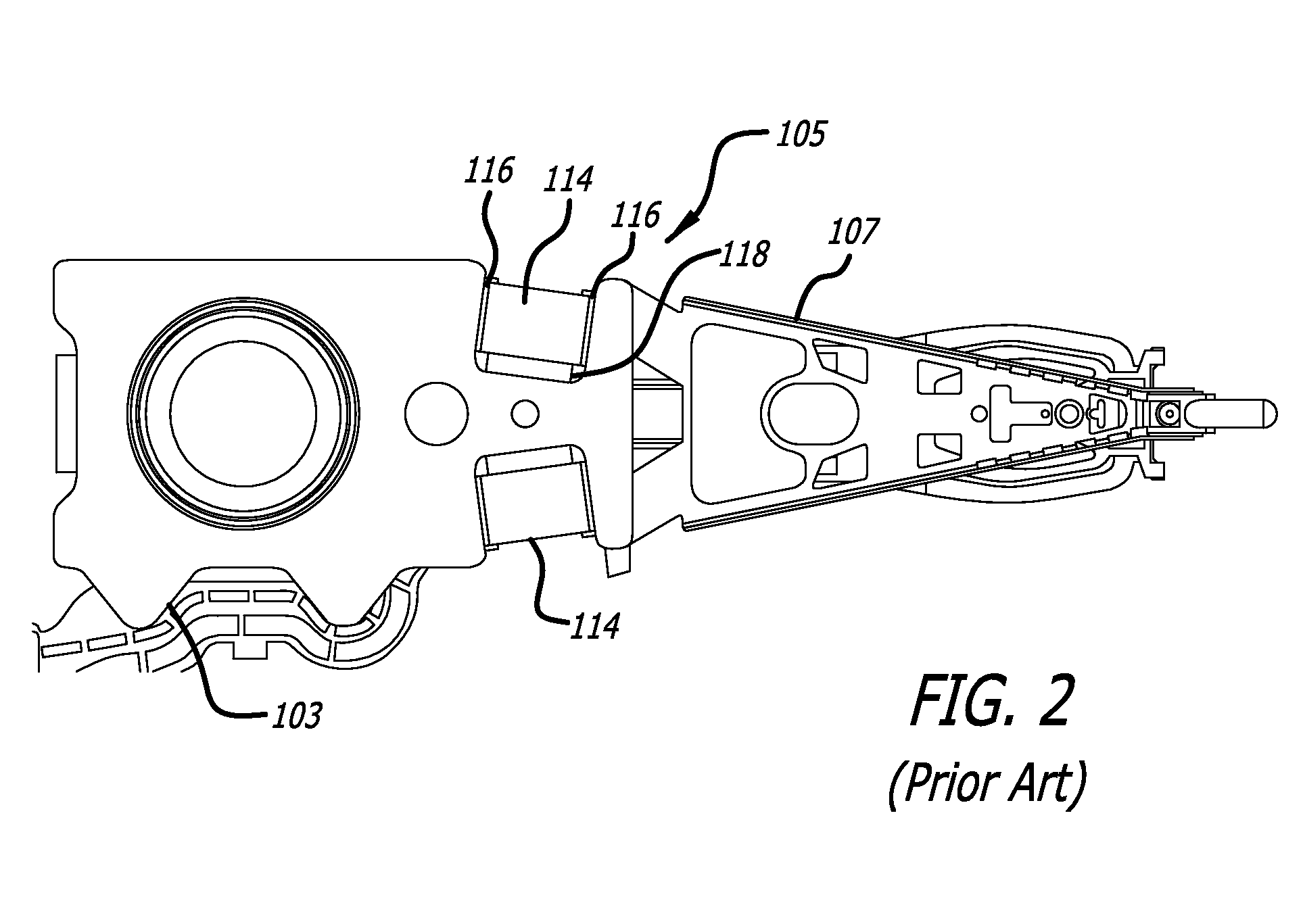

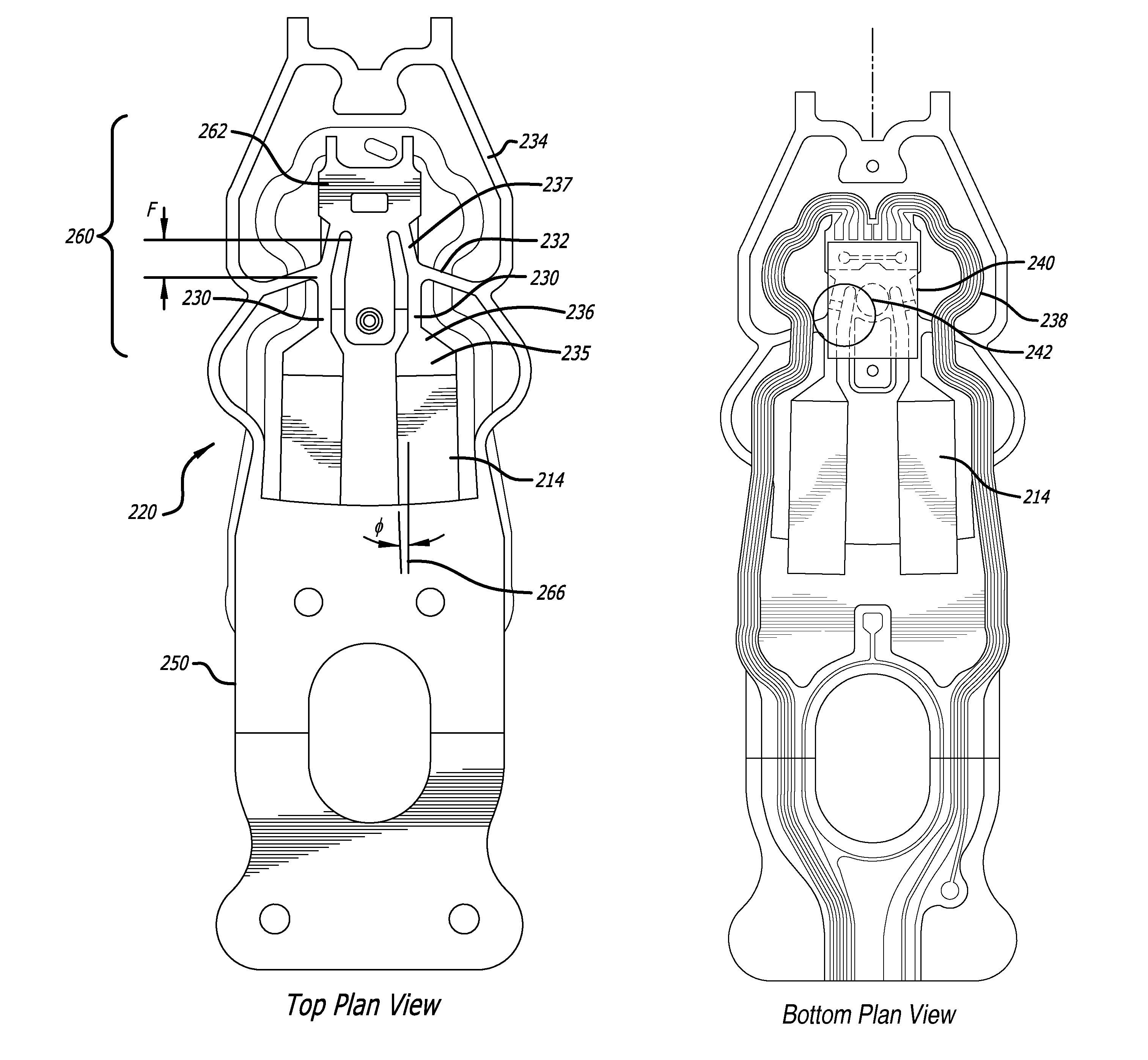

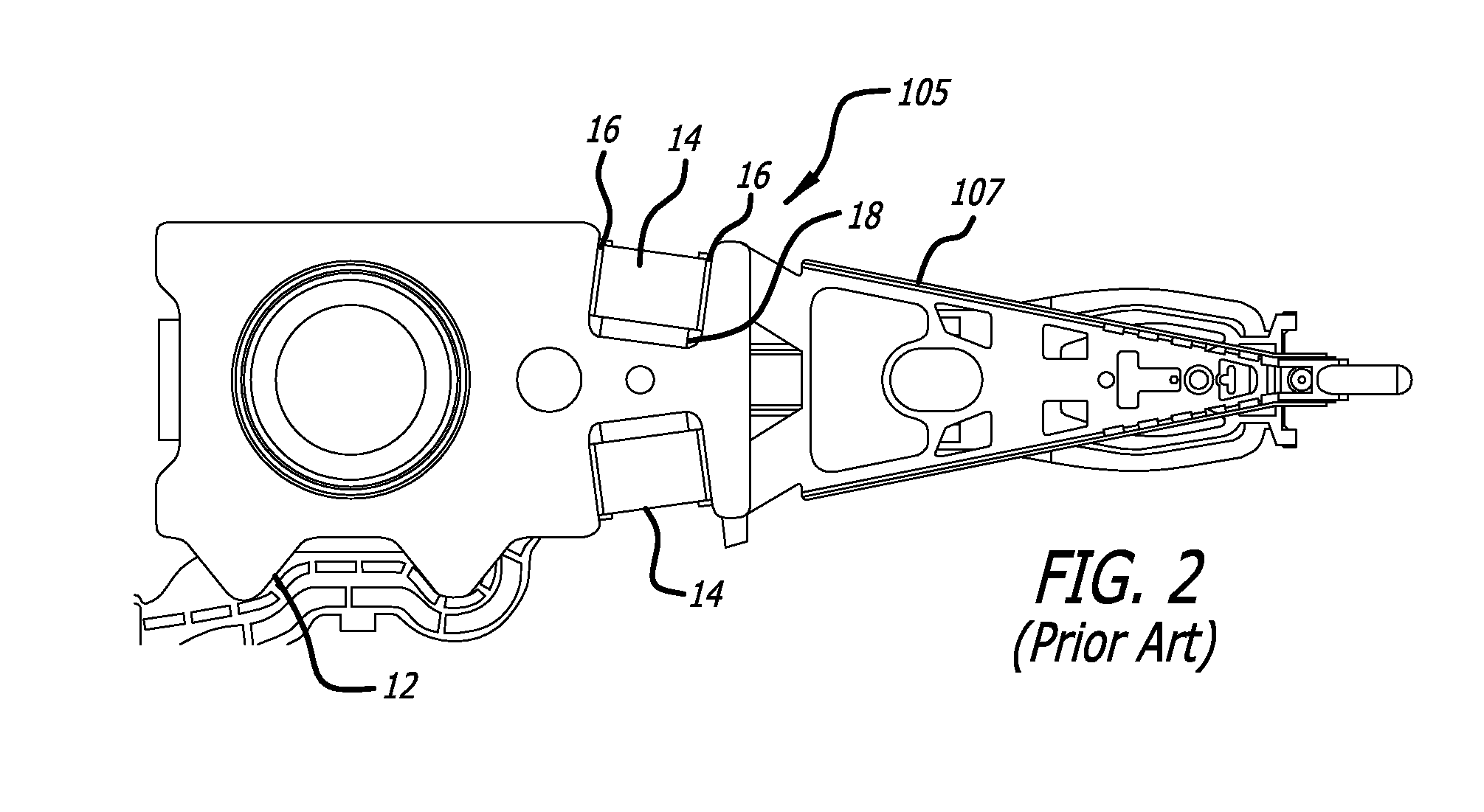

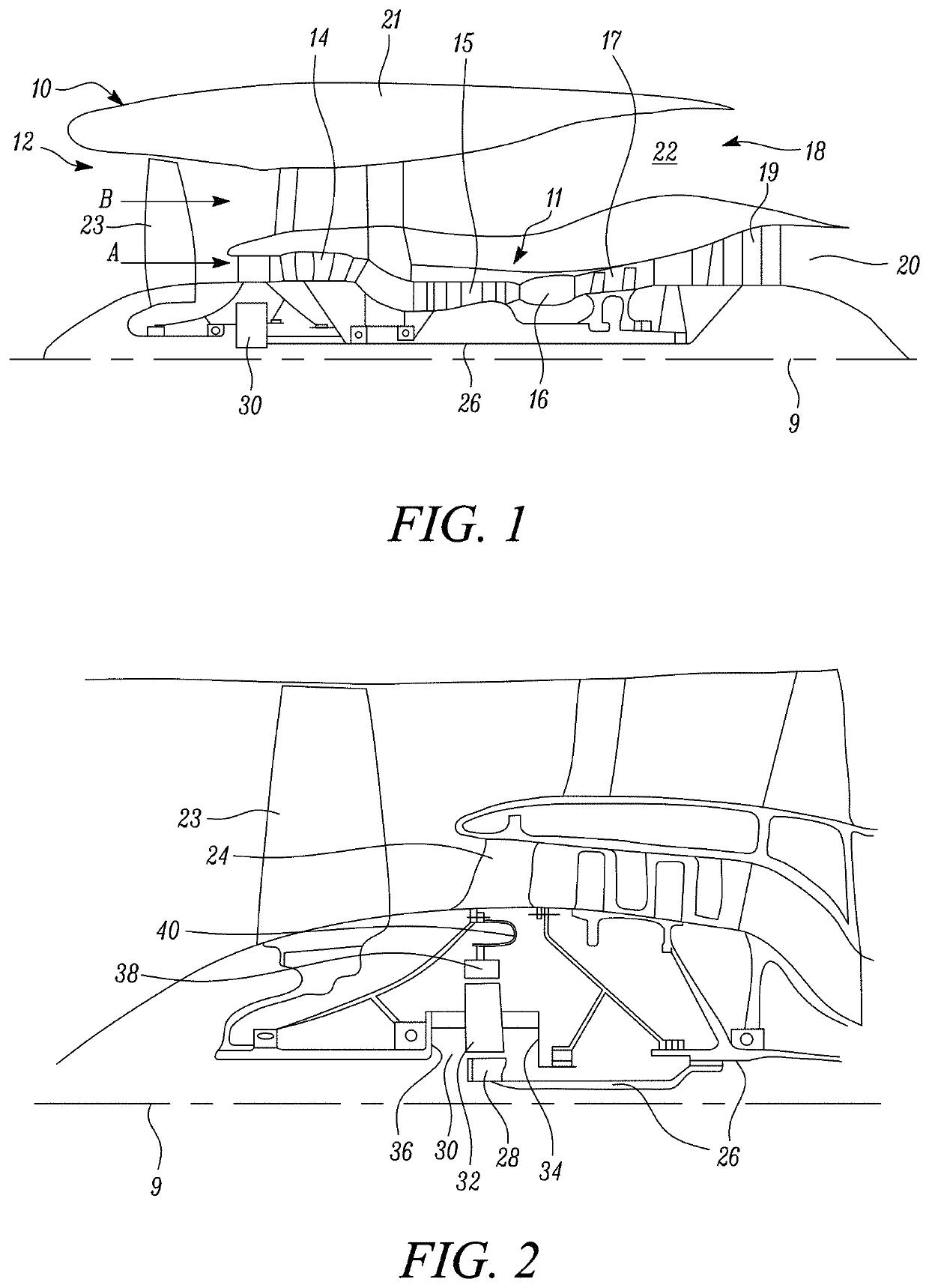

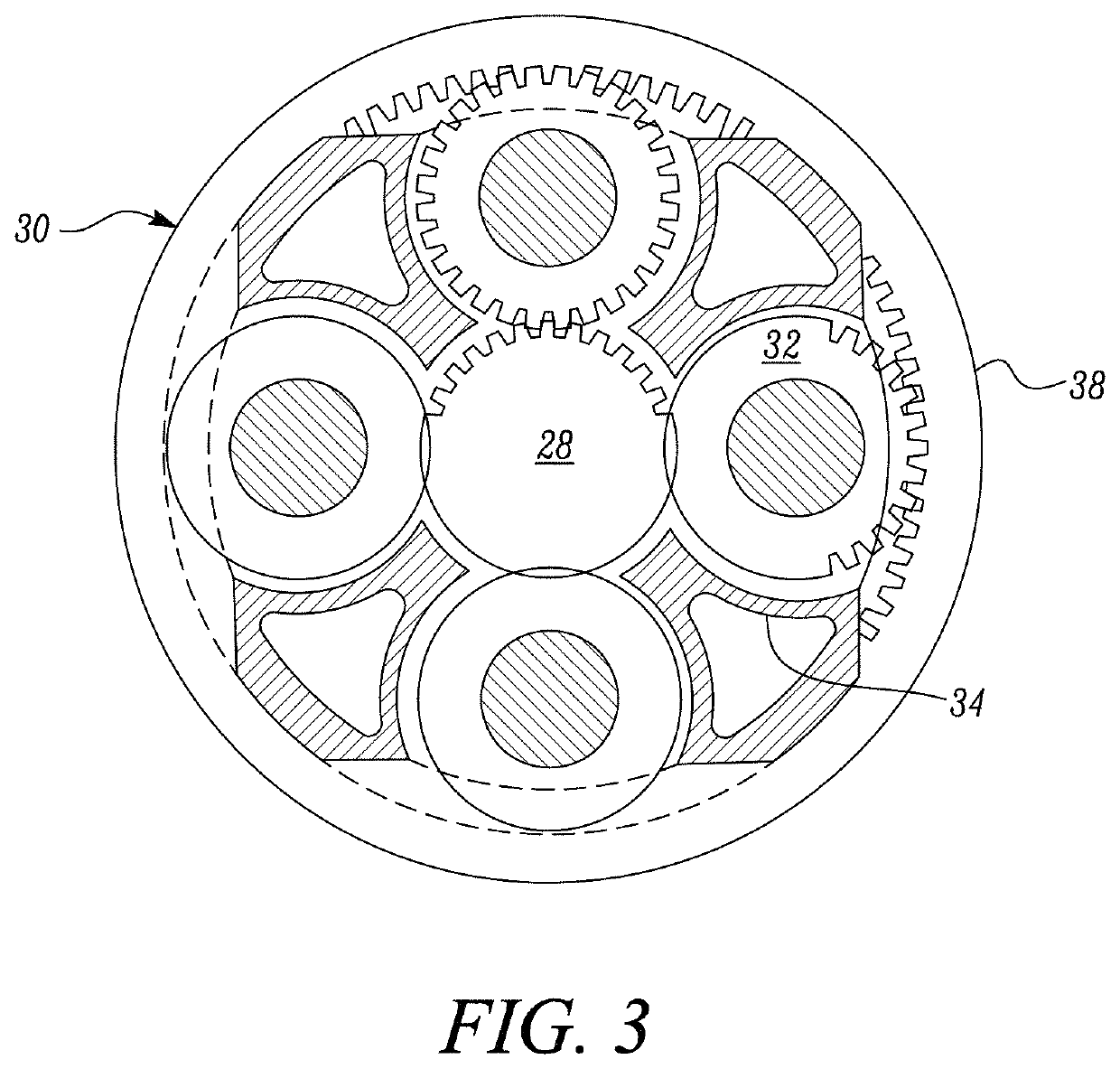

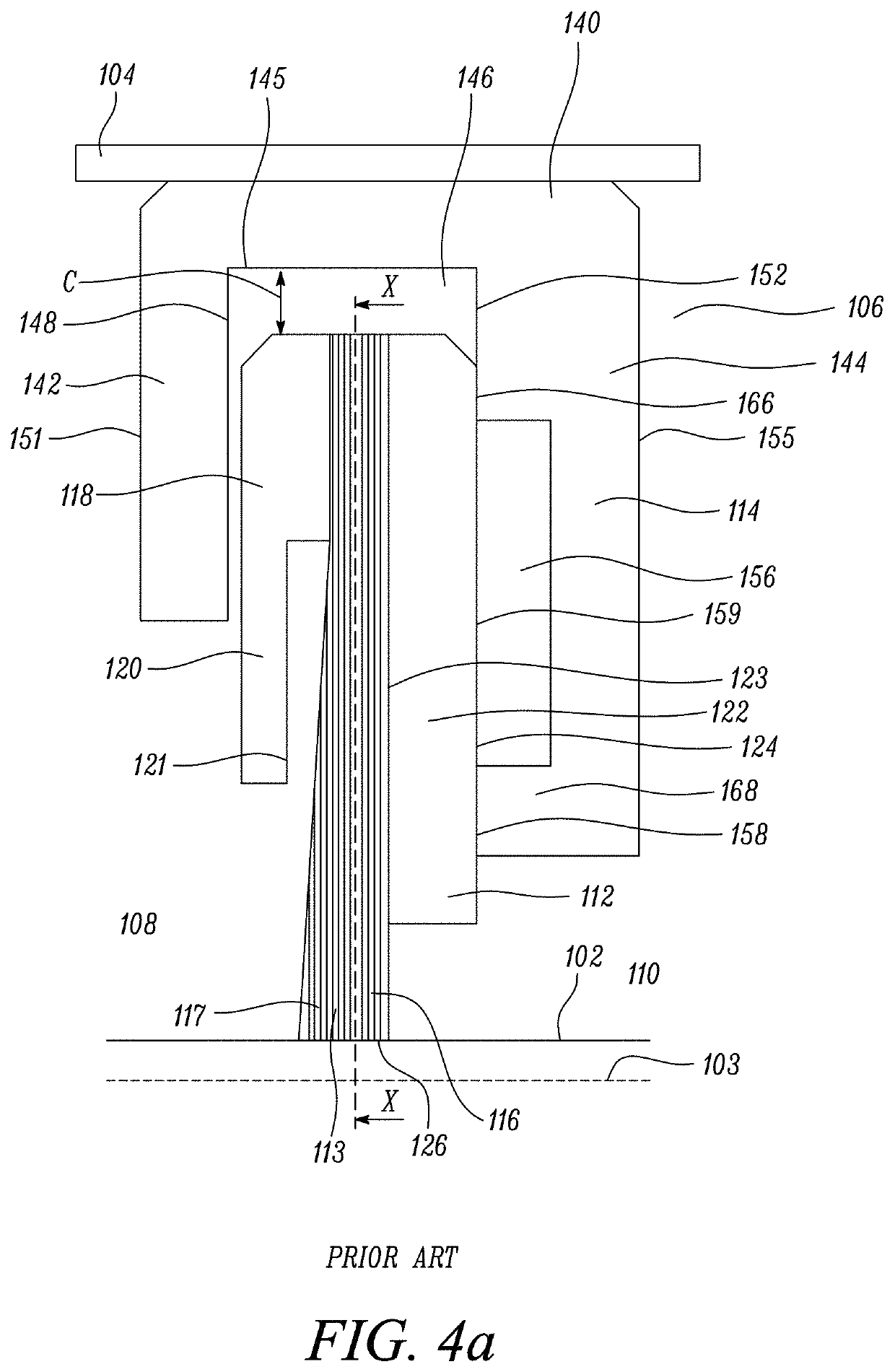

DSA suspension with microactuators extending to gimbal through flexible connectors

ActiveUS8879210B1Good stroke lengthHigh servo bandwidthArm with actuatorsRecord information storageDual stageEngineering

A dual stage actuated (DSA) suspension includes two PZT microactuators that are attached at their first ends to a non-gimbaled portion of the suspension such as the portion of the flexure that is rigidly attached to the load beam, and are attached at their second ends to the gimbaled portion of the suspension such as the gimbal tongue through flexible connectors that can be formed integrally with the suspension's flexure. The flexible connectors are flexible enough so as not to interfere with the suspension's gimballing action. The flexible connectors transmit force from the PZTs to the gimbal as the PZTs expand and contract in order to rotate the gimbal and thus effect fine movements of the head slider.

Owner:MAGNECOMP

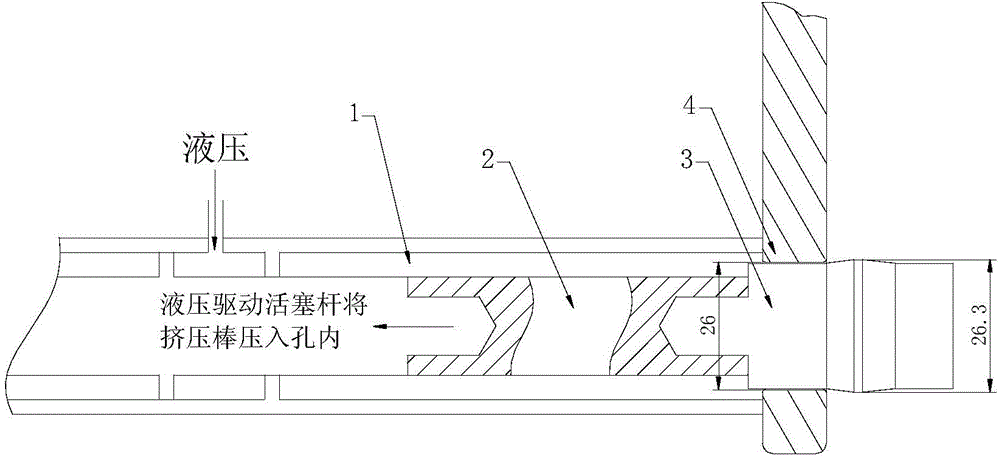

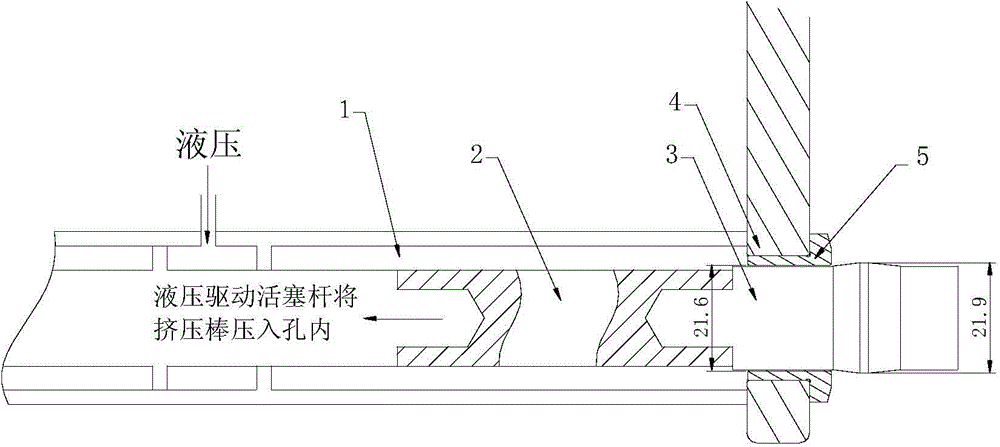

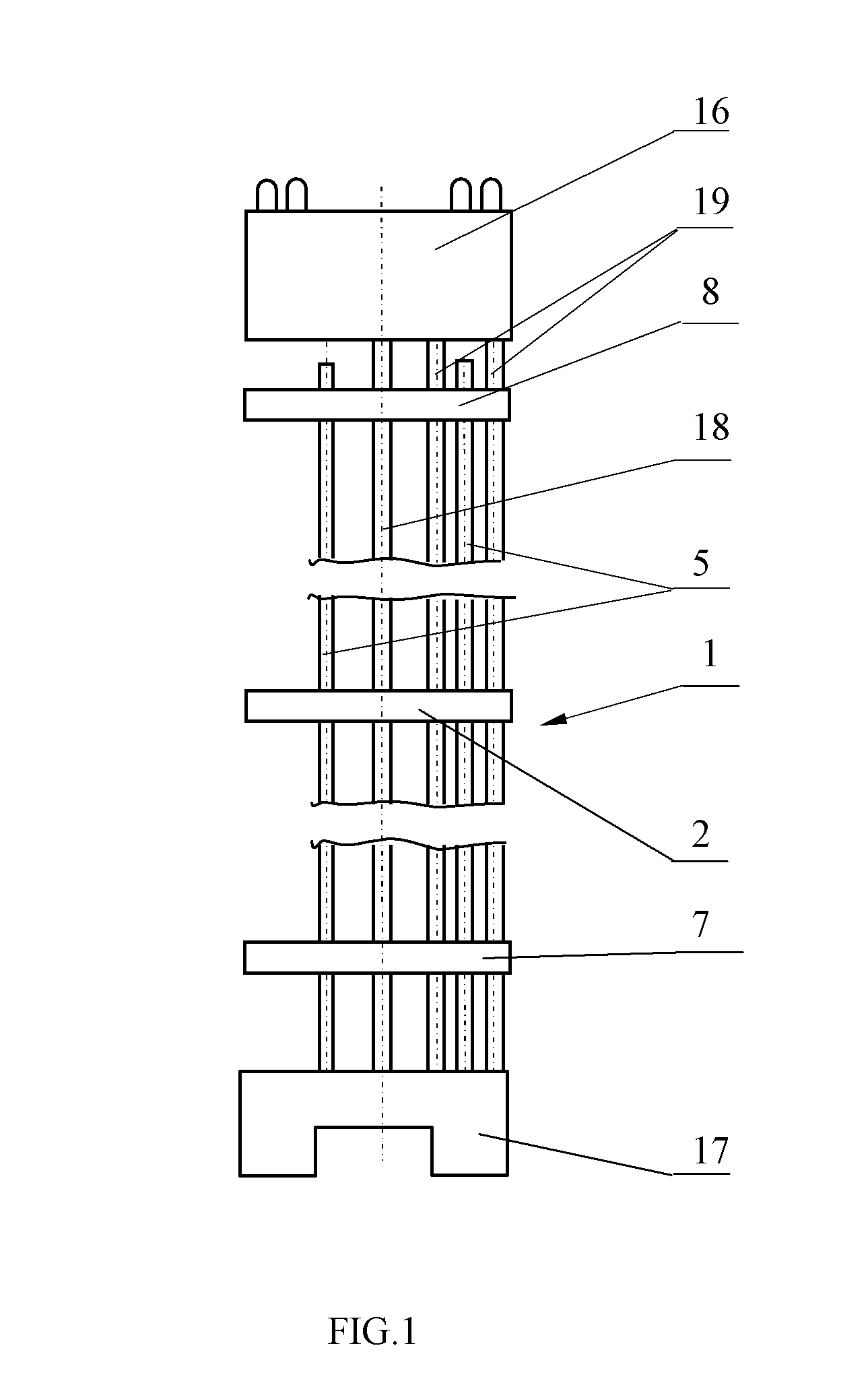

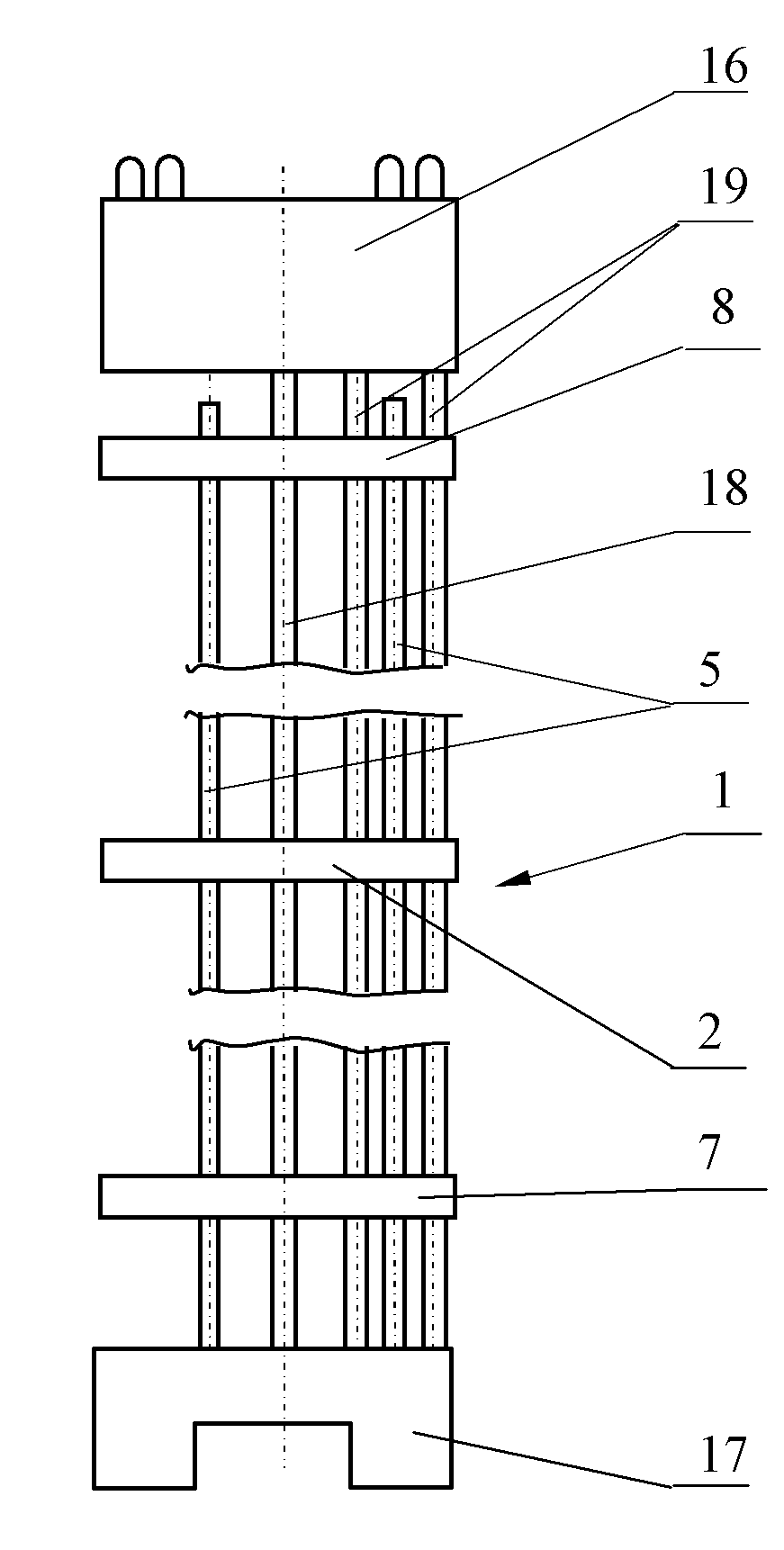

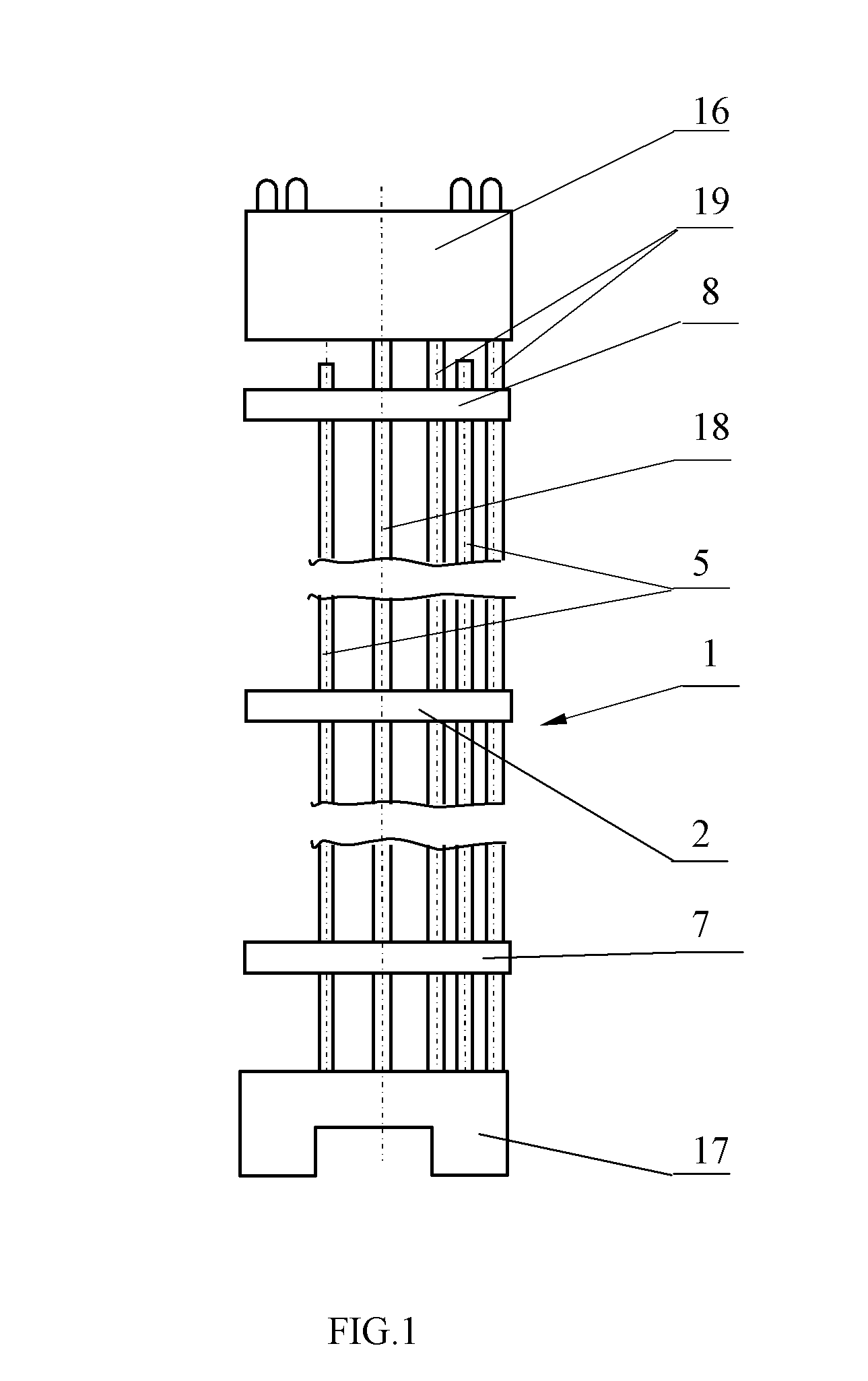

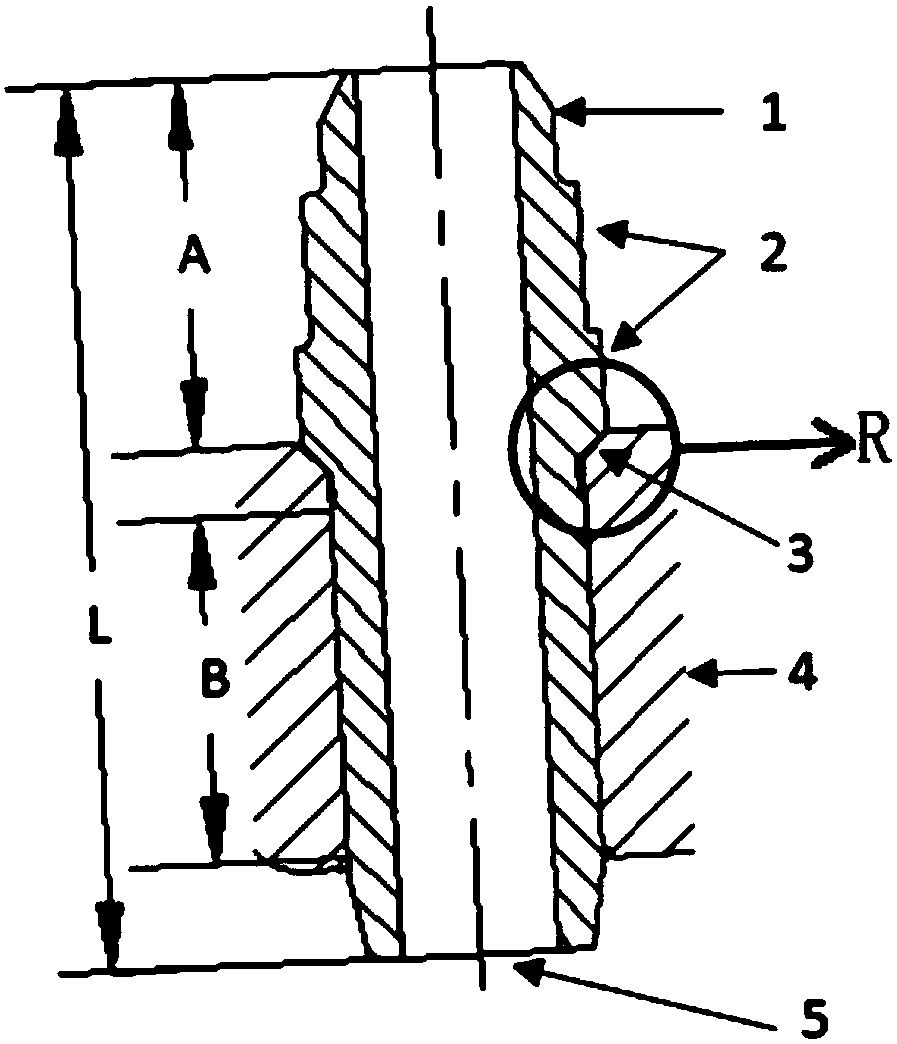

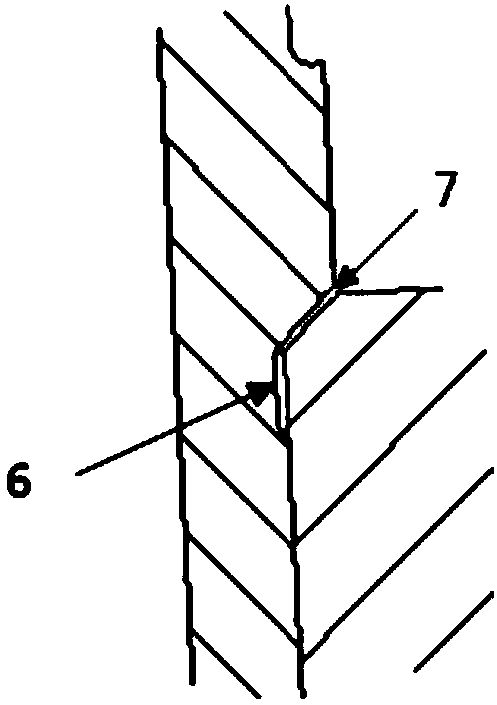

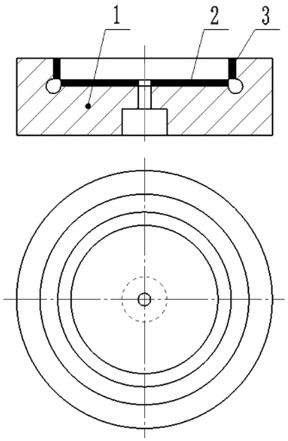

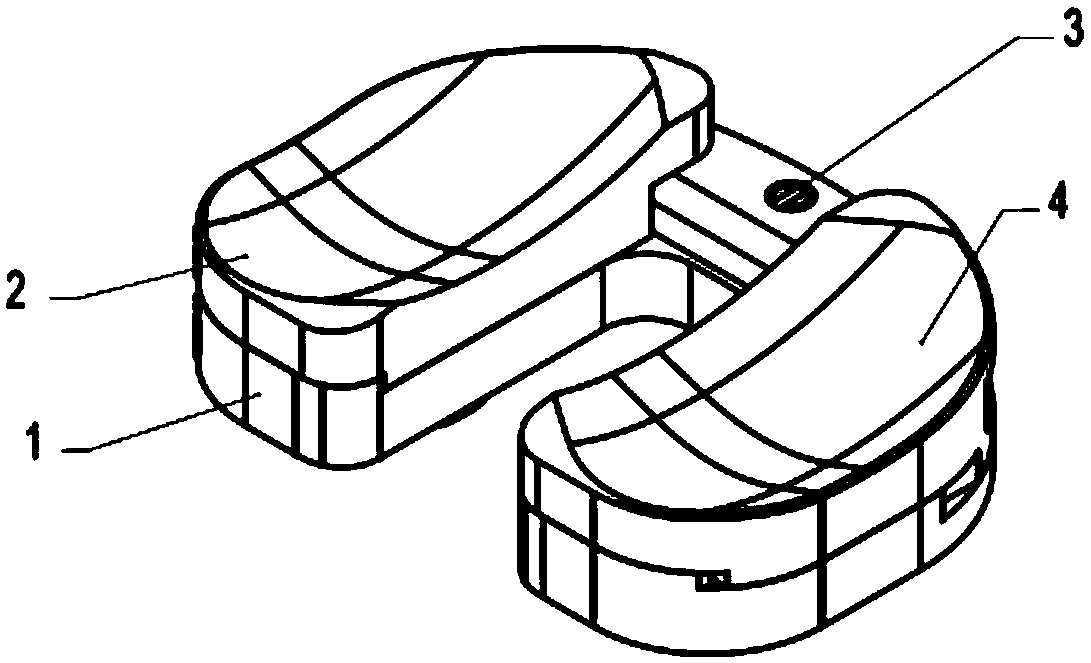

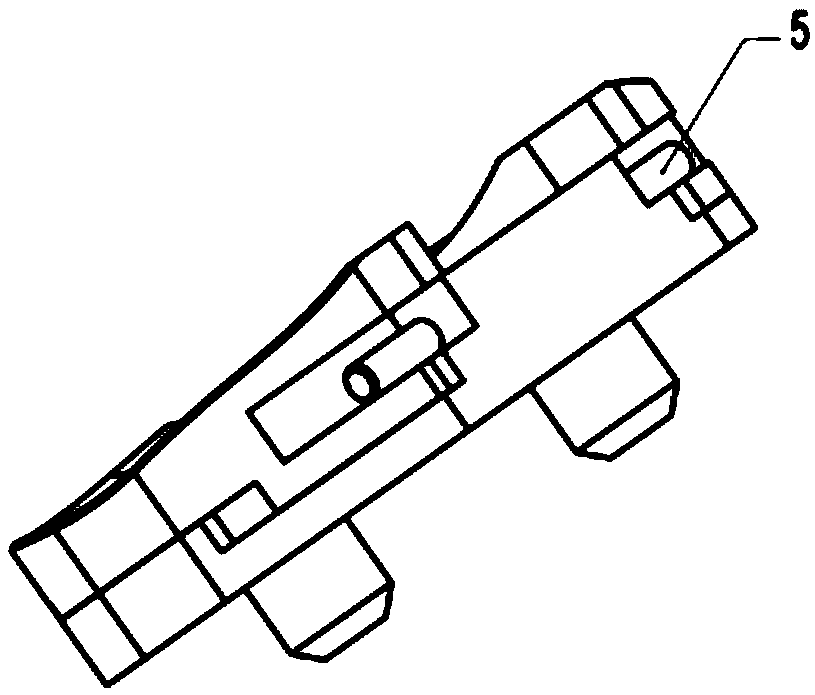

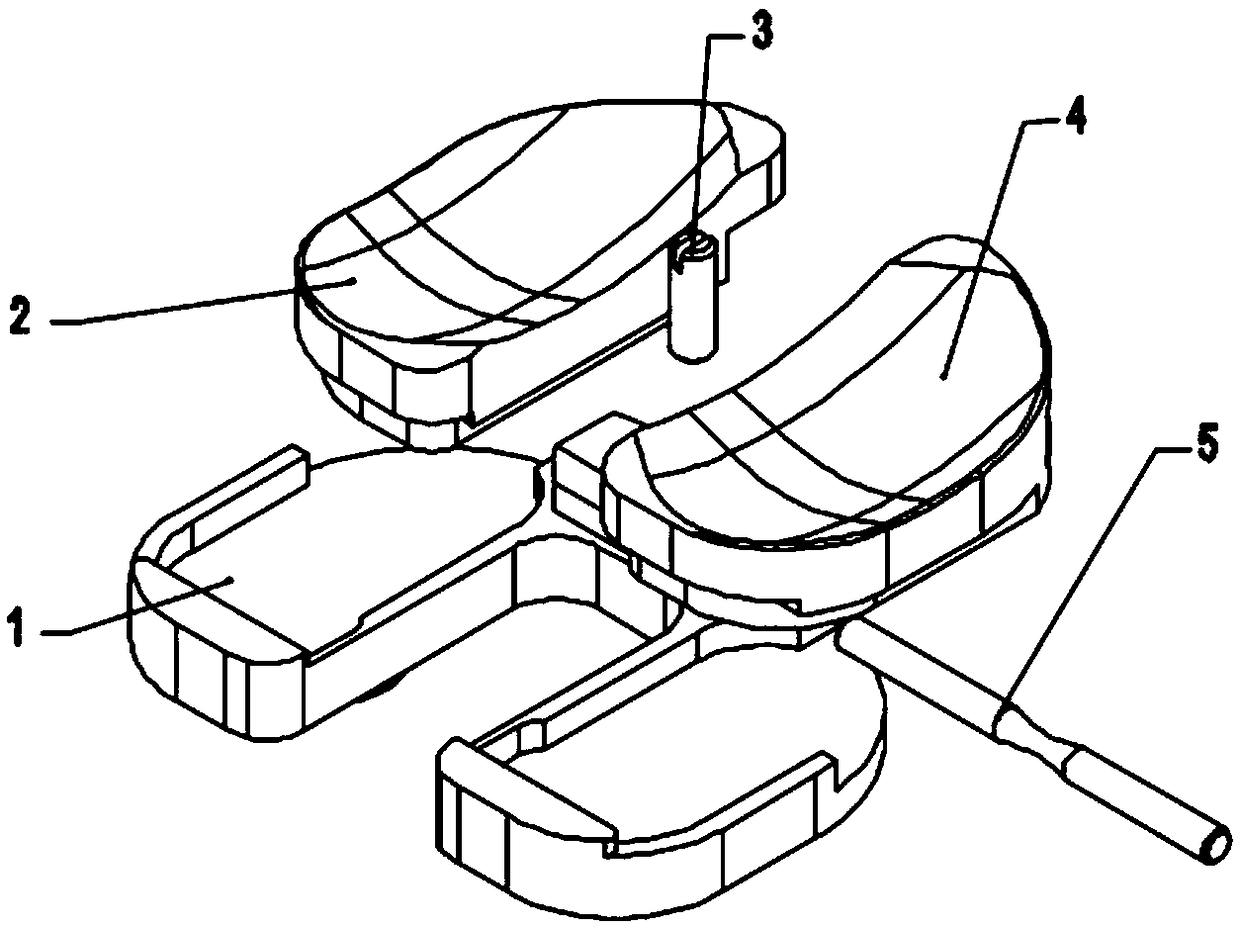

Assembly method capable of achieving hole and bush extrusion strengthening twice

The invention belongs to the field of squeezing and relates to an assembly method capable of achieving hole and bush extrusion strengthening twice. The assembly method comprises the steps that firstly, strengthening is conducted on a hole (4) for the first time by means of an extrusion bar (3) with certain extrusion capacity through an extrusion drawing gun (1); secondly, a bush (5) manufactured according to requirements is placed in the hole (4); and thirdly, strengthening is conducted on the hole (4) again by means of the extrusion bar (3) with certain extrusion capacity through the extrusion drawing gun (1), and assembly of the bush (5) is completed at the same time.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

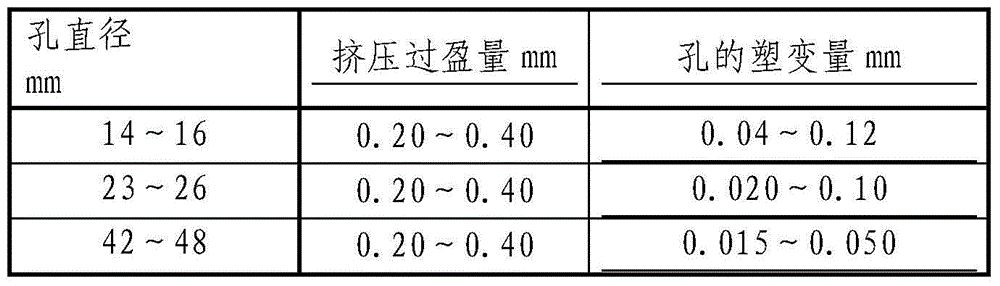

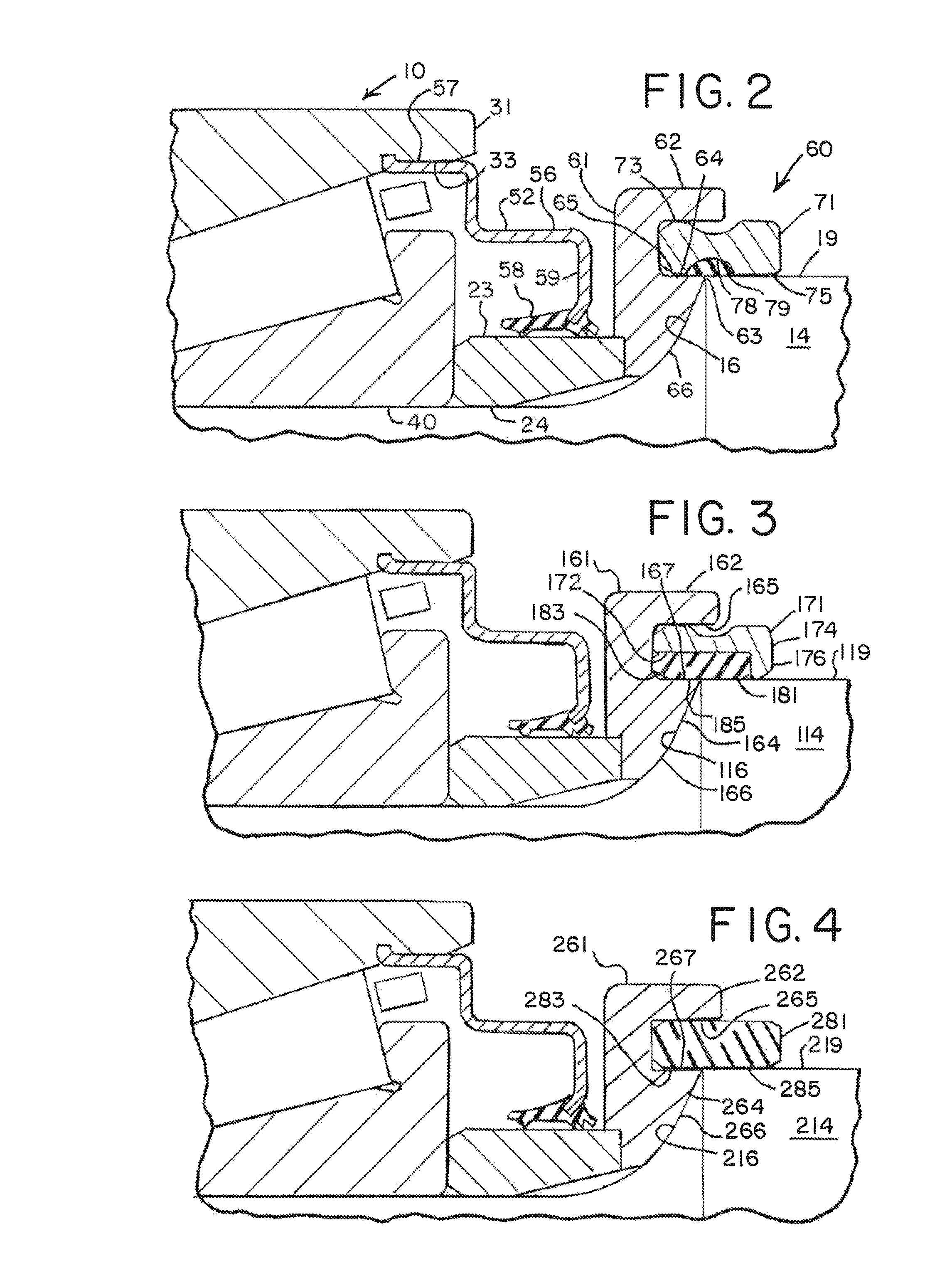

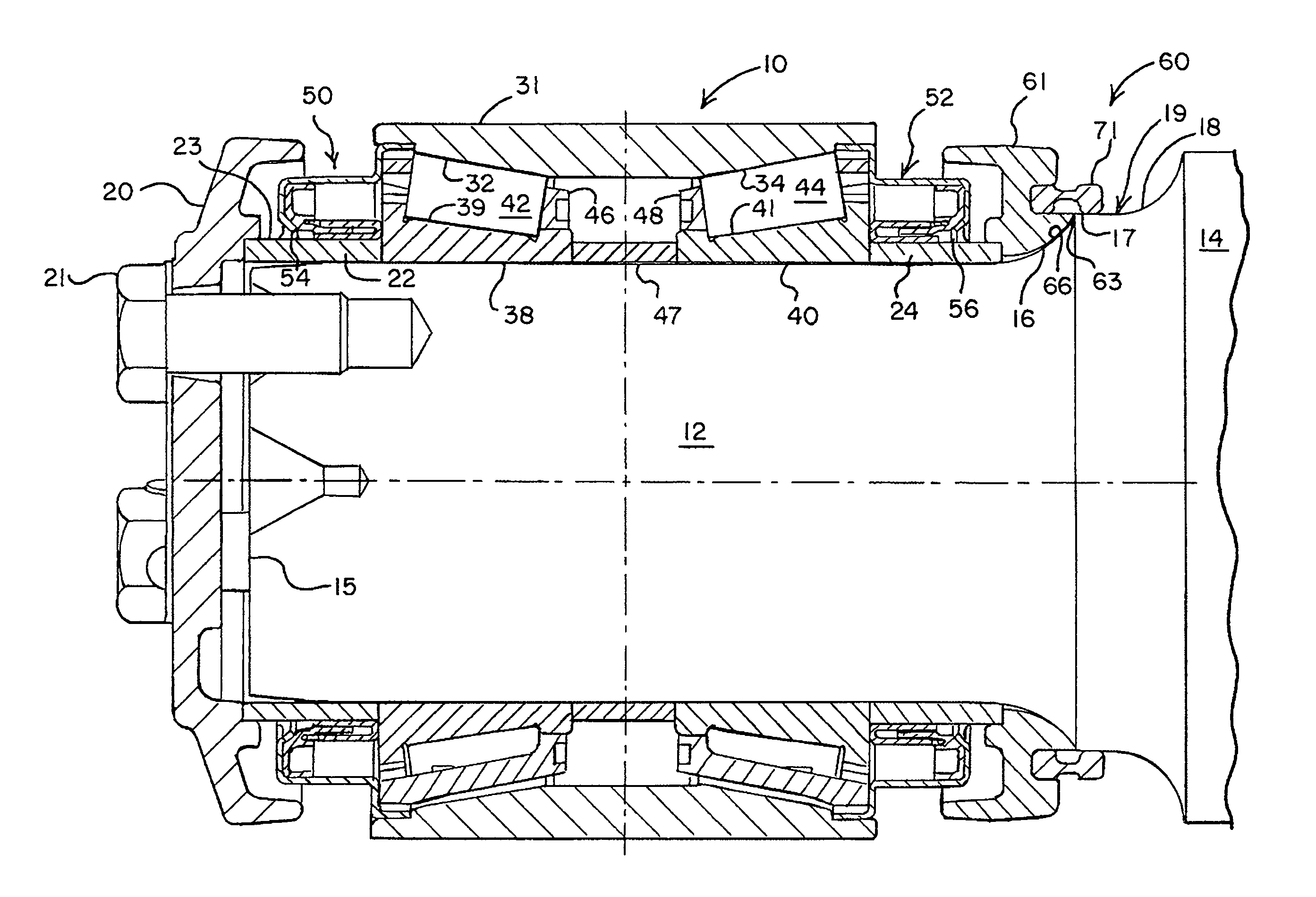

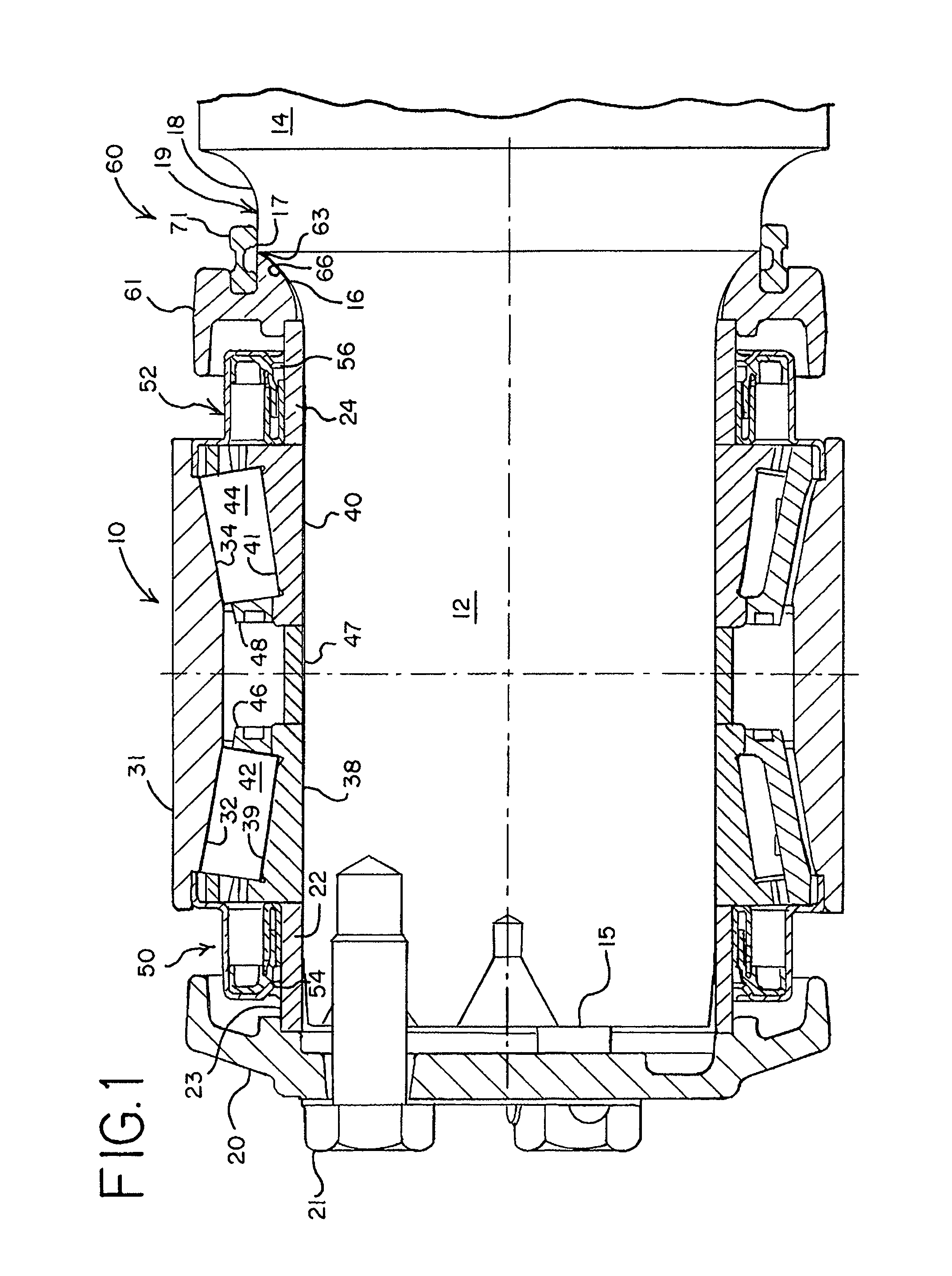

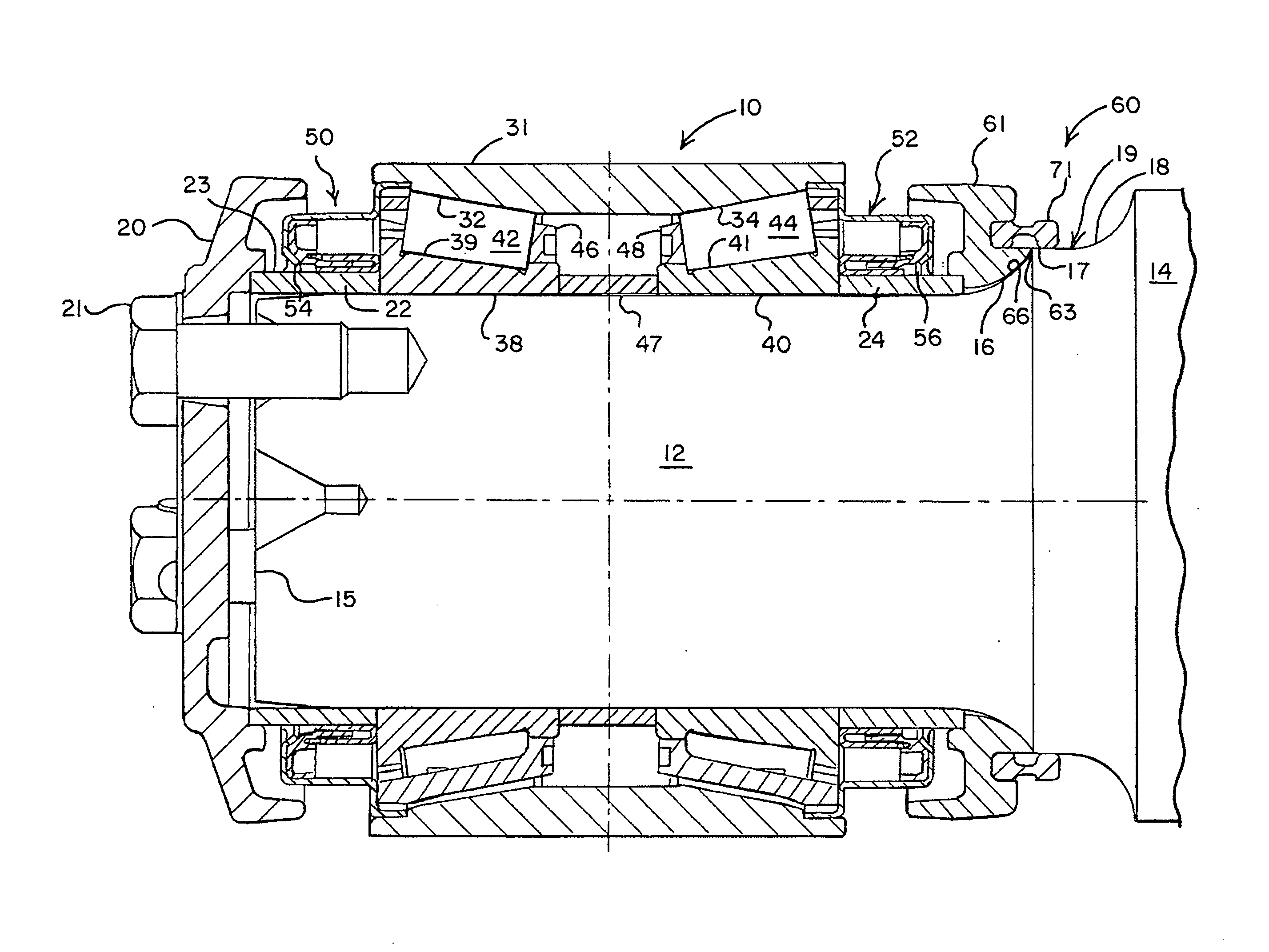

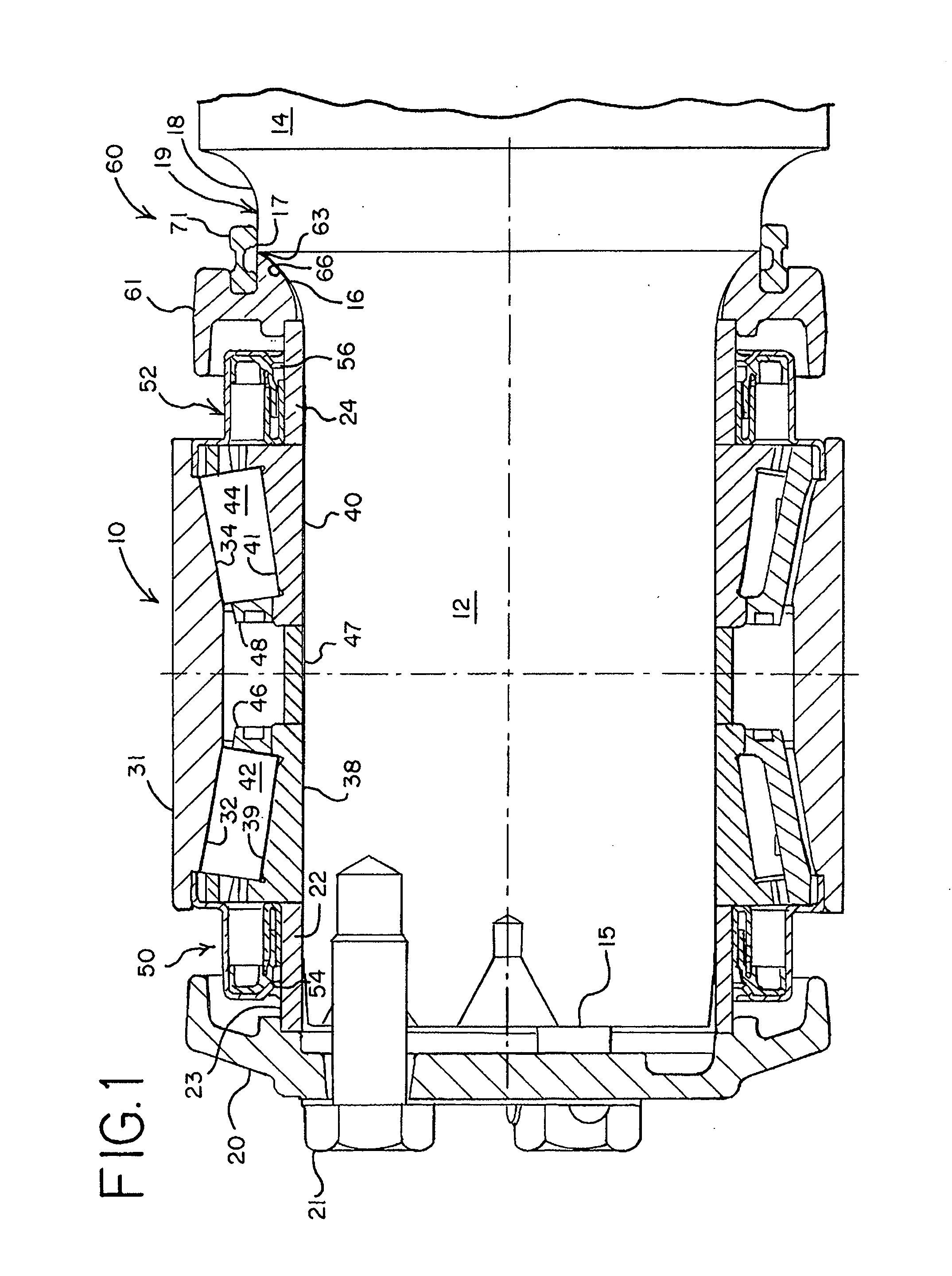

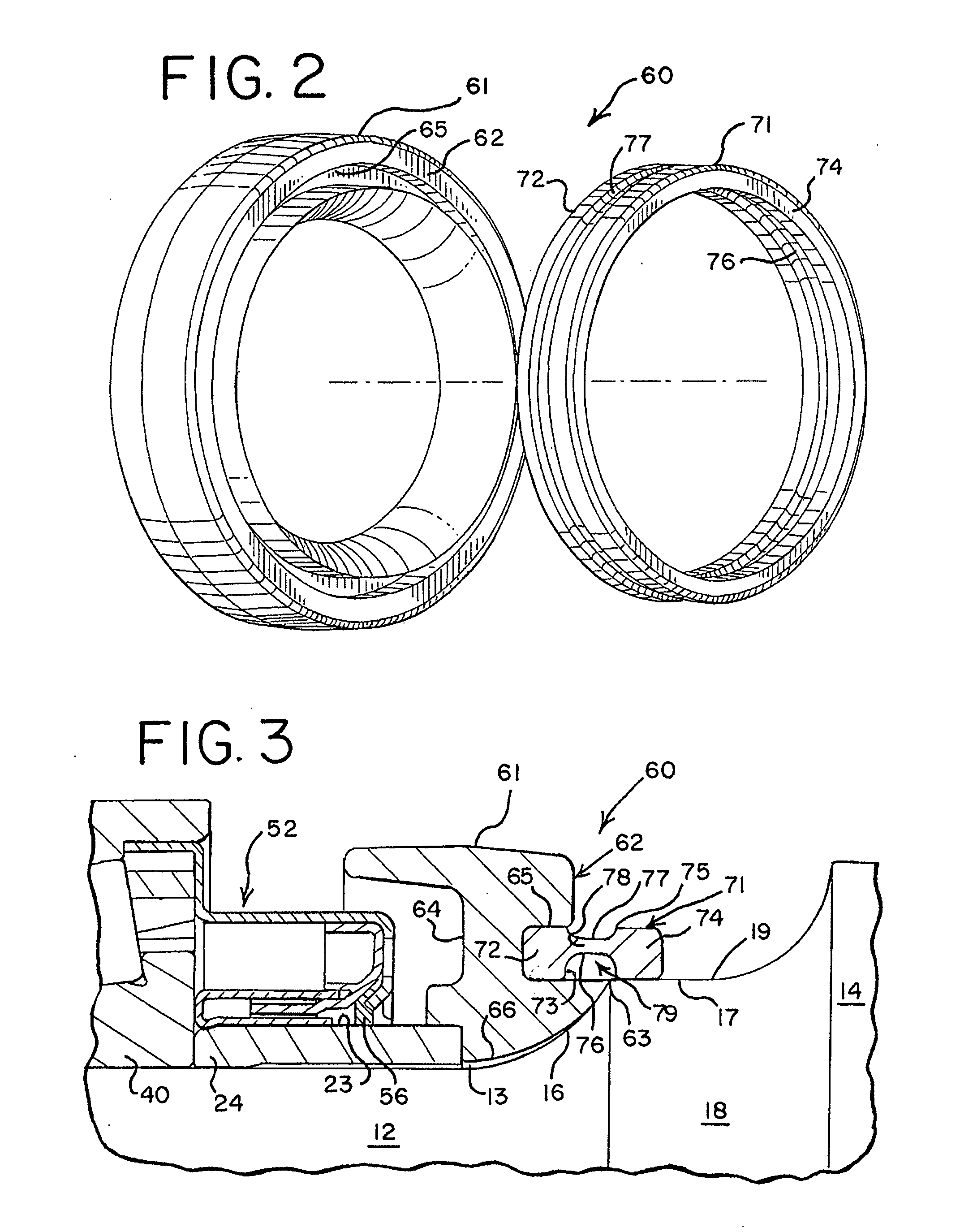

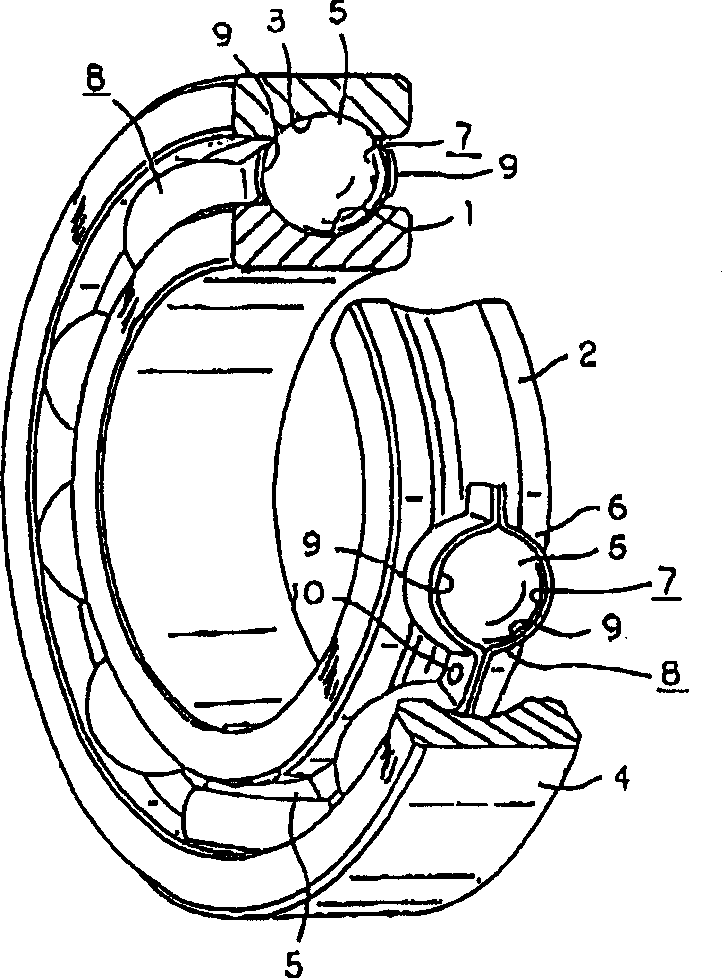

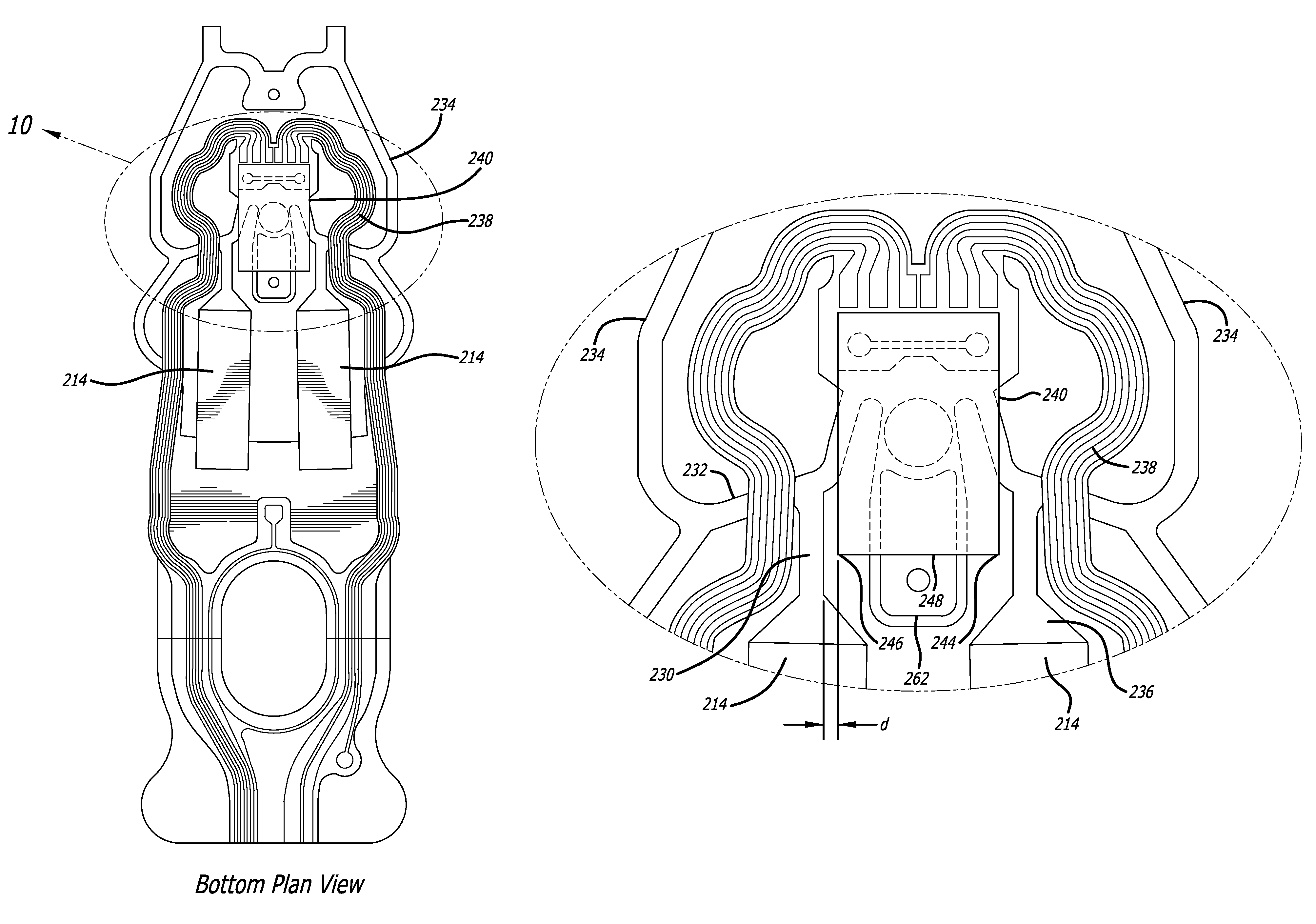

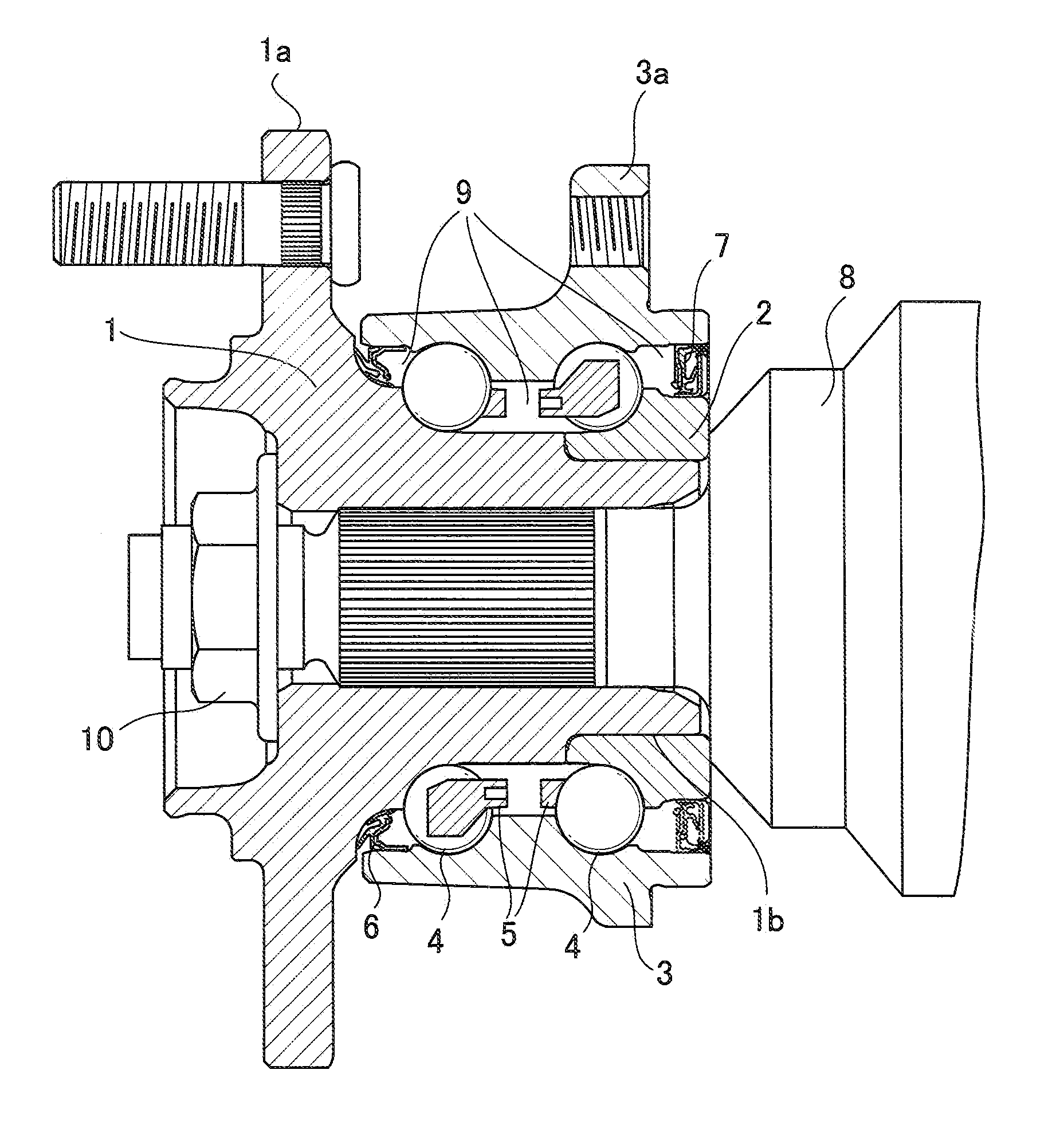

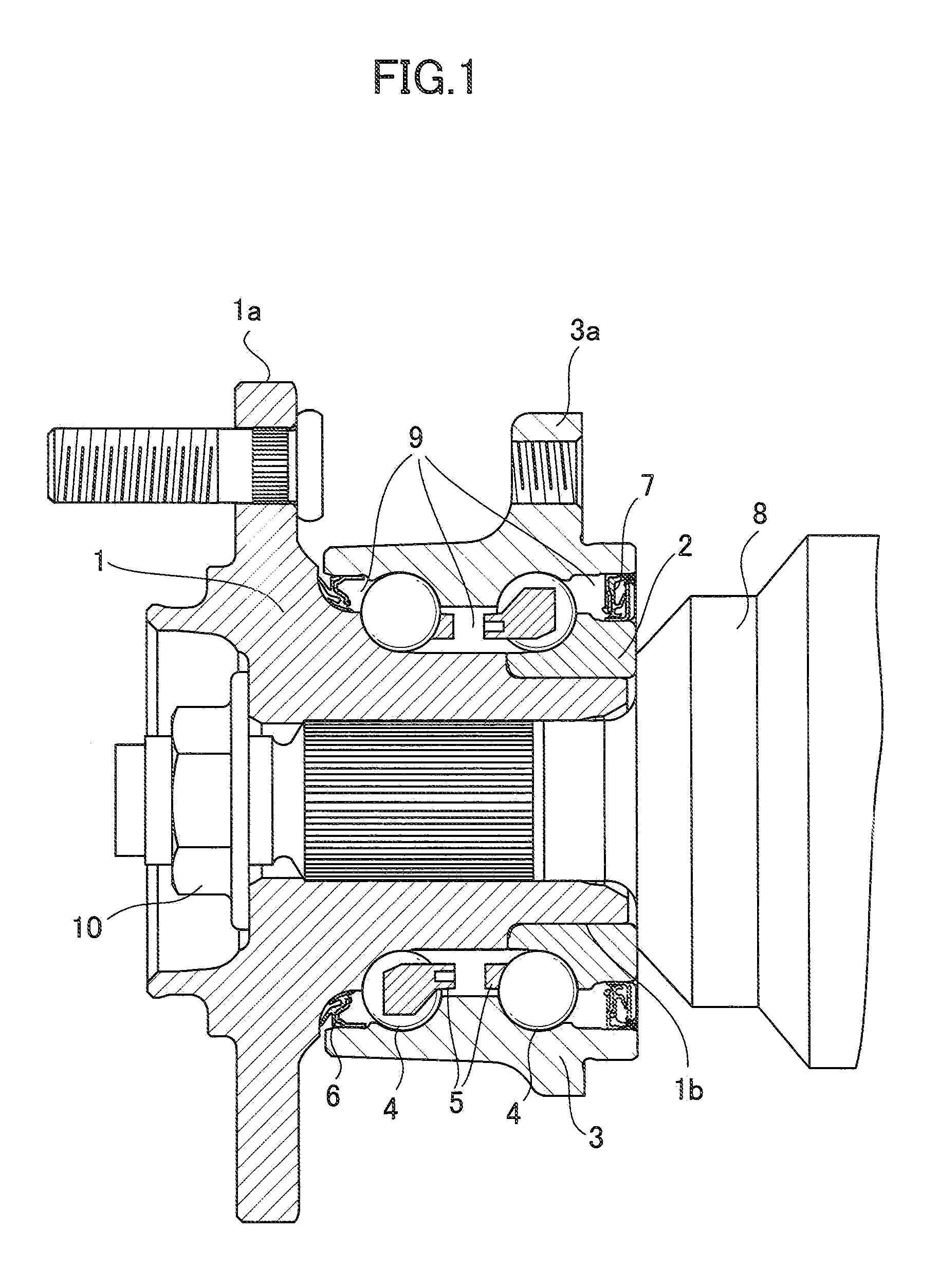

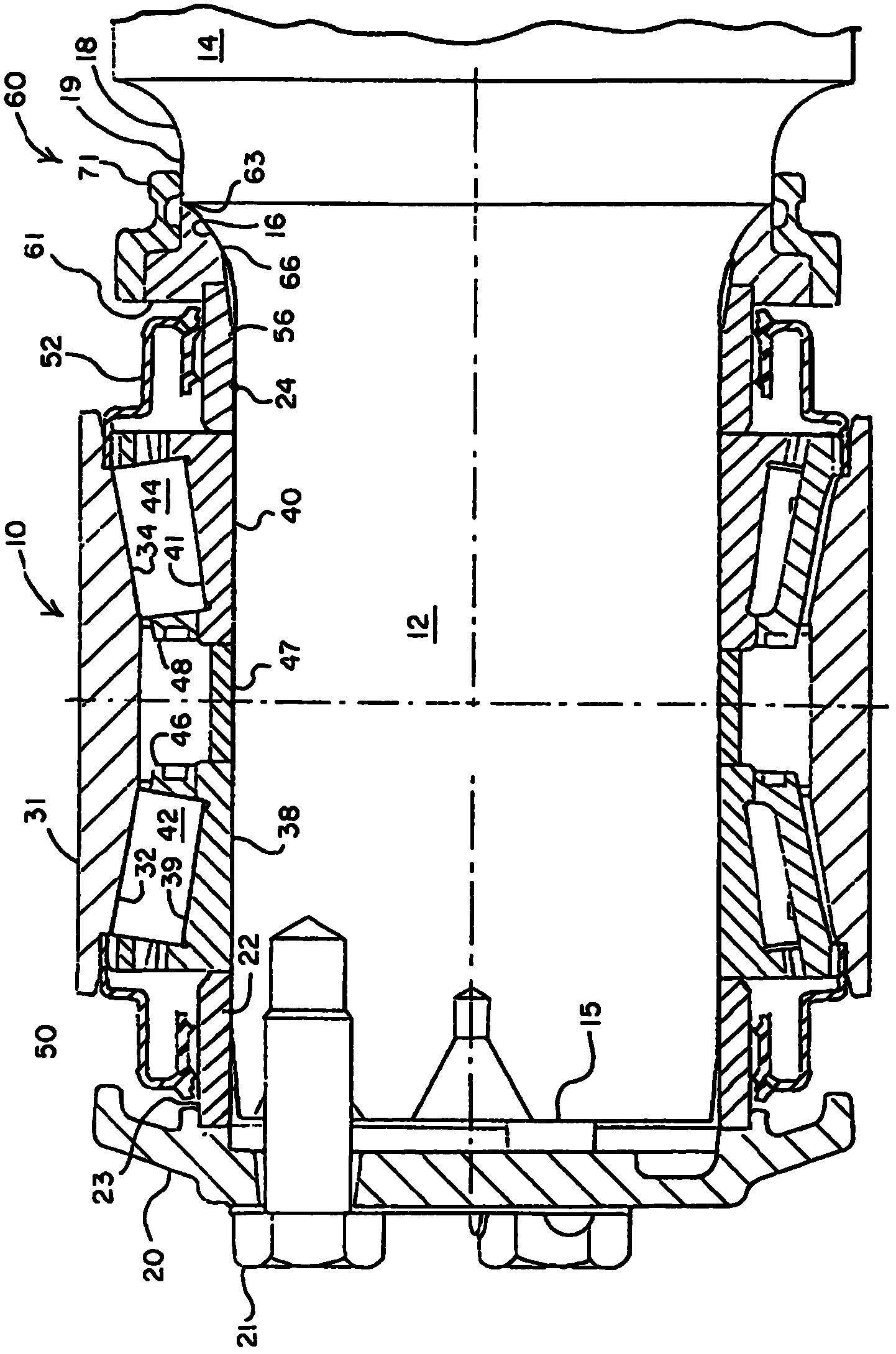

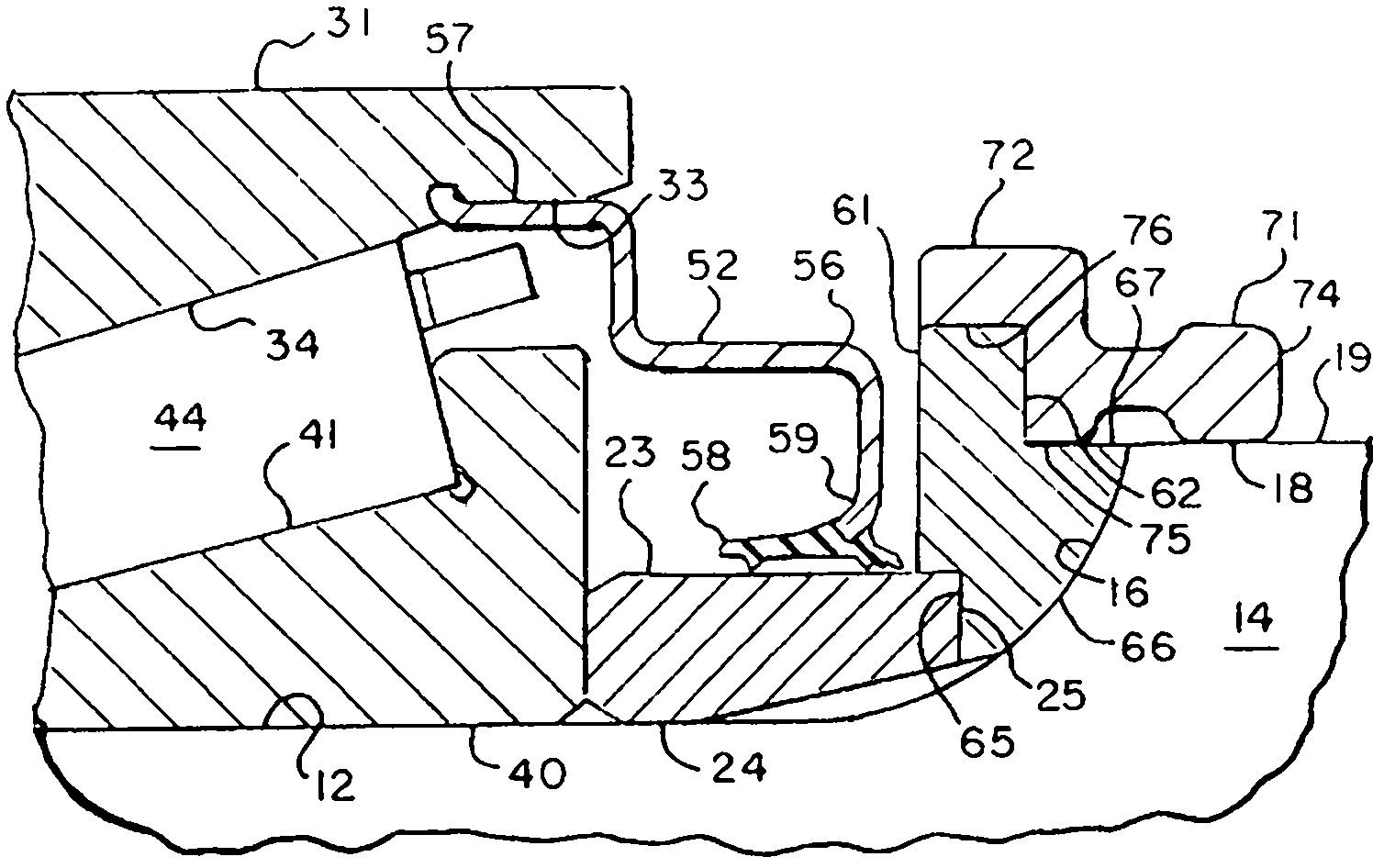

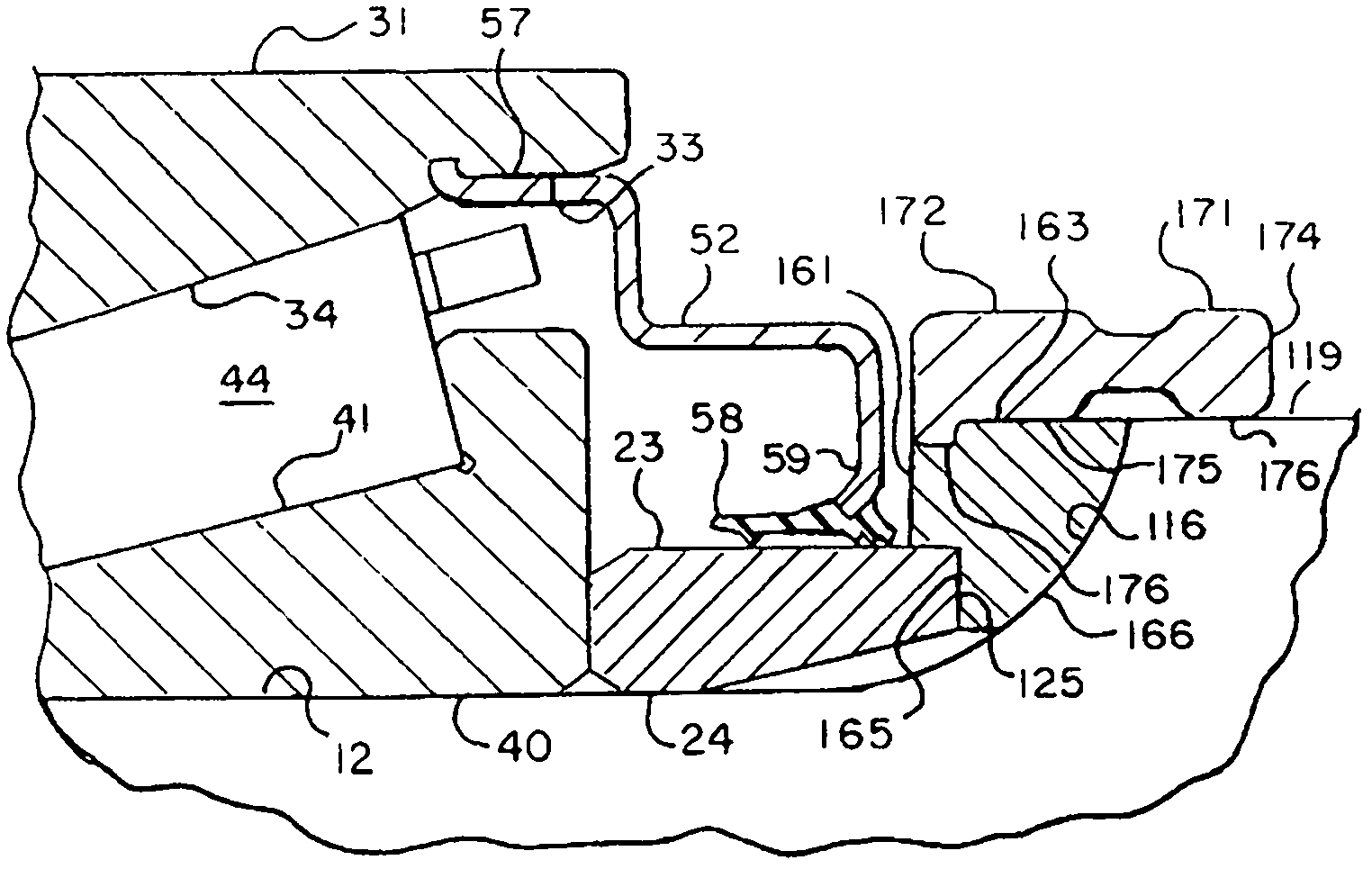

Roller bearing backing ring assembly

ActiveUS8696212B2Reduce axial movementReduced fretting wearRolling contact bearingsHubsEngineeringMechanical engineering

A novel assembly for a railcar axle bearing is presented. The assembly includes a backing ring affixed to the fillet of the journal of an axle and a locking ring for further affixing the backing ring the journal. The locking ring has an inboard end affixed to the dust guard of the axle and an outboard end for engaging the backing ring. The looking ring may include a resilient sealing ring.

Owner:AMSTED RAIL CO INC

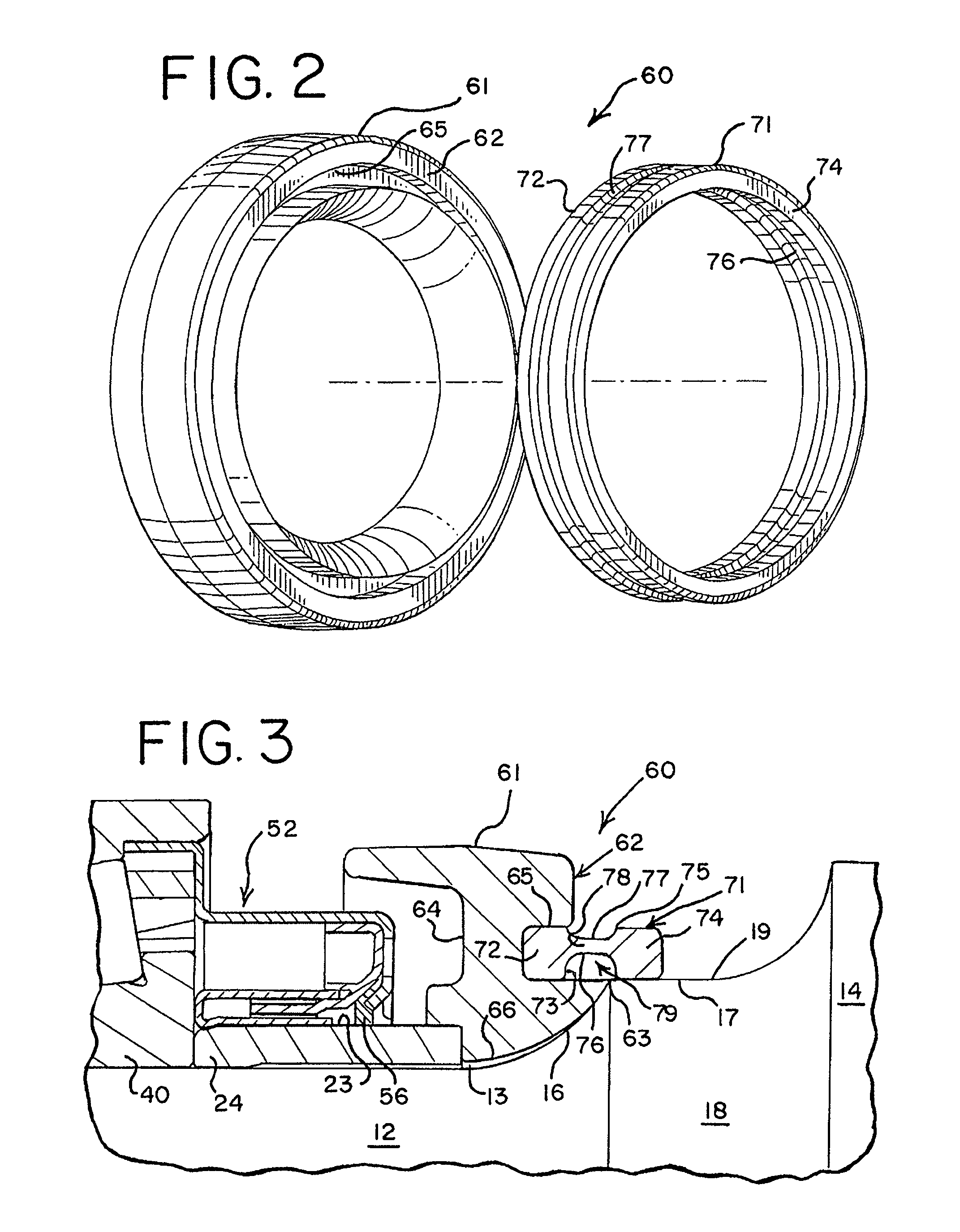

Roller bearing backing ring

ActiveUS8226299B2Reduce axial movementReduced fretting wearRolling contact bearingsRailway vehiclesMechanical engineeringFretting wear

A novel two-piece backing ring assembly for a railcar axle is presented. The backing ring assembly has an annular body affixed to the fillet of the journal and a locking ring for further affixing the annular body into position on the journal. The locking ring has an inboard end affixed to the dust guard of the shaft and an outboard end for engaging a slot in the annular body. The locking ring assembly may be retrofitted to older generation railcar axles to increase the structural rigidity of the bearing assembly and minimize fretting wear caused by railcar axle deflection.

Owner:AMSTED RAIL CO INC

Roller bearing backing ring

ActiveUS20110064347A1Reduced fretting wearReduce axial movementRolling contact bearingsRailway vehiclesEngineeringOrbit

A novel two-piece backing ring assembly for a railcar axle is presented. The backing ring assembly has an annular body affixed to the fillet of the journal and a locking ring for further affixing the annular body into position on the journal. The locking ring has an inboard end affixed to the dust guard of the shaft and an outboard end for engaging a slot in the annular body. The locking ring assembly may be retrofitted to older generation railcar axles to increase the structural rigidity of the bearing assembly and minimize fretting wear caused by railcar axle deflection.

Owner:AMSTED RAIL CO INC

GSA suspension with microactuators extending to gimbal through flexible connectors

ActiveUS8947831B1Convenient lengthHigh bandwidthArm with actuatorsRecord information storageDual stageEngineering

A dual stage actuated (DSA) suspension includes two PZT microactuators that are attached at their first ends to a non-gimbaled portion of the suspension such as the portion of the flexure that is rigidly attached to the load beam, and are attached at their second ends to the gimbaled portion of the suspension such as the gimbal tongue through flexible connectors that can be formed integrally with the suspension's flexure. The flexible connectors are flexible enough so as not to interfere with the suspension's gimballing action. The flexible connectors transmit force from the PZTs to the gimbal as the PZTs expand and contract in order to rotate the gimbal and thus effect fine movements of the head slider.

Owner:MAGNECOMP

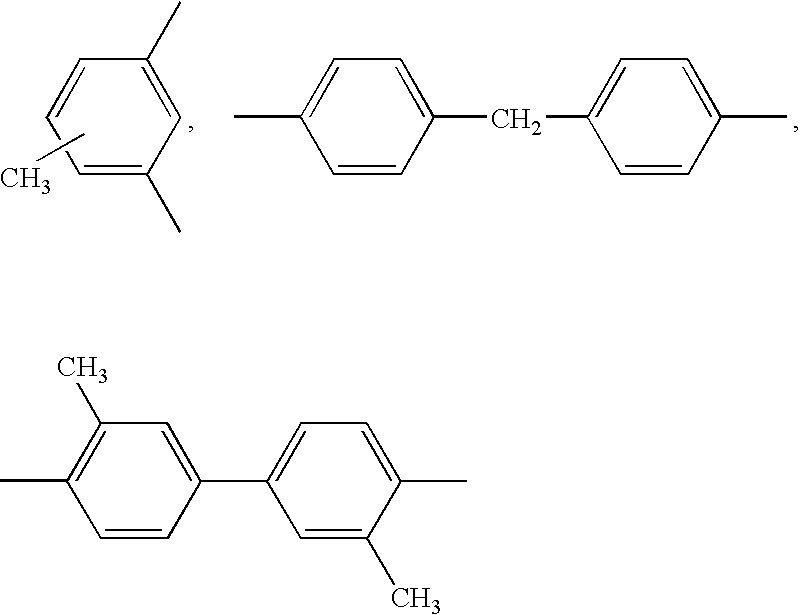

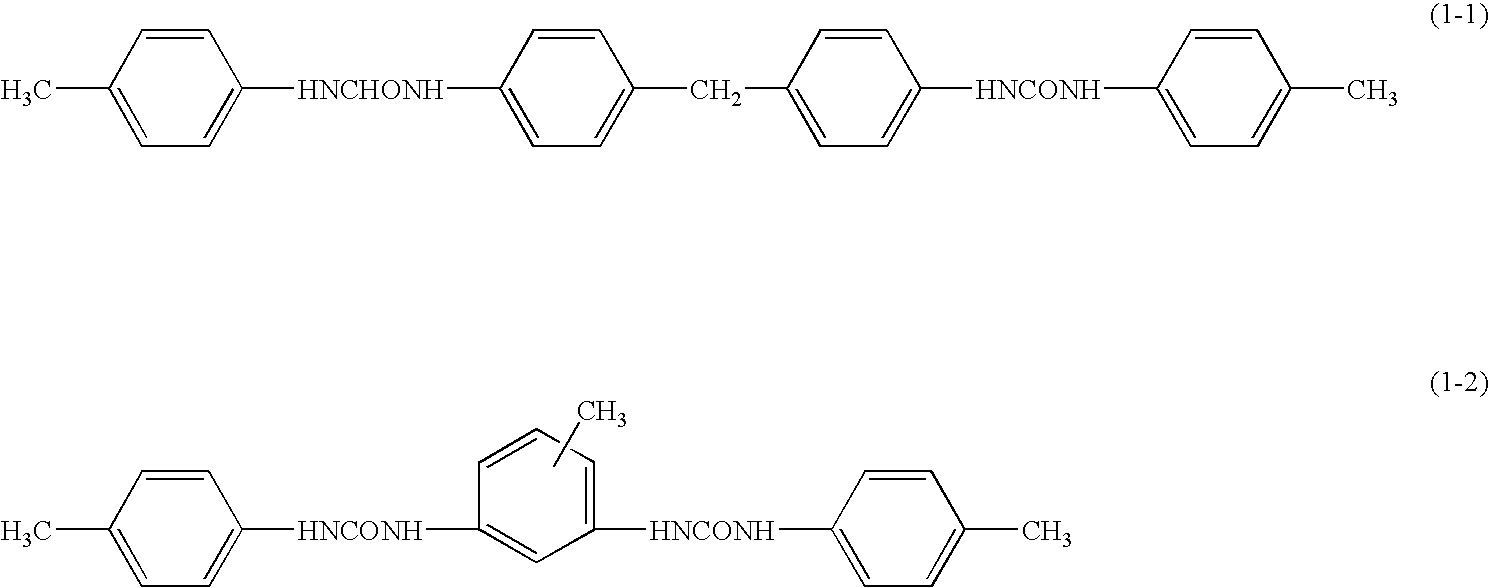

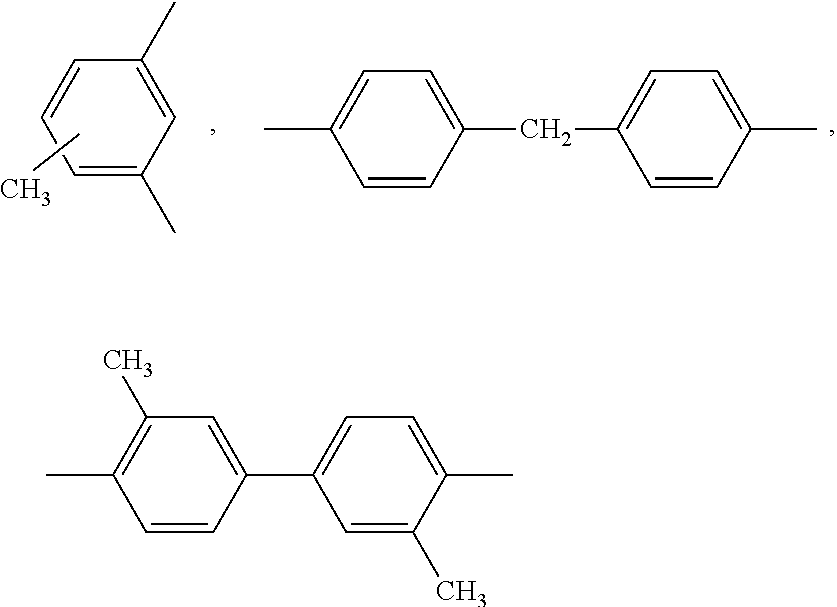

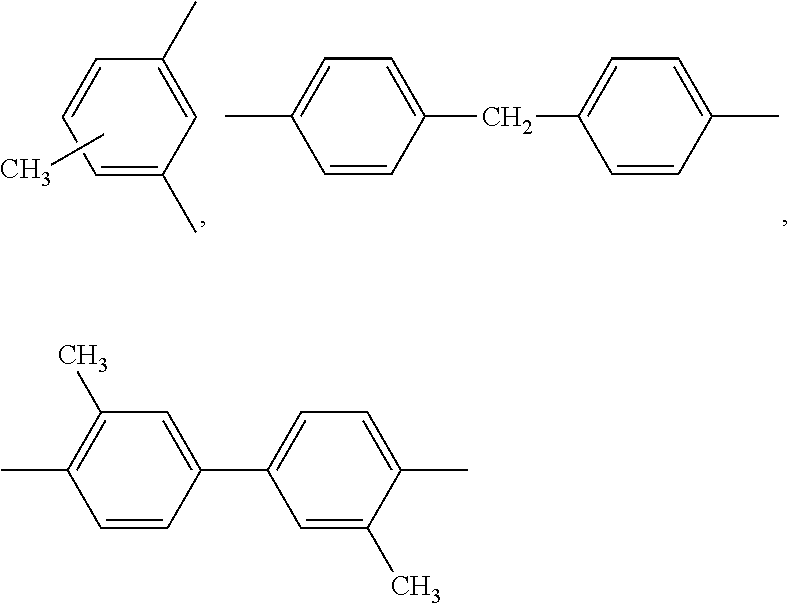

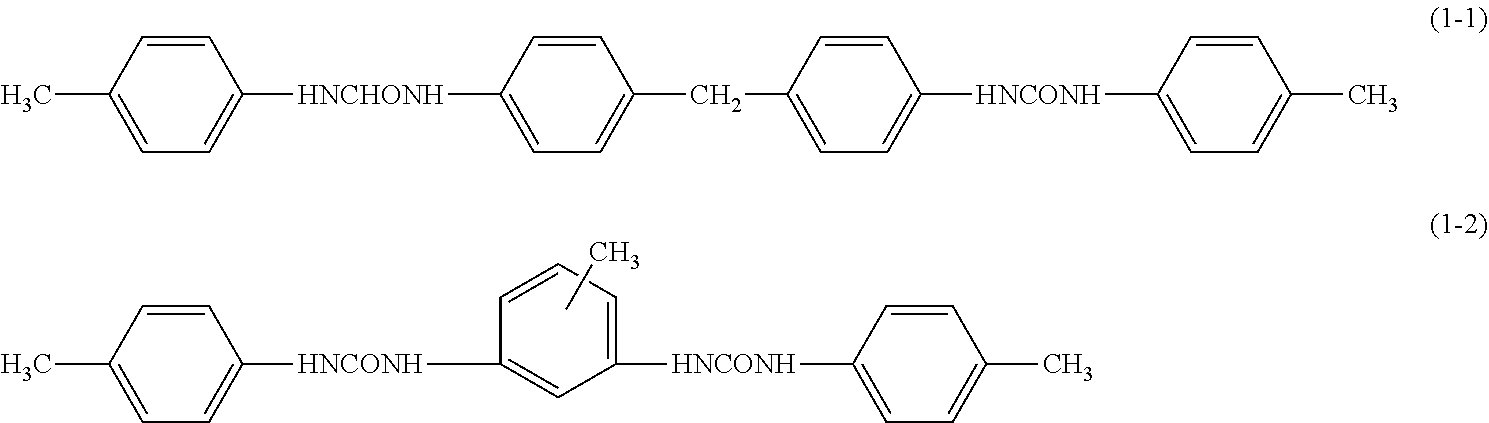

Grease composition for automobile wheel bearing

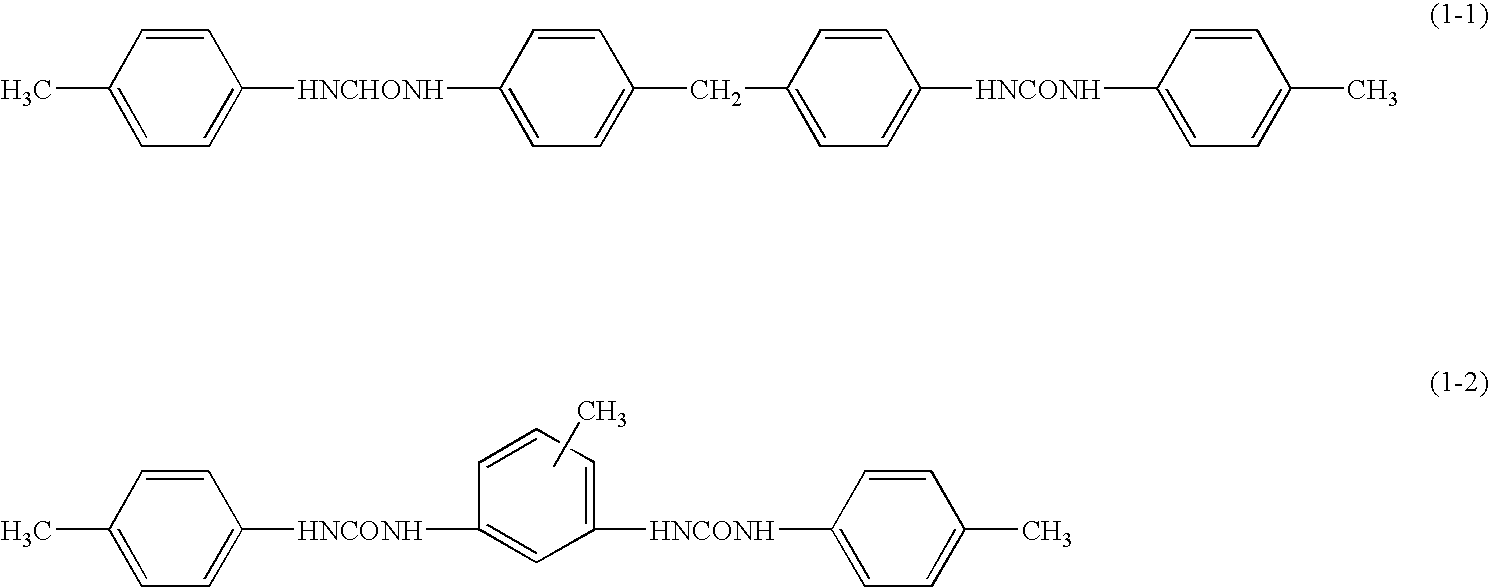

InactiveUS20070155634A1Extend flaking lifeReduced fretting wearAdditivesMolybdenum compoundsBase oil

The present invention provides a grease composition for automobile wheel bearings, which contains (a) an urea thickener represented by general formula (1): R1—NHCONH—R2—NHCONH—R3 (wherein R1 and R3 may be the same or different from each other and are each independently an aromatic hydrocarbon group having 6 to 12 carbon atoms, and R2 represents an aromatic hydrocarbon group having 6 to 15 carbon atoms); (b) an organic molybdenum compound; and (c) a base oil. The composition of the present invention can extend the flaking life and lubrication life, and reduce the fretting wear.

Owner:NTN CORP +1

Lubricant composition and rolling unit

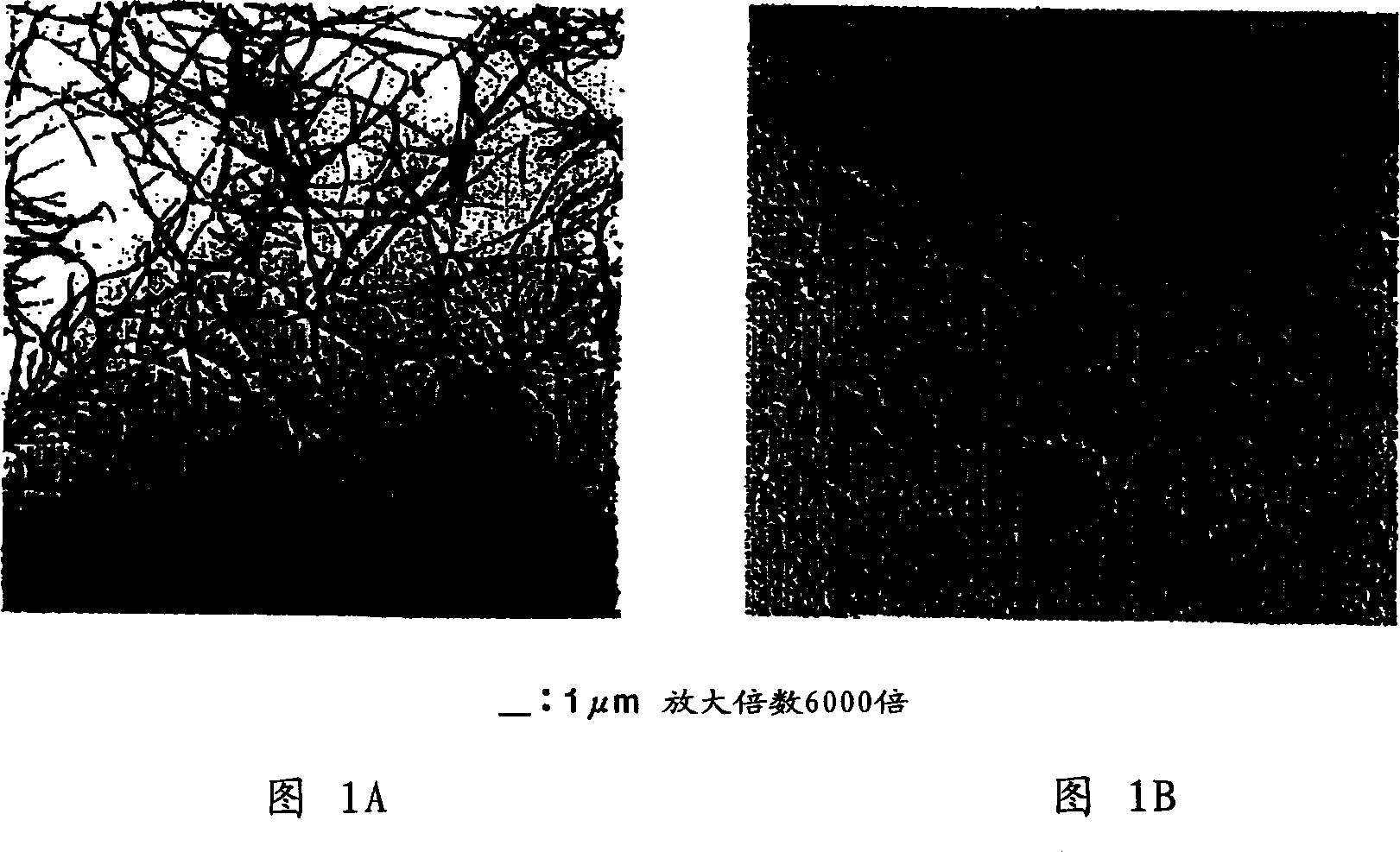

InactiveCN1356381ALower shear resistanceReduce rolling torqueBearing componentsThickenersFiberEngineering

A grease composition is disclosed, wherein a metallic soap-base thickener containing a long-fiber material having a major axis part length of at least 3 mum is blended with a base oil obtained by mixing a lubricating oil having a polar group within the molecule structure and a non-polar lubricating oil, which can improve the initial sound (cage sound) of bearing at the starting of operation in a low-temperature environment and is effective on the reduction of fretting damage (abrasion) or torque, and also a rolling bearing and a linear acting apparatus each obtained by packing the grease composition are disclosed, which exhibit excellent low-temperature acoustic property and are reduced in the fretting damage (abrasion) or torque.

Owner:NSK LTD

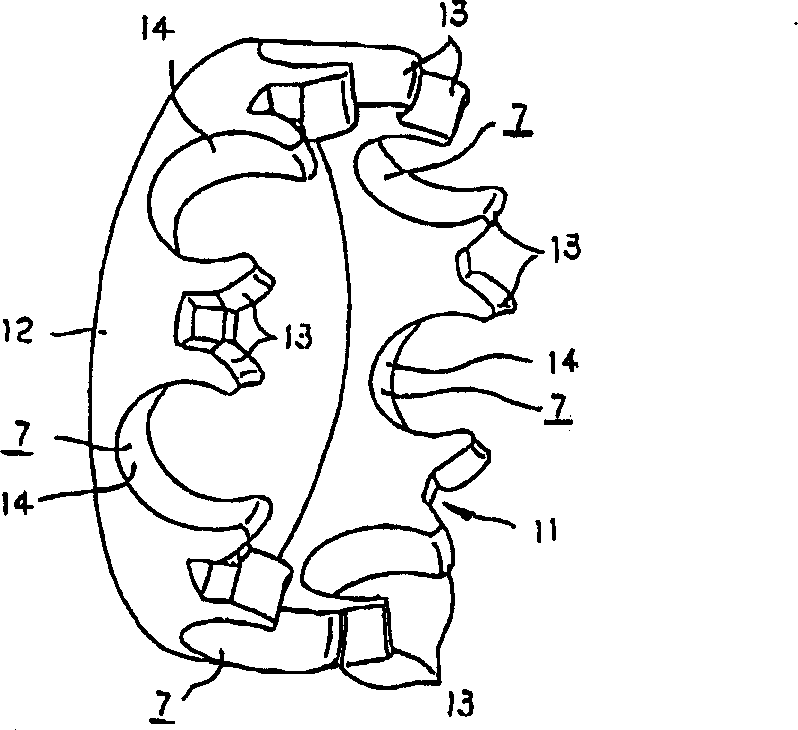

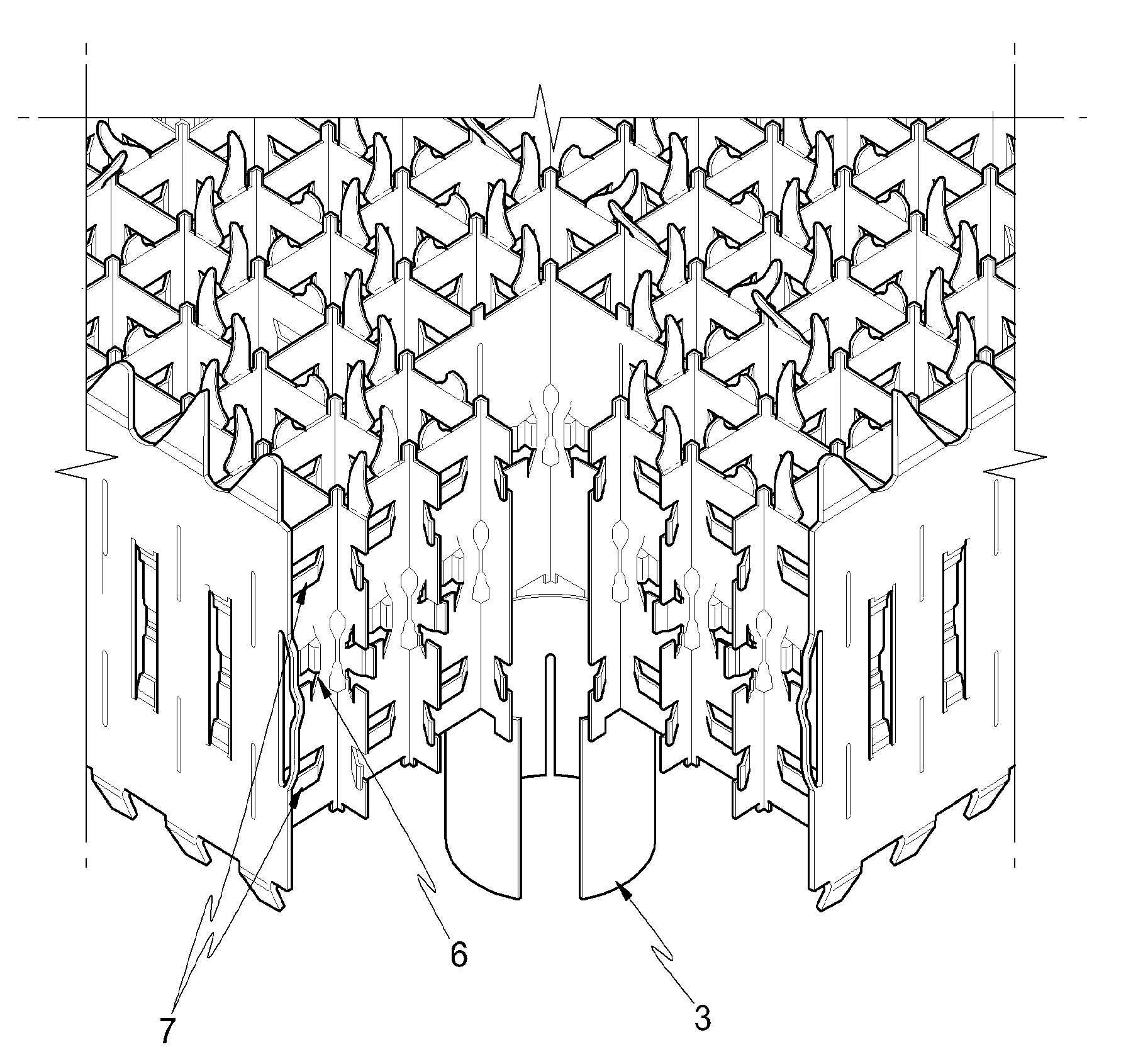

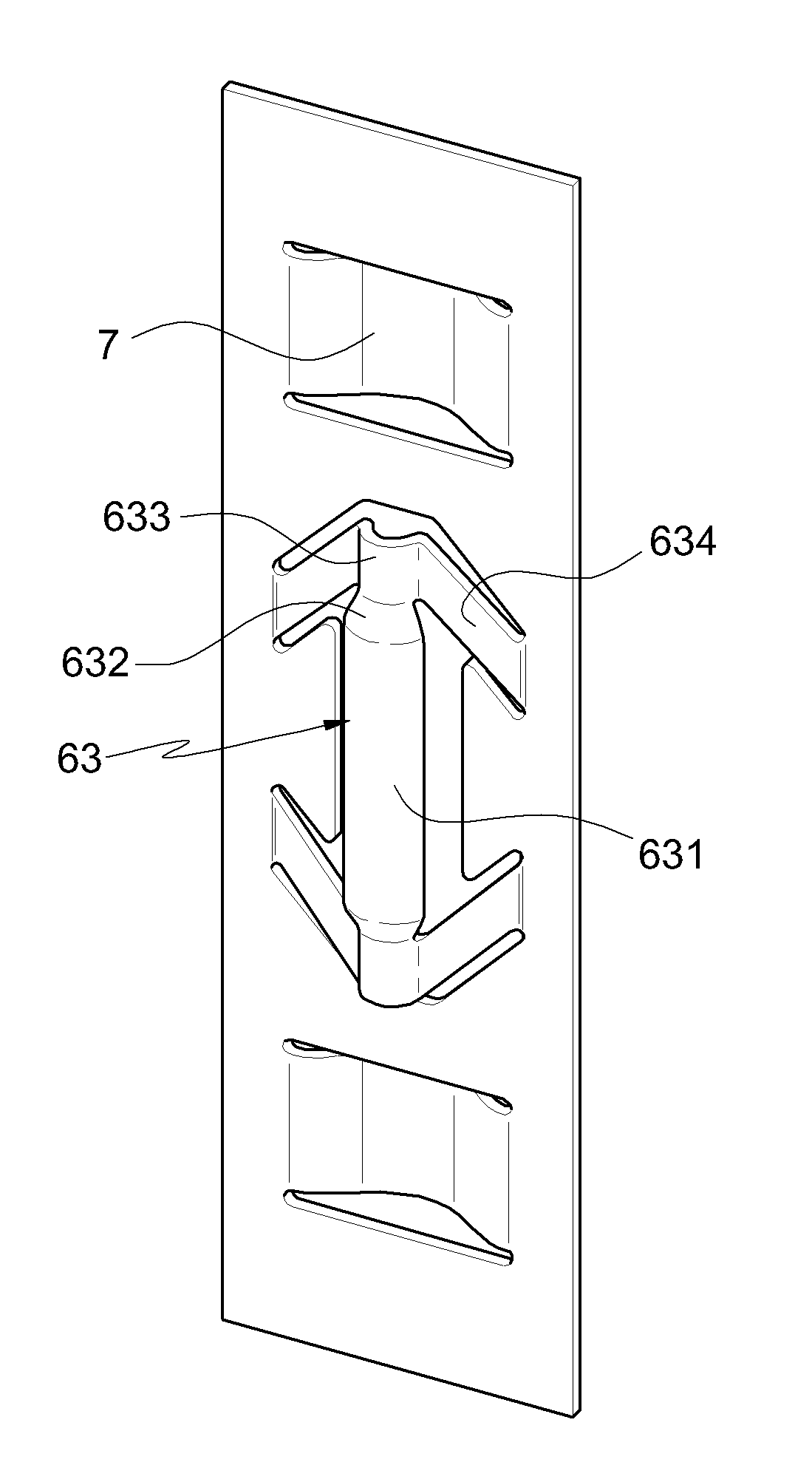

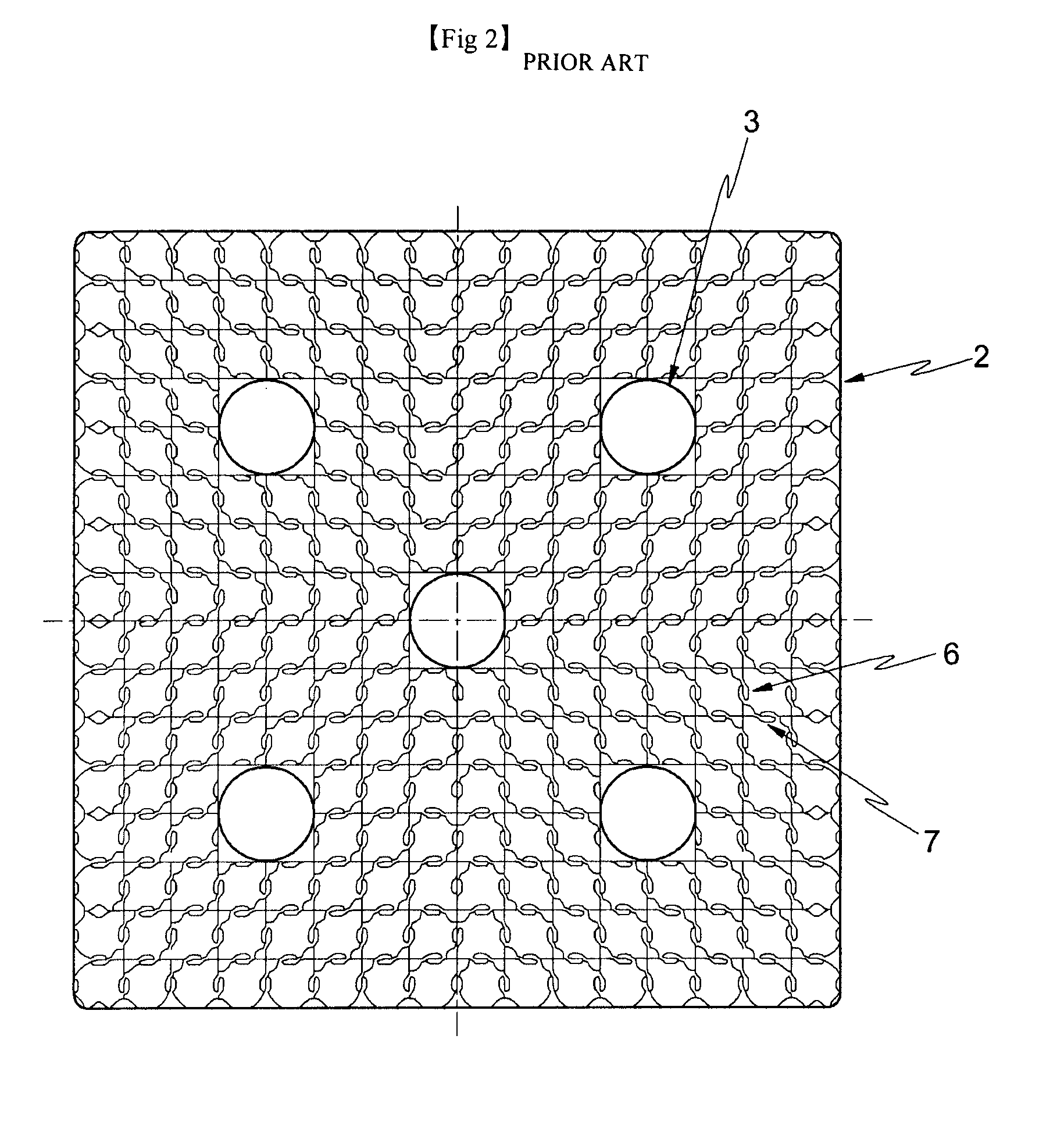

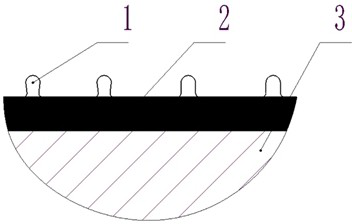

Anti-fretting Wear Spacer Grid With Canoe-Shaped Spring

ActiveUS20100098208A1Great reduction of fretting wear depthReduce local wearNuclear energy generationFuel element assembliesEngineeringGrid cell

The present invention relates to an anti-fretting wear spacer grid having a plurality of canoe-shaped springs formed thereon, wherein each of the canoe-shaped springs includes: a fuel rod-contacting part having a flat surface having a predetermined longitudinal length so as to have linear contact with the fuel rod; a curved face-connecting part formed on the upper and lower portions of the fuel rod-contacting part; a leg-connecting part formed on the end portion of the curved face-connecting part; and legs each being formed of a plate shape having a predetermined length and connecting the both sides of the leg-connecting part with one unit grid cell surface.

Owner:KEPCO NUCLEAR FUEL CO LTD

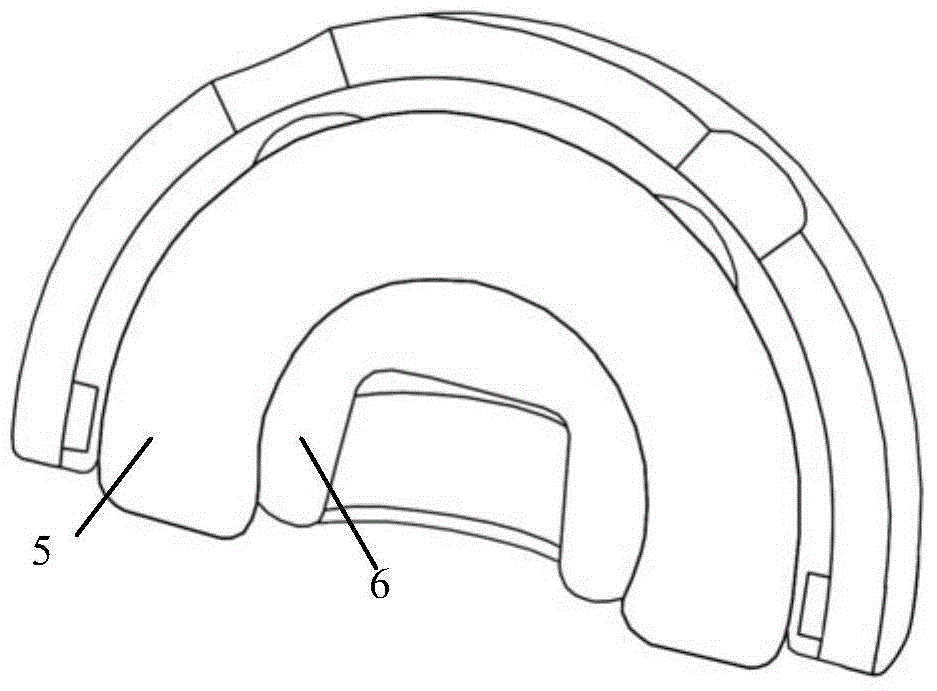

Combined artificial hip joint cup

InactiveCN105030380AReduce stress concentrationReduces risk of fretting wear and liner breakageJoint implantsCoatingsIonCorrosion

The invention relates to a combined artificial hip joint cup in a concave semi-arc shape. The combined artificial hip joint cup comprises an outer layer and an inner layer; the outer layer is provided with screw holes; the outer layer is made of biocompatible material; the inner layer is made of polyetheretherketone or its derivative polymer material; the inner layer and the outer layer are integrally fixed; the screw holes are covered by the inner layer. The joint of the surface of the PEEK (polyetheretherketone) inner layer and the outer surface of a different cup liner may reduce stress concentration and reduce the risk of fretting wear and liner damage; or the inner surface of the PEEK inner layer and the outer surface of a femoral prosthesis directly form a friction pair, decreasing wear of the outer surface of the femoral prosthesis. The surface of the PEEK inner layer has the advantages of corrosion resistance and fretting wear resistance, and the release of existing metal ions and granules of metal prostheses, causing harm to the human body, is avoided.

Owner:JIANSU OKANI MEDICAL TECH CO LTD

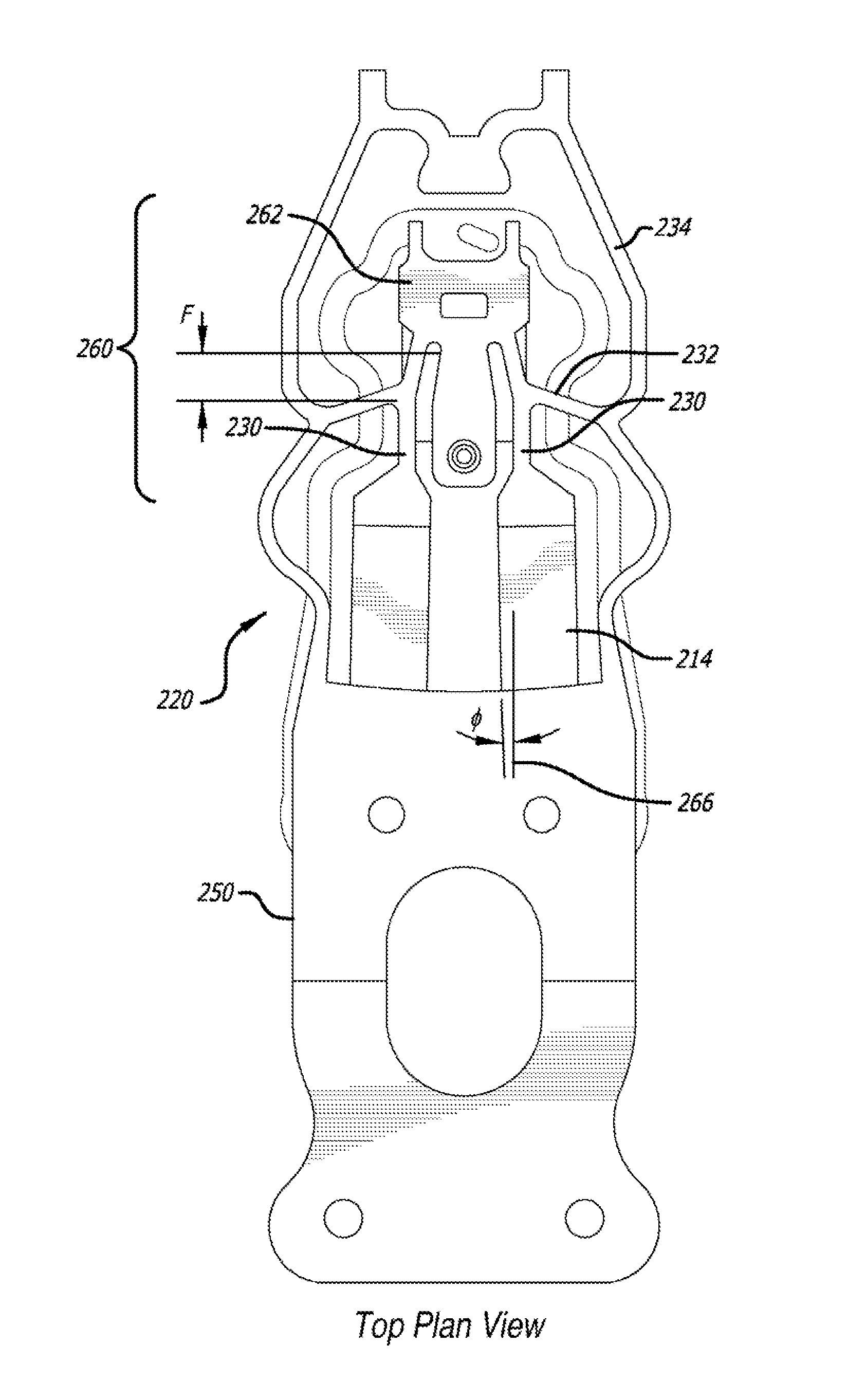

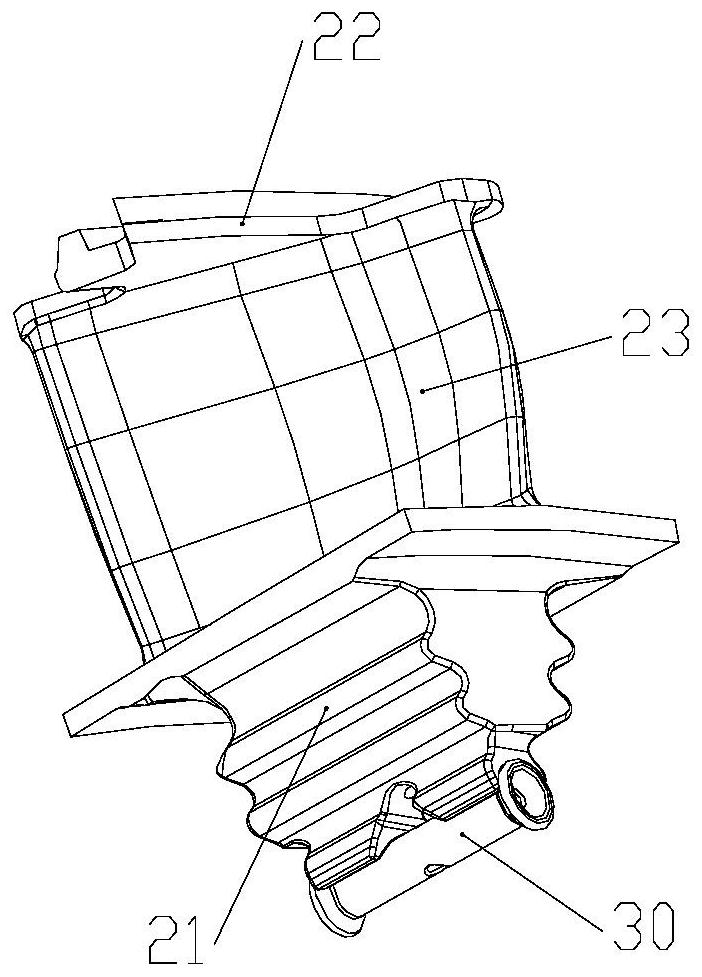

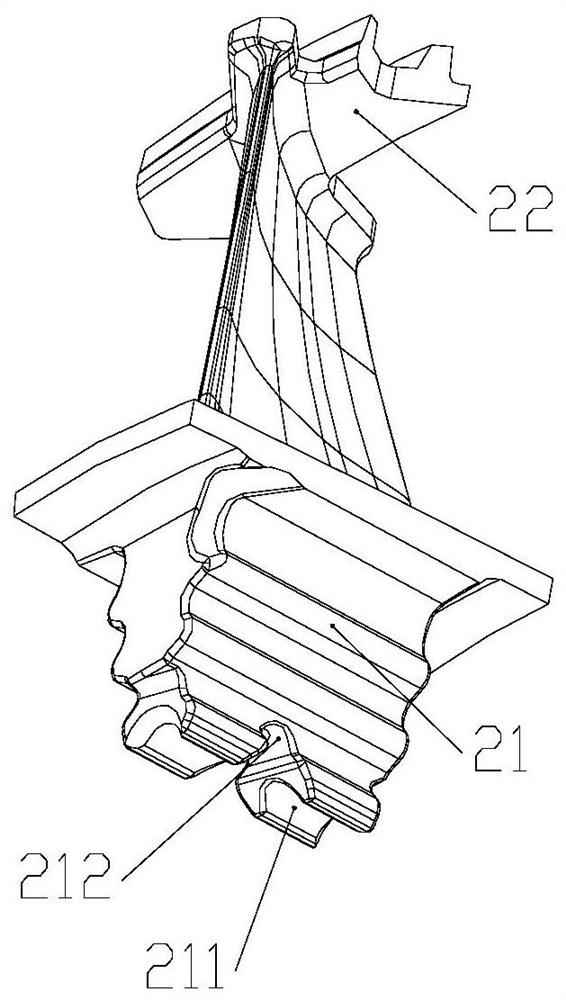

GSA suspension having slider clearance for shock performance

ActiveUS9190086B1Good stroke lengthHigh servo bandwidthArm with actuatorsMounting/attachment of transducer headLeading edgeDual stage

A dual stage actuated (DSA) suspension includes two PZT microactuators that are attached at their first ends to a non-gimbaled portion of the suspension, and are attached at their second ends to the gimbaled portion of the suspension such as the gimbal tongue through flexible connectors that can be formed integrally with the suspension's flexure. The flexible connectors are flexible enough so as not to interfere with the suspension's gimballing action. The flexible connectors transmit force from the PZTs to the gimbal as the PZTs expand and contract in order to rotate the gimbal and thus effect fine movements of the head slider. The flexible connectors are positioned laterally outwardly of the leading edge of the slider, thereby protecting both the connectors and the PZTs from damage induced by the slider striking the connectors during a shock event.

Owner:MAGNECOMP

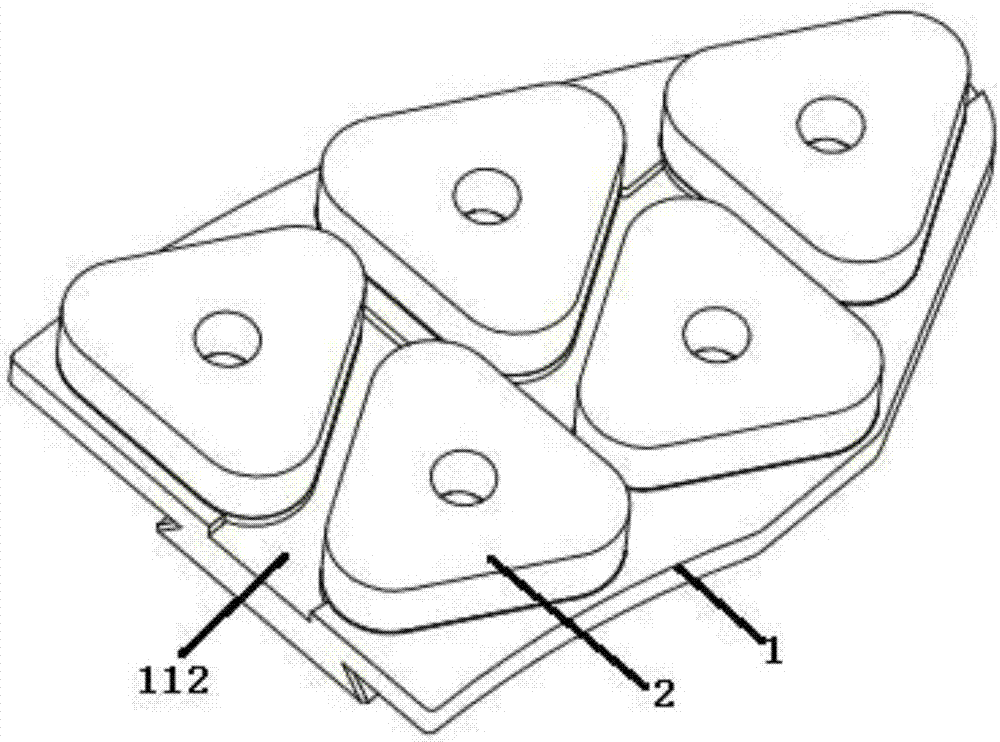

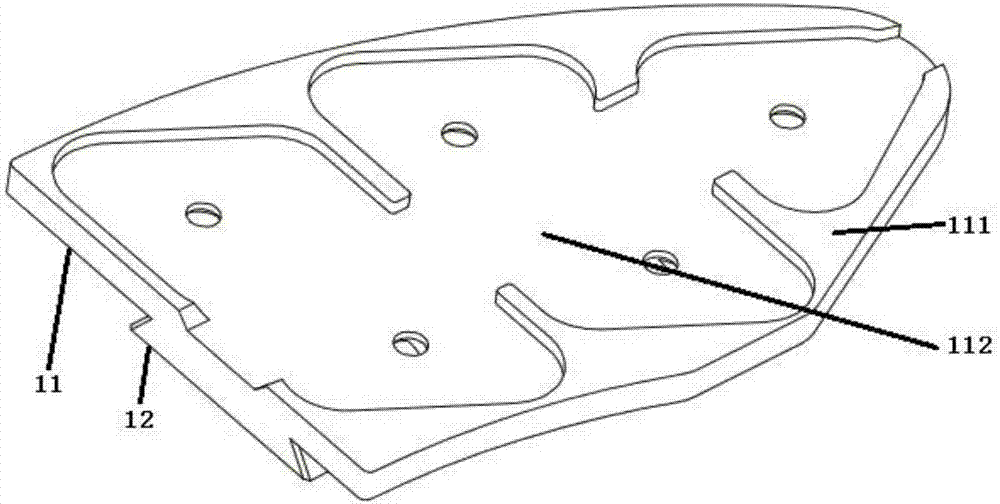

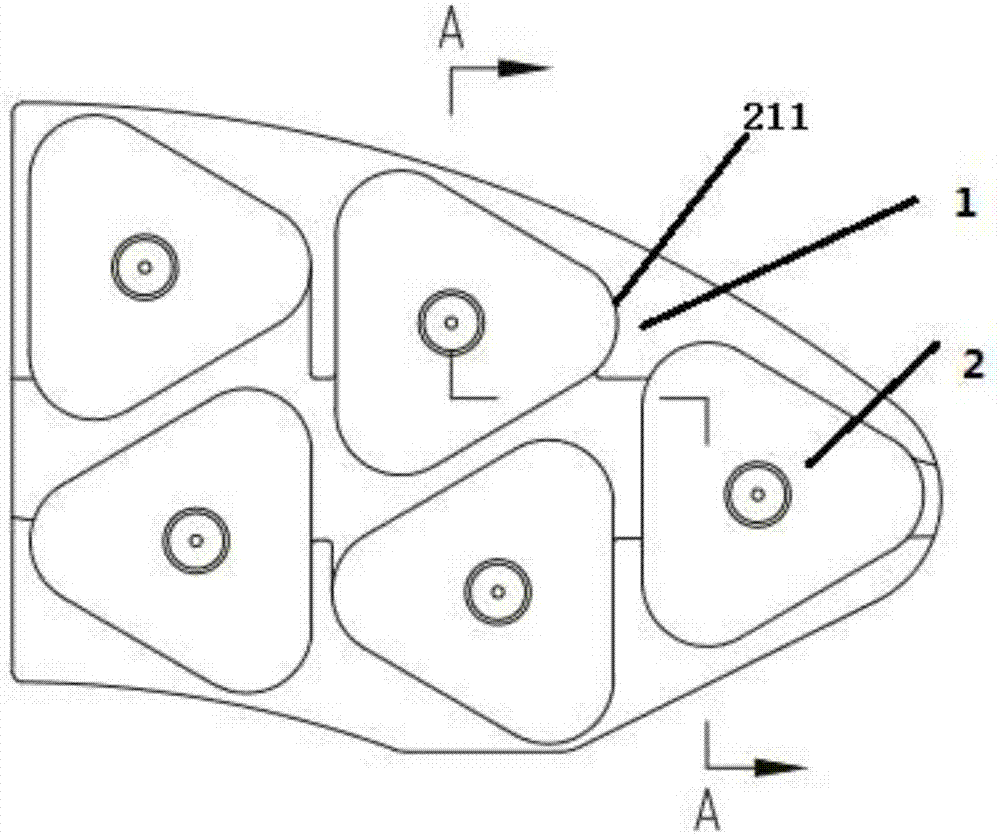

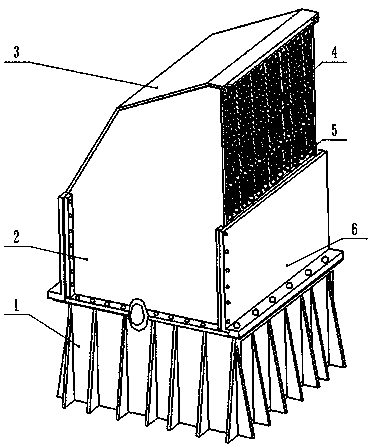

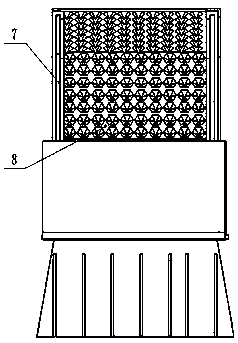

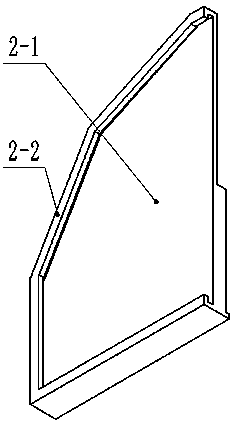

Powder metallurgy brake pad for D-series high-speed train set

PendingCN107061576AIncrease stiffnessImprove stress distributionFriction liningEngineeringMachining process

The invention discloses a powder metallurgy brake pad for a D-series high-speed train set. The powder metallurgy brake pad comprises a steel backboard, a dovetail block and a plurality of brake pad friction bodies. The steel backboard and the dovetail block are of an integrated forming structure, any brake pad friction body is fixed to the steel backboard through a big gasket and a rivet, each big gasket is located between the corresponding brake pad friction body and the steel backboard, and the positions, located on the edges of the brake pad friction bodies, of the steel backboard are provided with flanges matched with the brake pad friction bodies in shape. According to the brake pad, due to adoption of the structure of particular design, rigidity and reliability of the steel backboard are increased, the machining process and riveting process are simplified, the production cost of the brake pad is lowered, reliability of the brake pad is improved, the service life of the brake pad is prolonged, and the powder metallurgy brake pad can be widely applied to brake systems of various railway vehicles and high-speed D-series train sets.

Owner:湖南博科瑞新材料有限责任公司

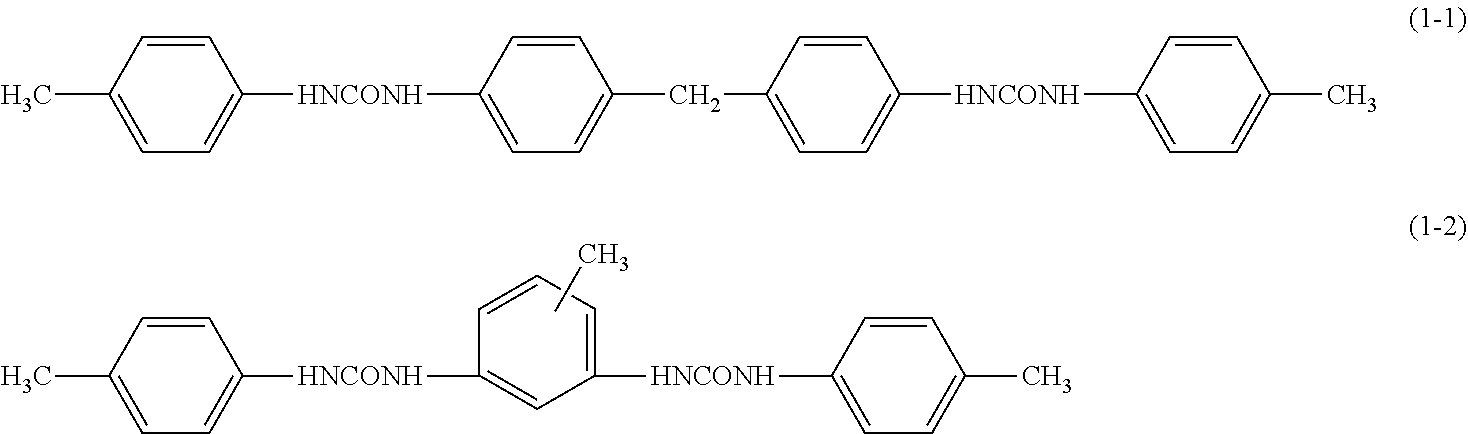

Grease composition for hub unit bearing

ActiveUS20130157915A1Reduced fretting wearImprove rust resistanceRolling contact bearingsCastorsSulfonateDiphenyl phosphate

The invention provides a grease composition for huh unit bearing, containing (a) an aromatic diurea thickener, (b) a base oil, (c) a metal salt of oxidized wax, (d) diphenyl hydrogen phosphate, and (e) at least one rust preventive selected from the group consisting of sulfonate rust preventives and carboxylic acid rust preventives. The grease composition of the invention shows excellent anti-fretting properties at low temperature, and at the same time, exhibit excellent rust preventing properties.

Owner:KYODO YUSHI CO LTD +1

Anti-fretting wear spacer grid with canoe-shaped spring

ActiveUS7835484B2Reduced fretting wearNuclear energy generationFuel element assembliesEngineeringGrid cell

Owner:KEPCO NUCLEAR FUEL CO LTD

Roller bearing backing ring assembly

InactiveCN102619881AReduce axial movementReduced fretting wearRolling contact bearingsRailway vehiclesMechanical engineeringRoller bearing

A novel assembly for a railcar axle bearing is presented. The assembly includes a backing ring affixed to the fillet of the journal of an axle and a locking ring for further affixing the backing ring the journal. The locking ring has an inboard end affixed to the dust guard of the axle and an outboard end for engaging the backing ring.

Owner:AMSTED RAIL CO INC

Grease composition for automobile wheel bearing

InactiveUS20110086785A1Prolong lifeReduced fretting wearBearing componentsLubricant compositionBase oilAromatic hydrocarbon

The present invention provides a grease composition for automobile wheel bearings, which contains (a) an urea thickener represented by general formula (1); R1—NHCONH—R2—NHCONH—R3 (wherein R1 and R3 may be the same or different from each other and are each independently an aromatic hydrocarbon group having 6 to 12 carbon atoms, and R2 represents an aromatic hydrocarbon group having 6 to 15 carbon atoms); (b) an organic molybdenum compound; and (c) a base oil. The composition of the present invention can extend the flaking life and lubrication life, and reduce the fretting wear.

Owner:NTN CORP +1

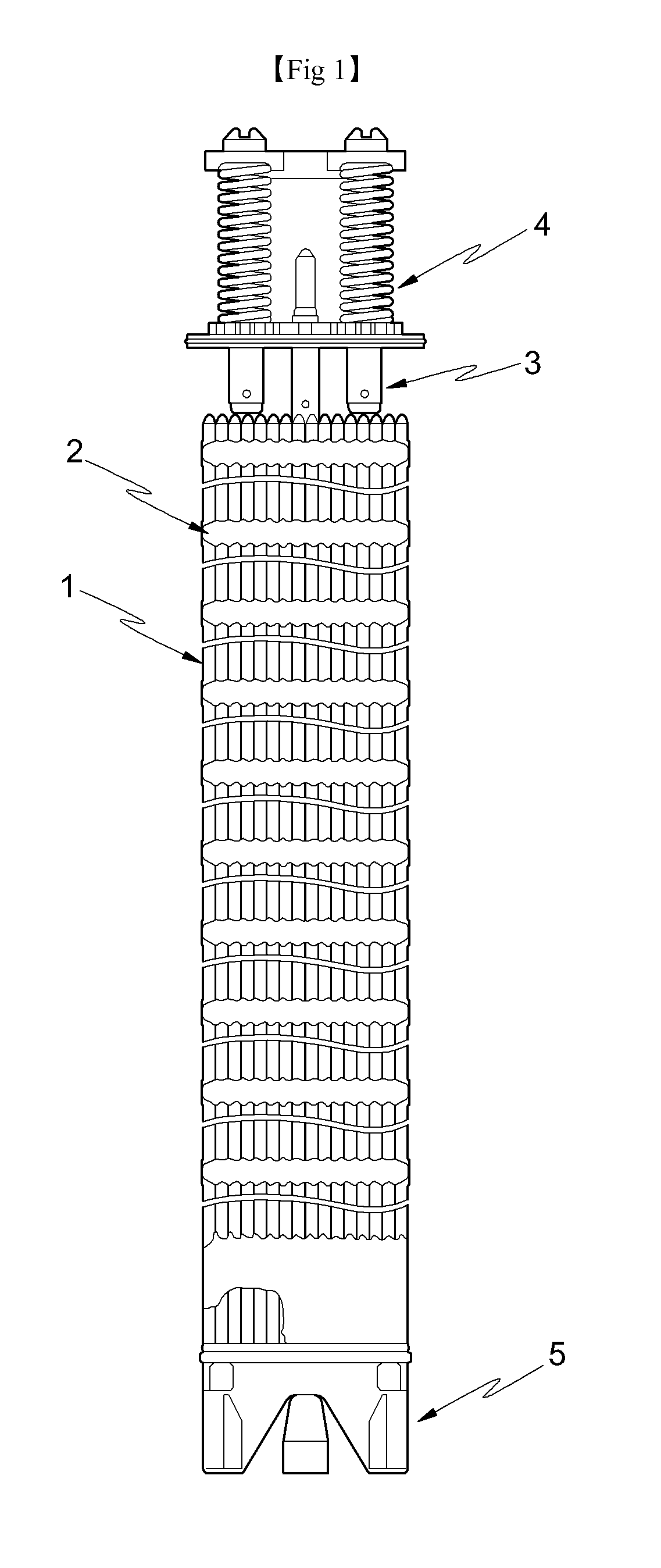

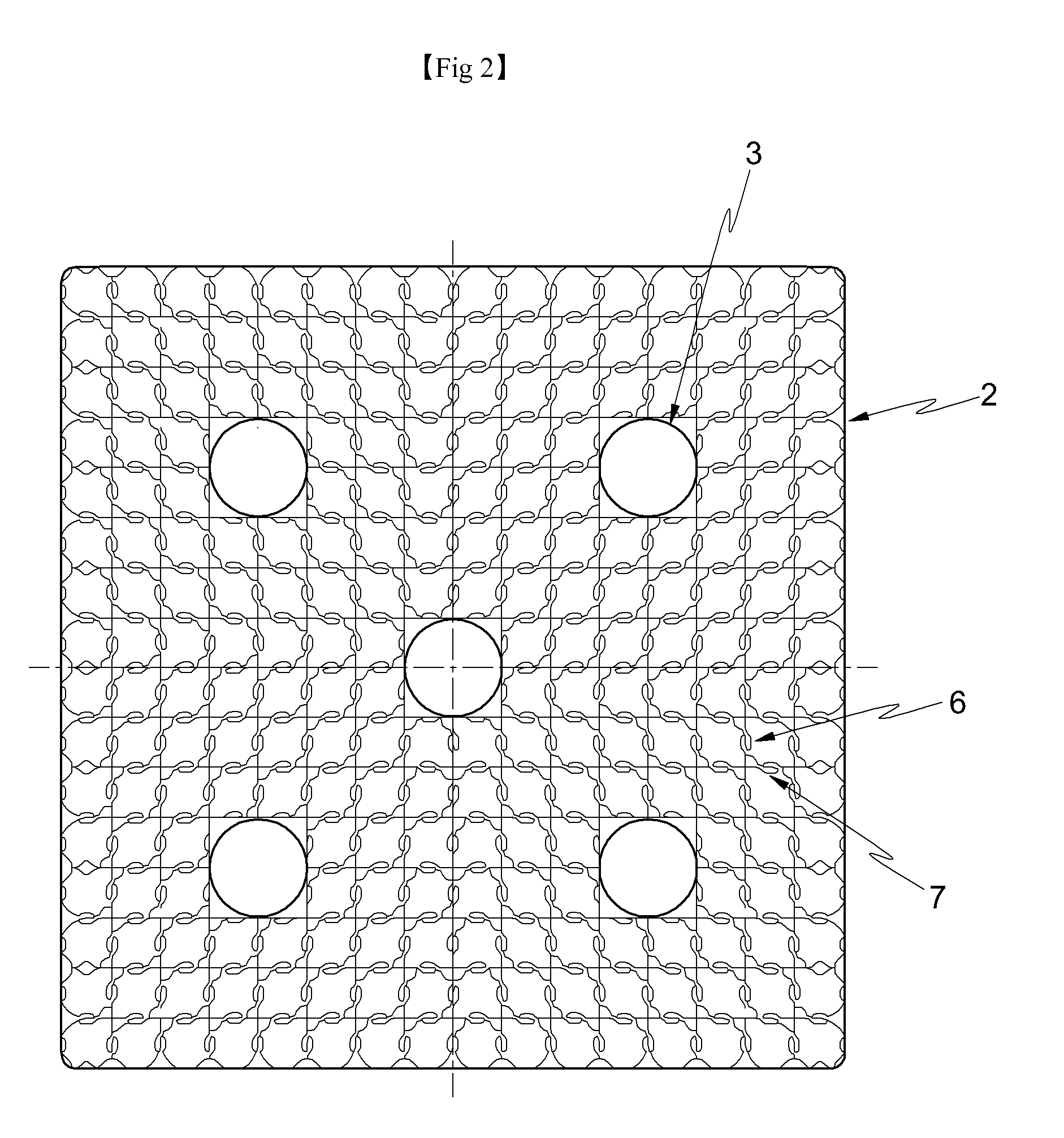

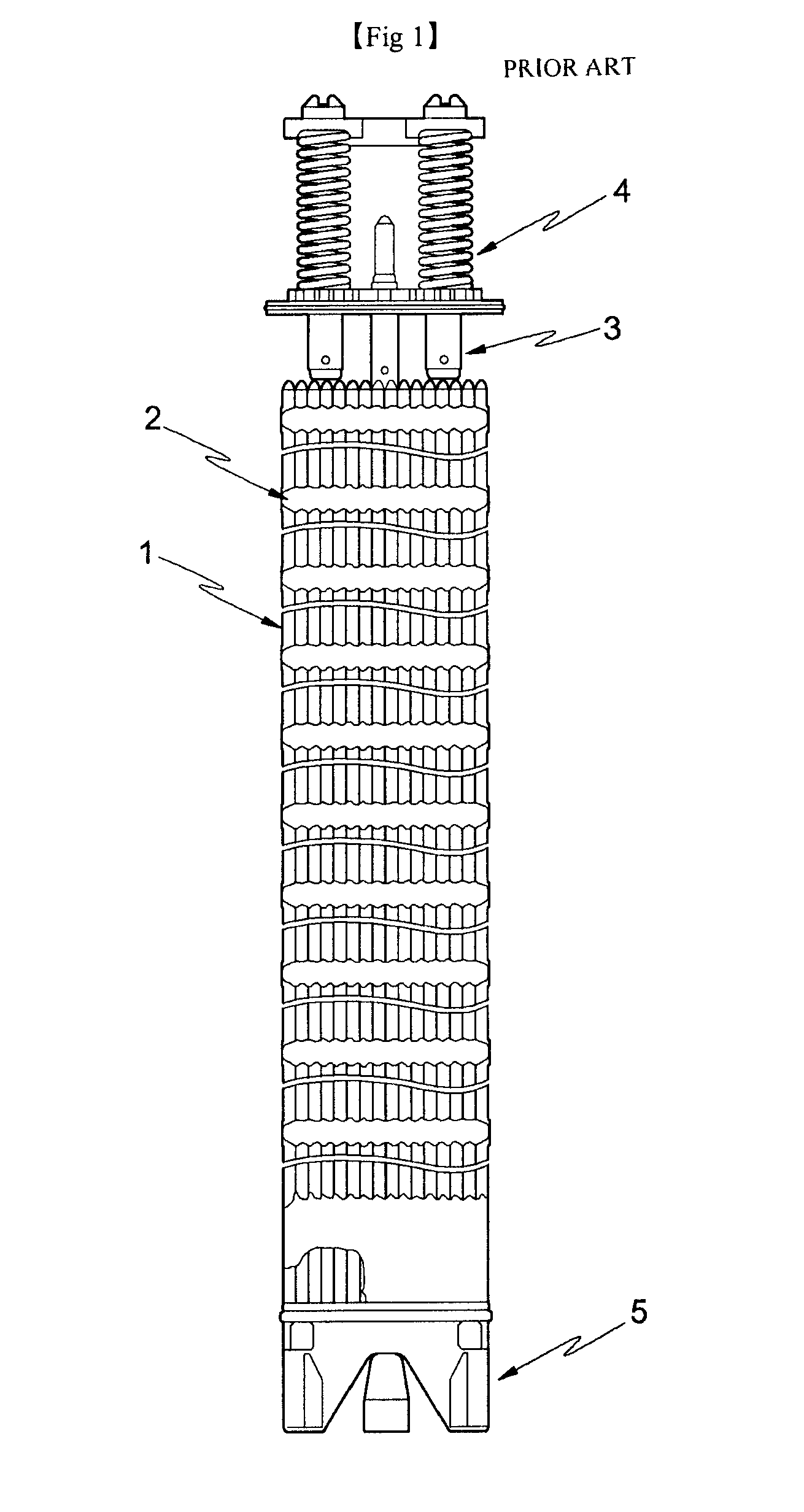

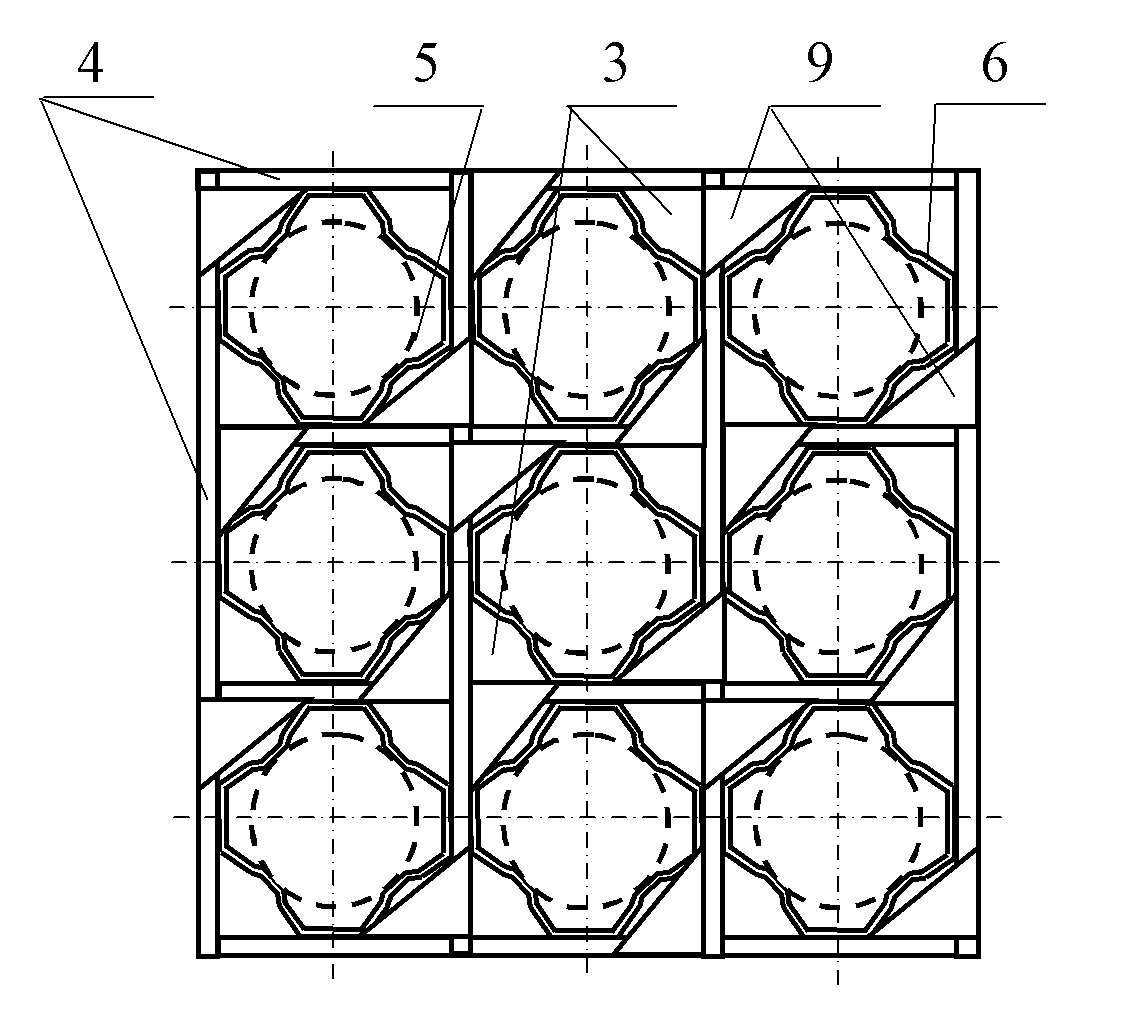

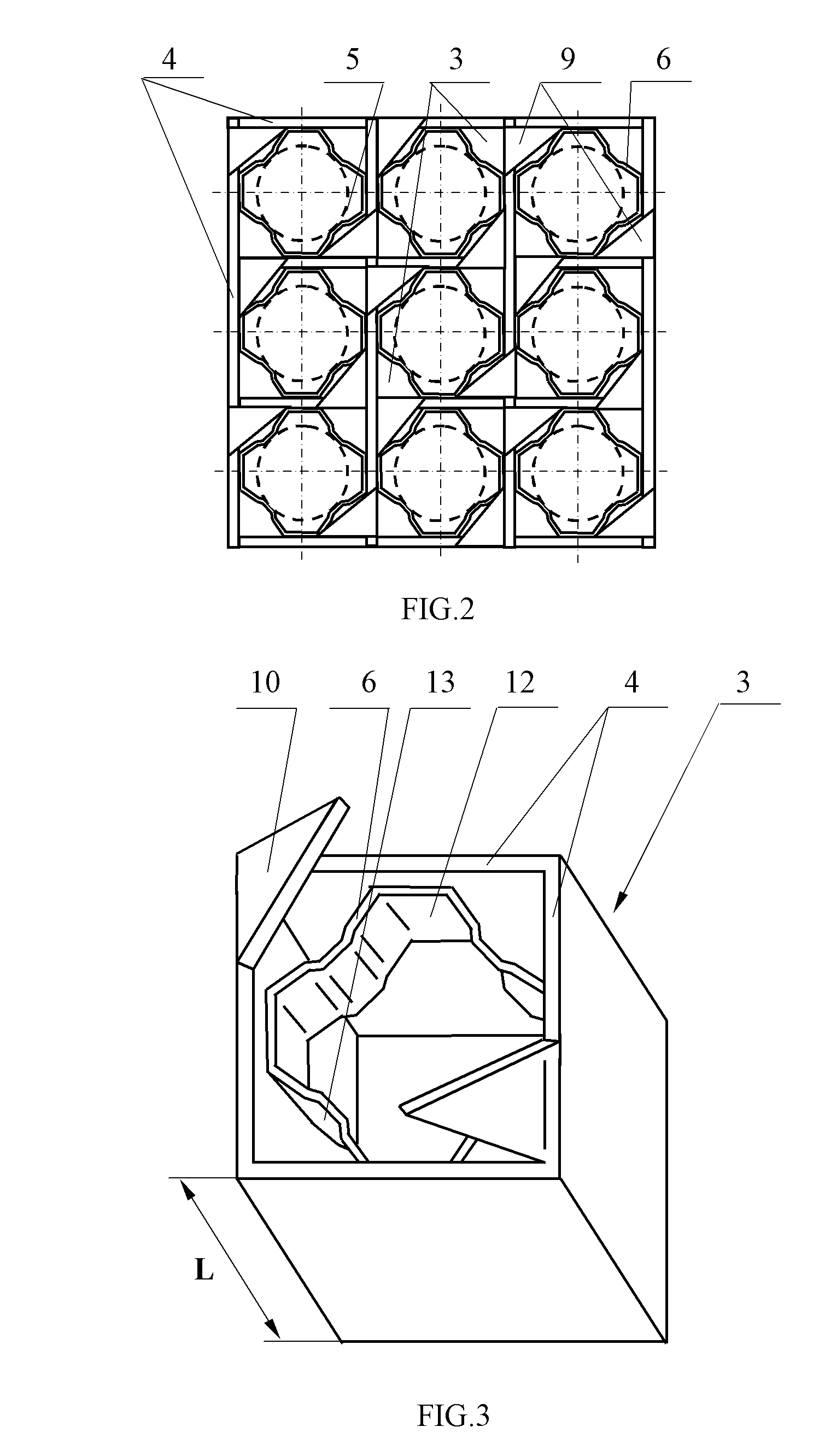

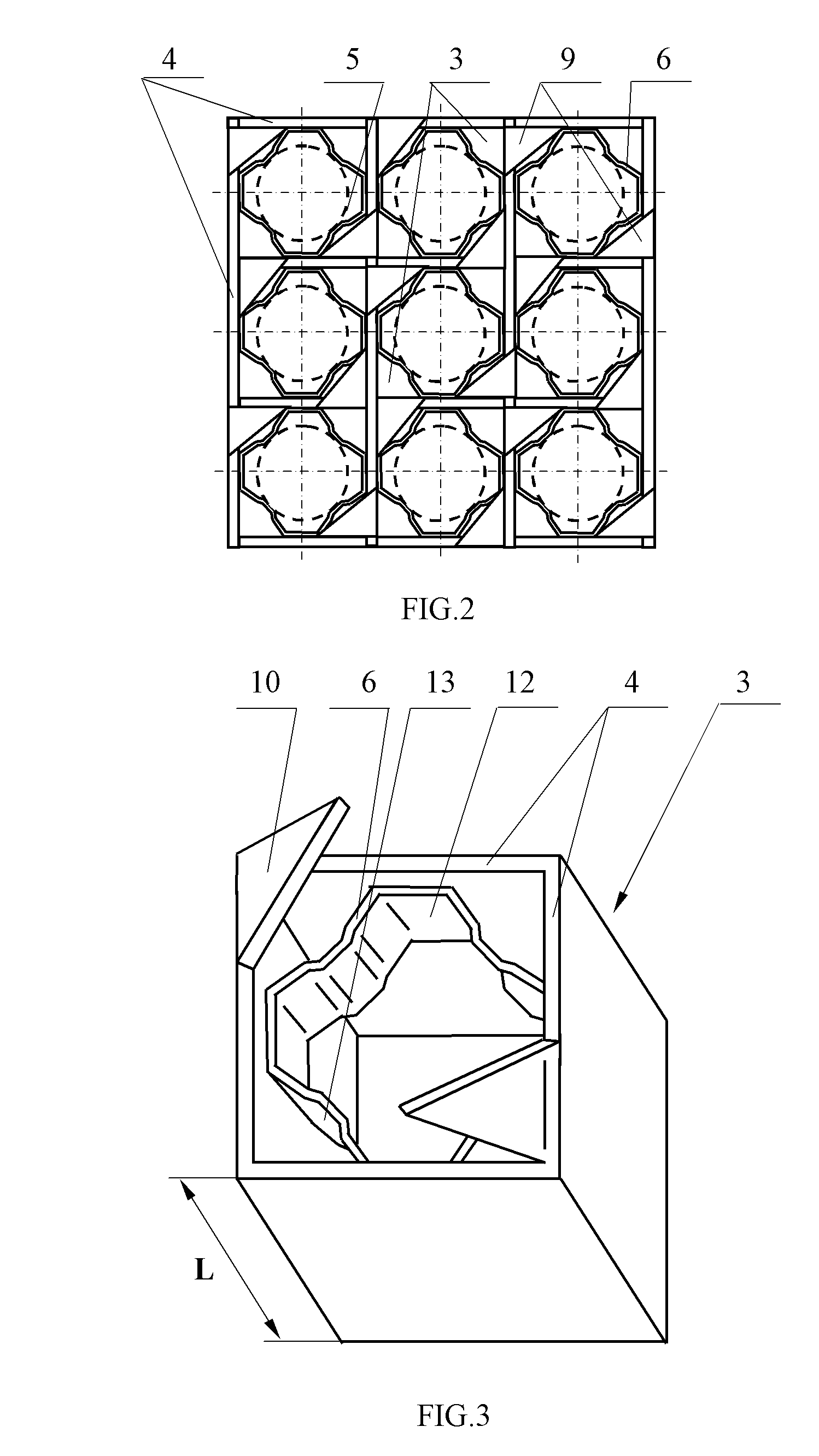

Fuel assembly and plug-in distance element

ActiveUS7792236B2Increase stiffnessReduce assemblyNuclear energy generationFuel element assembliesNuclear reactorElectrical battery

This invention relates to nuclear engineering and may be used in structures of nuclear fuel assemblies, especially those used in PWR and BWR nuclear reactors. A fuel assembly comprises spacing grids comprising cells formed by orthogonal crossing plates. An insertable spacing element is installed in each cell, which is designed for fixing the fuel rod passing through the cell. In the spacing grids that are arranged between the first spacing grid and the last spacing grid downstream the coolant flow at least some cells, through which the fuel rods pass, are provided with deflectors designed for mixing the coolant flow. The insertable spacing element comprises a shell, which has a cross-section in the form of an octagon formed by four facets that are rounded and convex in the direction from the center of said element and by four facets located therebetween that are shaped and concave toward the center of the said element. The result is that cell stiffness is increased, and hydraulic resistance to a coolant flow is reduced.

Owner:OTKRYTOE AKTSIONERNOE OBSCHESTVO TVEL +1

Fuel assembly and plug-in distance element

ActiveUS20090067566A1Increase stiffnessReduce assemblyNuclear energy generationFuel element assembliesNuclear reactorElectrical battery

This invention relates to nuclear engineering and may be used in structures of nuclear fuel assemblies, especially those used in PWR and BWR nuclear reactors. A fuel assembly comprises spacing grids comprising cells formed by orthogonal crossing plates. An insertable spacing element is installed in each cell, which is designed for fixing the fuel rod passing through the cell. In the spacing grids that are arranged between the first spacing grid and the last spacing grid downstream the coolant flow at least some cells, through which the fuel rods pass, are provided with deflectors designed for mixing the coolant flow. The insertable spacing element comprises a shell, which has a cross-section in the form of an octagon formed by four facets that are rounded and convex in the direction from the center of said element and by four facets located therebetween that are shaped and concave toward the center of the said element. The result is that cell stiffness is increased, and hydraulic resistance to a coolant flow is reduced.

Owner:OTKRYTOE AKTSIONERNOE OBSCHESTVO TVEL +1

DSA suspension with microactuators extending to gimbal through flexible connectors

ActiveUS9129624B1Convenient lengthHigh bandwidthArm with actuatorsMounting heads on rotating supportDual stageMicro actuator

Owner:MAGNECOMP

Novel valve guide pipe structure

InactiveCN108412571AStructural advantageImprove reliabilityMachines/enginesLift valveEngineeringHigh power density

The invention provides a novel valve guide pipe structure. The novel valve guide pipe structure comprises a valve guide pipe body, the middle of the valve guide pipe body is provided with a guide pipehole, the middle of the outer side of the valve guide pipe body is provided with an assembling rabbet, the position, on the upper side of the assembling rabbet, of the outer side of the valve guide pipe body is circumferentially provided with a plurality of stepped bosses, and the assembling rabbet is provided with a groove inwards in the circumferential direction. The novel valve guide pipe structure has the beneficial effects of being suitable for an air cylinder cover compact in structure, high in reliability and capable of being popularized to other high power density engine air cylindercovers.

Owner:CHINA NORTH ENGINE INST TIANJIN

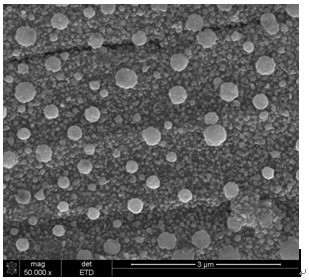

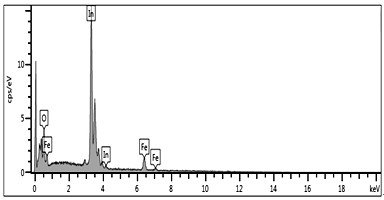

Indium composite microcrystal bump texture

PendingCN113540934AReduce thermal stressReduce fretting fatigueActive medium shape and constructionSolid state laser constructional detailsIndiumMaterials science

The invention relates to an indium composite microcrystal salient point textur. According to the invention, a composite material layer containing more than 60% (Wt%) of indium and more than 70% (Wt%) of indium and iron is arranged on the surface of a part, and a plurality of salient point microcrystals are arranged on the surface of the composite material layer. The height of each salient point microcrystal is larger than 100 nm and smaller than 500 microns, the top of each salient point microcrystal with the diameter larger than 100 nm and smaller than 500 microns is spherical or approximately spherical, the indium content exceeds 60% (Wt%), the total indium and iron content exceeds 70% (Wt%), and the salient point microcrystals and the composite material layer are integrated. And the shape and the size of the salient point microcrystal can be changed.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

Tire gauge part

ActiveCN113504002AGood cooling performanceReduce thermal stressInflated body pressure measurementMetal layered productsAutomotive engineeringIndium

The invention discloses a tire gauge part. A composite material layer containing more than 60% (Wt%) of indium, more than 8% (Wt%) of iron and more than 70% (Wt%) of indium and iron is arranged on the surface of the tire gauge part, and a plurality of salient point microcrystals are arranged on the surface of the composite material layer. The height of each salient point microcrystal is larger than 100 nm and smaller than 500 microns, the top of each salient point microcrystal with the diameter larger than 100 nm and smaller than 500 microns is spherical or approximately spherical, the indium content exceeds 60% (Wt%), the iron content exceeds 8% (Wt%), the total indium and iron content exceeds 70% (Wt%), and the salient point microcrystals and the composite material layer are integrated. The part surface composite material layer and the base material are integrated. The material layer attached to each small hole is removed to form the tire gauge part.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

Preparation method of medical Ti6Al4V artificial implant

ActiveCN109550077AHigh hardnessImprove structural stabilityAdditive manufacturing apparatusTissue regenerationStress protectionAlloy

The invention relates to a preparation method of a medical Ti6Al4V artificial implant. The preparation method comprises the following steps of with Ti6Al4 alloy powder as a raw material, preparing theraw material into block-shaped Ti6Al4V alloy by an electron beam melting deposit method; and performing heat treatment on the block-shaped Ti6Al4V alloy to obtain the implant. The tensile strength achieves 960-990MPa, the yield strength can achieve 940-970MPa, the modulus of elasticity can achieve 30-40GPa and is close to the modulus of bones of human bodies, and the stress shielding and the stress protection are reduced.

Owner:SHANGHAI JIAO TONG UNIV

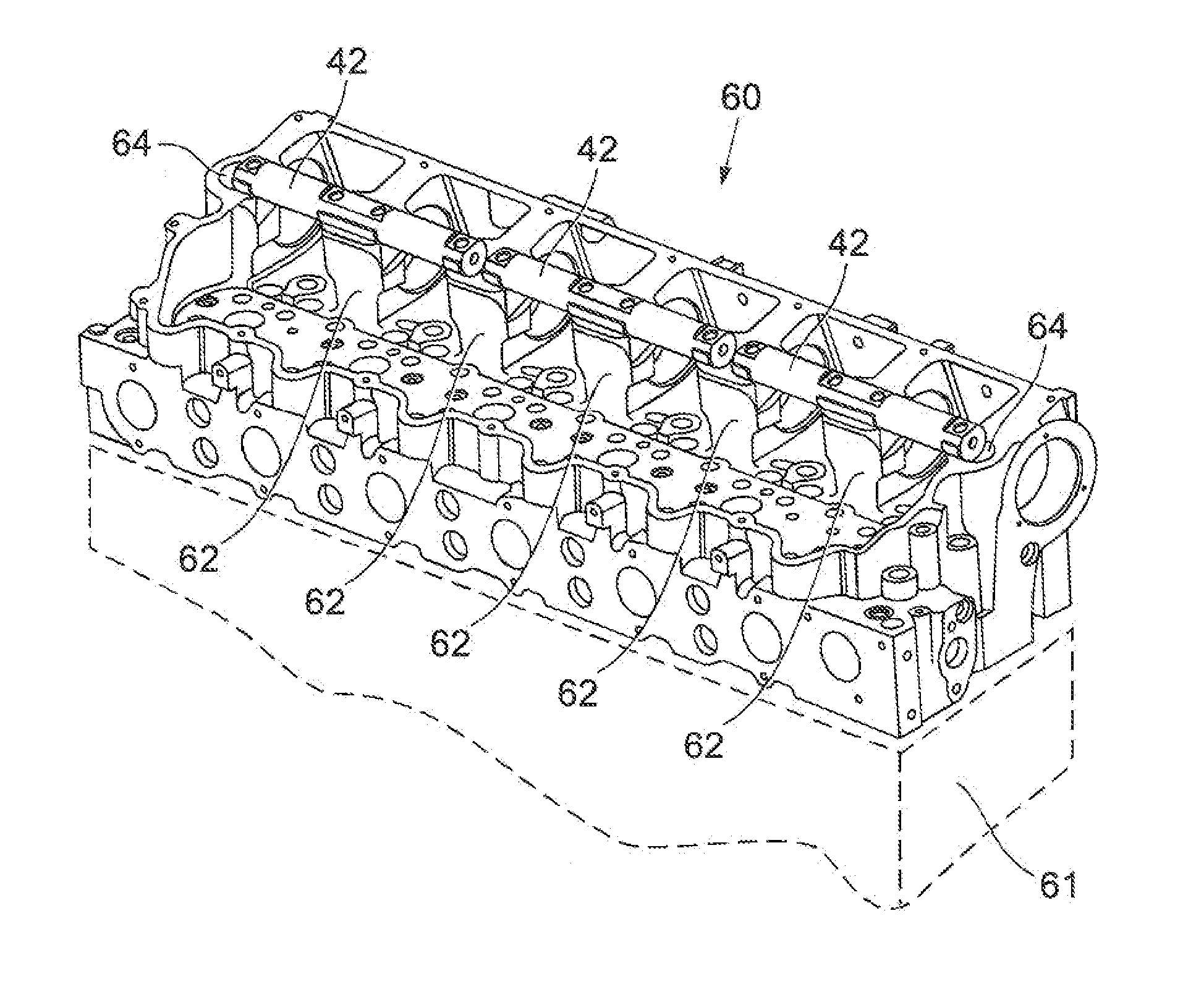

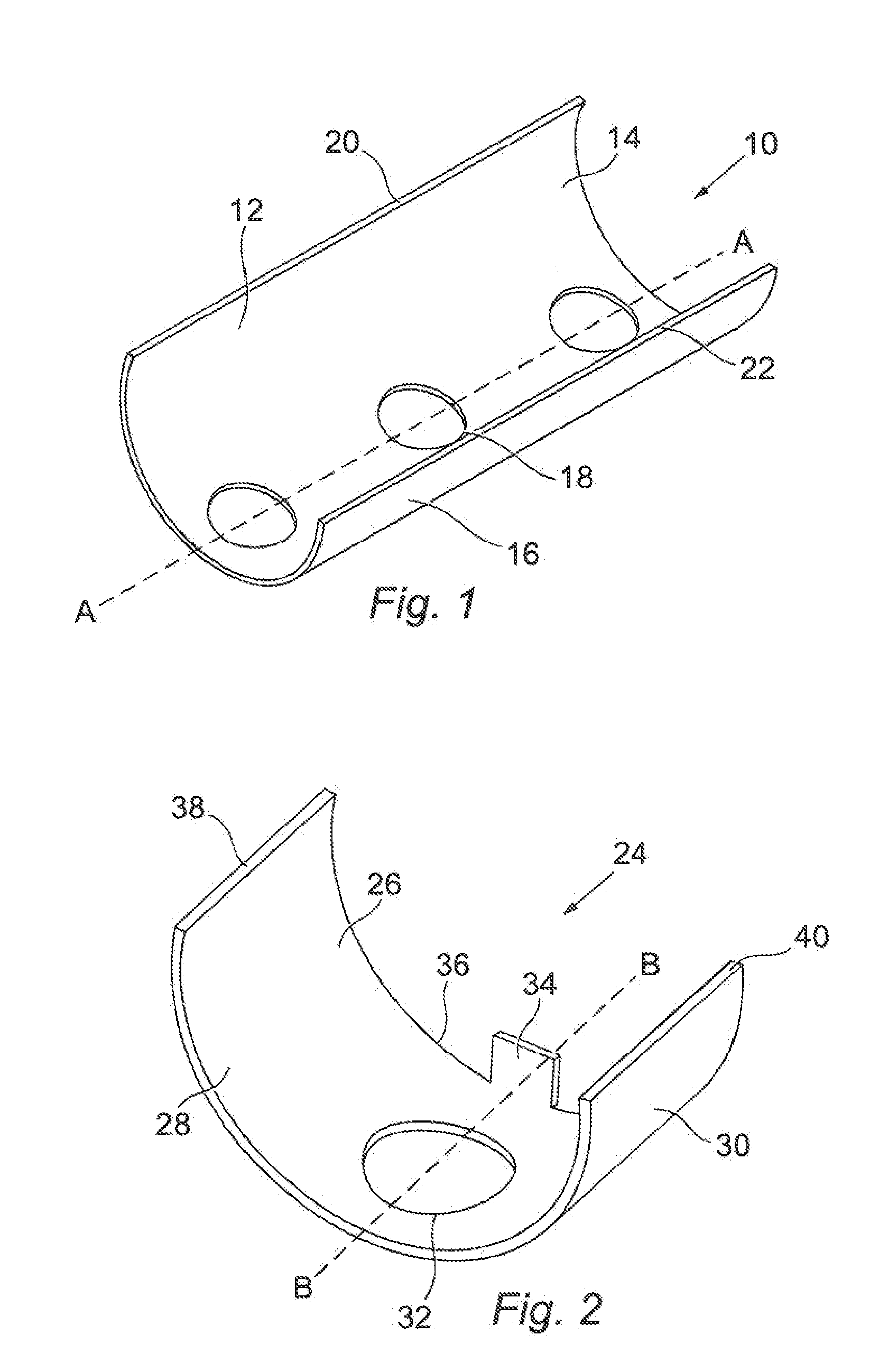

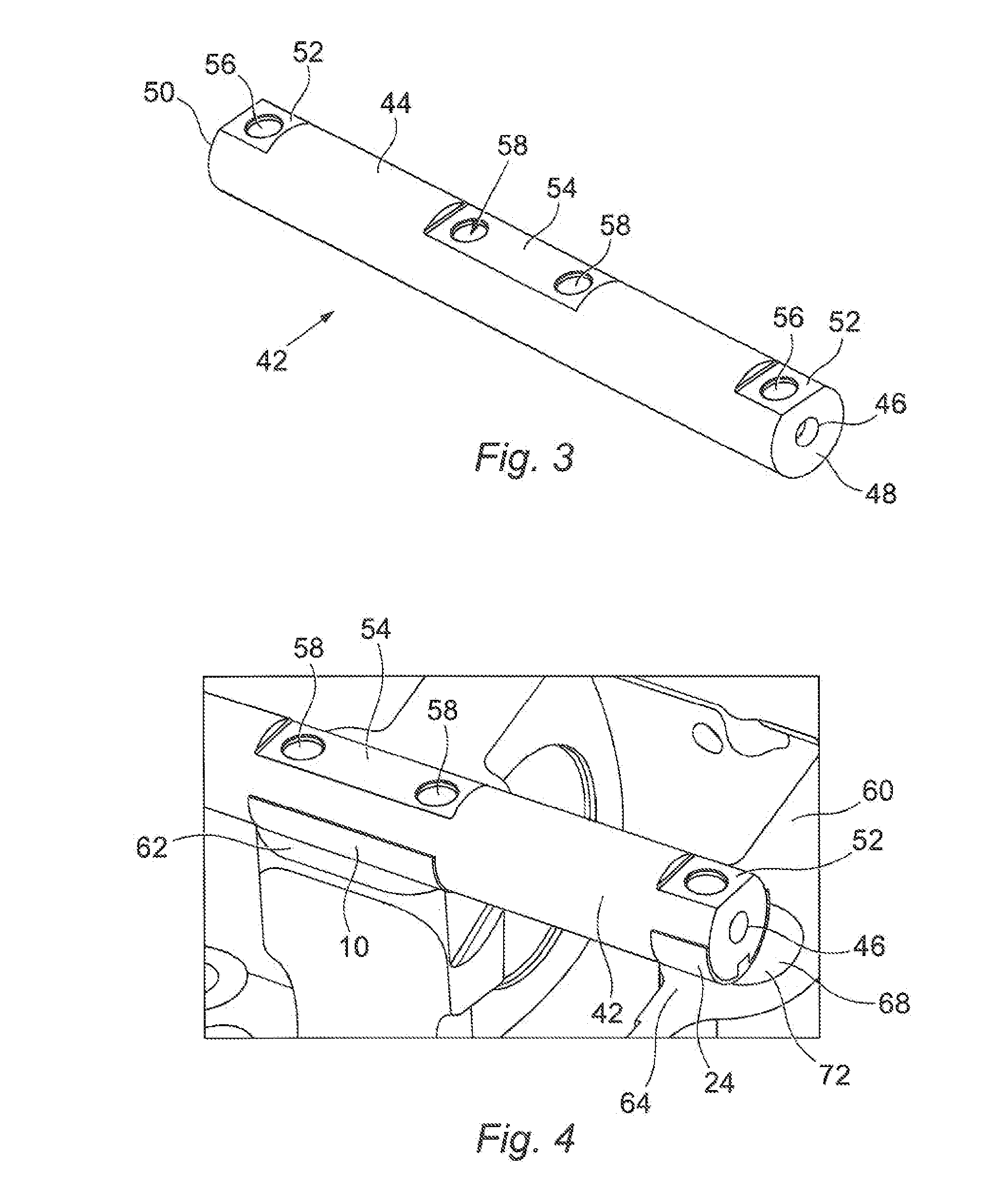

Rocker shaft shim

ActiveUS20120152196A1Reduced fretting wearValve arrangementsPig casting plantsCylinder headEngineering

The present disclosure relates to shims 10, 24 adapted for placement between a rocker shaft 42 and rocker shaft mounts 62, 64. The rocker shaft mounts 62, 64 project from the cylinder head 60 of an internal combustion engine. The shims 10, 24 are composed of a copper alloy, preferably bronze.

Owner:CATERPILLAR INC

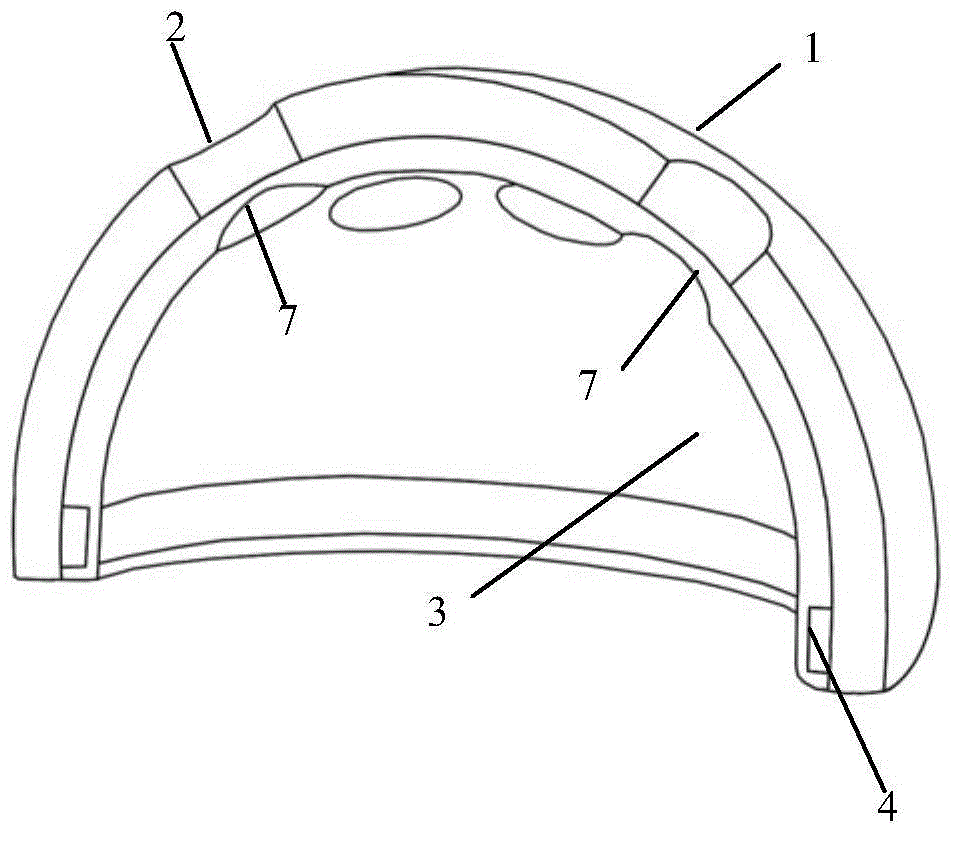

Knee joint tibial system and knee joint medical device

The invention belongs to the technical field of medical instruments, and discloses a knee joint tibial system. The knee joint tibial system is provided with a tibial bone support, wherein the tibial bone support is clamped and fixed with a first tibial bone pad and a second tibial bone pad through a tibial bone support groove. The tibial support structure of the knee joint tibial system is simplein design, and the tibial spacer can be conveniently installed into the tibial support structure, and the operation process is simple. Compared with the products on the market, it is not necessary touse the clipping tool to clip in more forcefully, nor will it cause damage to the tibial structure during the clipping process; the tibial pad can be fixed stably by setting the tibial pad structure,which provides a stable structure surrounded by the tibial pad, so that the tibial pad can be fixed stably, the fretting wear between the tibial pad and the tibial pad can be effectively reduced, andthe phenomenon of osteolysis around the joint system after the operation can be reduced. The tibia bracket of the knee joint tibial system is simple to manufacture and low in cost, can be stably produced, can be processed by forging castings, and can also be directly processed by bars.

Owner:北京华康天怡生物科技有限公司

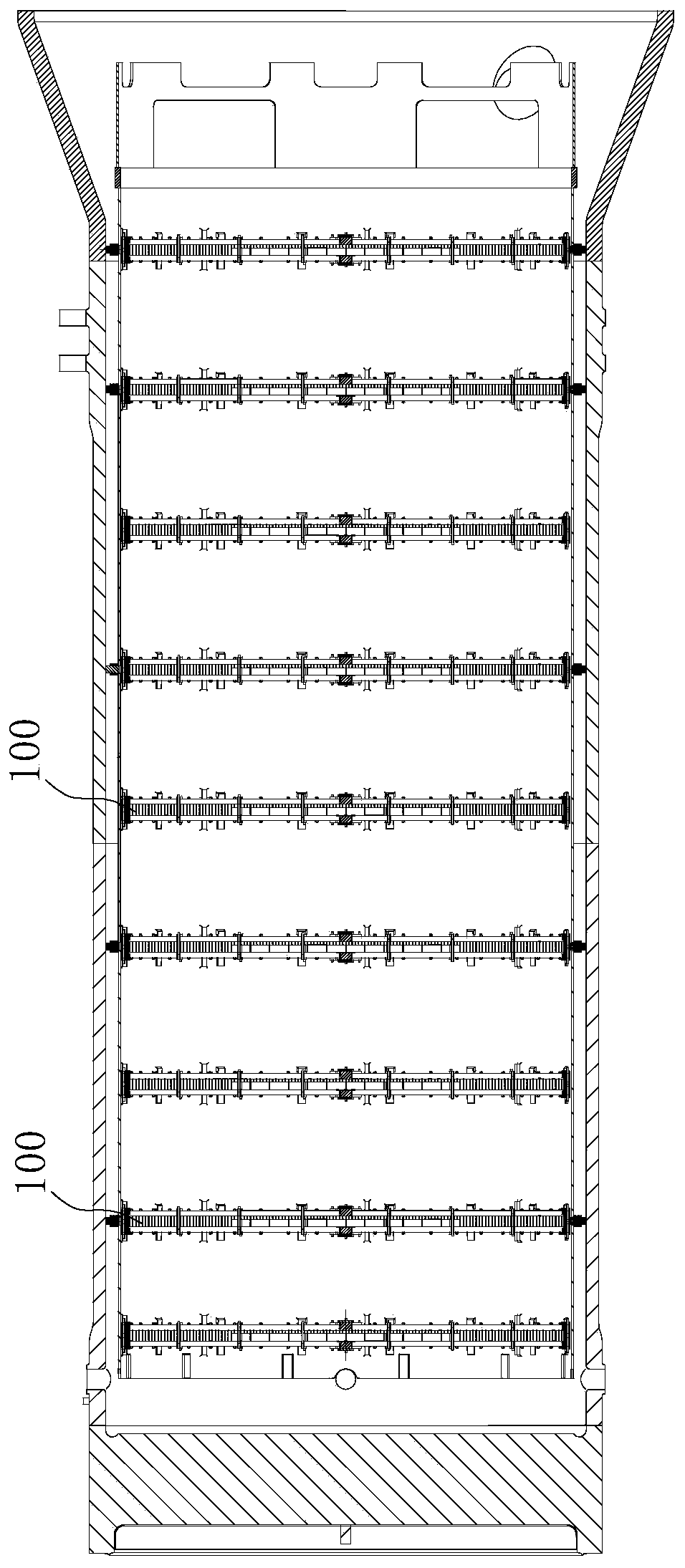

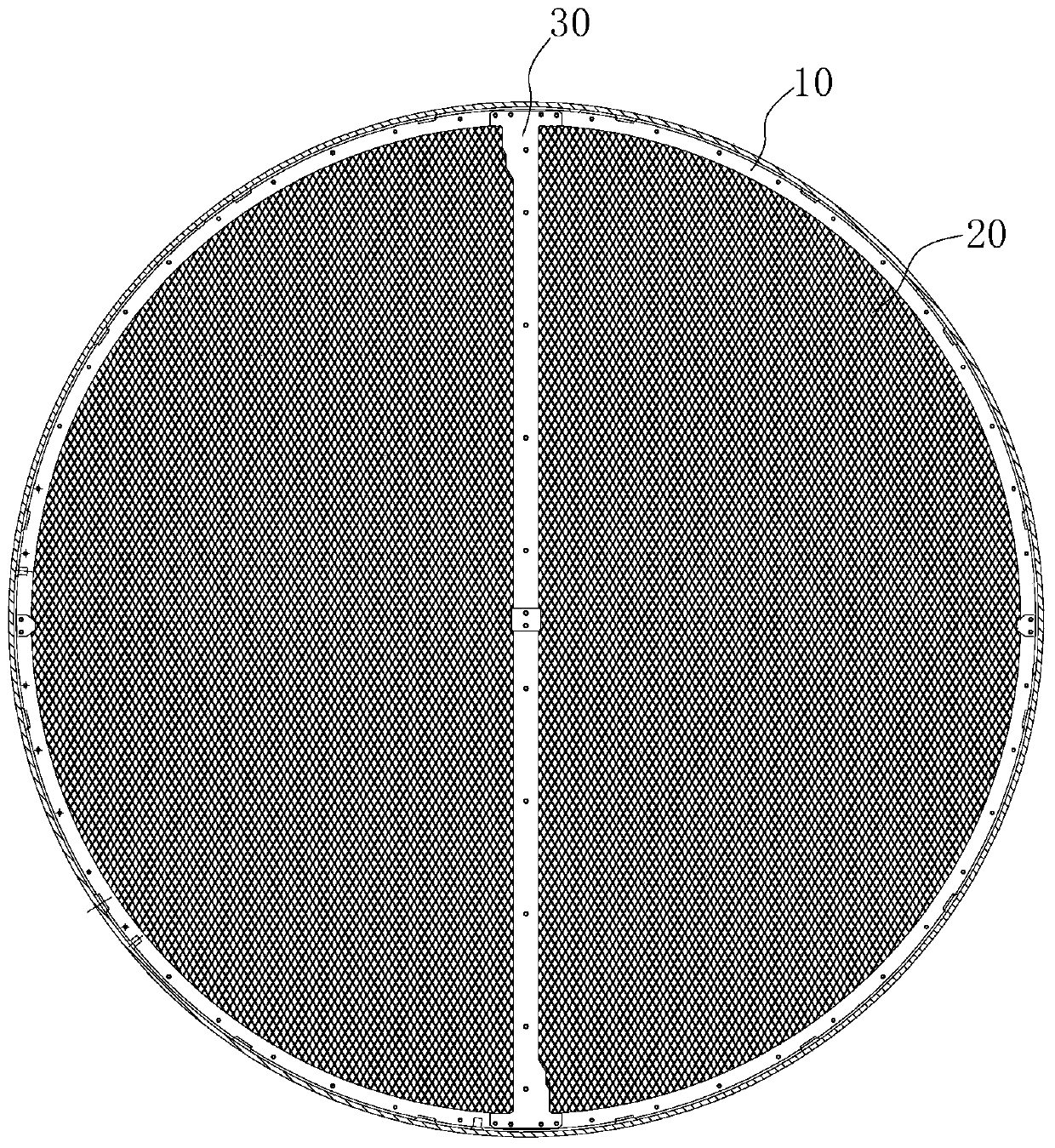

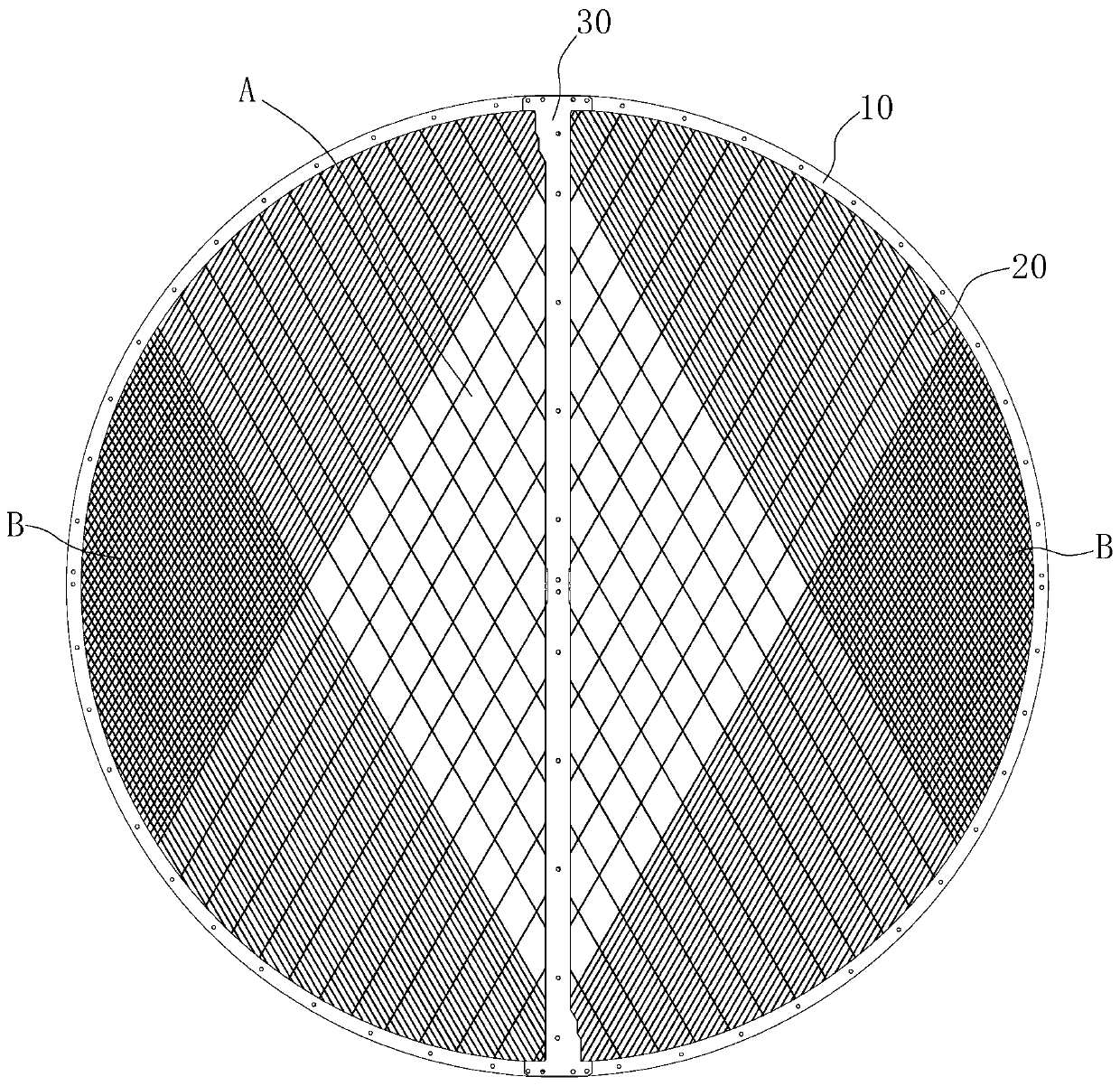

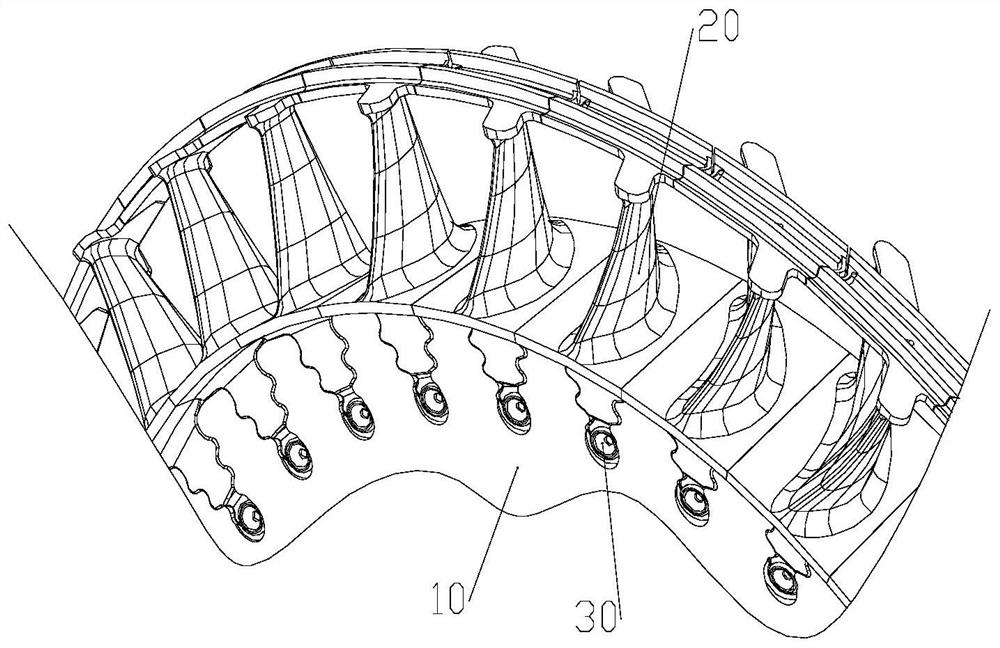

Grid supporting piece

PendingCN111256511AEffectively fixedCompensation for thermal expansionHeat exchanger casingsSteam boilersThermal dilatationEngineering

The invention discloses a grid supporting piece. The grid supporting piece comprises an annular frame and a grid assembly arranged in the annular frame, the grid assembly comprises a plurality of highsupporting strips and a plurality of low supporting strips, the high supporting strips are provided with a plurality of first inserting grooves formed at intervals, the high supporting strips comprise first high supporting strips and second high supporting strips, a plurality of second inserting grooves are formed between every two adjacent first inserting grooves in the high supporting strips, and the low supporting strips are inserted into the second inserting grooves of the first high supporting strips and the second high supporting strips in an embedded mode. According to the grid supporting piece, the first high supporting strips and the second high supporting strips are mutually inserted and embedded, the high supporting strips and the low supporting strips are mutually inserted andembedded, a self-locking stable supporting assembly is formed, the high supporting strips and the low supporting strips are in a strip shape, the structure formed by mutual embedding of the high supporting strips and the low supporting strips has certain flexibility, uneven thermal expansion of a heat exchange pipe can be compensated, the grid supporting piece has good performance of preventing the heat exchange pipe from vibrating, so that the possibility of micro-vibration abrasion is reduced, and the grid supporting piece is applied to the technical field of steam generators.

Owner:DONGFANG (GUANGZHOU) HEAVY MASCH CO LTD

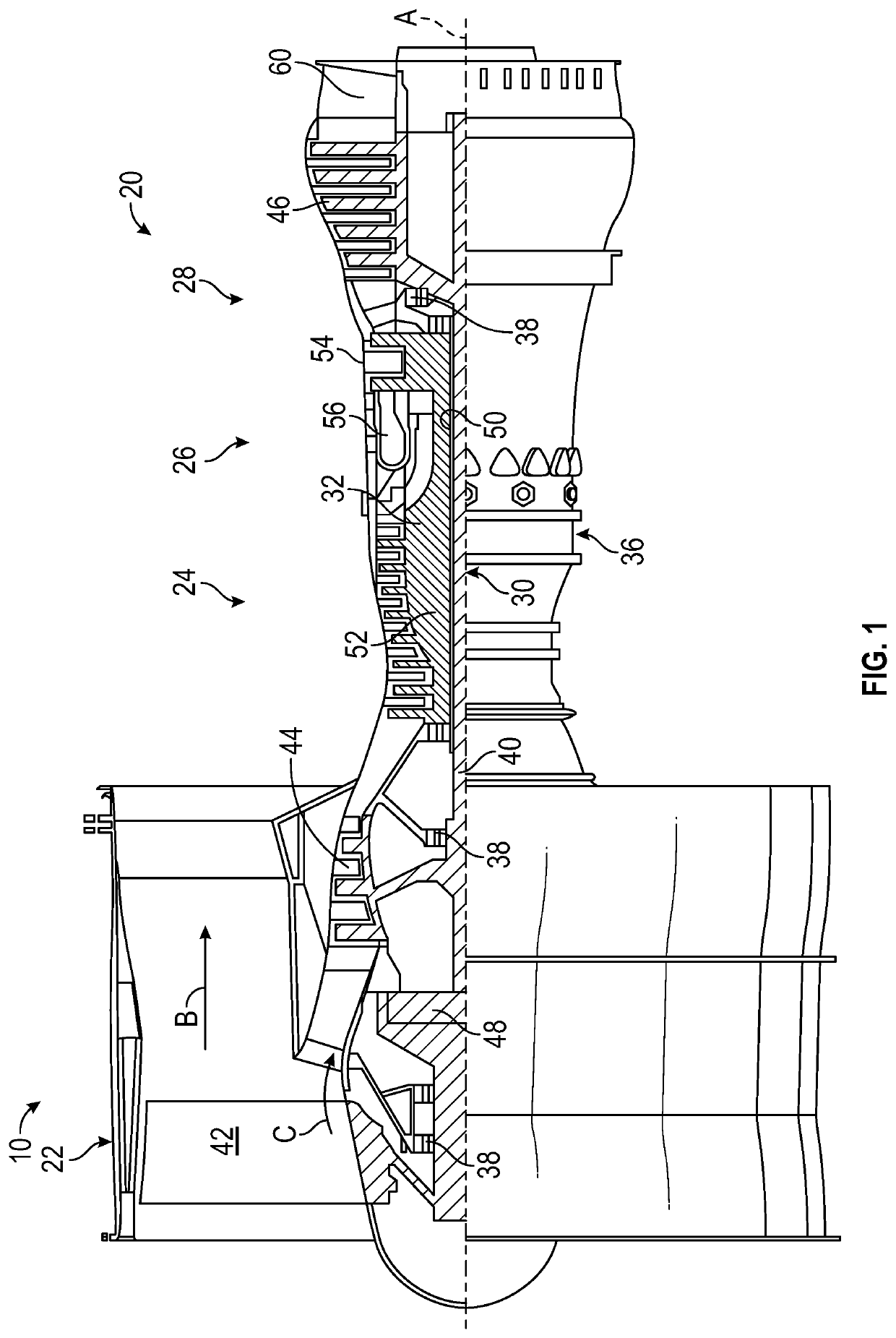

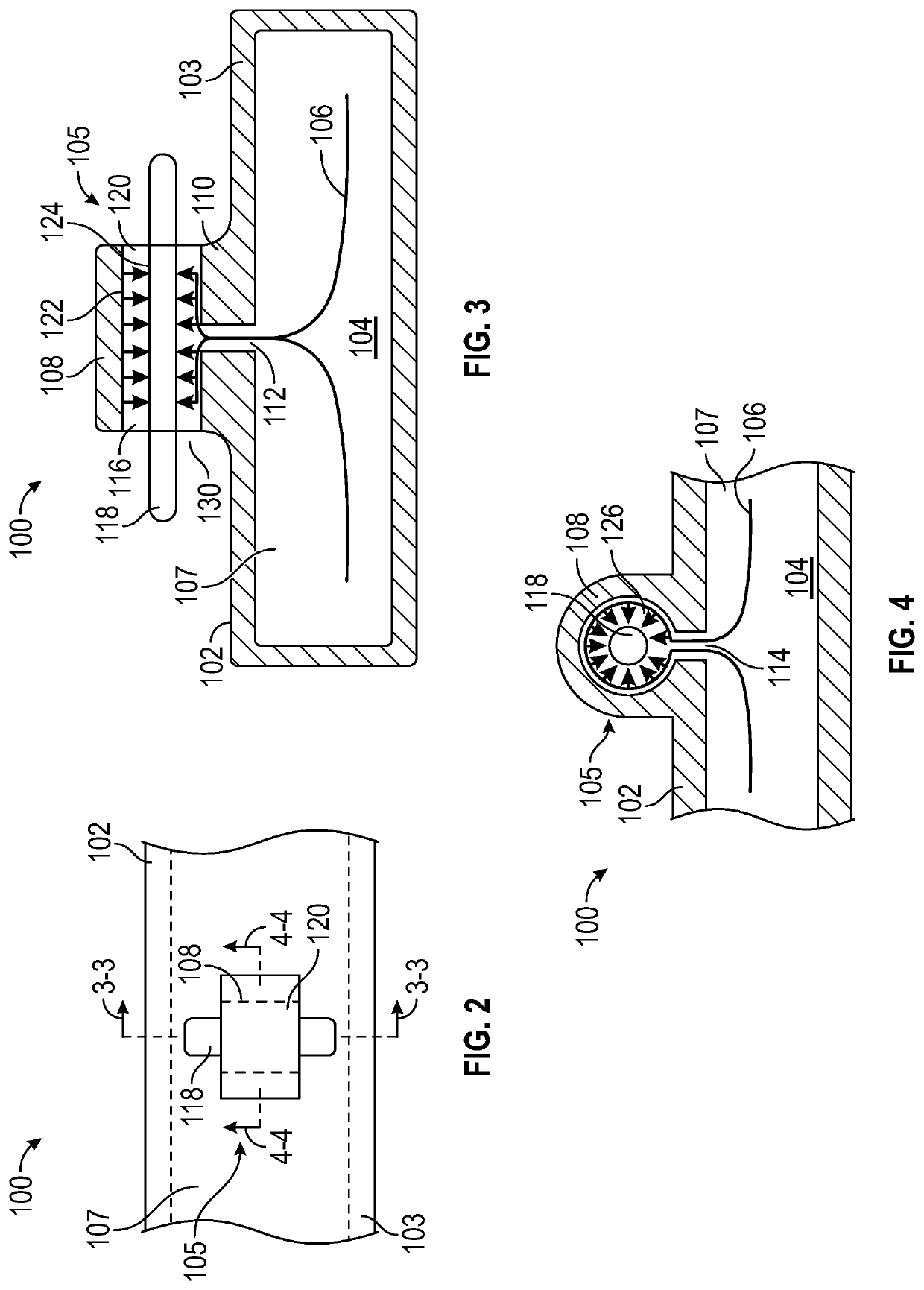

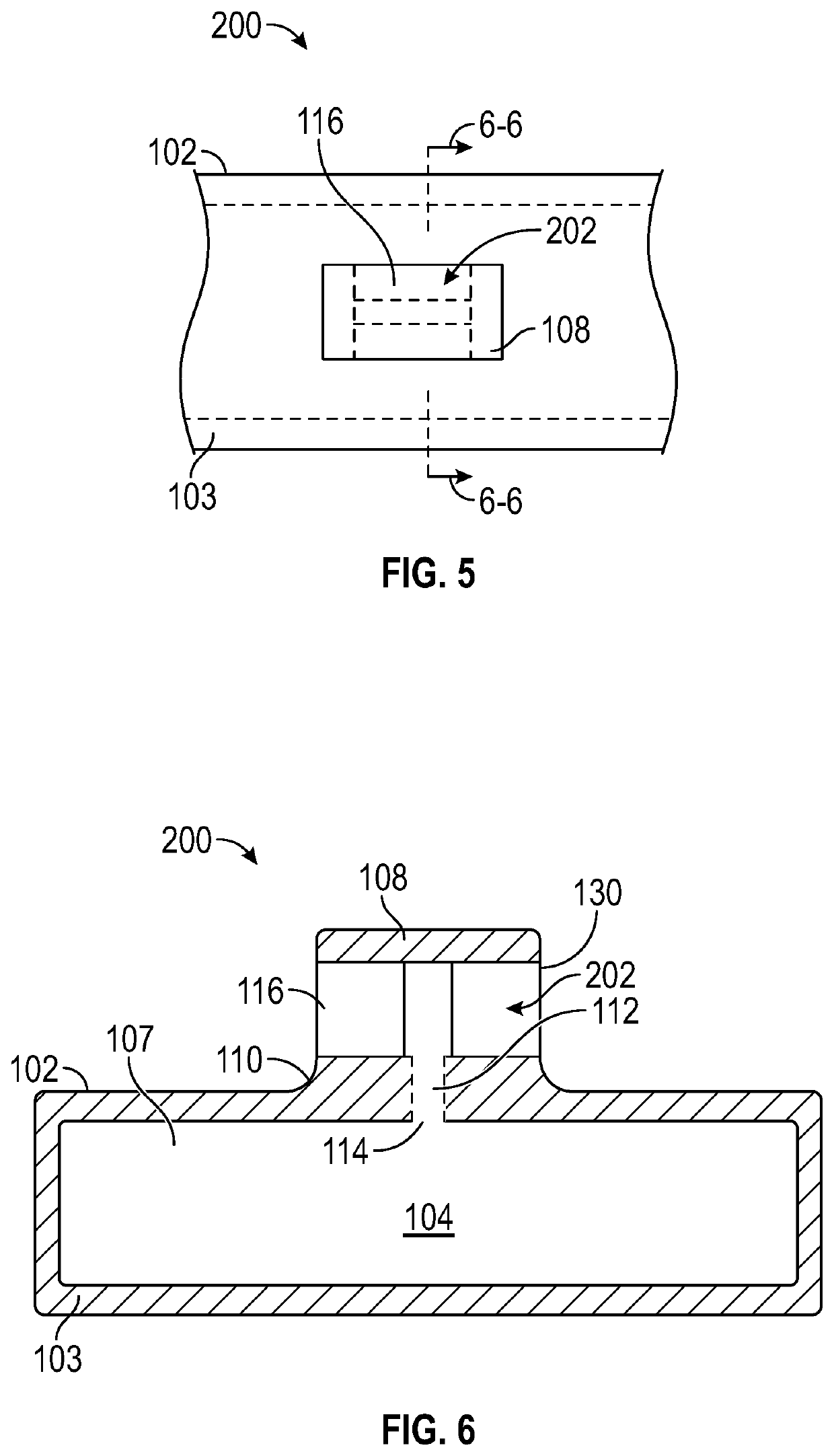

Gas damper and bearing in a propulsion system

ActiveUS11092036B2Reduce vibrationReduce premature expulsionEngine fuctionsEfficient propulsion technologiesPlenum chamberShock absorber

A component assembly of a propulsion system includes a component housing having a plenum configured to receive a pressurized gas flow of the propulsion system. The component assembly also includes a lug integrally formed with the component housing, a lug base region including a vent hole forming a gas path between the plenum and an interior of the lug, and a pin. The pin is configured to be positioned within the interior of the lug, where a cavity is formed between an interior surface of the lug and an exterior surface of the pin as positioned within the lug, thereby forming a compressed gas layer to reduce vibration of the pin within the cavity based on the pressurized gas flow passing from the plenum through the vent hole into the cavity.

Owner:RTX CORP

Novel rock crusher shell body

InactiveCN108970726AReduced fretting wearPrevent looseningGrain treatmentsEngineeringVibration absorption

The invention discloses a novel rock crusher shell body and belongs to the technical field of rock crushing, aiming at solving the problems that a crusher is continuously impacted in a crushing process of rocks so that the crusher has strong vibration and fretting wear and noise pollution is serious. The novel rock crusher shell body is technically characterized by comprising a base, a side plate,a top plate, a stopping door, front and rear wear-resisting plates, front and rear baffle plates, a side wear-resisting plate and an impact plate, wherein the side plate, the top plate and the frontand rear baffle plates are located at the upper part of the base and are connected through bolts; the front and rear wear-resisting plates, the side wear-resisting plate and the impact plate are mounted in grooves of the front and rear baffle plates, the side plate and the top plate respectively and are further fixed through bolts. The novel rock crusher shell body is simple in structure and rapidto mount, has obvious noise elimination and vibration-absorption effects, and can effectively prevent dust from flying. In order to realize the aim, the novel rock crusher shell body is realized through the following technical scheme.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

Micro turbine for aero-engine

ActiveCN112196626AHigh positioning tightnessReduced fretting wearBlade accessoriesEfficient propulsion technologiesTurbine bladeStator

The invention discloses a micro turbine for an aero-engine. The micro turbine comprises a turbine disc, and turbine blades sequentially distributed on the turbine disc along the circumferential direction of the turbine disc, wherein the turbine disc further comprises locking pipes used for locking the turbine blades in corresponding mortises on the turbine disc; the locking pipe is arranged at theconnecting position of the small end of a tenon and the mortise of the turbine blade; and the locking pipe deforms under the action of external force punching and riveting so as to be squeezed in thetenon and the mortise at the same time to lock the turbine blade, and then the turbine blade is prevented from moving backwards towards the exhaust end of the turbine. According to the micro turbinefor the aero-engine, due to the fact that deformation of the locking pipes under the action of punching and riveting force is spatial multi-dimensional deformation, the positioning locking tightness of the locking pipes to the turbine blades is larger than the locking tightness of locking pieces, and therefore the turbine blade can be effectively prevented from moving backwards towards the exhaustend of the turbine, and then the breaking fault of the turbine blade occurring after the turbine blade scrapes a rear stator is reduced; and the turbine blades are high in positioning tightness, so that the fretting wear of the tenon contact surface is small, and the vibration stress of the tenon contact surface is small.

Owner:CHINA HANGFA SOUTH IND CO LTD

Radially displaceable brush seal

ActiveUS11174944B2Reduce wearReduced fretting wearEngine sealsEngine fuctionsEngineeringRadial displacement

A brush seal for sealing a leakage gap in an axial flow path between a relatively higher fluid pressure region and a relatively lower fluid pressure region, that includes an outer housing and an inner housing located at least partially within and configured for radial displacement relative to the outer housing, wherein the upstream facing inner surface of the outer housing is free of any protrusion toward the first downstream facing outer contact surface and second downstream facing outer contact surface.

Owner:ROLLS ROYCE PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com